Automatic control switch valve and process method thereof

A process method and technology for switching valves, applied in the hydraulic field, can solve the problems of hydraulic shock, difficult processing, and high valve precision requirements, and achieve the effects of small hydraulic shock, easy processing and manufacturing, and stable processing dimensions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

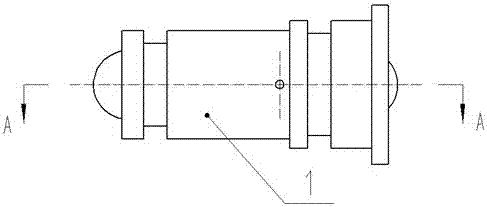

[0019] Embodiment 1, an automatic control switching valve, including a switching valve body, a switching valve core, a left steel ball, and a right steel ball, the switching valve core is installed in the valve hole of the switching valve body, and the left steel ball is installed in the switching valve body The left side and the right steel ball are installed on the right side of the switching valve body. The center of the switching valve body is designed with a straight-through valve hole, the left side of the switching valve body is designed with a large-angle sealing cone surface, the right side of the switching valve body is designed with a small-angle sealing cone surface, and the switching valve body is designed with a damping hole. There are two O-ring grooves. The switching spool is designed as a slide valve spool with a large middle and small ends.

Embodiment 2

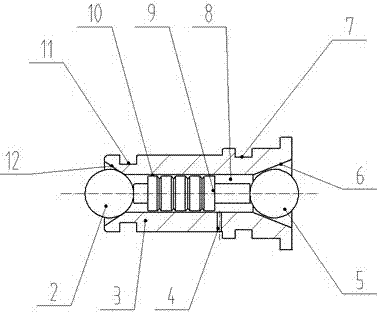

[0020] Embodiment 2, with reference to Figure 1 to Figure 4 As shown, an automatic control switching valve includes a switching valve body, a switching valve core, a first steel ball, and a second steel ball. The switching valve body (3) is processed with a straight-through valve hole (8). The right side of the switching valve body (3) is processed with a small-angle sealing cone surface (6), the left side of the switching valve body (3) is processing a large-angle sealing cone surface (12), and the switching valve body (3) is The damping hole (4) is processed on the top, and the switching valve body is provided with a first O-ring groove (7) and a second O-ring groove (11) on both sides of the damping hole (4); the switching The spool (9) is installed in the valve hole (8) of the switching valve body (3); the first steel ball (2) is installed on the left side of the switching valve body (3); the second steel ball (5) Installed on the right side of the switching valve body (...

Embodiment 3

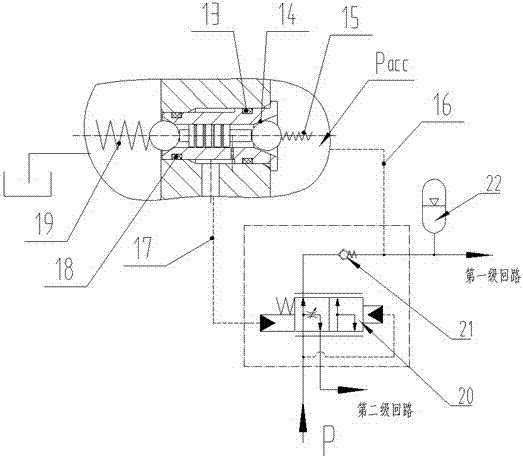

[0021] Embodiment 3, the oil outlet of the hydraulic pump is connected to the oil port P to supply oil to the hydraulic system. When the control pressure Pacc of the first control oil passage (16) is lower than the set lower limit pressure value Pd, it acts on the second steel ball (5) The hydraulic pressure F5 (F5=Pd*S5) and the spring force F15 of the return spring (15) are smaller than the spring force F19 of the pressure regulating spring (19), and the spring force F19 of the pressure regulating spring (19) passes the first The steel ball (2) and the switching spool (9) force the second steel ball (5) to leave the small-angle sealing cone (6) on the right side of the switching valve body (3), and the second steel ball (5) and the small-angle sealing The conical surface (6) forms a gap (14), the hydraulic oil of the first stage circuit enters the right side of the switching valve (1) through the first control oil passage (16), and passes through the second gap (14), the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com