Numerical control lathe clamp for machining of thin-wall parts prone to deformation

A technology for parts processing and CNC lathes, used in manufacturing tools, metal processing equipment, metal processing machinery parts, etc. Dimensionally stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

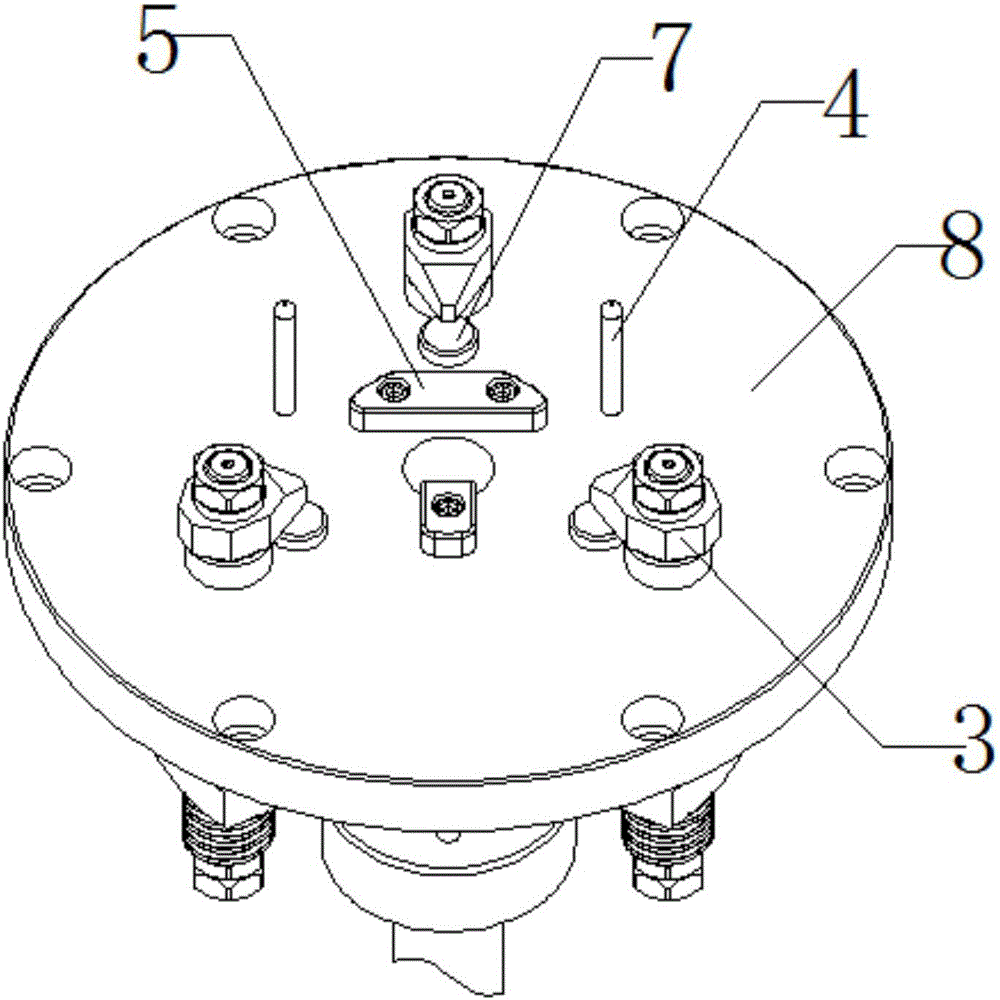

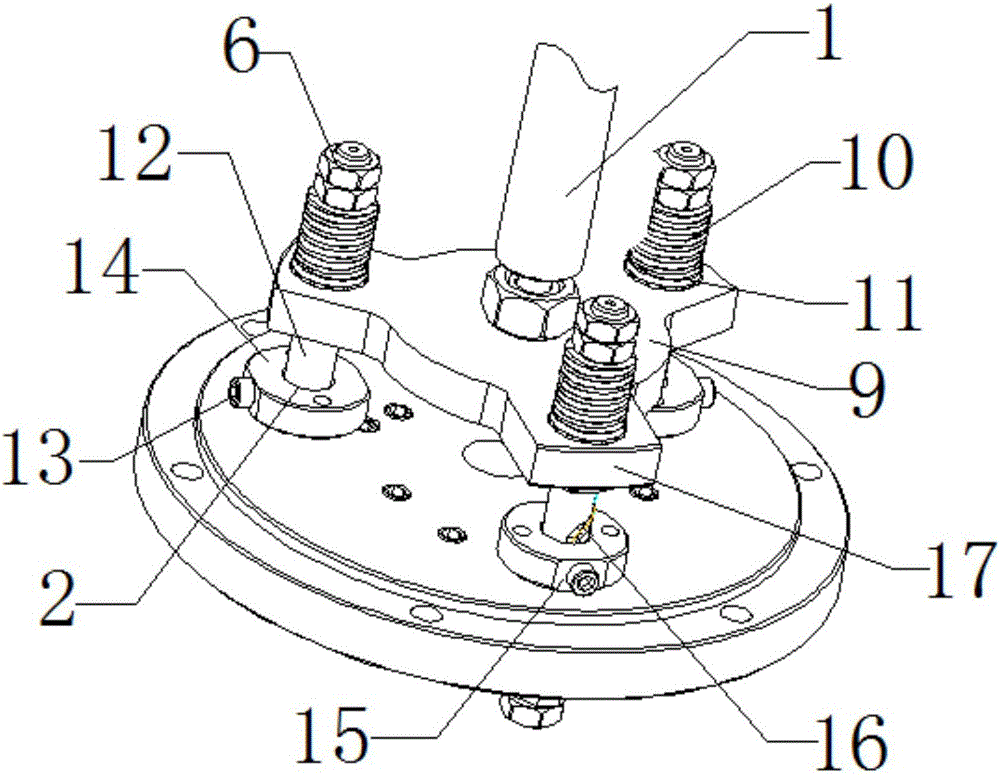

[0022] When the product is processed, the product is positioned first, and the product is placed in the positioning block 5 along the product guide pin 4 for positioning. After the product position is adjusted until the support nail 7 stabilizes the lower end surface of the product, the hydraulic mechanical braking system of the CNC lathe pulls the pull rod 1 Drive the pull plate 9 to compress the spring 10, and transmit the elastic force to the steering shaft 12 through the thrust ball bearing 11 to make it pull down, the guide screw 13 moves along the spiral guide rail 16, the pressure plate 3 turns and compresses the product, and the product is ready After processing, the hydraulic mechanical braking system of the machine tool pushes out the pull rod 1, drives the pull plate 9, and pushes up the steering shaft 12 through the thrust ball bearing 11, so that the pressure plate 3 is released, and the product is taken out. The invention has the characteristics of no displacement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com