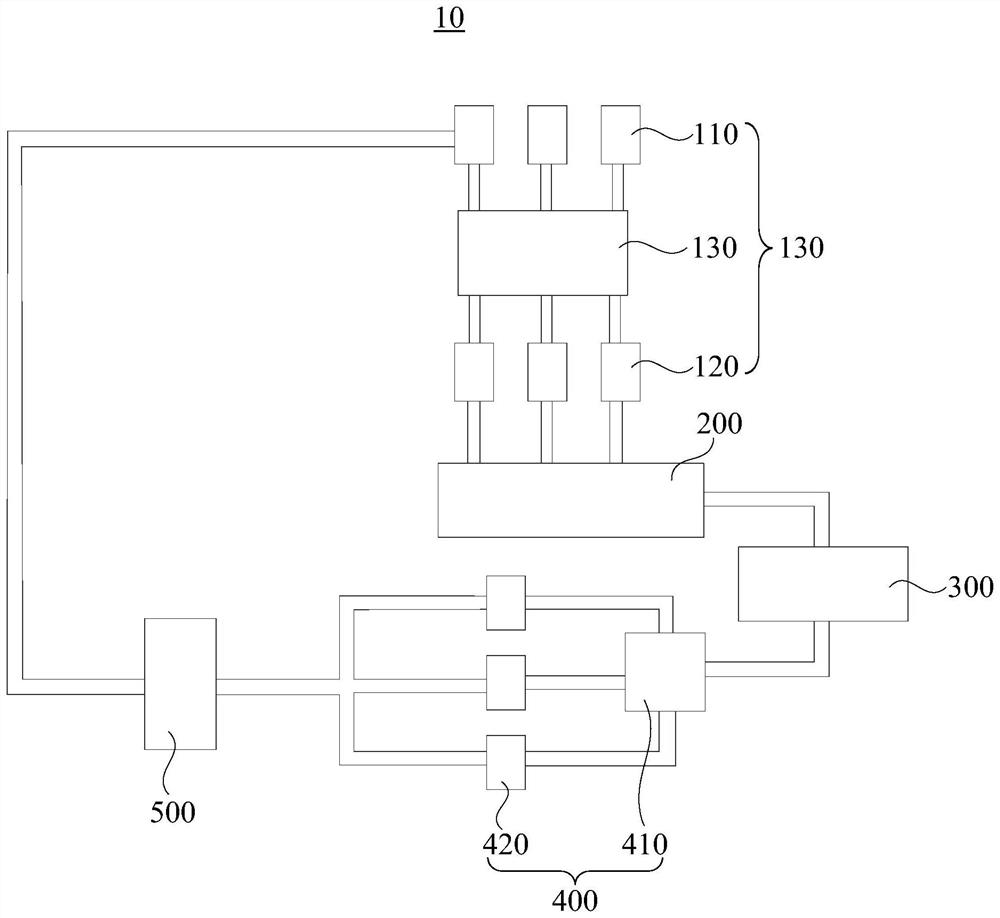

Cutting fluid circulating constant-temperature fluid supplementing treatment method and integrated treatment system for CNC (computer numerical control) system

A processing system and processing method technology, which is applied in the field of cutting fluid circulation and constant temperature rehydration processing method for CNC system and integrated processing system, can solve the problems of poor processing size and insufficient process capability, so as to improve stability, ensure stability and circular effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

