A radial long knife device for multi-axis box

A multi-axis box and tool holder technology, which is applied to the lathe tool, feeding device, tool holder accessories, etc., can solve the problem that it is difficult to ensure the high verticality of the spindle end face and the spindle hole, and reduce input costs. The effect of reducing the process and stabilizing the feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

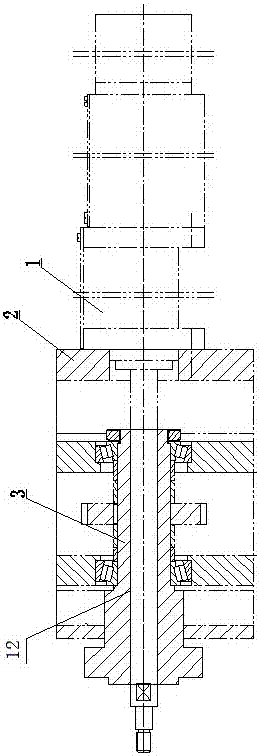

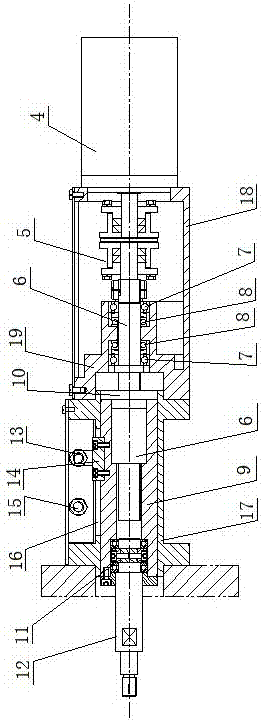

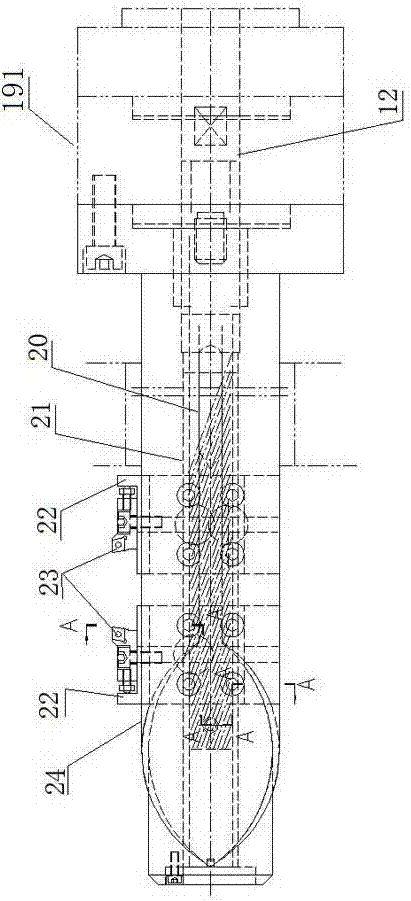

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, this embodiment includes a numerical control radial long knife device 1, a hollow main shaft 3 manufactured according to the precision and tolerance of the main shaft of the multi-axis box 2, a hollow boring bar 24 for machining the main shaft hole, a rack 20, a gear block 25, and a tool holder 22 and boring tool 23. The hollow main shaft 3 is installed in the multi-axis box 2 according to the coordinate position of the machining hole, and the numerical control radial long knife device 1 is positioned and fixed at the corresponding position of the back cover of the multi-axis box 2 . The CNC radial long knife device 1 includes a servo motor 4 , a ball screw 6 , a ball screw nut 10 , a sliding sleeve 9 and a pull rod 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com