Automatic cutting machining device for spherical surface roller

A cutting and spherical roller technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of low processing efficiency and unstable dimensions, and achieve convenient operation, compact structure and high processing accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

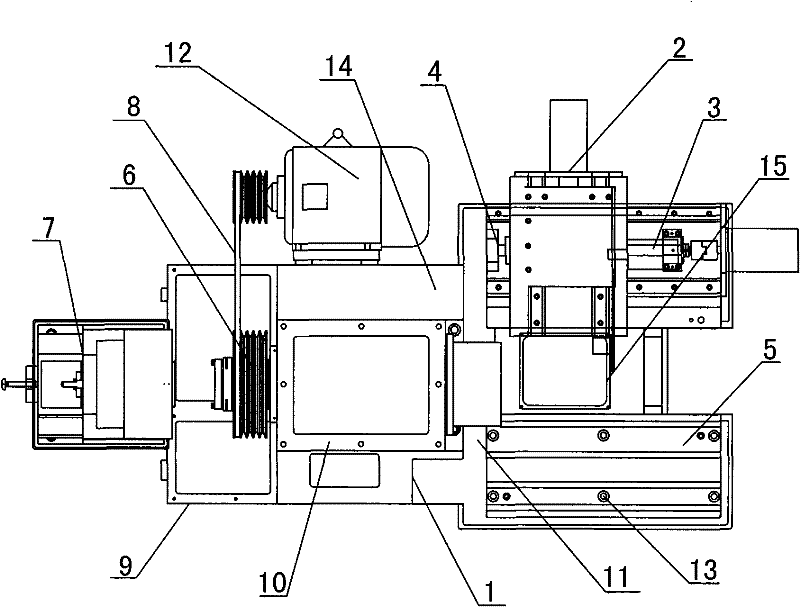

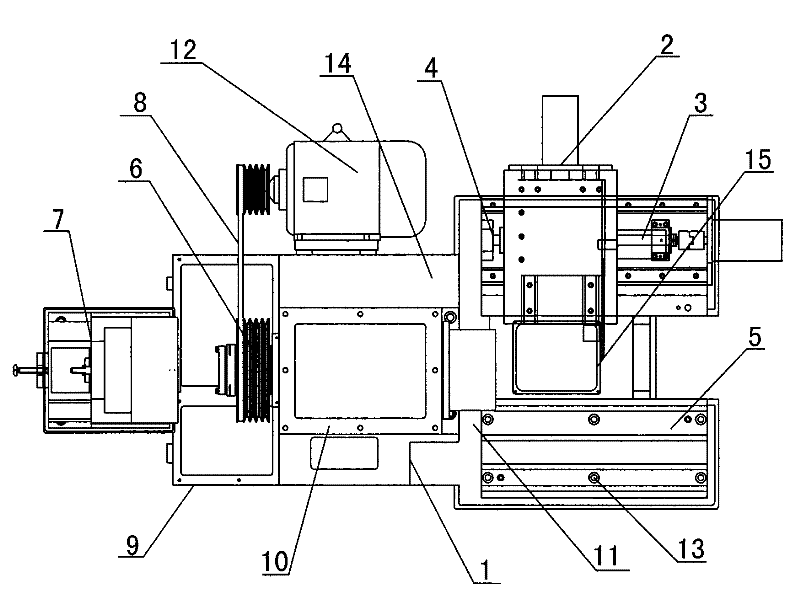

[0011] like figure 1 As shown, the automatic cutting processing device for spherical rollers of the present invention includes a casting box bed 1, a transmission assembly 6, an axle box 10, a feeding mechanism 11, and a clamping mechanism 15. The casting box bed The upper left part of the body 1 is provided with an axle box 10, and a transmission assembly 6 is installed in the housing 9 on one side of the axle box 10. The transmission assembly 6 is connected with the motor drive mechanism 12 outside the housing 9 through a transmission rod 8, and the transmission The other side of the shell of the assembly 6 is provided with a blanking mechanism 7; the lower side of the axle box 10 is a processing unit 14 composed of a cutting head, a numerical control tool holder, a workpiece processing mechanism, etc., and one side of the processing unit 14 is installed with a clamp Clamping mechanism 15, the bed tail of the clamping mechanism 15 is provided with a frame body 5 fixed by bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com