Patents

Literature

41results about How to "Dimensionally stable processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thin-wall aluminum alloy material tube-shell part cutting processing heat treatment process

InactiveCN104233125AImprove cutting performanceGuaranteed processing deformationSolution treatmentMachine parts

The invention relates to a thin-wall aluminum alloy material tube-shell part cutting processing heat treatment process which comprises the following steps: carrying out quenching and aging solution treatment by adopting a blank; improving the cutting property of a material; relieving stress by adopting aging heat treatment after rough machining; carrying out semi-finishing, and then carrying out the aging heat treatment to further relieve machining stress so as to ensure the stress inside a machined part is completely released; after turning is completed, carrying out low-temperature heat treatment for stabilizing machining size for the last time. Practices indicate that the heat treatment process method can be used for achieving the purposes of eliminating the machining deformation of the part and stabilizing the machining size and ensuring that the size accuracy and form and location tolerance of the part meet the technical requirements.

Owner:无锡市森信精密机械厂

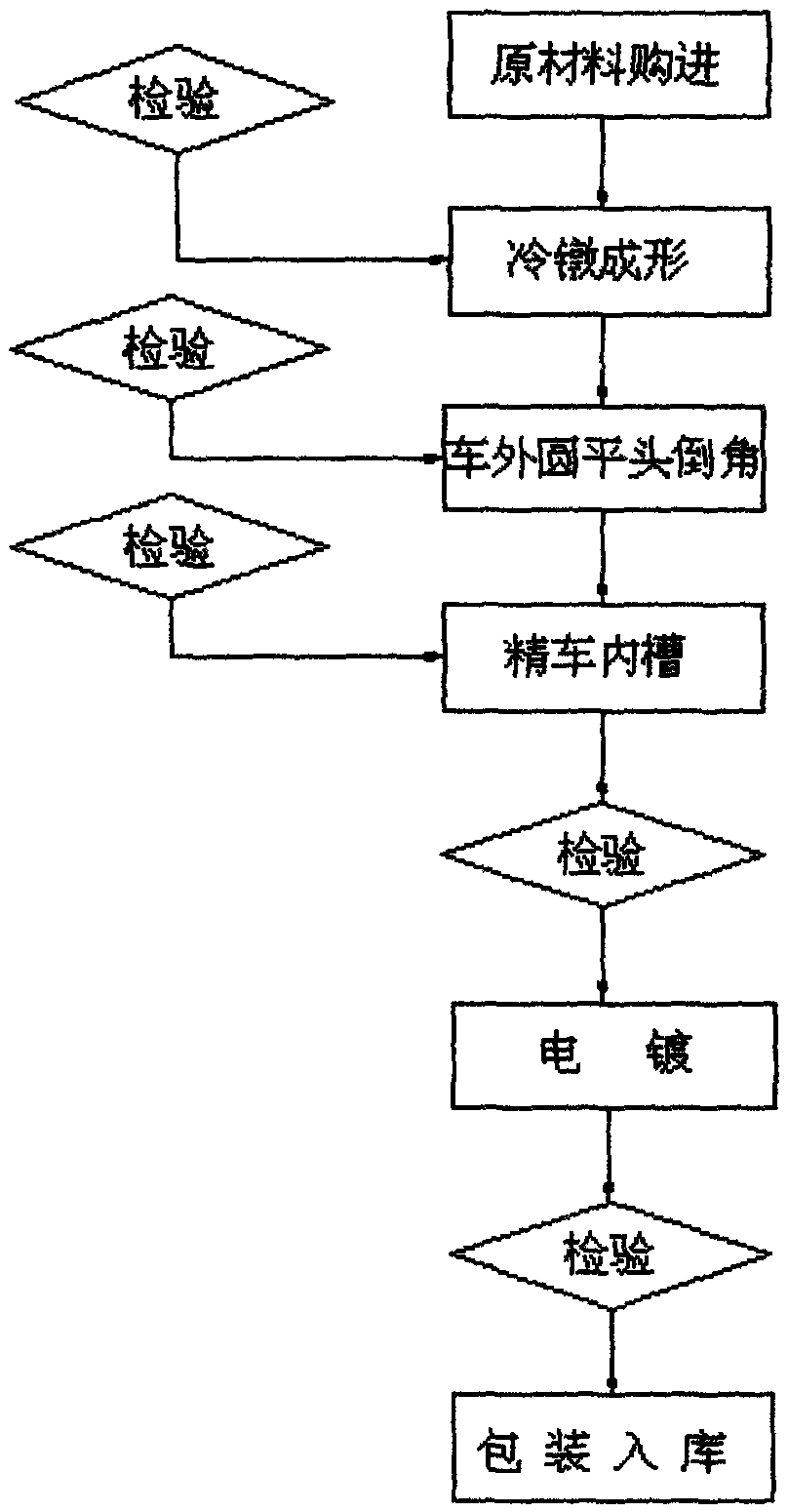

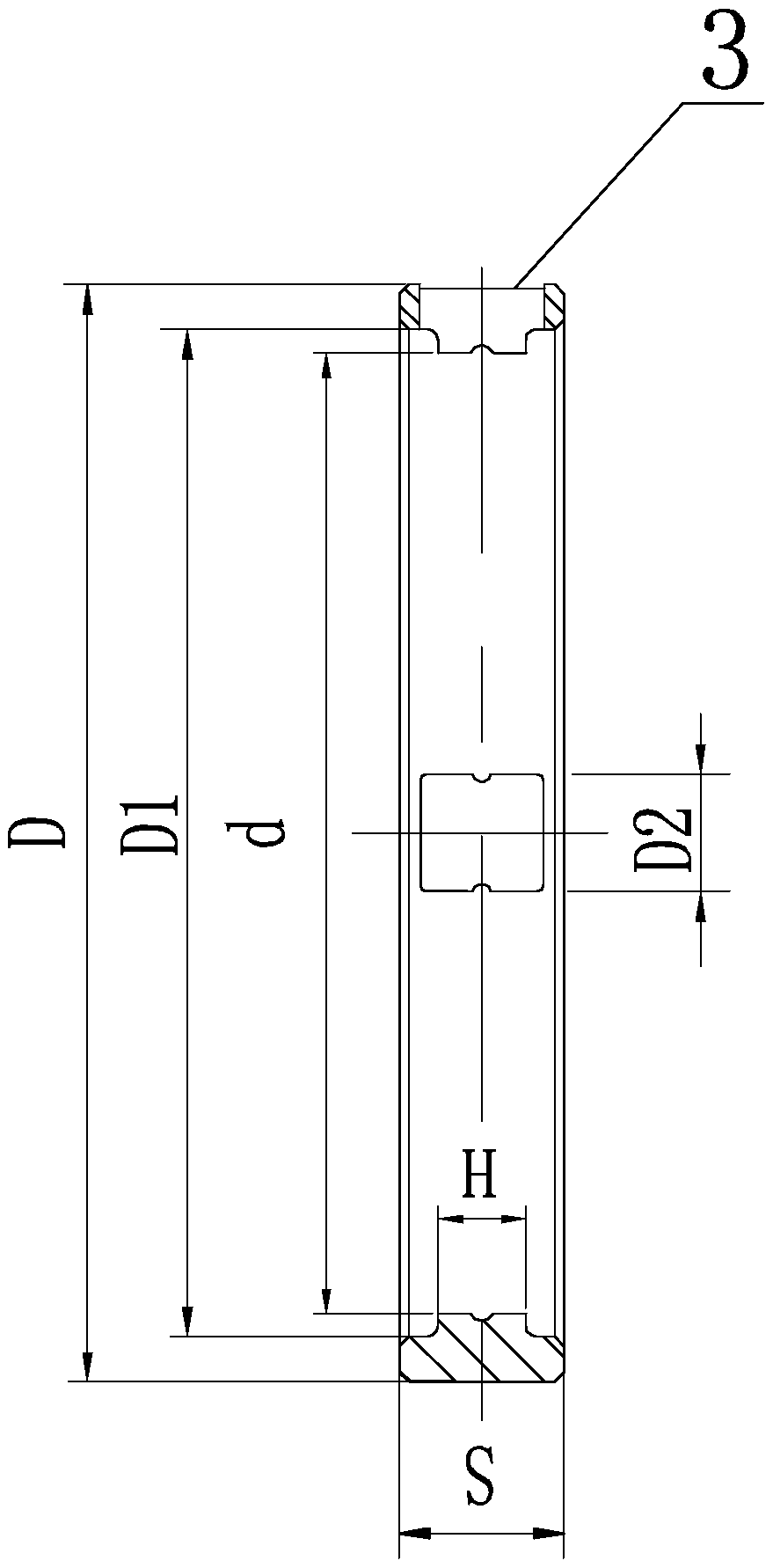

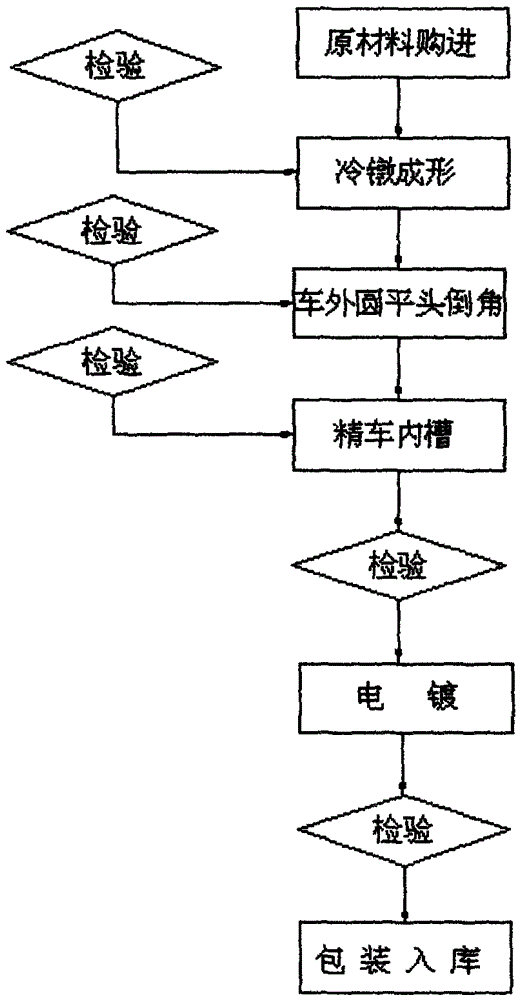

Cold heading sleeve processing process

The invention discloses a cold heading sleeve processing process, which comprises the following concrete steps: (1) screening and inspecting blank materials, carrying out corresponding incoming inspection on the blanks according to the specification of a product, and selecting the blank materials with right size, wherein the blanks are round bar materials with the diameter of 39mm and the weight of 390g; (2) selecting and using a multistage cold former for direct cold heading form, and processing to obtain required product size through four times of cold heading; (3) turning excircle chamfering R1 of the blanks, and inspecting if the product is qualified or not after chamfering; (4) rough machining an inside groove reserved by the blanks, finishing machining the inside groove, and carrying out product inspection on the blanks after finishing machining the inside groove; (5) electroplating the blanks; and (6) packaging and storing the finished products after electroplating. For each product, the blank usage amount is saved by 231.9g, so that the cost is reduced by 37.29 percent, the processing difficulty is reduced, the consumption is reduced, the processing cost is saved, and meanwhile, the production efficiency is improved.

Owner:NINGBO COFAR HOSE & FITTINGS

Processing method for inner-ring-free cylindrical roller bearing alloy steel solid retainer

InactiveCN109500549AImprove mutual differenceSmall machining allowanceSurface roughnessStress relief

The invention discloses a processing method for an inner-ring-free cylindrical roller bearing alloy steel solid retainer, and relates to the technological field of bearings. The problems that after anexisting bearing retainer processing process, the working accuracy of a pocket hole of the bearing retainer and the surface roughness of the pocket hole do not reach the standard, and rolling surfacecan generate cracks in the lock opening rolling process are solved. The processing method comprises the following processes of lathe forming, hardening and tempering, rough grinding of the outer diameter, fine lathing of the two end faces, fine lathing of the inner diameter, even grinding of the two end faces, final grinding of the outer diameter, final grinding of the inner diameter, turning ofinner steps, marking, drilling, milling of square holes, pulling of the square holes, deburring, cleaning, stress relief annealing, glazing, lock opening rolling, dynamic balancing, magnetic powder inspection, silver plating, final inspection and packaging. According to the processing method, stress relief annealing is carried out before lock opening rolling is carried out, and the cracks generated by machining stress superposition and a surface cold hardening layer on the rolling surface are avoided. The processing method is suitable for processing the inner-ring-free cylindrical roller bearing alloy steel solid retainer.

Owner:AVIC HARBIN BEARING

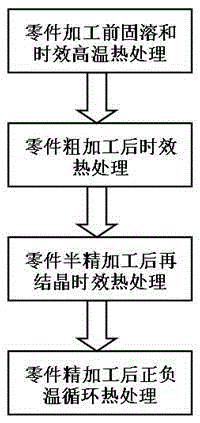

Thermal treatment process for thin-wall aluminum alloy component

The invention provides a thermal treatment process for a thin-wall aluminum alloy component. The thermal treatment process comprises the following steps: a) carrying out solid solution treatment and ageing high-temperature thermal treatment before component processing; b) carrying out ageing thermal treatment after component rough processing; c) carrying out crystallization ageing thermal treatment after component semifinishing; and d) carrying out positive-negative-temperature circulating thermal treatment after component finishing. The invention discloses the thermal treatment process for the thin-wall aluminum alloy component. The thermal treatment process effectively solves the stress deformation problem of thin-wall aluminum alloy component cutting processing, not only stabilizes the processing dimension, but also guarantees that component dimension tolerance and component geometric tolerance reach technical requirements.