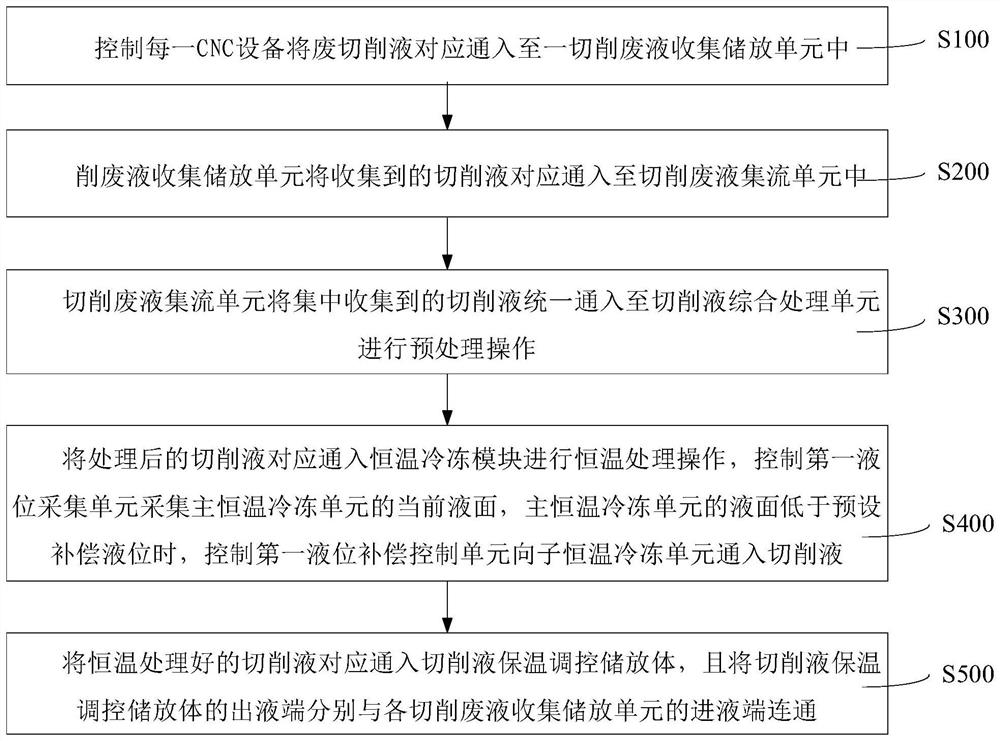

Embodiment 1

[0065] Control each CNC equipment to correspondingly pass the waste cutting fluid into a cutting waste liquid collection and storage unit for subsequent recycling; then the cutting waste liquid collection and storage unit will pass the collected cutting fluid to the cutting fluid correspondingly In the waste liquid collecting unit, the cutting waste liquid collecting unit will uniformly pass the collected cutting fluid to the cutting fluid comprehensive processing unit for pretreatment operation, and correspondingly pass the processed cutting fluid into the constant temperature freezing module for constant temperature treatment operation. , control the first liquid level acquisition unit to collect the current liquid level of the main constant temperature freezing unit, when the liquid level of the main constant temperature freezing unit is lower than the preset compensation liquid level, control the first liquid level compensation control unit to pass cutting to the sub constan...

Embodiment 2

[0067] Control each CNC equipment to correspondingly pass the waste cutting fluid into a cutting waste liquid collection and storage unit for subsequent recycling; then the cutting waste liquid collection and storage unit will pass the collected cutting fluid to the cutting fluid correspondingly In the waste liquid collecting unit, the cutting waste liquid collecting unit will uniformly pass the collected cutting fluid to the cutting fluid comprehensive processing unit for pretreatment operation, and correspondingly pass the processed cutting fluid into the constant temperature freezing module for constant temperature treatment operation. , control the first liquid level acquisition unit to collect the current liquid level of the main constant temperature freezing unit, when the liquid level of the main constant temperature freezing unit is lower than the preset compensation liquid level, control the first liquid level compensation control unit to pass cutting to the sub constan...

Embodiment 3

[0069] Control each CNC equipment to correspondingly pass the waste cutting fluid into a cutting waste liquid collection and storage unit for subsequent recycling; then the cutting waste liquid collection and storage unit will pass the collected cutting fluid to the cutting fluid correspondingly In the waste liquid collecting unit, the cutting waste liquid collecting unit will uniformly pass the collected cutting fluid to the cutting fluid comprehensive processing unit for pretreatment operation, and correspondingly pass the processed cutting fluid into the constant temperature freezing module for constant temperature treatment operation. , control the first liquid level acquisition unit to collect the current liquid level of the main constant temperature freezing unit, when the liquid level of the main constant temperature freezing unit is lower than the preset compensation liquid level, control the first liquid level compensation control unit to pass cutting to the sub constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com