Owner:CHANGSHU MIAOQUAN COMPRESSOR ACCESSORIES

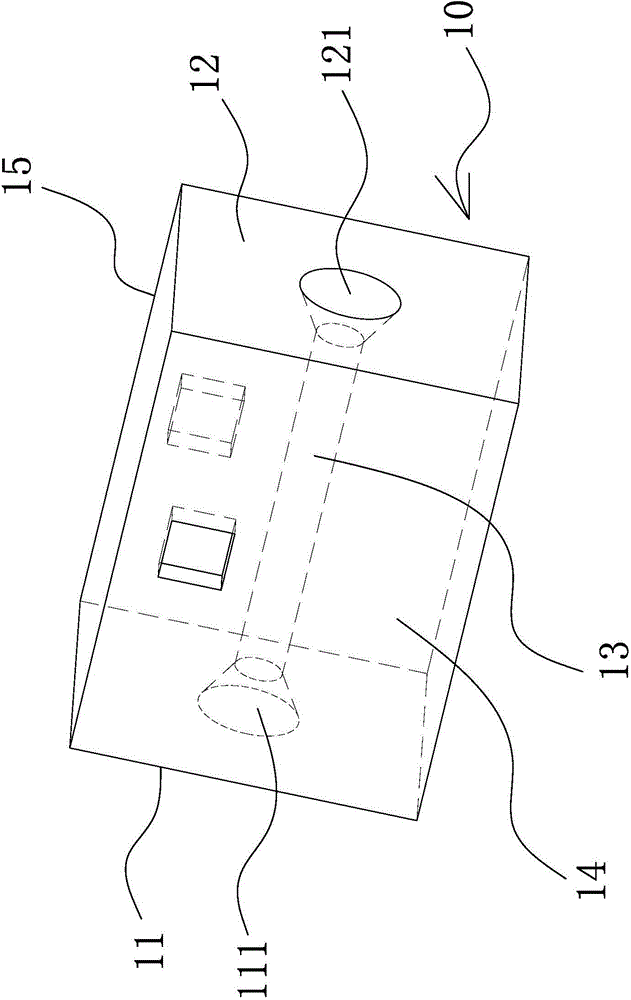

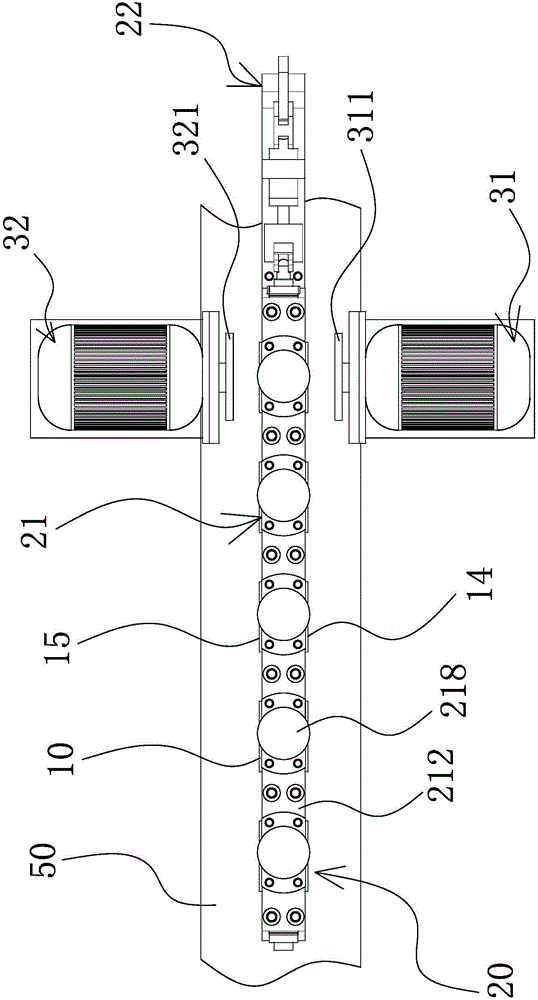

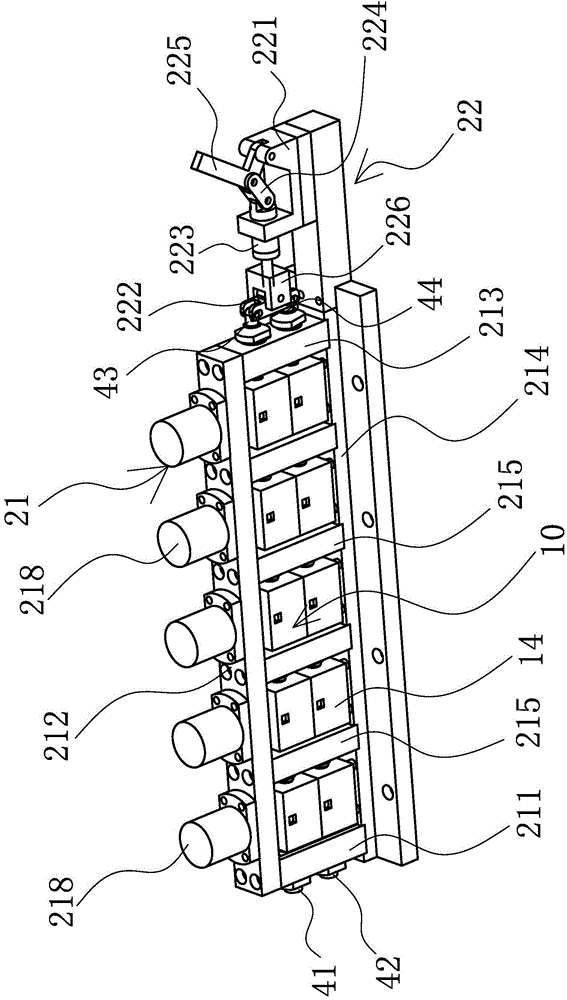

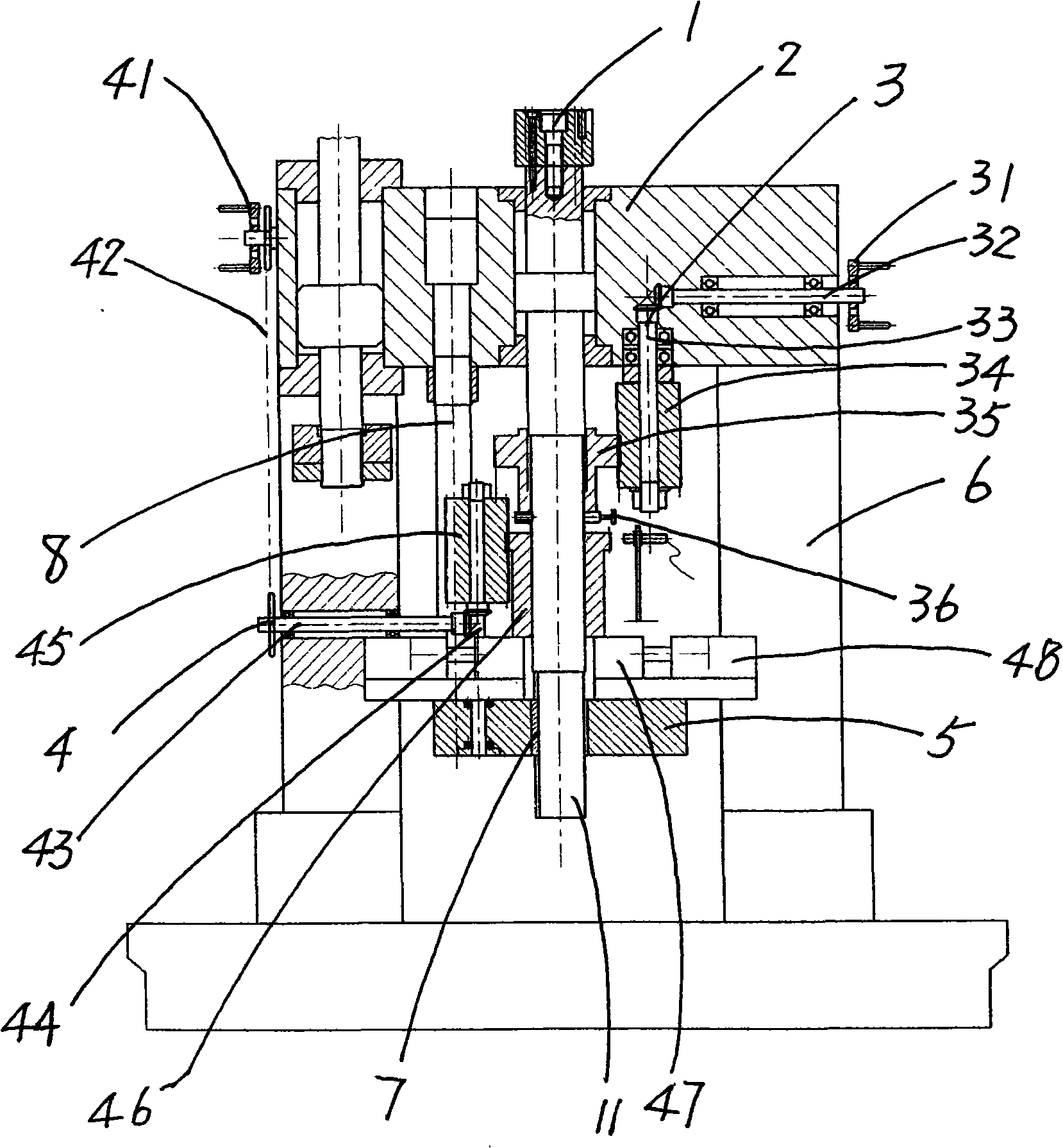

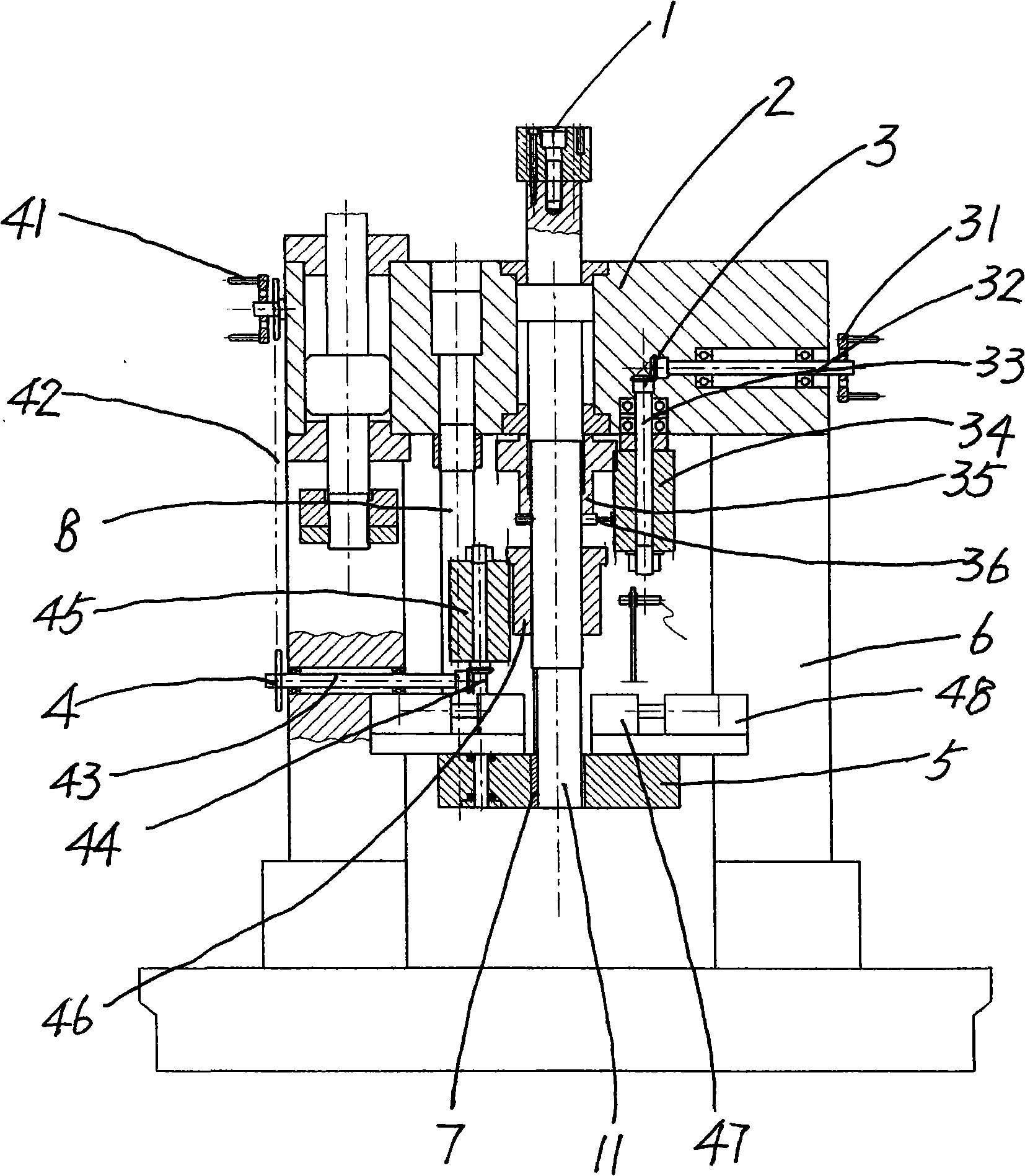

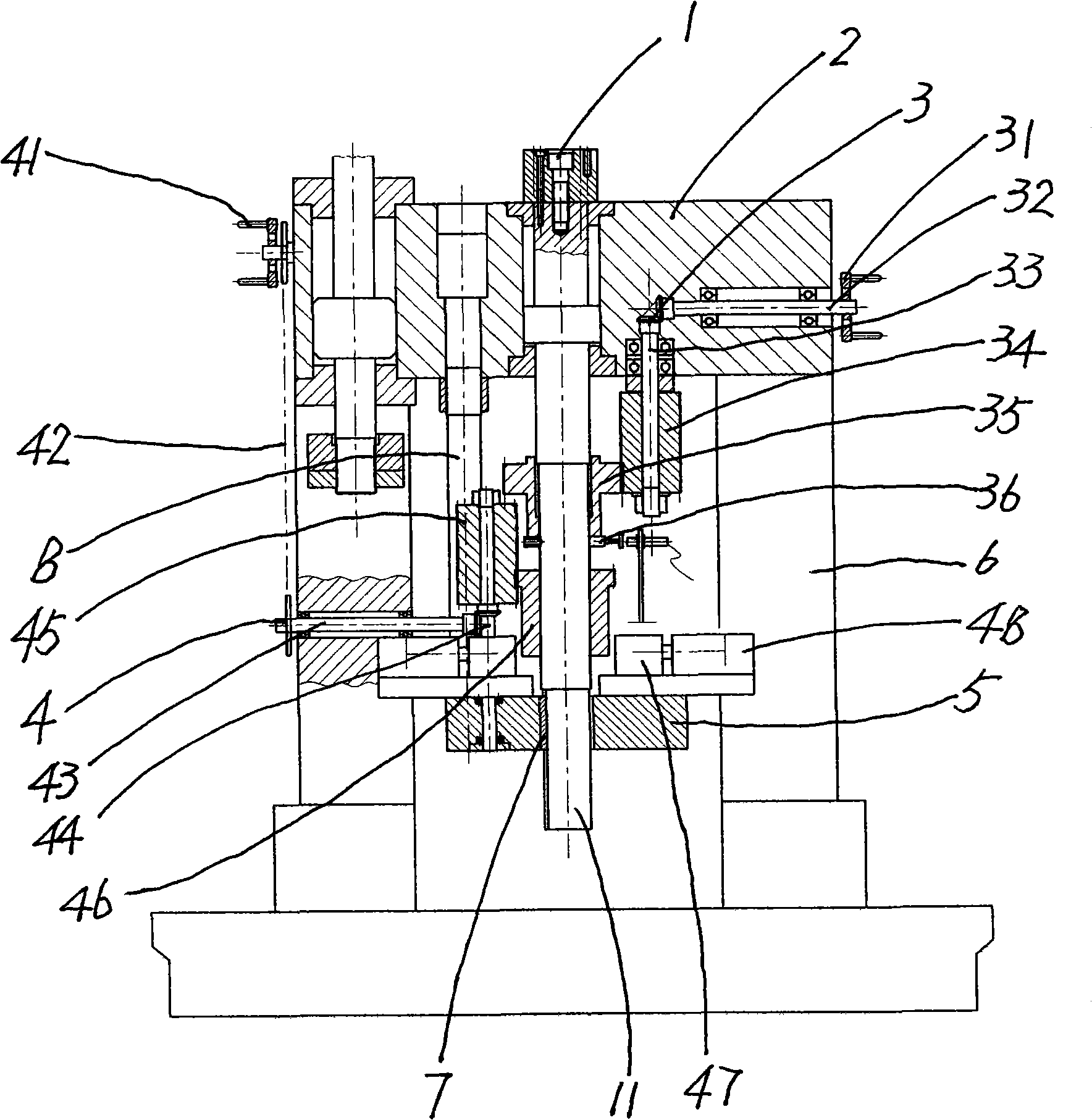

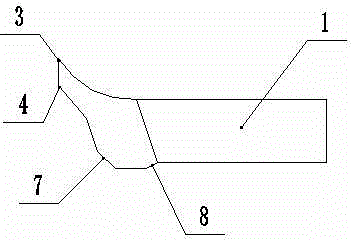

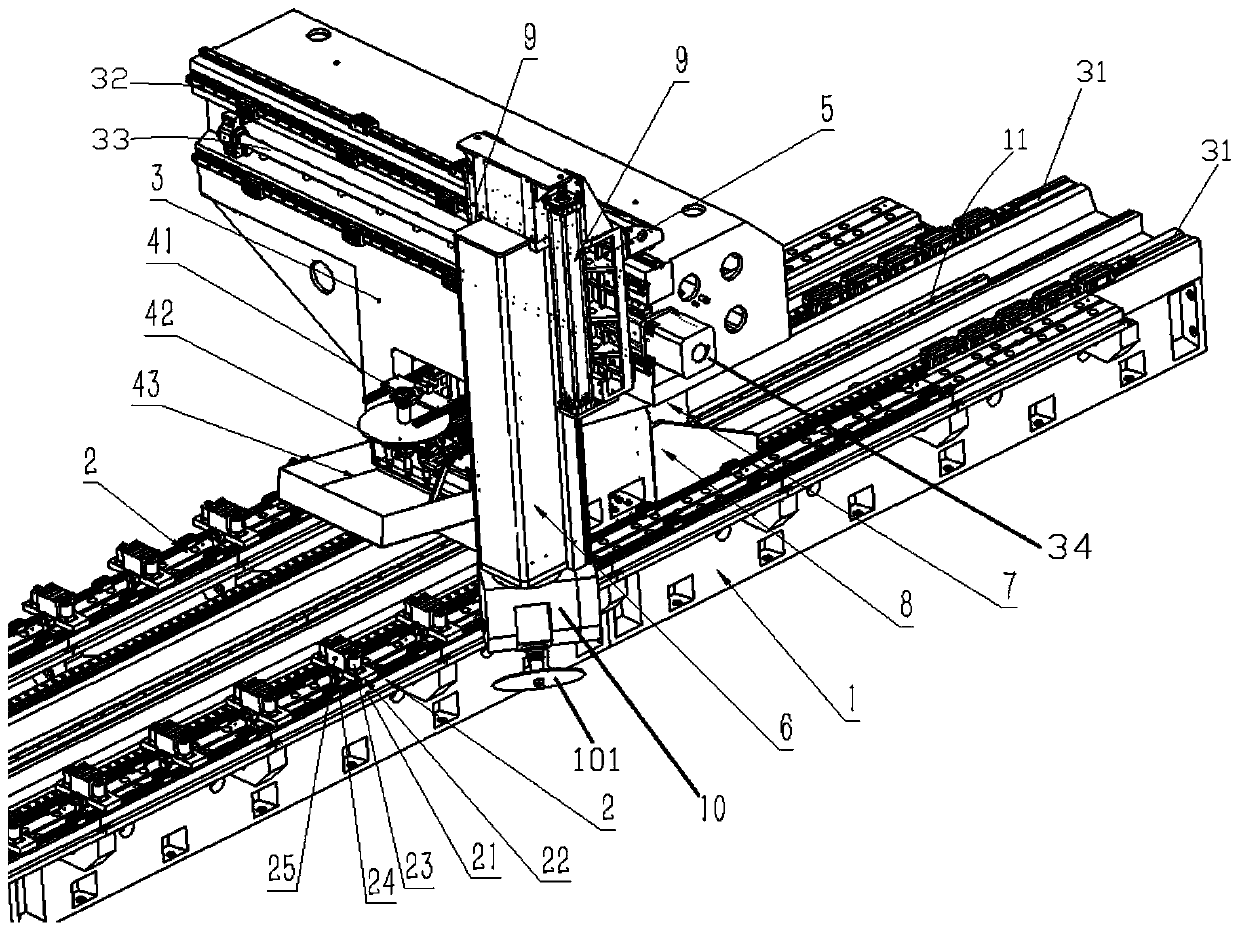

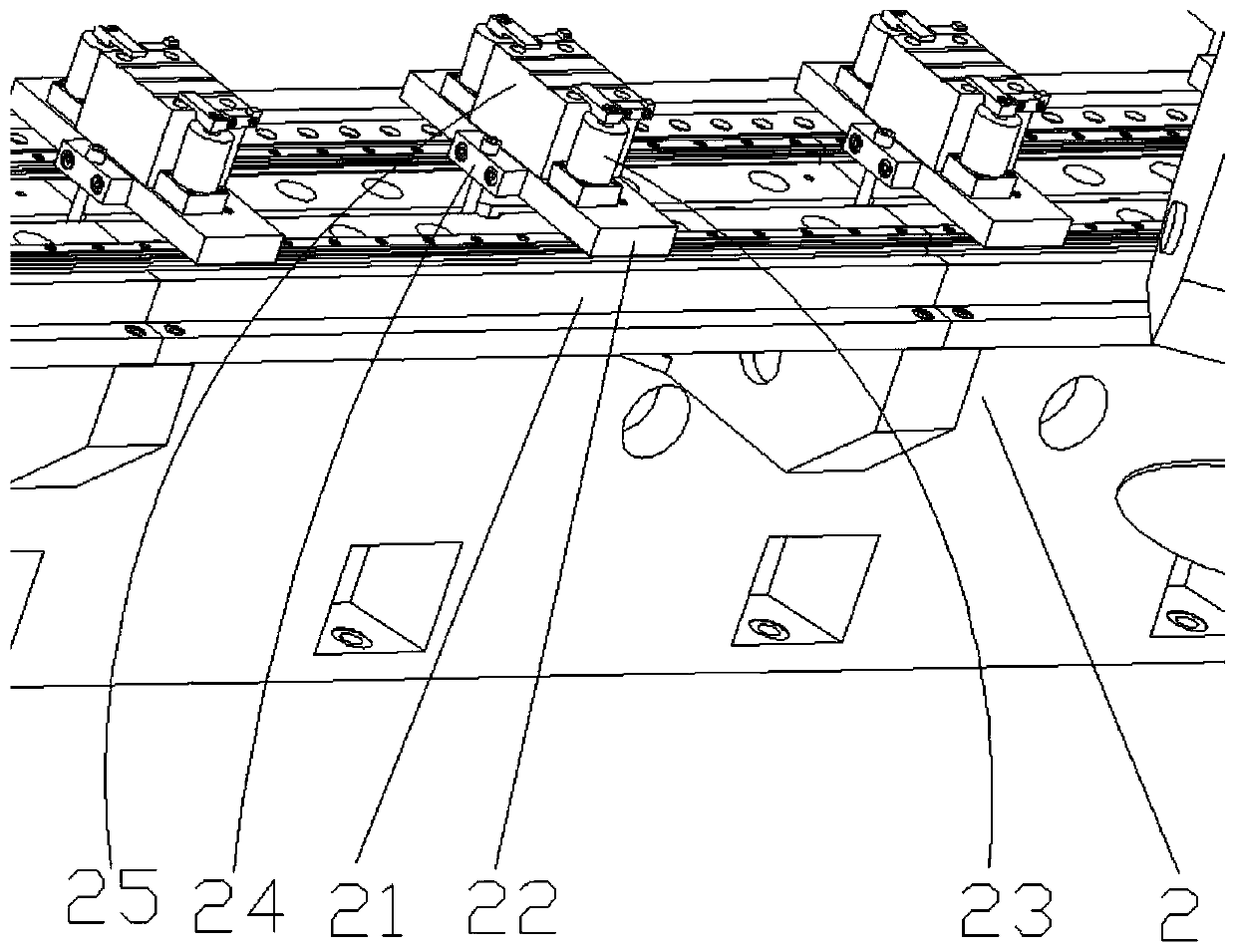

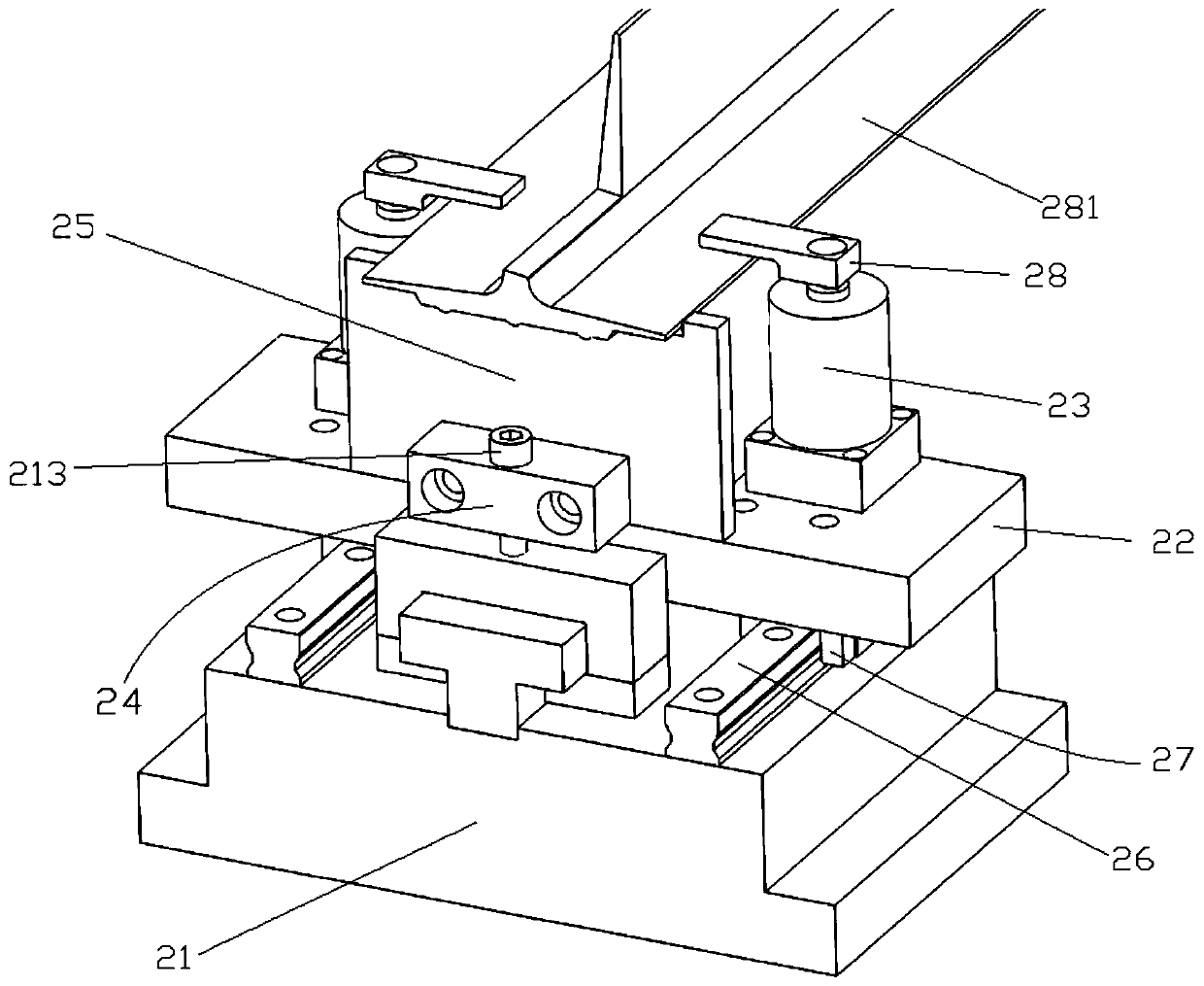

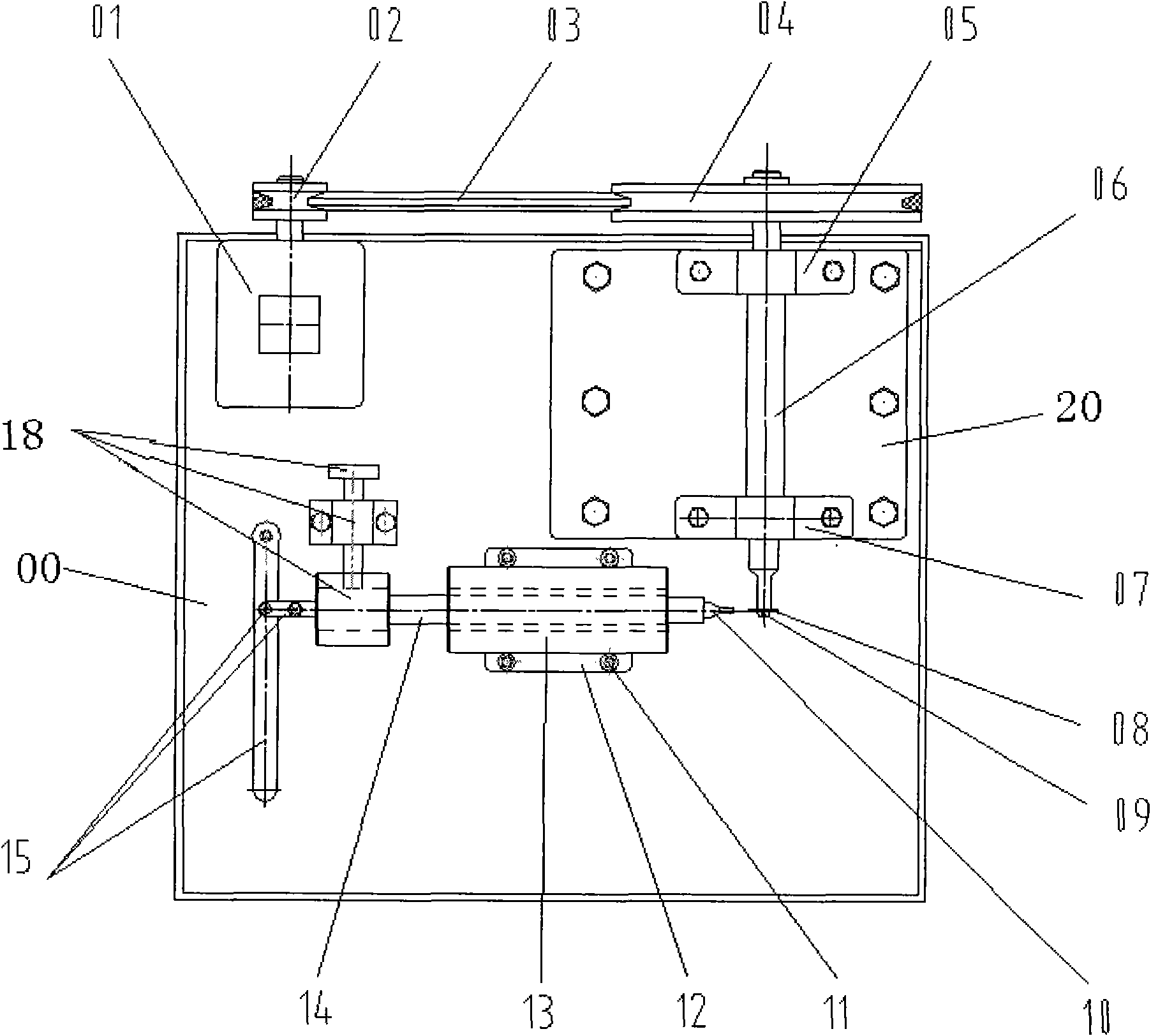

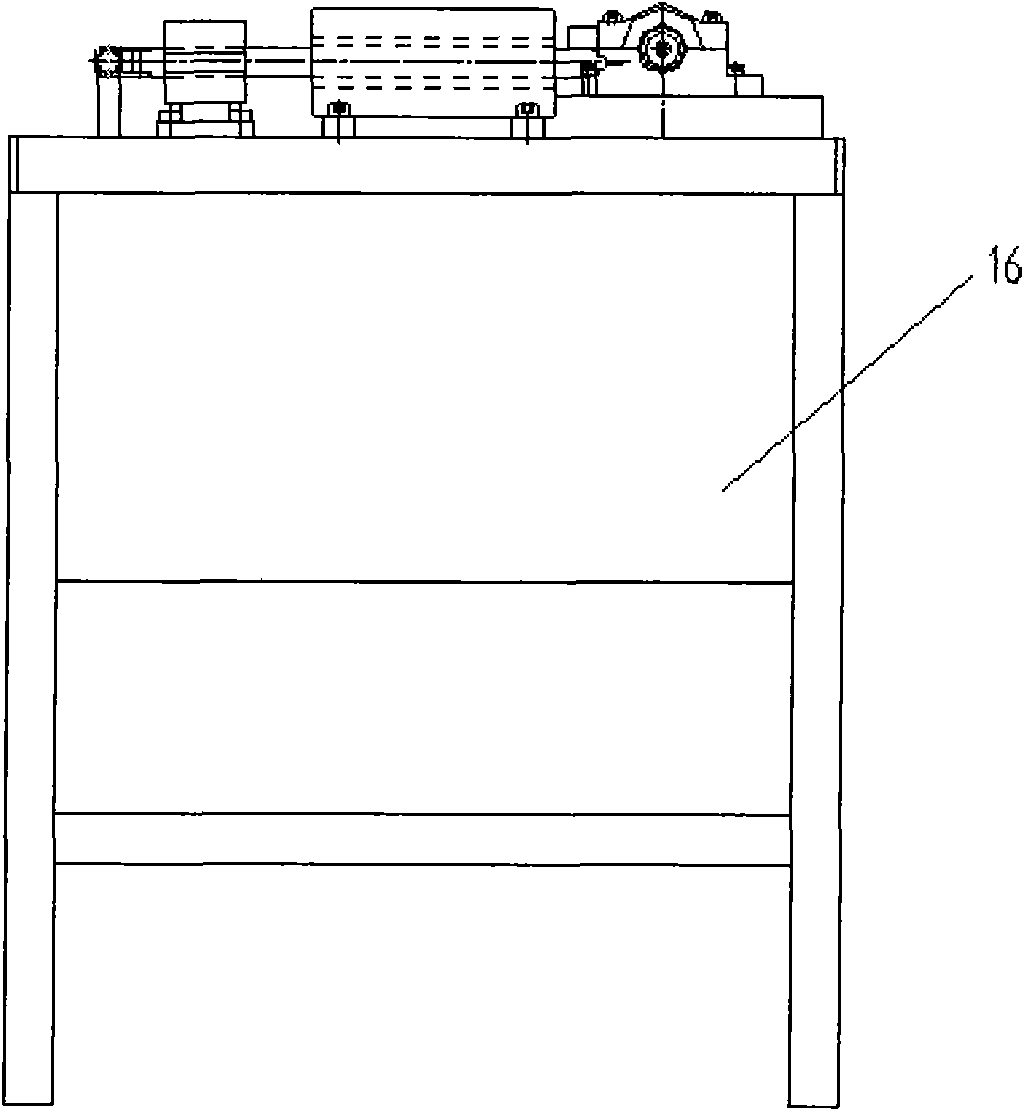

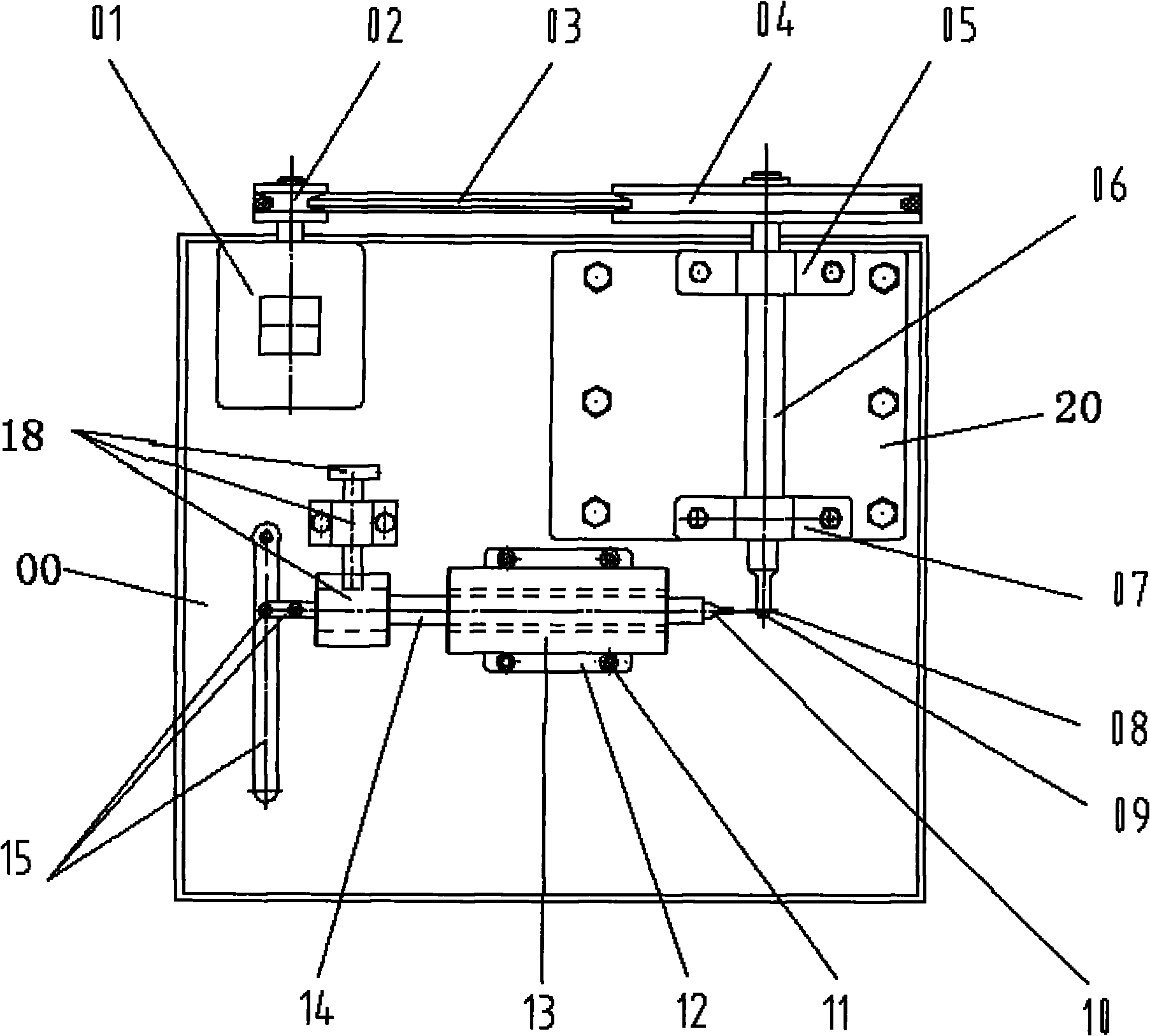

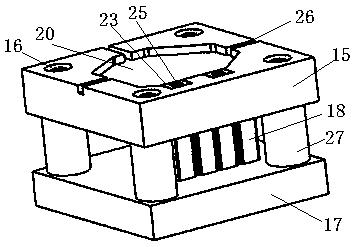

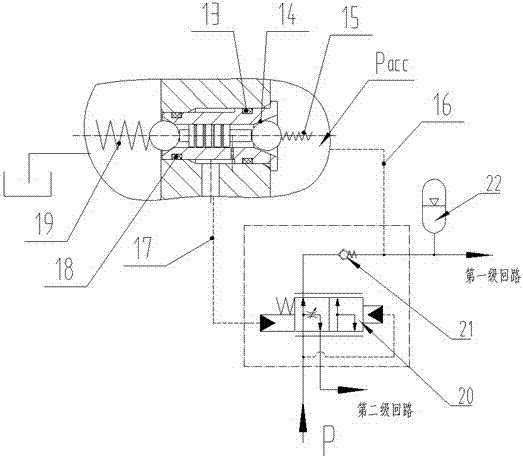

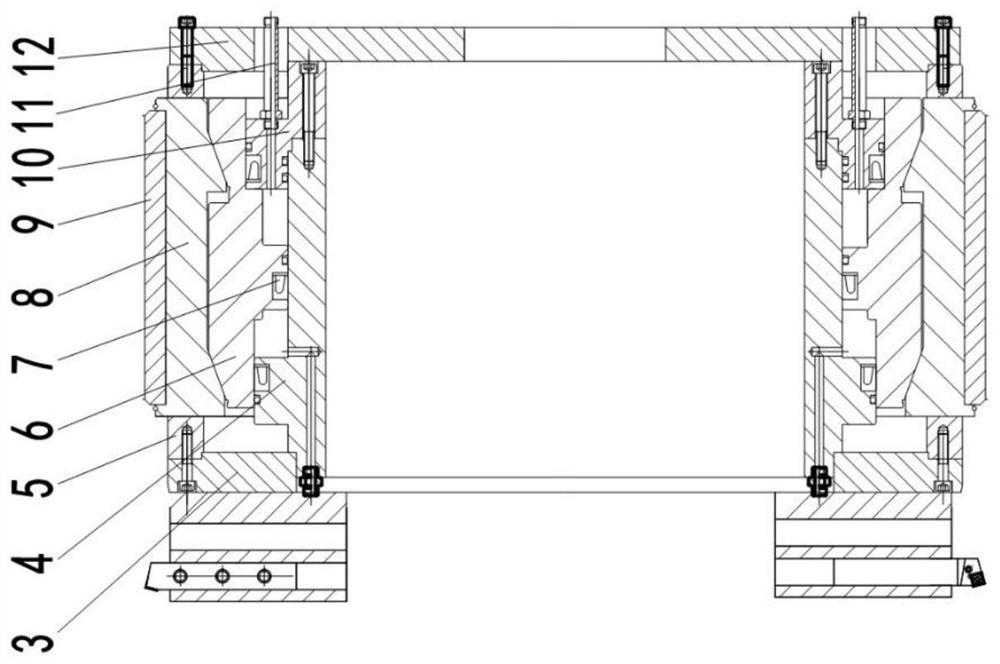

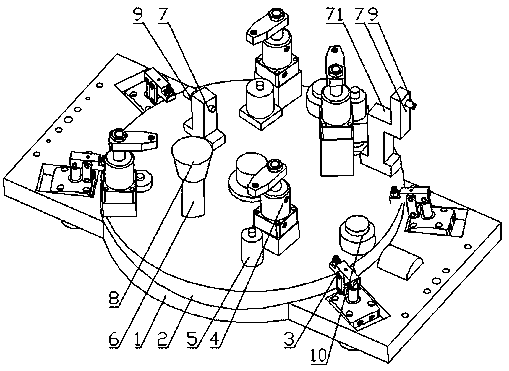

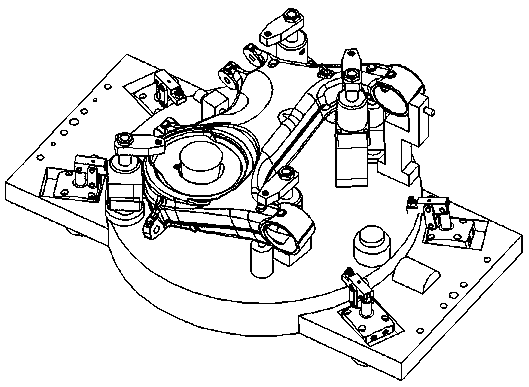

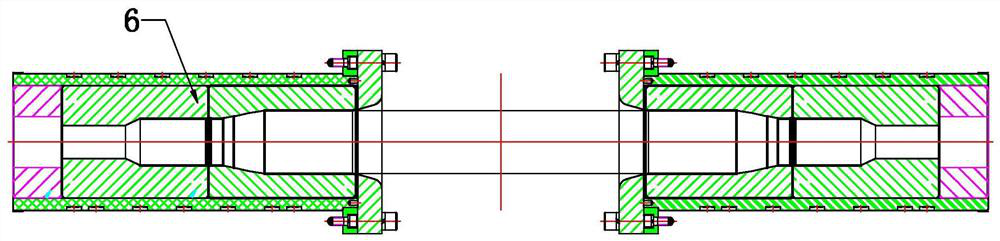

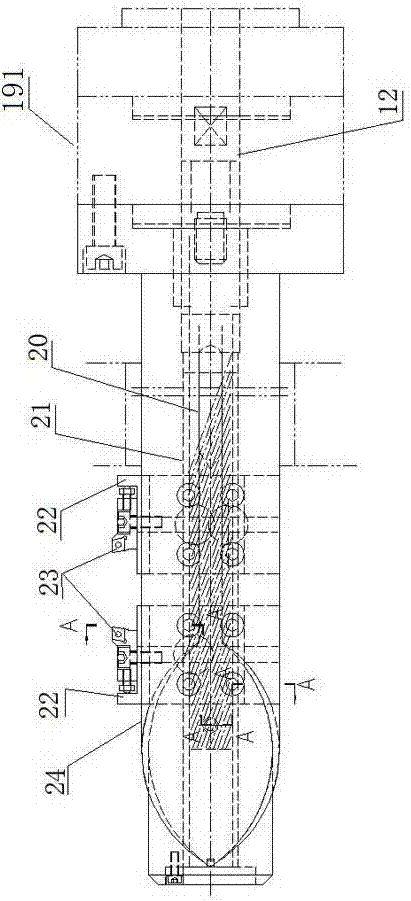

Double-faced milling mechanism

InactiveCN104400094AOptimize layoutDimensionally stable processingWork clamping meansMilling equipment detailsMilling cutterAgricultural engineering

The invention provides a double-faced milling mechanism, which belongs to the machinery technical field. The double-faced milling mechanism comprises a milling machine clamp, a first milling machine and a second milling machine arranged at two sides of the milling machine clamp, the milling machine clamp comprises a clamp assembly used for clamping a valve blank and an adjusting assembly arranged outside the clamp assembly and used for clamping valve blanks, the clamp assembly comprises a left side plate, a cover plate, a right side plate, and a bottom plated which are capable of encircling a frame form structure, at least an intermediate baffle plate which is vertically arranged is provided between the left side plate and the right side plate, two ends of each intermediate baffle plate are respectively connected to the cover plate and the bottom plate, the left side plate, the cover plate, the right side plate, the bottom plate and the intermediate baffle plate are capable of encircling at least two clamp chambers used for placing the valve blank; a first milling cutter used for milling the right side of the valve blank is vertically arranged on the first milling machine, a second milling cutter used for milling the back side of the valve blank is vertically arranged on the second milling machine. The double-faced milling mechanism has the advantages of reasonable design, high work efficiency and wide versatility.

Owner:NINGBO HOYEA MACHINERY MFG

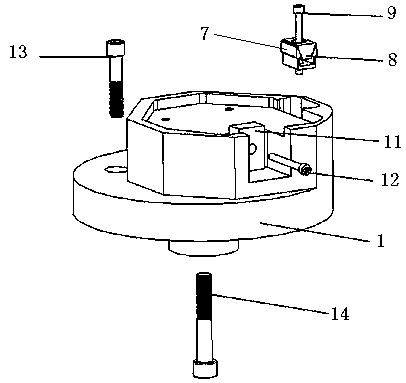

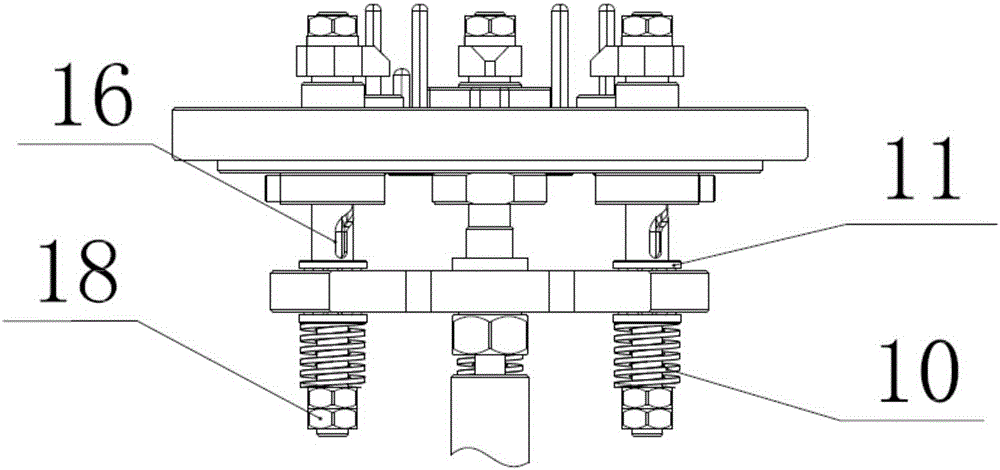

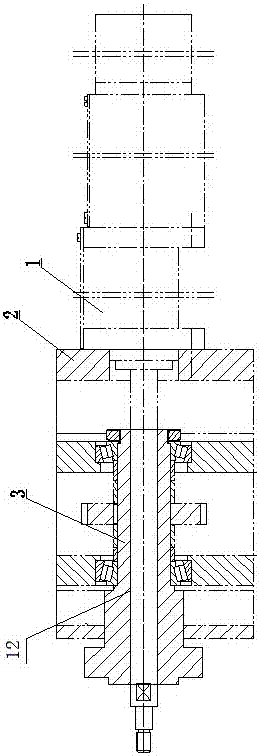

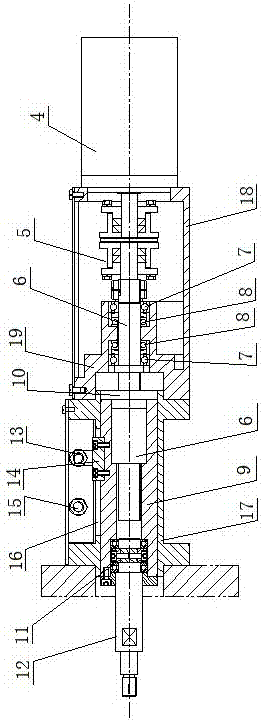

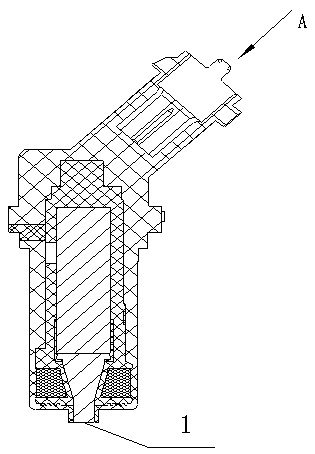

Mold base device for pressing component with stepped mandrel

The invention relates to a mold base device for pressing a component with a stepped mandrel, which is used for powder metallurgy pressing on a hydraulic press. The mold base comprises a lower central cylinder, an upper fixing template, a put-out feeding-height regulation device, a mandrel-step limit device, a lower fixing template, a bearing plate, a guide key and a connecting bar, wherein the lower central cylinder is arranged on the upper fixing template; the put-out feeding-height regulation device which is connected with the lower central cylinder and is used for regulating feeding height is arranged on the upper fixing template; and the mandrel-step limit device for regulating the height of mandrel steps is arranged on the lower fixing template. Due to the put-out feeding-height regulation device, the feeding height of power can be conveniently regulated; due to the mandrel-step limit device, the limit height of the mandrel steps can be effectively controlled; and due to a stroke controller combined with a limit block, the mold base device can perform powder metallurgy pressing on the stepped mandrel so as to ensure stable machining dimension.

Owner:南通天王液压成套厂

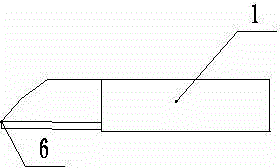

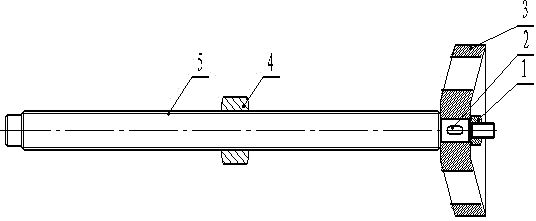

Annular deep and narrow groove turning tool

InactiveCN104785807ADimensionally stable processingImprove surface roughnessCutting insertsWorkpiecesDeflection angleMachining

An annular deep and narrow groove turning tool comprises a rough turning tool body and a finish turning tool body. The rough turning tool body and the finish turning tool body both comprise a tool handle, a tool bit arc, a tool bit front angle, a tool bit rear angle, a tool bit auxiliary rear angle, a tool bit auxiliary deflection angle, a front chamfer and a rear chamber, wherein the tool handles are arranged on the left sides of the turning tool bodies, the tool bit arcs are arranged on the forefronts of the turning tool bodies, the tool bit front angles are located at the most pointed ends of the arcs, the tool bit rear angles are located at the rear ends of the tool bit front angles, the tool bit auxiliary rear angles are located at the upper ends of the tool bit arcs, the tool bit auxiliary deflection angles are located below the tool bit rear angles, the front chambers are arranged at the lower ends of the tool bit arcs, the rear chamfers are arranged at the rear ends of the front chamfers, the tool bit arcs, the tool bit front angles, the tool bit rear angles, the tool bit auxiliary rear angles, the tool bit auxiliary deflection angles, the front chambers and the rear chambers form tool bit assemblies, and then the tool bit assemblies and the tool handles are welded and combined into a whole. By means of the annular deep and narrow groove turning tool, it can be guaranteed that the machining size is stable, the surface roughness is effectively improved, and the annular deep and narrow groove turning tool is simple in structure, low in machining cost and low in price.

Owner:HENGYANG FENGSHUN AXLE CO LTD

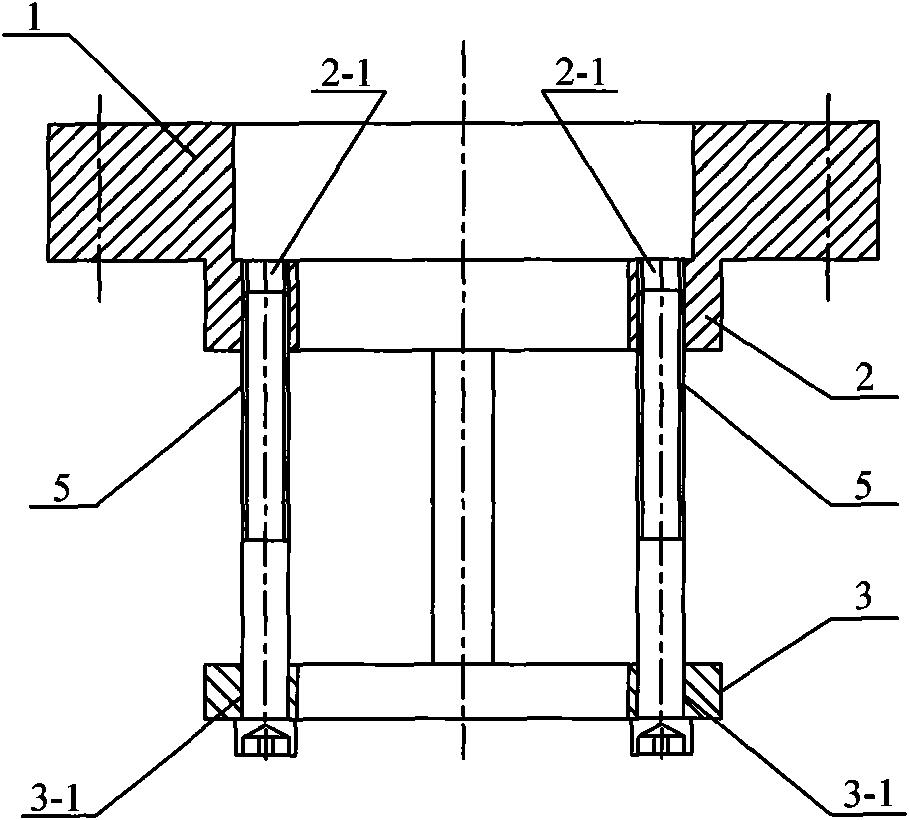

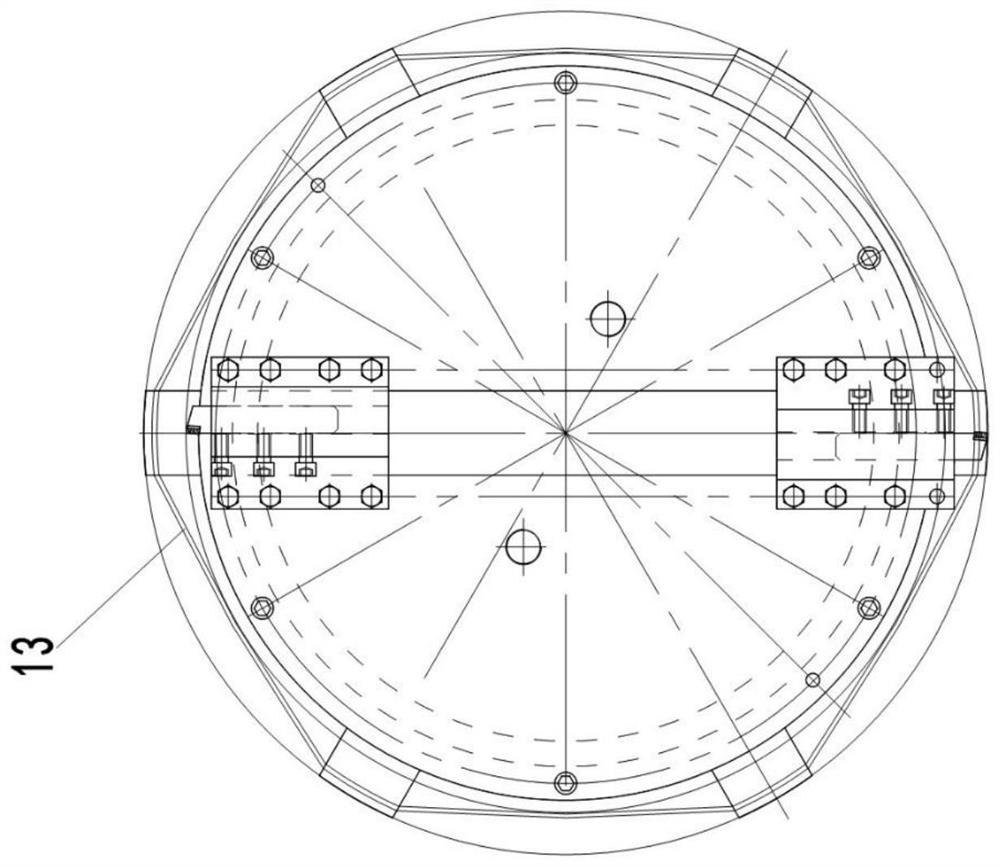

Numerical control lathe clamp for machining of thin-wall parts prone to deformation

InactiveCN106514314ADimensionally stable processingEasy to carryWork clamping meansPositioning apparatusNumerical controlEngineering

The invention relates to a numerical control lathe clamp for machining of thin-wall parts prone to deformation. The numerical control lathe clamp comprises a fixing plate and steering shafts. A positioning block is arranged in the position, close to the circle center, of the upper end face of the fixing plate, and a plurality of fixing blocks are evenly arranged on the lower end face of the fixing plate around the circle center. A cylindrical hole allowing the corresponding steering shaft to pass through is formed in the middle of each fixing block. A pulling plate is arranged below the fixing plate in parallel, and a pulling rod is vertically connected to the center of the lower end face of the pulling plate. The upper end of each steering shaft vertically penetrates through the pulling plate, the corresponding fixing block and the fixing plate and is connected with a pressing plate. A hexagon nut is fixedly installed at the lower end of the corresponding steering shaft, and the portion, located between the hexagon nut and the lower end face of the pulling plate, of the corresponding steering shaft is sleeved with a spring. A spiral rail is arranged on the side wall of the corresponding steering shaft, and a guiding screw is horizontally installed on the side wall of one end of the corresponding fixing block. One end of the guiding screw is embedded into the corresponding spiral rail, and the guiding screw slides along the corresponding spiral rail along with movement, in the corresponding cylindrical hole, of the corresponding steering shaft. The numerical control lathe clamp for machining of thin-wall parts prone to deformation has the characteristics that the phenomena of displacement, knife vibration and deformation do not occur in the process of machining, and positioning is accurate.

Owner:NINGBO LONGYUAN PRECISION MACHINERY

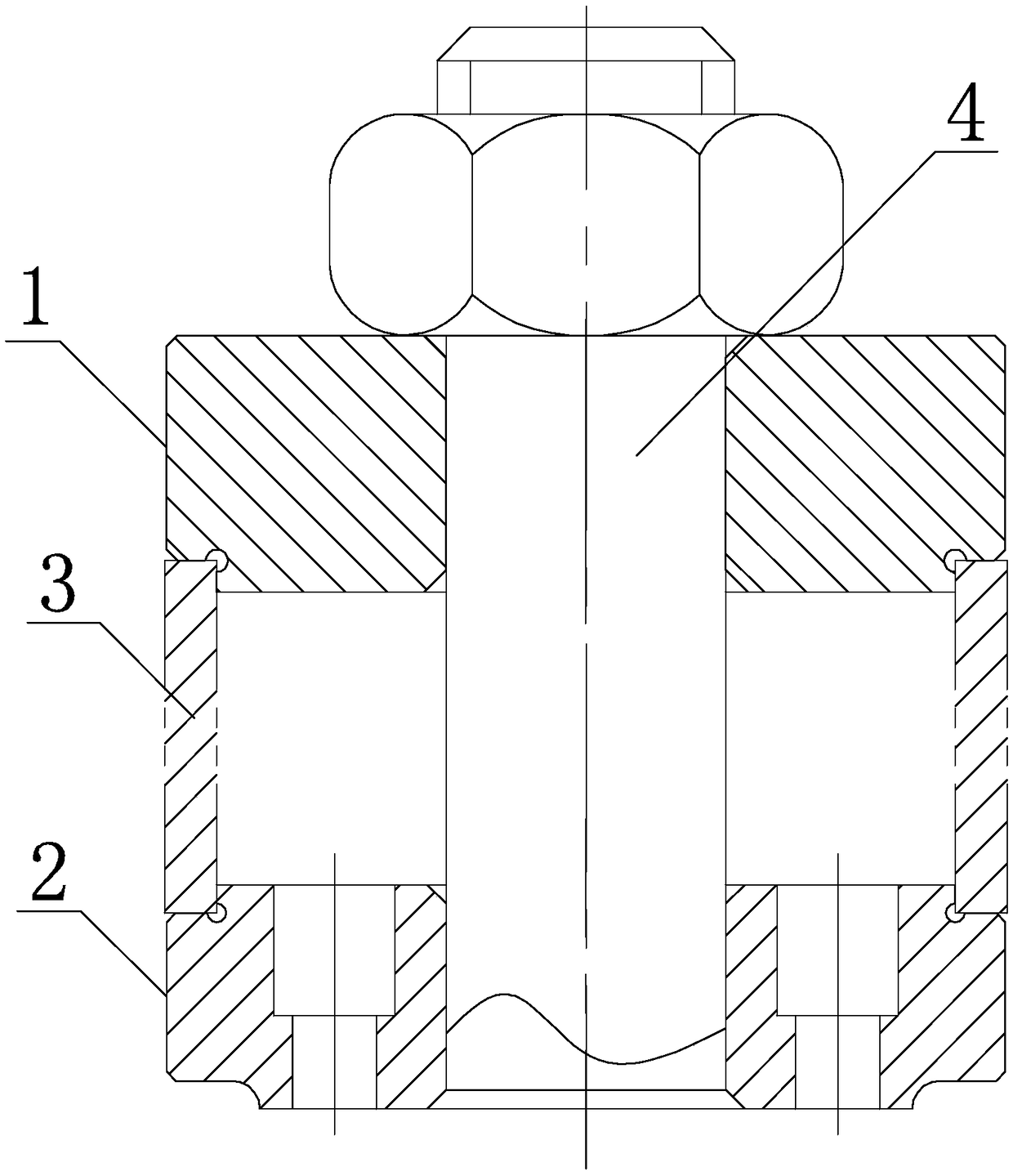

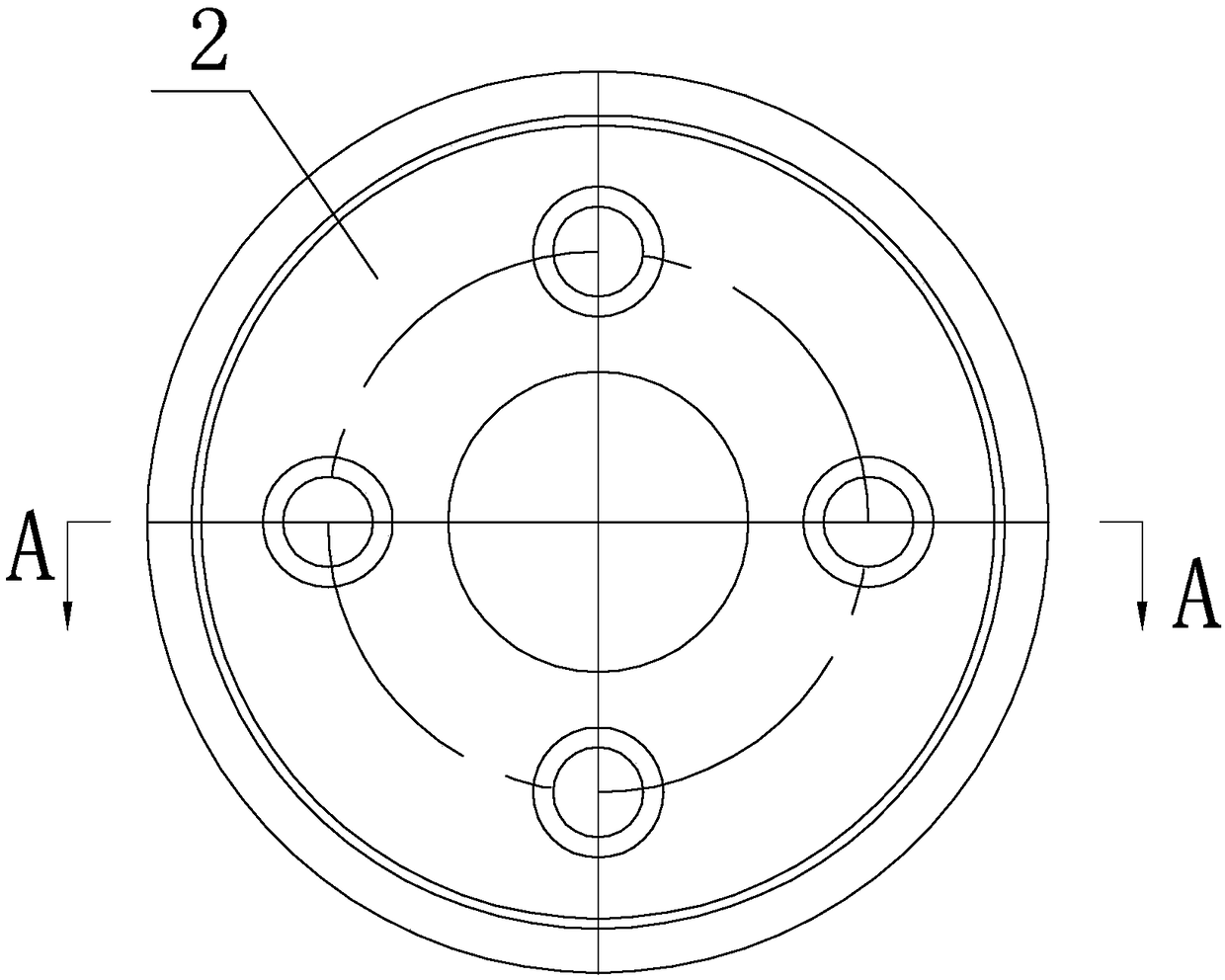

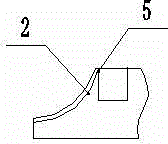

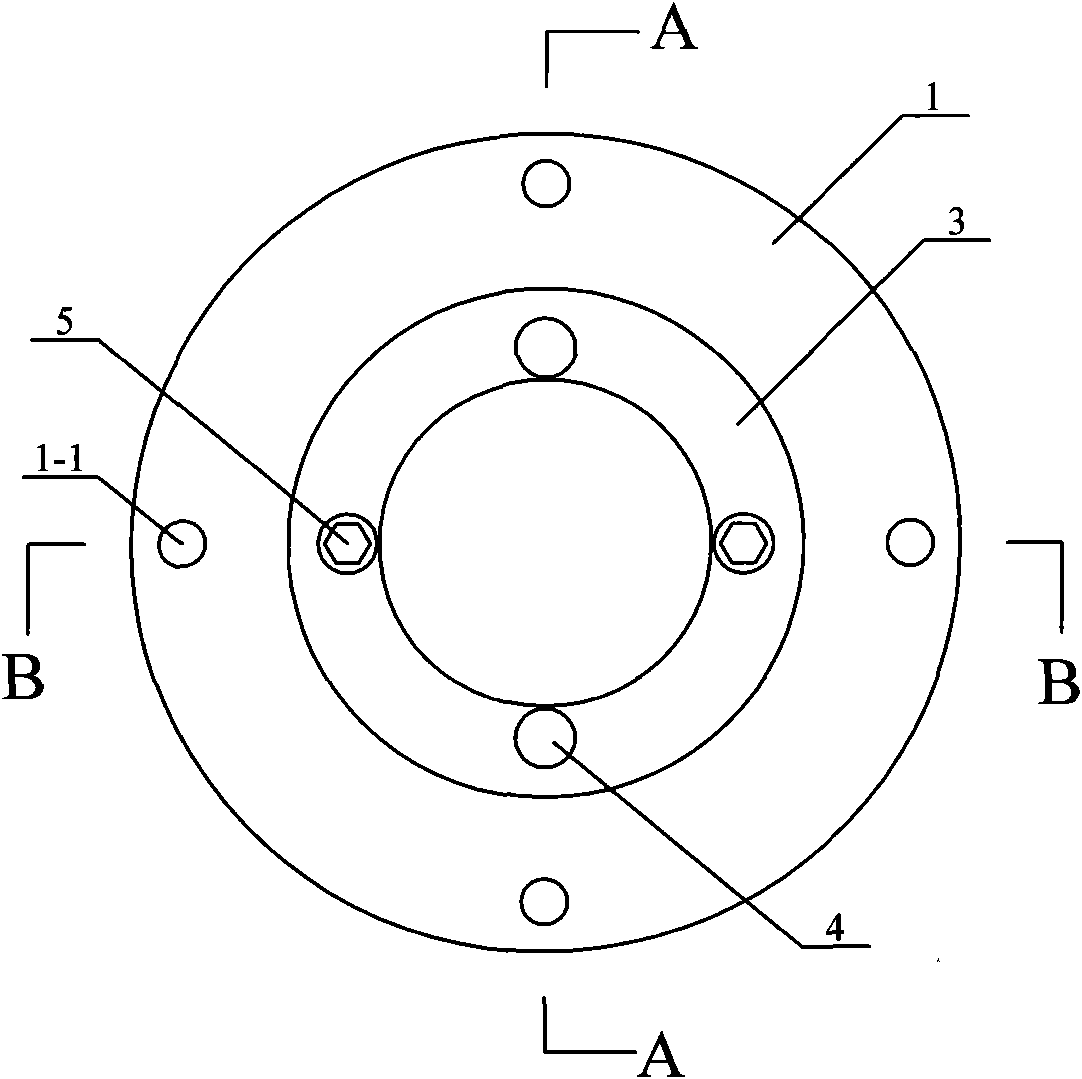

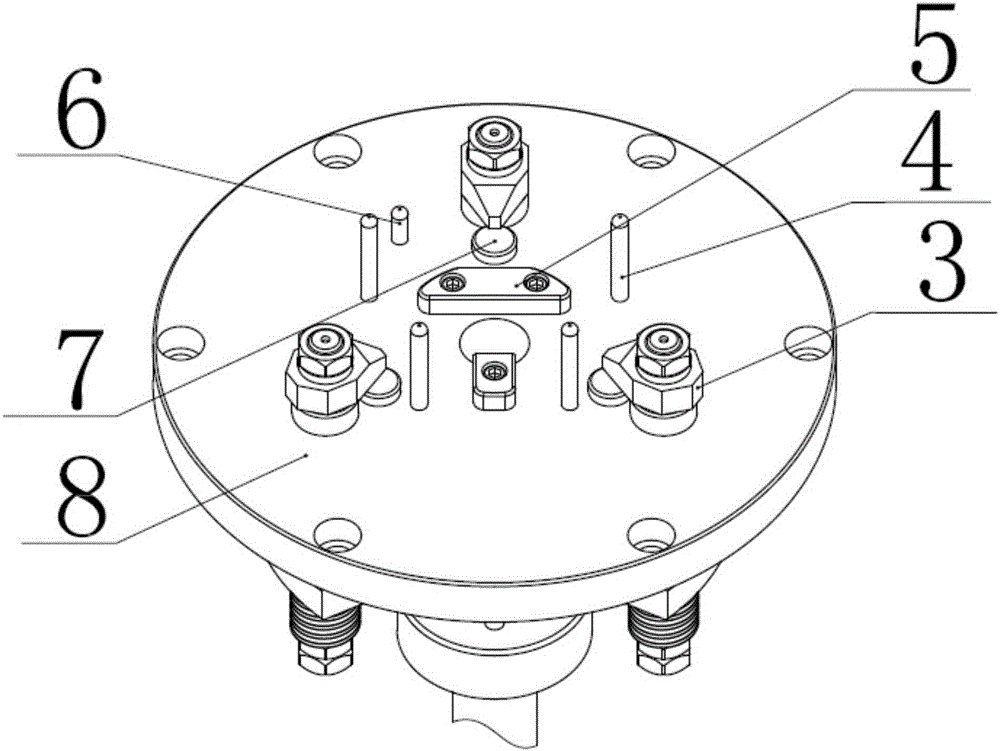

Clamp for machining inside diameters and outer diameters of fixed ball races

InactiveCN101637872AHigh concentricityReduce distortionPositioning apparatusMetal-working holdersEngineeringScrew thread

The invention discloses a clamp for machining inside diameters and outer diameters of fixed ball races. The clamp can simultaneously machine the inside diameters and the outer diameters of a pluralityof fixed ball races; and the processed fixed ball races have good concentricity, high processing work efficiency and stable processing size. An underpan, connecting blocks and a briquette of the clamp are all circular; the connecting blocks and the underpan are concentric; the inside diameters of the connecting blocks are smaller than the inside diameter of the underpan; a part of connecting blocks are connected with the pan surface of the underpan; the other part of connecting blocks are respectively provided with two or more screw holes and two or more positioning pin mounting holes; the briquette is provided with two or more bolt connecting holes and two or more positioning pin connecting holes; one end of each positioning pin is tightly matched and connected with a corresponding positioning pin mounting hole; and the other end of each positioning pin is arranged in the corresponding positioning pin connecting hole; and each connecting bolt penetrates through a corresponding bolt connecting hole and is in threaded connection with a corresponding thread hole.

Owner:WUJIANG SHUANGJING BEARING

Five-axis machine tool with tool magazine arranged in stand column

PendingCN110193754AImprove processing efficiencyCompact structureMetal working apparatusPositioning apparatusGear wheelEngineering

The invention discloses a five-axis machine tool with a tool magazine arranged in a stand column. The five-axis machine tool comprises a tool body. Two parallel stand column guide rail pairs are arranged on the middle portion of the tool body. The stand column is connected to the stand column guide rail pairs in a sliding manner. The stand column moves forwards and backwards on the stand column guide rail pairs through gear and rack pairs. Clamping mechanisms are arranged on the two sides of the tool body. Carriage guide rail pairs are arranged above the stand column. A carriage is connected to the carriage guide rail pairs in a sliding manner and is connected with a slide base through a linear guide rail pair. A five-axis head is arranged at the bottom of the slide base. A tool bit is detachably connected to the five-axis head. According to the five-axis machine tool with the tool magazine arranged in the stand column, the two clamping mechanisms are arranged on the two sides of the machine tool, the replacing and cleaning work of feeding and discharging can be conducted on a workpiece on the other side while a workpiece on one side is machined, and the machining efficiency is improved.

Owner:CHANGZHOU FAER LIN PRECISION MACHINERY

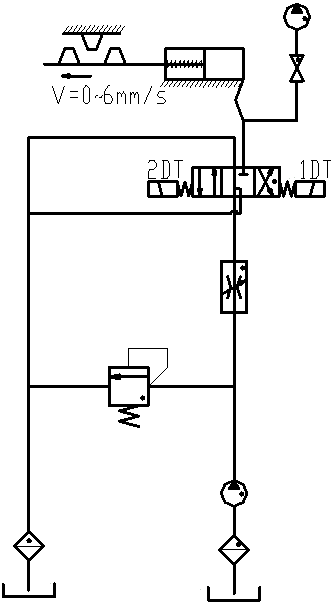

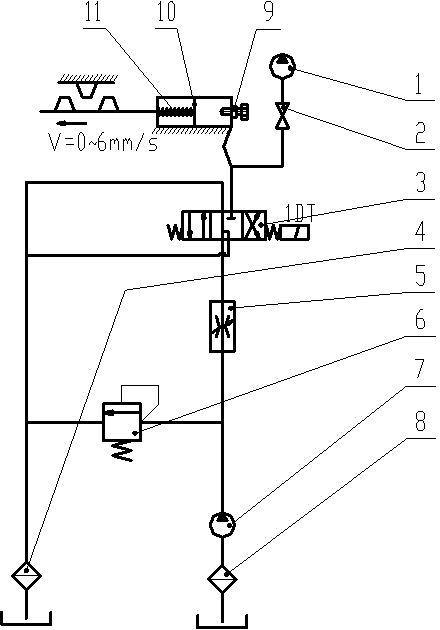

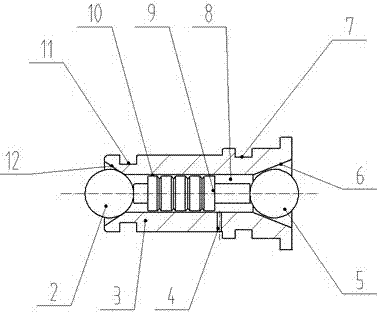

Hydraulic system for thread roller

InactiveCN104454692ADimensionally stable processingImprove work efficiencyServomotor componentsServomotorsElectricityEngineering

The invention relates to a hydraulic system for a thread roller. The hydraulic system mainly comprises a pressure meter, a pressure meter switch, a two-position four-way reversing valve, an oil return pipeline oil filter, a precision oil economizing valve, a pilot overflow valve, a vane pump, an oil suction port filter, an idle running adjustable mechanism, a piston and a spring. By means of the two-position four-way reversing valve of the hydraulic system, all hydraulic oil in an oil cylinder flows back to enable the piston to smoothly return to a rear stop point under the condition that 1DT loses power, and the control of the position limit switch over a 2DT is eliminated at the same time. The rear stop point adjustable mechanism is additionally arranged at the rear end of the oil cylinder, so that the position of the rear stop point where the piston returns is adjustable, and the idle running distance is reduced. The idle running adjustable mechanism is composed of a large nut, a small nut, a flat key, a handle and a screw. The handle is fixedly connected with the screw through the small nut and the flat key, and the large end of the screw is sleeved with the large nut. The hydraulic system for the thread roller is improved on the basis of an existing hydraulic system for the thread roller, the machining size is stable after the improvement, and the working efficiency is also greatly improved.

Owner:GUIZHOU JINGLI HANGTAI TECH

Post-treatment method for MC nylon composite material

InactiveCN109651637ACrystallization intactImprove mechanical strength propertiesPlastic materialsSlow cooling

The invention belongs to the technical field of plastic materials, and concretely relates to a post-treatment method for an MC nylon material. The temperature of a movable oven and the starting temperature of a slow cooling device are all designed in a range of 150-190 DEG C, and the temperature range is close to the maximum temperature of polymerization of MC nylon and the temperature required for crystallization, so an MC nylon blank material has a certain temperature condition to continuously complete the crystallization process; the crystallization process of the MC nylon blank material isa slow process from heat absorption to heat release, and a corresponding slow cooling condition must be set to crystallize the MC nylon blank material completely and make crystals regularized, and slow cooling is carried out for several hours to 100 DEG C or less to meet the condition, so the obtained MC nylon composite material has stable high mechanical strength and good toughness; and the lowly cooled MC nylon composite material can be aged for several days to ensure the stability of the finish size, so the processing precision of the product is ensured, and the production efficiency is guaranteed.

Owner:江苏易元新材料科技有限公司

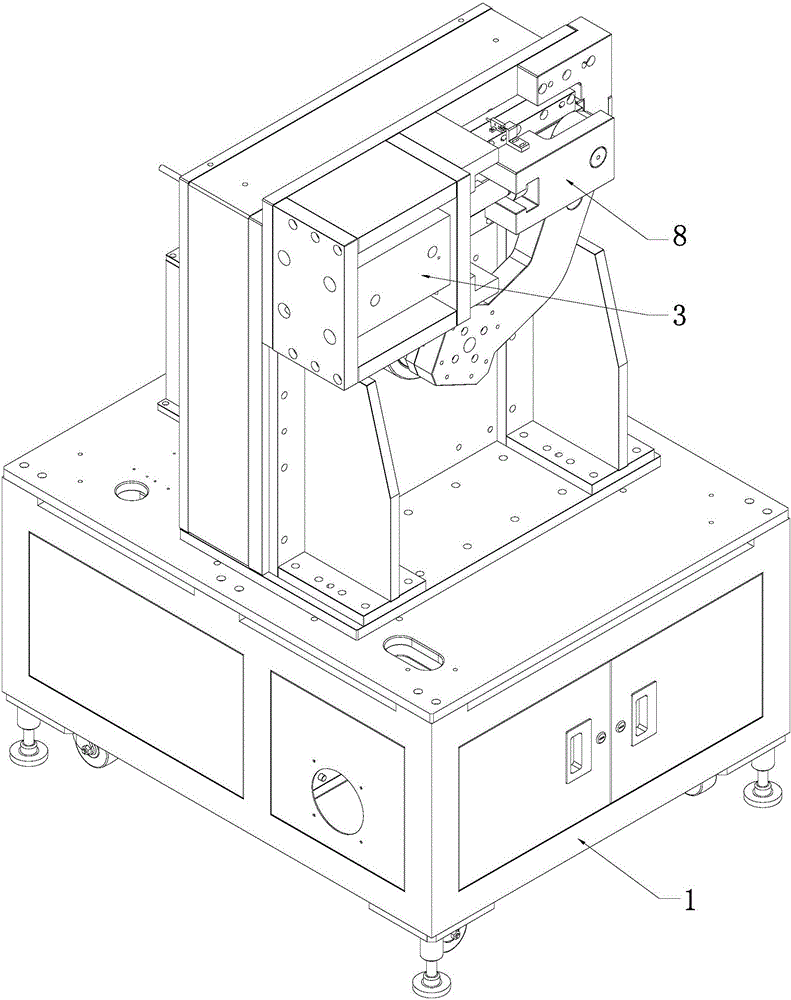

HDMI (high-definition multimedia interface) wiring harness shielding ring hexagonal crimping one-step forming machine

InactiveCN106825336AImprove the efficiency of six-sided moldingDimensionally stable processingSoldered/welded connectionsHydraulic cylinderNeedle roller bearing

The invention discloses a hexagonal crimping molding machine for an HDMI wire harness shielding ring, which includes a frame on which a needle roller bearing is connected with the bearing inner ring of the needle roller bearing to drive the inner ring of the bearing. The hydraulic cylinder for rotary motion; the driving ring fixed coaxially with the bearing inner ring of the needle bearing; the guide ring arranged coaxially on the inner radial side of the drive ring; Six extrusion blocks in the hole; the inner wall surface of the drive ring is composed of six arc-shaped slopes distributed sequentially along the circumferential direction, and these six arc-shaped slopes are respectively in contact with the six extrusion blocks, so that the six extrusion The blocks are movable inwardly in the radial direction of the drive ring by means of the rotational movement of the drive ring. This molding machine can complete the simultaneous crimping and forming of six sides of the shielding ring at one time, which improves the molding efficiency of the six sides of the shielding ring of the HDMI cable harness, stabilizes the processing size, and reduces the process sequence.

Owner:苏州科米隆机电有限公司

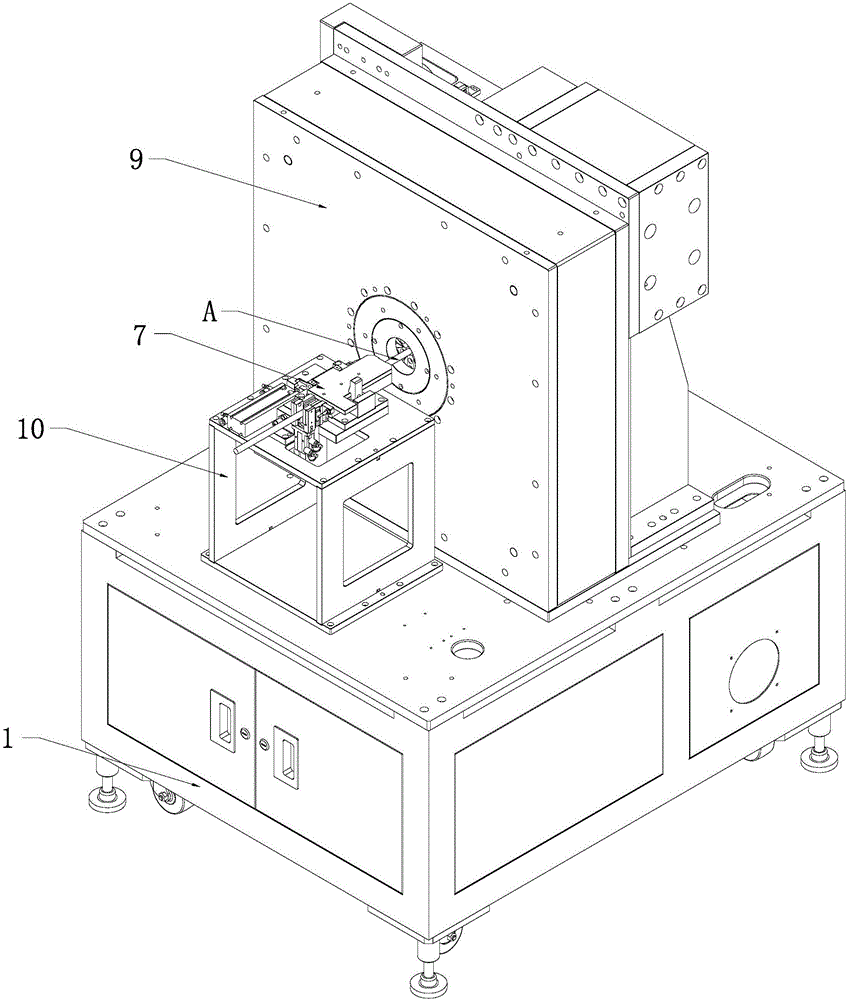

Notching machine

ActiveCN102009394AFast cutting speedDimensionally stable processingGrinding devicesEngineeringMachining

The invention discloses a notching machine comprising a base and a motor, wherein the motor is connected with the base through a connecting plate; a saw blade shaft is driven by a belt on the motor; the front end of the saw blade shaft is fixed through a front bearing and a supporting seat, and the rear end is fixed by a rear bearing and a bearing seat; a saw blade is arranged on the top end of the saw blade shaft and fixed by a lock nut; a workpiece connecting shaft is matched and connected with a guide sleeve through a workpiece main shaft; the guide sleeve is fixed on the base through the connecting plate; the workpiece main shaft is fixedly connected with a mandril dividing mechanism and a lever feeding mechanism; and the mandril dividing mechanism and the lever feeding mechanism are directly connected and fixed with the base through bolts. The notching machine can realize the circumferential dividing notching, the feeding in a cutting direction and the regulation of the notch depth and has fast cutting and stable machining dimension.

Owner:沈阳中科超硬磨具磨削研究所

CNC five-axis machining special-shaped part combined clamp and clamping method

PendingCN111331394AEven by forceStable forcePositioning apparatusMetal-working holdersCutting fluidPhysics

The invention provides a CNC five-axis machining special-shaped part combined clamp. Multiple uniform forcing clamping and fixing is adopted to be clamped with wedge blocks, the machining size is stable, the production efficiency is improved, a clamp A and a clamp B both adopt special-shaped positioning grooves to adapt to workpieces with different shapes, clearance and weight reduction are convenient, the clamp A provides pressure in at least two directions to clamp the workpieces through the wedge blocks and pressing plates, and the forcing of the workpieces is more uniform; and on the one hand, the clamp B is provided with a plurality of groups of pressing grooves to enable the workpieces to be more forced during clamping, the pressure is applied through air cylinder pull rods, and theclamping is more stable. In addition, air discharging grooves are further formed, cutting fluid can be assisted to be discharged, the machined workpieces can be blown through the air discharging grooves, the workpieces are convenient to take out, and the technical problem that although the clamping of workpiece fit positioning surfaces is more stable during tradition clamping, taking out is relatively difficult is solved.

Owner:强龙科技(苏州)有限公司

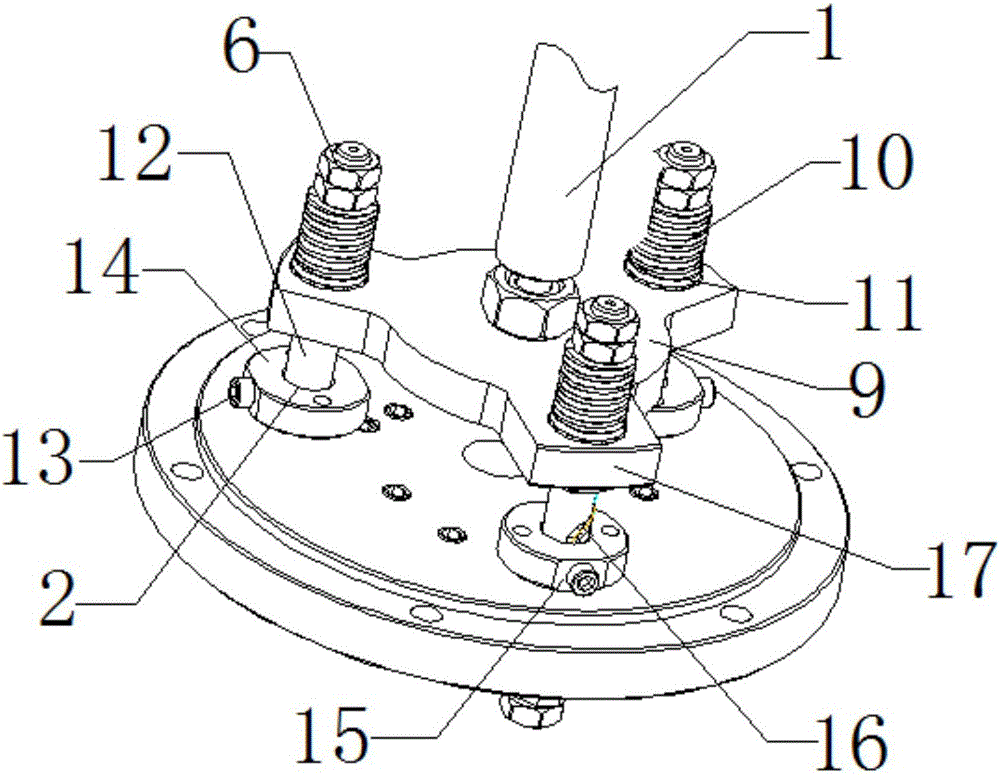

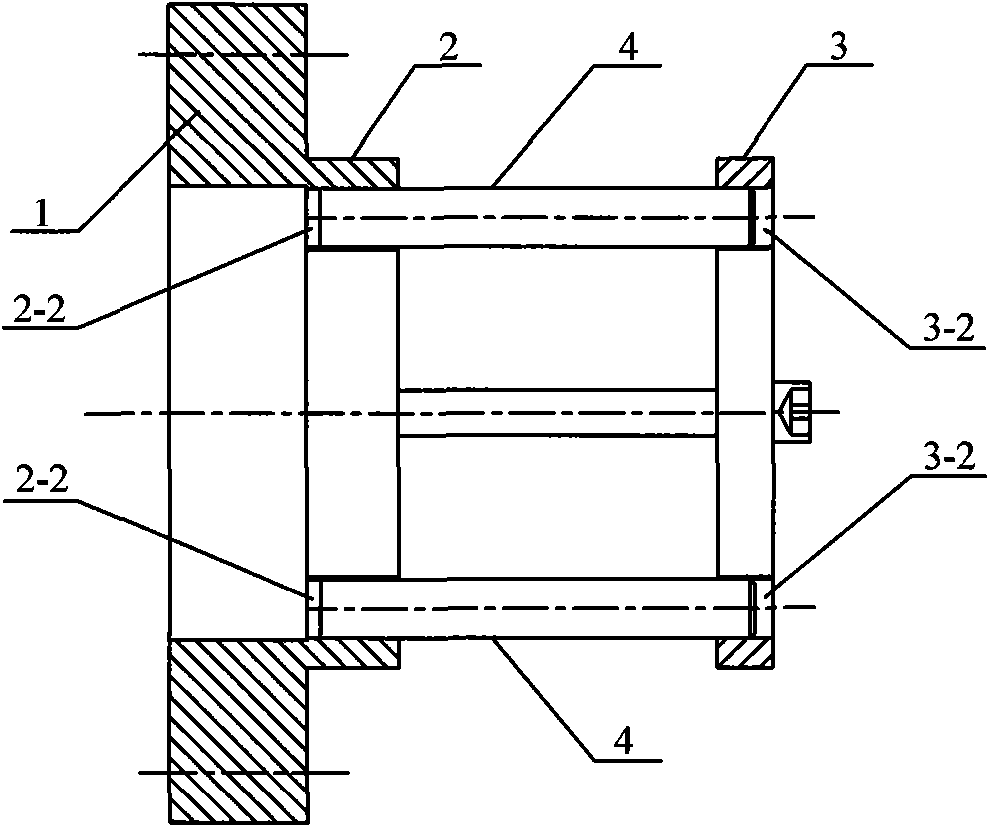

Spiral steering clamp for numerical control machine tool

InactiveCN105215698ADimensionally stable processingEasy to carryWork clamping meansPositioning apparatusNumerical controlEngineering

The invention relates to a spiral steering clamp for a numerical control machine tool. The spiral steering clamp comprises a fixing plate and steering shafts. A positioning block is arranged at the position, close to the circle center, of the upper end face of the fixing plate. Multiple fixing blocks are evenly arranged at the positions, around the circle center, of the lower end face of the fixing plate. Cylindrical holes allowing the steering shafts to pass are formed in the middle portions of the fixing blocks. A pulling plate is arranged below the fixing plate in parallel. A pulling rod is vertically connected to the center of the lower end face of the pulling plate. The steering shafts vertically penetrate the pulling plate, the fixing blocks and the fixing plate from bottom to top. A pressing plate is installed at the upper ends, penetrating the fixing plate, of the steering shafts. Hexagon nuts are fixedly installed at the lower ends of the steering shafts. The portions, between the hexagon nuts and the lower end face of the pulling plate, of the steering shafts are sleeved with springs. Spiral rails are arranged on the side walls of the steering shafts. A guiding screw is horizontally installed on the side wall of one end of each fixing block. One ends of the guiding screws are embedded into the spiral rails and slide along the spiral rails along with movement of the steering shafts in the cylindrical holes. The spiral steering clamp has the beneficial effects that no displacement or tool vibration or deformation is generated in the machining process, and positioning is accurate.

Owner:NINGBO LONGYUAN PRECISION MACHINERY

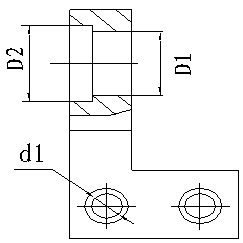

Automatic control switch valve and process method thereof

InactiveCN107246419ASimple structureEasy to processServomotor componentsServometer circuitsAutomatic train controlAutomatic control

The invention discloses an automatic control switch valve and a process method thereof. The automatic control switch valve is characterized in that a switch valve element is installed in a valve hole of a switch valve body; a first steel ball is installed on the left side of the switch valve body; a second steel ball is installed on the right side of the switch valve body; a straight through valve hole is formed in the switch valve body; a small-angle sealing cone face is designed on the right side of the switch valve body; a large-angle sealing cone face is designed on the left side of the switch valve body; a damping hole is designed in the switch valve body; the switch valve body is provided with a first O-shaped ring groove and a second O-shaped ring groove which are located in the two sides of the damping hole; and the switch valve element is designed into a sliding valve element with the large middle and the two small ends. The automatic control switch valve can be arranged in a sequence valve, a priority valve and a liquid charging valve in a plug-in mounting manner, and has the beneficial effects of being simple in structure, easy to machine and manufacture, stable in machining size, reliable in action, small in hydraulic impacting of a system and the like.

Owner:GUANGDONG TINGJIA HYDRAULIC TECH CO LTD

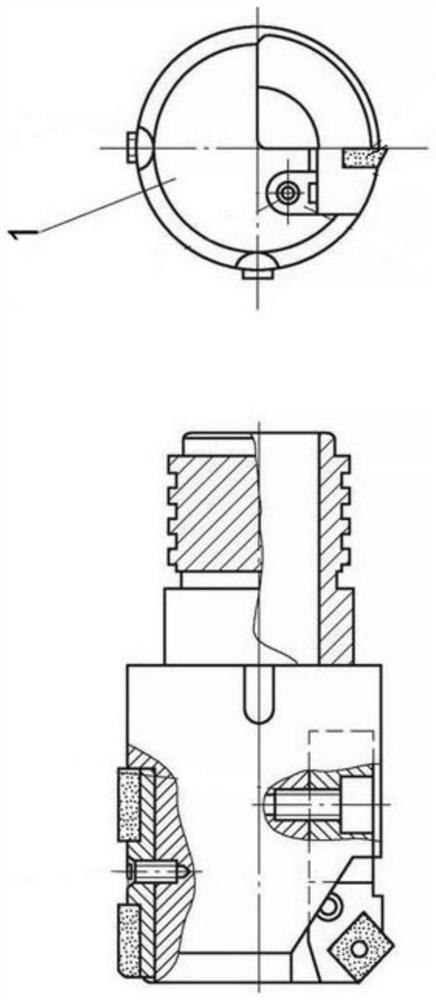

Numerical control large-diameter deep hole semi-fine boring head device

InactiveCN113290262AEnsure consistencyReduce operator skill requirementsTurning toolsBoring headsNumerical controlStructural engineering

The invention relates to the technical field of deep hole machine tools, in particular to a numerical control large-diameter deep hole semi-fine boring head device. The semi-fine boring head device comprises a boring head body, a cutter body, a supporting strip compensation structure and a cutter body compensation structure, wherein the supporting strip compensation structure comprises a fixed piston, a driving part and a moving body, the fixed piston is fixed to the boring head body, the driving part can move in the axial direction of the boring head body, a supporting strip is installed on the moving body, and the moving body is movably supported on the boring head body; the driving part and the moving body are provided with conical surfaces which are matched with each other; and the cutter body compensation structure comprises a driving mechanism and a taper mandrel, a conical surface is arranged at one end of the taper mandrel, the cutter body can abut against the conical surface, and the taper mandrel axially moves to push the cutter body to move in the radial direction of the boring head body. According to the embodiment , the supporting strip and the cutter body can compensate the abrasion loss in the radial size, the consistency of front and back machining sizes of a workpiece is ensured, consumables for replacing the supporting strips are omitted, the machining size is stable, and deep hole machining of the inner hole size of phi 800-phi 1900 mm is smoothly carried out.

Owner:SHANDONG HUAYU UNIV OF TECH

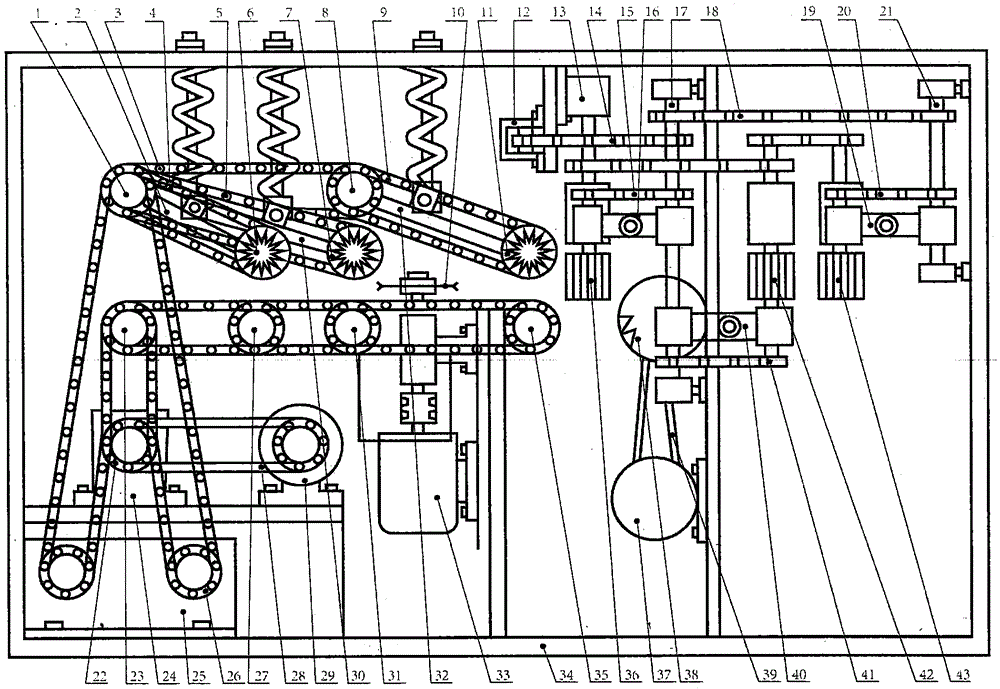

Automatic saw for processing wood processing leftover triangular materials

InactiveCN105798992ARealize automatic mechanizationDimensionally stable processingFeeding devicesCircular sawsAgricultural engineeringReducer

Disclosed is an automatic saw for processing wood processing leftover triangular materials. According to the technical scheme, a transverse cutting system is installed on the left side of a whole machine; a vertical cutting system is installed on the right side; a transverse cutting saw is arranged in the middle of the left side; a transverse cutting motor is installed on one side of the lower portion of a saw shaft and connected with a saw shaft triangular belt; a horizontal fixed feeding system is installed under a transverse cutting saw blade; the transverse cutting saw blade is provided with a horizontal swinging feeding system; a feeding motor is installed under the fixed feeding system and connected with a speed reducer triangular belt installed on the left side; a first reversing wheel mechanism is installed under a speed reducer; a vertical cutting saw is installed in the middle of the right side of the whole machine; a vertical cutting motor is installed on one side under the saw shaft and connected with the saw shaft triangular belt; a vertical fixed feeding system and a vertical swinging feeding system are installed on two sides of a vertical cutting saw blade; a cross-shaped transmission commutator is installed on one side of the vertical swinging feeding system; a second reversing wheel mechanism is installed on the left side of the cross-shaped transmission commutator; the cross-shaped transmission commutator is connected with the speed reducer through a sprocket and a chain.

Owner:穆朝富 +1

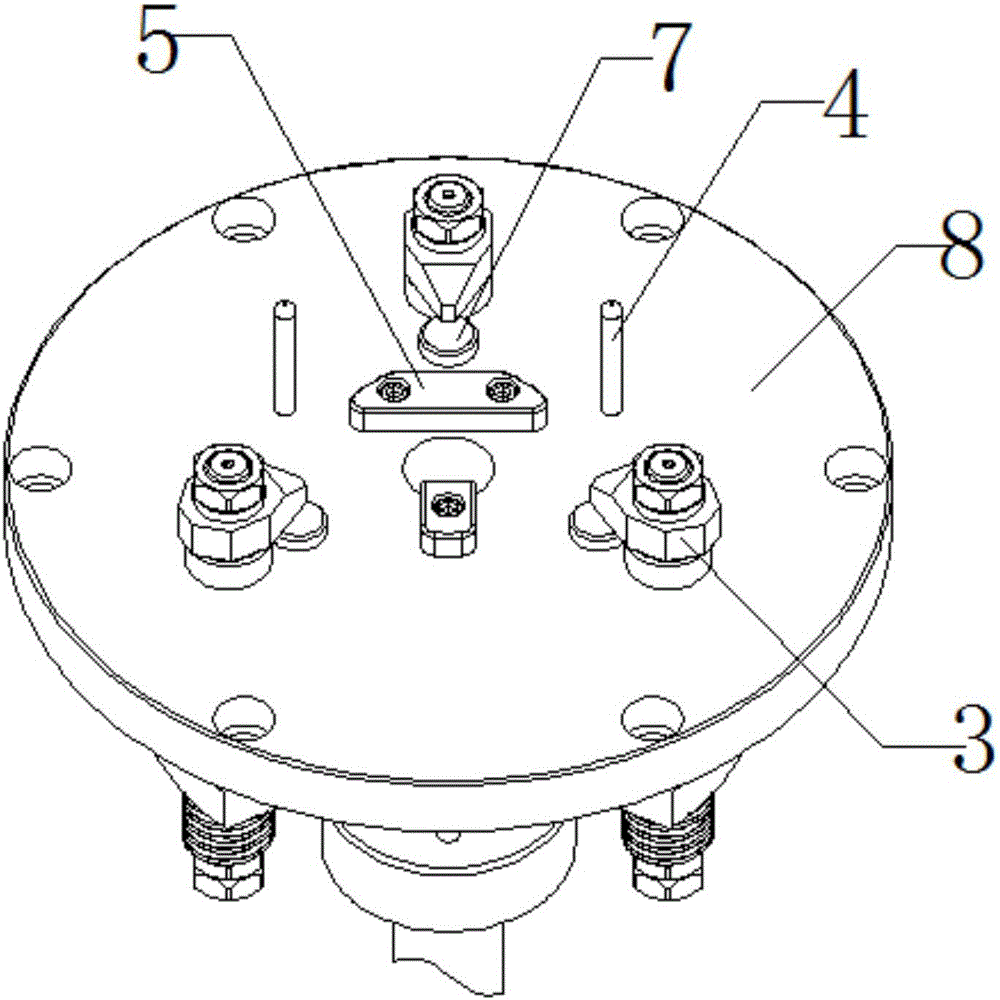

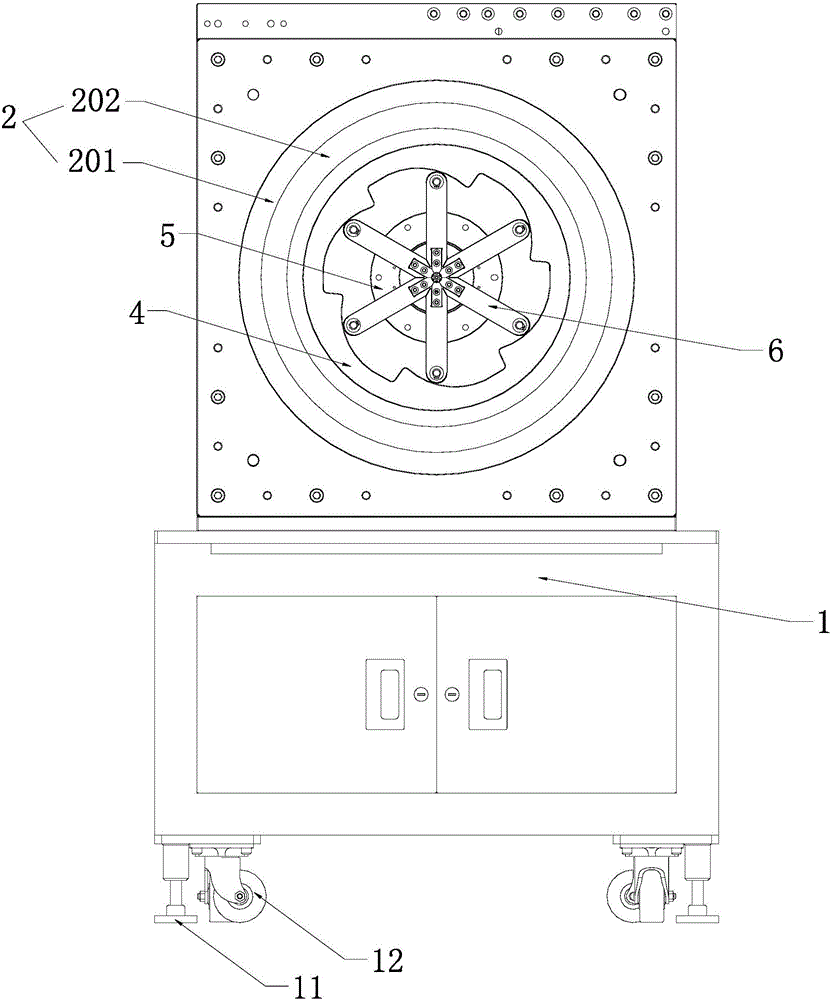

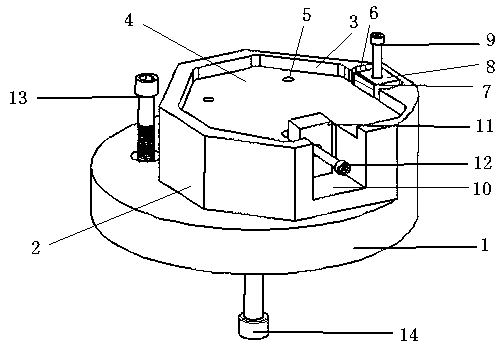

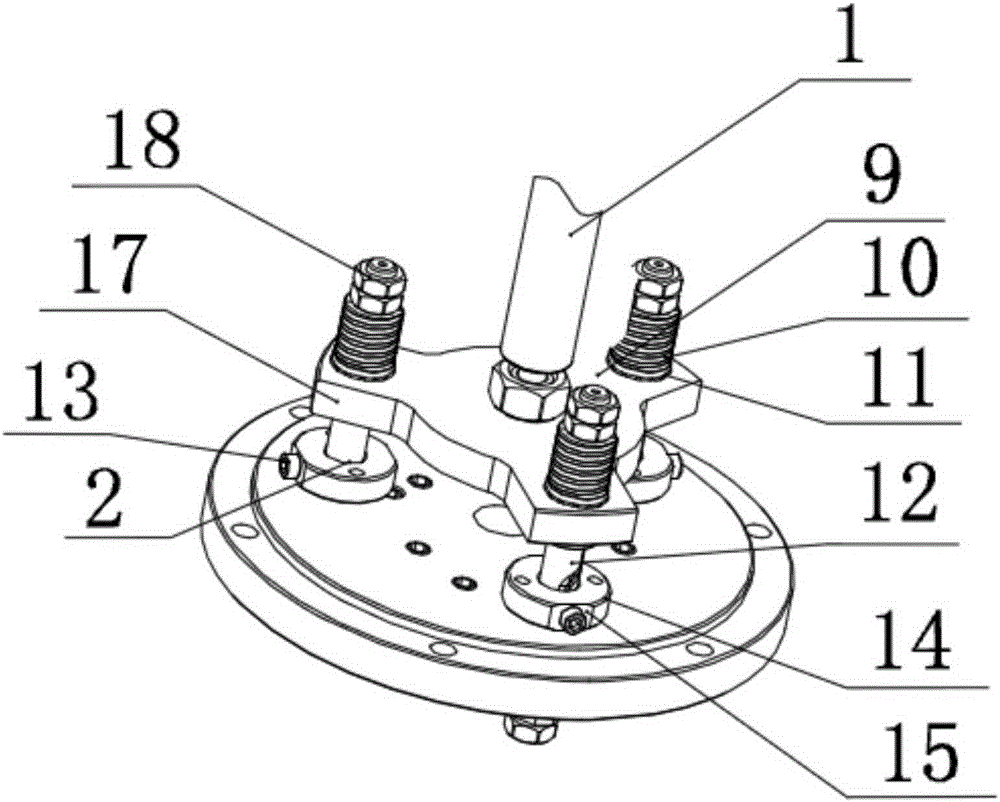

Machining clamp for aluminum alloy control arm

PendingCN111055145AEasy and fast to rotateDimensionally stable processingWork clamping meansPositioning apparatusPhysicsEngineering

The invention relates to a machining clamp for an aluminum alloy control arm. The machining clamp comprises an underframe (1), a rotary table (2), a pneumatic clamping jaw (3) for locking the rotary table (2), four rotary clamping air cylinders (4), four supporting columns (5), a positioning column (6) and a pair of limiting tables (7). The rotary table (2) is installed on the underframe (1) through a rotary shaft. The pneumatic clamping jaw (3) is detachably installed on the underframe (1), and the rotary table (2) is locked through movement of the pneumatic clamping jaw (3). Pressing blocksare arranged on the rotary clamping air cylinders (4), the four rotary clamping air cylinders (4) and the four supporting columns (5) are all fixedly installed on the rotary table (2), and the pressing blocks of the four rotary clamping air cylinders (4) correspond to the four supporting columns (5) in position. The machining clamp for an aluminum alloy control arm has the advantages that: the tool is light and fast to rotate, and one time rotation does not exceed 15 seconds; the machining size is stable, fully meet the drawing precision requirement, and customers are satisfactory; 16 minutesare needed for machining one workpiece, the production efficiency is high, and the project target is achieved.

Owner:湖北航特装备制造股份有限公司

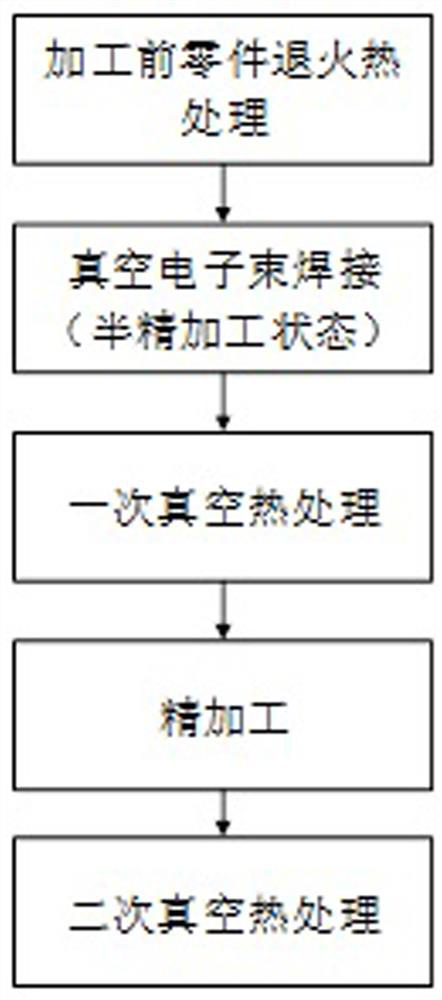

Heat treatment method of thin-wall damage tolerance type TC4-DT titanium alloy part

The invention discloses a heat treatment method of a thin-wall damage tolerance type TC4-DT titanium alloy part. The method comprises the following steps: 1) before machining, carrying out primary annealing heat treatment on the thin-wall damage tolerance type TC4-DT titanium alloy part, and then machining the thin-wall damage tolerance type TC4-DT titanium alloy part to enable the thin-wall damage tolerance type TC4-DT titanium alloy part to be in a semi-finish machining state; 2) putting the thin-wall damage tolerance type TC4-DT titanium alloy part in the the semi-finish machining state into a vacuum welding furnace for 1-2h for primary vacuum electron beam welding; 3) then putting the part into a semi-finish machining heat treatment tool, putting the tool into an annealing furnace forvacuum heat treatment, and carrying out primary vacuum heat treatment; 4) taking out the part, machining the part to enable the part to be in a finish machining state, and then putting the part into afinish machining heat treatment tool; 5) carrying out secondary vacuum heat treatment through the annealing furance for vacuum heat treatment. According to the method, the problem of stress deformation of the thin-wall damage tolerance type TC4-DT titanium alloy part during cutting machining is effectively solved, the machining size is stabilized, and it is guaranteed that the dimensional tolerance and the geometric tolerance of the part meet the technical requirements.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

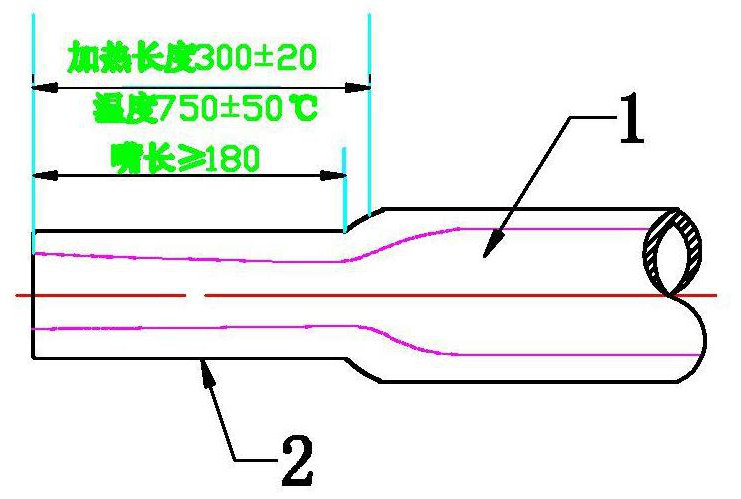

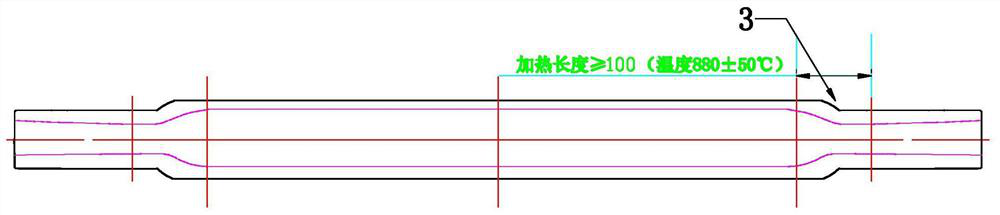

A kind of hot extrusion processing method for North American axles

The invention discloses a hot extrusion processing method for North American axles. It includes the following steps: A. Heating the entire shaft head of the shaft tube before thickening, and thickening extrusion after heating; B. Cooling the shaft tube after thickening, and closing the shaft head of the shaft tube Carry out one-time extrusion heating on the part, and perform a closing extrusion after the heating is completed; C. After the first closing extrusion is completed, perform a second extrusion heating on the transition joint part of the shaft head of the shaft tube, and perform a second extrusion heating after the second extrusion heating is completed. The second pre-forming extrusion and the third extrusion form the preliminary shaft tube oil seal; D. After the preliminary shaft tube oil seal is formed and extruded, the shaft tube is left to stand, and the entire shaft head of the shaft tube is extruded four times Pressing and heating, four times of extrusion and five times of extrusion are performed after four times of extrusion and heating to form the final shaft tube oil seal. The advantages are: it can stably produce North American axles with large and small axle heads, reduces rework rate, reduces manufacturing cost, and improves production efficiency and product quality.

Owner:江苏宝京汽车部件有限公司

A cold heading sleeve processing technology

The invention discloses a cold heading sleeve processing process, which comprises the following concrete steps: (1) screening and inspecting blank materials, carrying out corresponding incoming inspection on the blanks according to the specification of a product, and selecting the blank materials with right size, wherein the blanks are round bar materials with the diameter of 39mm and the weight of 390g; (2) selecting and using a multistage cold former for direct cold heading form, and processing to obtain required product size through four times of cold heading; (3) turning excircle chamfering R1 of the blanks, and inspecting if the product is qualified or not after chamfering; (4) rough machining an inside groove reserved by the blanks, finishing machining the inside groove, and carrying out product inspection on the blanks after finishing machining the inside groove; (5) electroplating the blanks; and (6) packaging and storing the finished products after electroplating. For each product, the blank usage amount is saved by 231.9g, so that the cost is reduced by 37.29 percent, the processing difficulty is reduced, the consumption is reduced, the processing cost is saved, and meanwhile, the production efficiency is improved.

Owner:NINGBO COFAR HOSE & FITTINGS

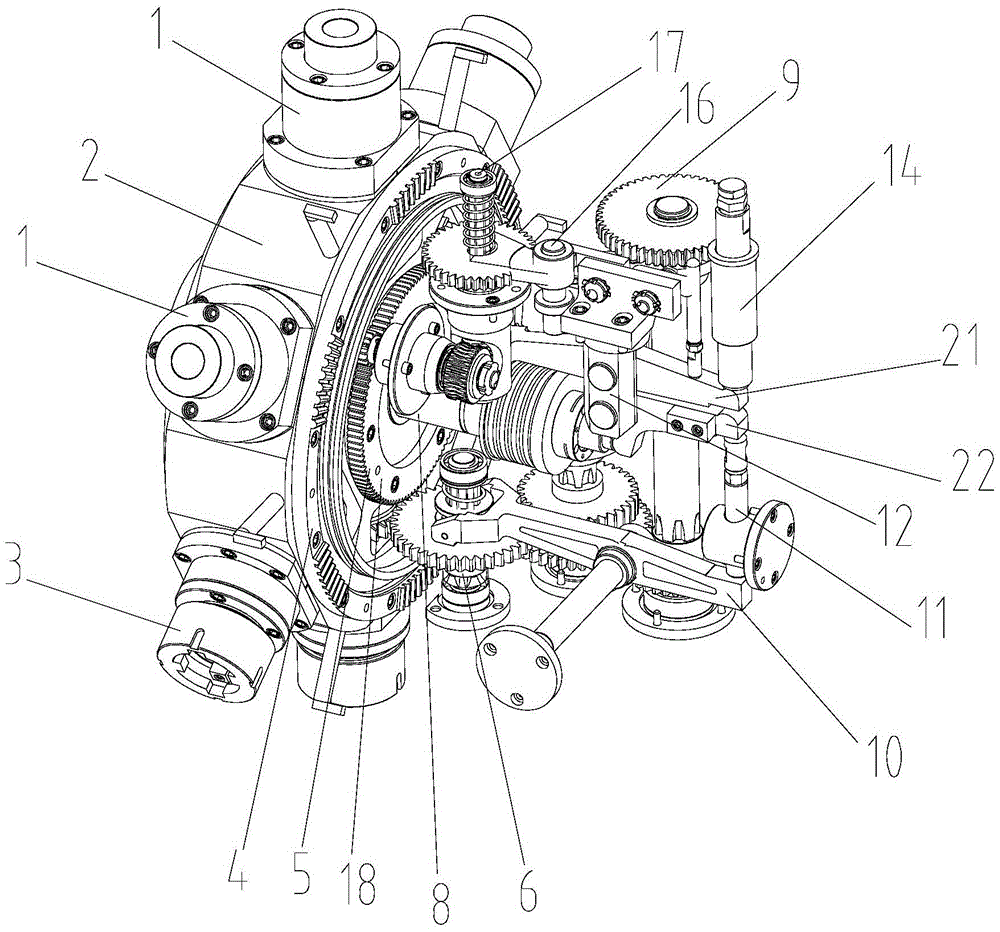

A radial long knife device for multi-axis box

ActiveCN105855575BImprove verticalityLow input costTurning toolsFeeding apparatusNumerical controlBall screw

The invention discloses a radial revolving knife device for a multi-shaft box. A hollow spindle is arranged in the multi-shaft box. A numerical control radial revolving knife device is positioned and fixed to the corresponding position of a rear cover of the multi-shaft box and comprises a servo motor, a ball screw, a ball screw nut, a sliding sleeve and a pull rod. The rotation movement of the servo motor is changed into the linear movement of the pull rod through the ball screw and the ball screw nut. A hollow boring rod is fixed to the front end of the hollow spindle. The pull rod penetrates the hollow spindle and stretches into a hollow part of the hollow boring rod. The gear end of a rack is fixed to the front end of the pull rod. Two knife bin holes are machined in the front end of the hollow boring rod. Two cutter clamps are arranged in the knife bin holes in a sliding manner, and tooth blocks engaged with the rack are fixed to the middle portions of the cutter clamps. Boring cutters are fixed to the cutter clamps in a fine adjustment manner. According to the radial revolving knife device, machining of a spindle hole and scraping of the two end faces of the spindle hole can be conducted at the same time, and the high perpendicularity of the end faces of the spindle and the spindle hole is guaranteed. Meanwhile, one machine tool is omitted, one procedure is omitted, and the production efficiency is improved.

Owner:BAODING BIAOZHENG MACHINE TOOL

A heat treatment method for thin-walled aluminum alloy parts

ActiveCN107099761BResolve Stress DeformationImprove pass rateSoldering apparatusSolid state diffusion coatingMachining processDeformation Problem

The invention belongs to the technical field of heat treatment, and provides a heat treatment method of thin-wall aluminum alloy parts. The method comprises the steps of high temperature heat treatment, vacuum brazing, heat treatment, second vacuum brazing and standard aging heat treatment, and the stress deformation problem of the thin-wall aluminum alloy parts in the cutting and machining process can be solved; not only the machining dimensions are stabilized, but also the dimensional tolerance and geometric tolerance of the parts are ensured to meet the technical requirements; and the qualification rate of the thin-wall aluminum alloy parts is improved.

Owner:宁波杰克达五金制造有限公司

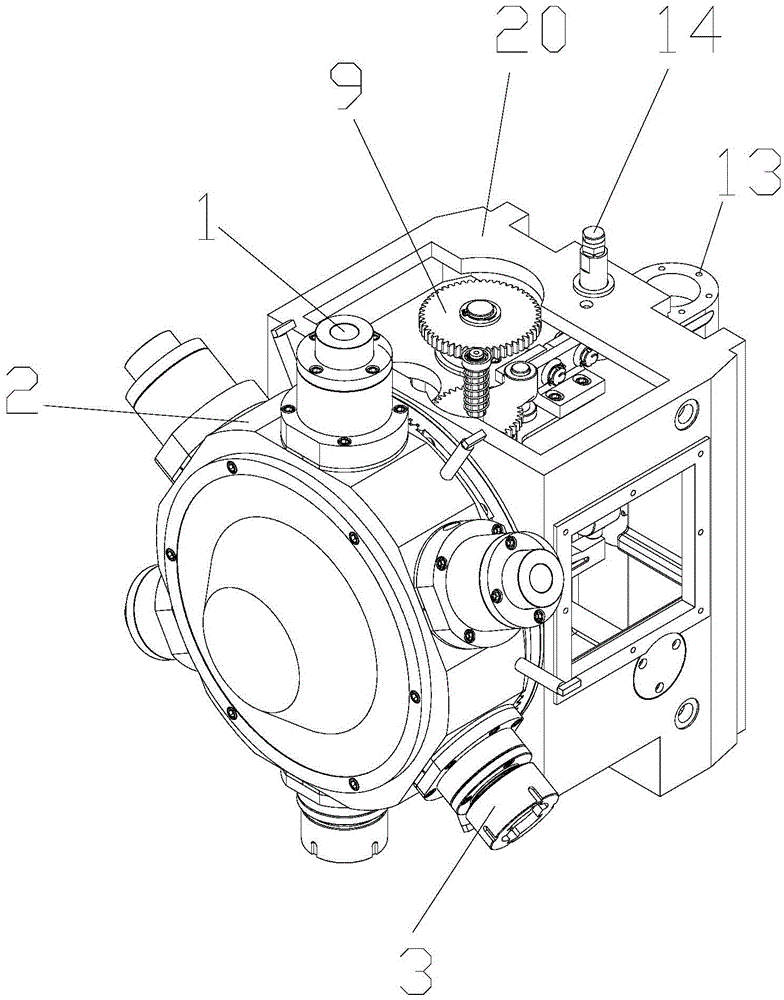

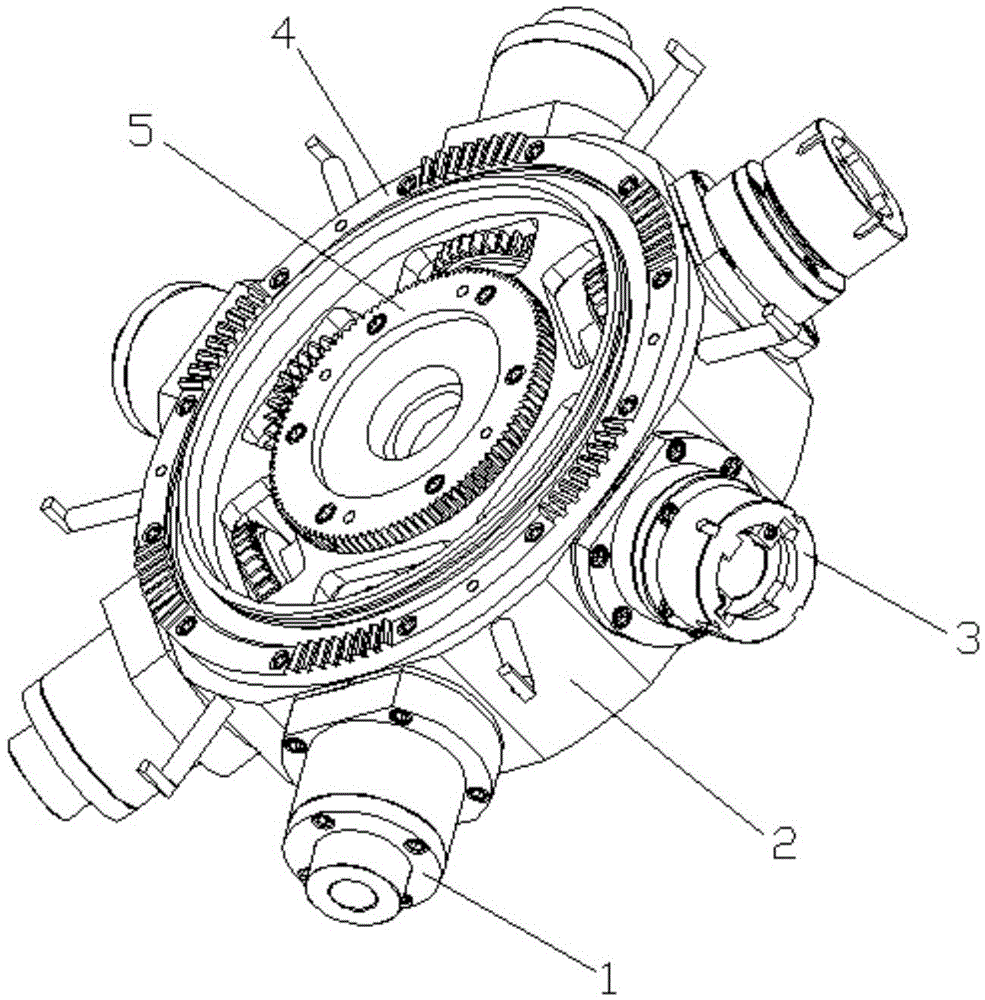

A multifunctional drilling and milling mechanism

ActiveCN103949887BRealize heavy cutting drilling and millingImprove machining accuracyOther manufacturing equipments/toolsLarge fixed membersGear wheelMouse Tooth

The invention discloses a multifunctional drilling and milling mechanism. The multifunctional drilling and milling mechanism comprises a main shaft head and a main shaft box, wherein the main shaft head comprises four drilling power heads, a main shaft box shell, two milling power heads, a mouse-tooth disc and a cutter disc gear, wherein the four drilling power heads and the two milling power heads are uniformly distributed along the circumferential direction of the cylindrical profile of the main shaft box shell, and are arranged on the main shaft box shell by rolling bearings; the mouse-tooth disc is arranged on the end surface of one side of the main shaft box shell, and the cutter disc gear is arranged on the center of the main shaft box shell; the main shaft head is connected to one end of the main shaft box by virtue of the mouse-tooth disc; the main shaft box comprises a shaft VIII, a shaft II, an indexing main shaft, a main transmission shaft, a shaft X, a shaft III, a shaft IV, a shaft IX, a worm shaft VI, a shaft VII and a turbine shaft which adopt the main shaft box body as support, as well as a lead-screw support, a connecting rod mechanism and a main driving clutch device. The multifunctional drilling and milling mechanism disclosed by the invention is applied on a machine tool and realizes drilling and milling processing of workpieces under the condition of once clamping, so that the accuracy of shapes and positions of holes or key grooves is ensured and the environment-friendly and energy-saving effects are achieved.

Owner:安阳市海之达新型建材有限公司

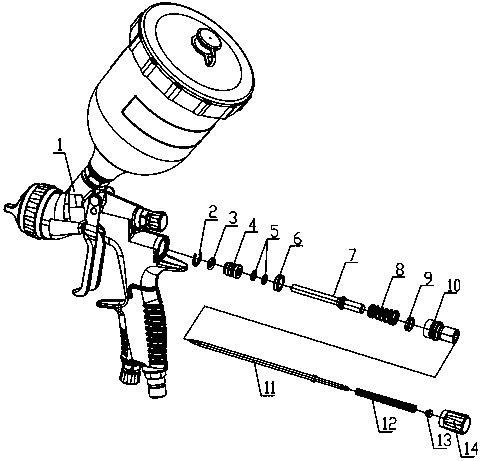

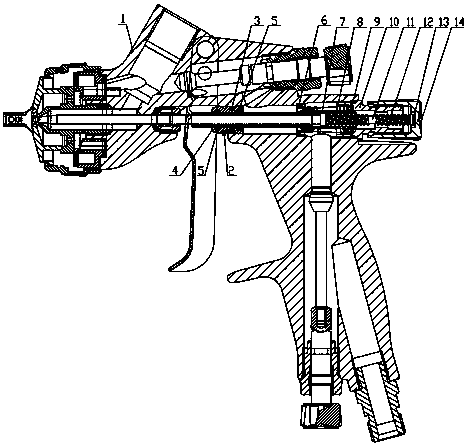

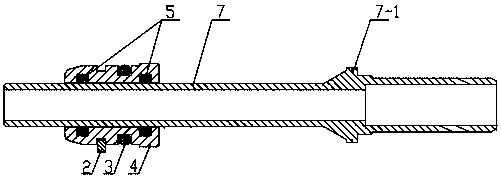

Spray gun provided with valve sealing structure

PendingCN107803287ADimensionally stable processingWon't fall offSingle-unit apparatusMetallic materialsEngineering

The invention discloses a spray gun provided with a valve sealing structure. The spray gun comprises a gun body, wherein a valve ejection rod is arranged in the gun body, a valve sleeve is arranged between the front end of the valve ejection rod and the inner wall of the gun body, the inner wall of the valve sleeve is provided with front and back inner seal ring grooves for accommodating inner seal rings, a space for storing grease is formed between the two inner seal rings arranged in the inner seal ring grooves, the outer wall of the valve sleeve is provided with an outer seal ring groove for accommodating an outer seal ring, and the outer wall of the valve sleeve is also provided with a retainer ring groove for accommodating a retainer ring. The spray gun adopts the valve sleeve made ofa metal material, the valve sleeve machining size is stable, and the influence of environment temperature change on the performance of the valve sleeve is tiny.

Owner:ZHEJIANG AUARITA PNEUMATIC TOOLS L L C

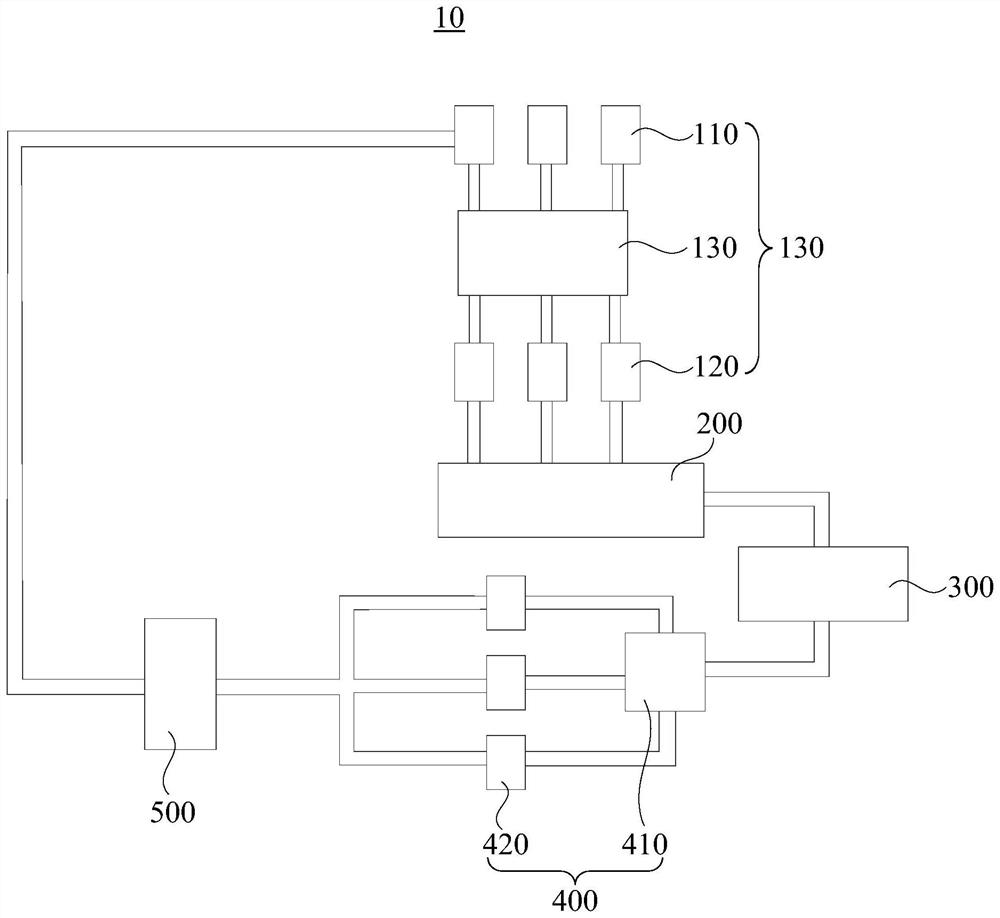

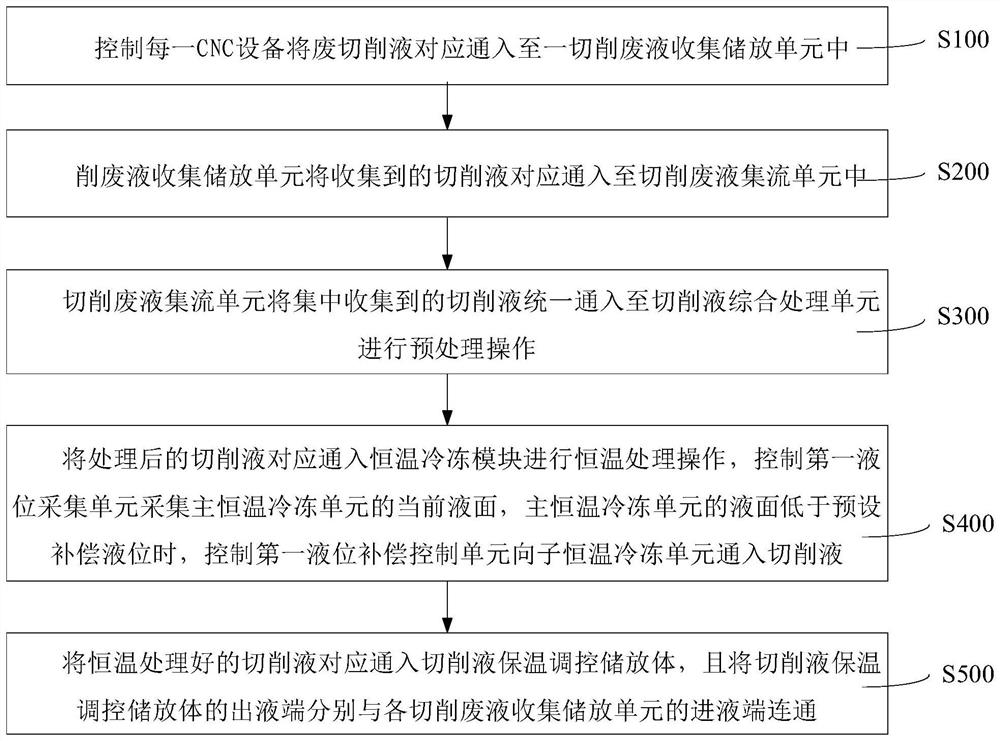

Cutting fluid circulating constant-temperature fluid supplementing treatment method and integrated treatment system for CNC (computer numerical control) system

PendingCN114749988ALiquidEasy to recycleMaintainance and safety accessoriesNumerical controlThermodynamics

The invention provides a cutting fluid circulating constant-temperature fluid supplementing treatment method for a CNC system and an integrated treatment system. The cutting fluid circulating and constant-temperature fluid supplementing integrated treatment system for the CNC system comprises a CNC module, a cutting waste fluid collecting unit, a cutting fluid comprehensive treatment unit, a constant-temperature freezing module and a cutting fluid heat preservation regulation and control storage body. The constant-temperature freezing module comprises a main constant-temperature freezing unit and at least one sub constant-temperature freezing unit, the liquid inlet end of the main constant-temperature freezing unit is communicated with the liquid outlet end of the cutting fluid comprehensive treatment unit, and the liquid inlet ends of the sub constant-temperature freezing units are communicated with the liquid outlet end of the cutting fluid comprehensive treatment unit. By means of the cutting fluid circulating constant-temperature fluid supplementing integrated treatment system for the CNC system, the consistency of the temperature of a product and the temperature during machining can be improved, and the stability of the machining size of the product is improved.

Owner:DONGGUAN MODERN METAL PRECISION DIE CASTING CO LTD

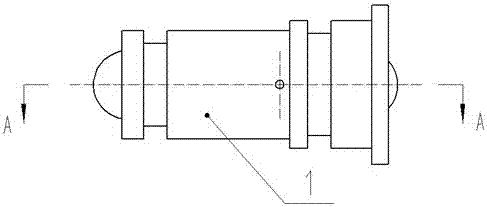

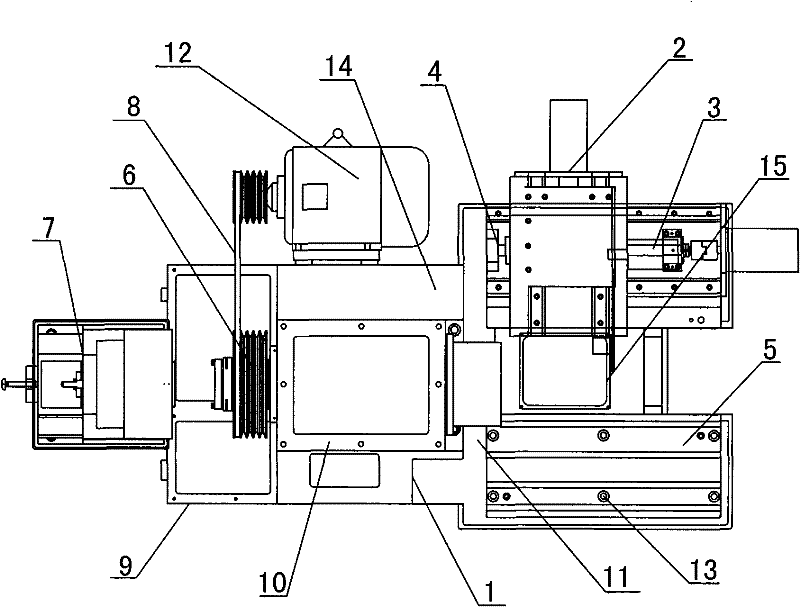

Automatic cutting machining device for spherical surface roller

The invention relates to an automatic cutting machining device for a spherical surface roller, comprising a cast box type bed body, a driving assembly, a shaft box, a feeding mechanism and a clamping mechanism. The left upper part of the cast box type bed body is provided with the shaft box, the driving assembly is arranged in a shell of one side of the shaft box and is connected with a motor driving mechanism outside the shell by a driving rod, the lower side of the shaft box is provided with a processing unit consisting of a cutting head, a numeric control cutter frame, a workpiece processing mechanism, and the like, the feeding mechanism is arranged between the shaft box and the frame body, and a rolling shaft mechanism is arranged on the other side of the clamping mechanism. The automatic cutting machining device for the spherical surface roller has compact structure and convenient operation, adopts the structures of a linear sliding guide rail and a ball screw rod and has higher machining precision and stable processing size, and the surface roughness of processing members conforms to a standard.

Owner:WUXI YITONG PRECISION MACHINERY

A milling fixture for crankshaft speed sensor main body assembly

ActiveCN105312920BAchieve removalEasy to usePositioning apparatusMetal-working holdersLeft halfEngineering

The title of the present invention is a milling fixture for crankshaft speed sensor main body assembly. It belongs to the technical field of fixtures. It mainly solves the problem that the existing wire cutting process cannot meet the mass production of factories due to low production efficiency. Its main features are: including the right body and the left body; the upper part of the right body is the right half-step hole body, the lower part is the right seat body, and the right seat body is provided with two identical right step holes, and the hole direction of the right step hole is It is perpendicular to the hole direction of the right half-step hole body; the upper part of the left body is the left half-step hole body, the lower part is the left base body, and the left base body is provided with two identical left step holes, and the left step hole is aligned with the left The hole direction of the half-step hole body is vertical; the right base body is the same as the left base body, and the right half-step hole body and the left half-step hole body have the same size and opposite directions. The invention has the characteristics of quickness, convenience and high processing efficiency, and is mainly used for the milling process of the main body assembly of the crankshaft speed sensor and the similar ABS body assembly whose shape of the clamping end cannot be clamped.

Owner:DONGFENG AUTOMOBILE ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com