A kind of hot extrusion processing method for North American axles

A processing method and hot extrusion technology, applied in the direction of mechanical equipment, engine components, etc., can solve the problems of high temperature control requirements of equipment, insufficient oil sealing position forming, reducing product qualification rate, etc., to eliminate tissue defects, improve Production efficiency and product quality, the effect of reducing the rework rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

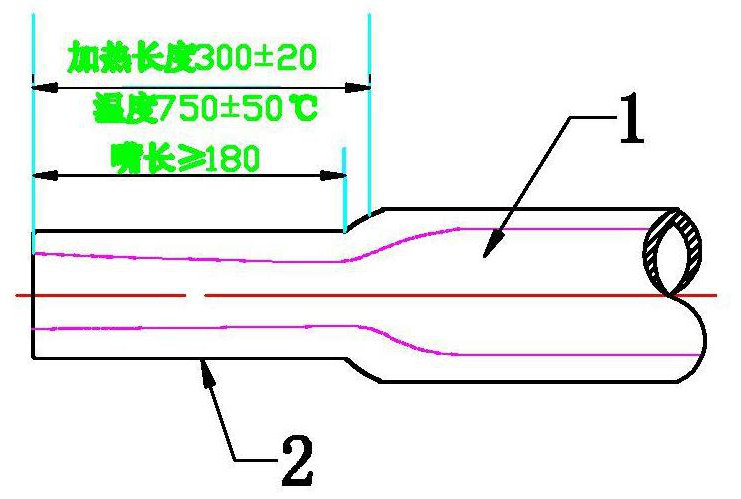

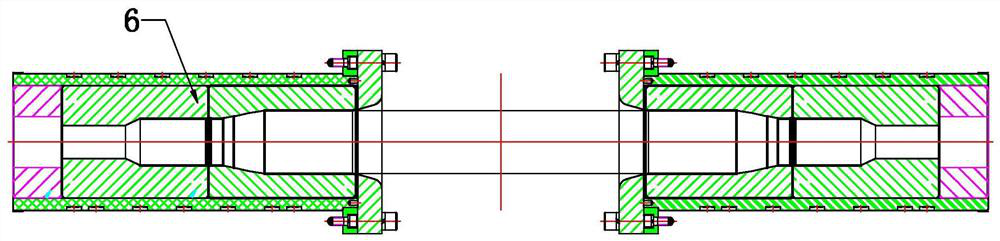

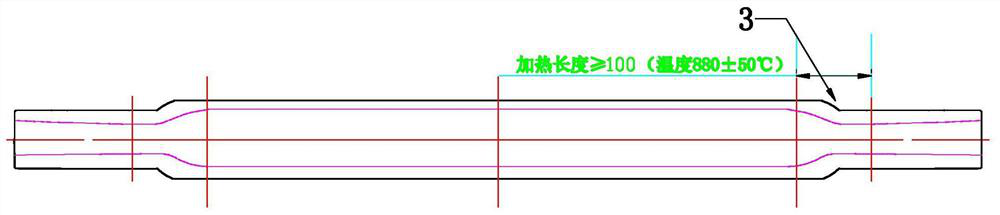

[0029] The hot extrusion processing method for North American axles of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

[0030] The hot extrusion processing method for North American axles of the present invention is mainly aimed at the production of U27-sized axle blanks, and its specific production equipment mainly adopts three-stage intermediate frequency heating equipment and axle horizontal double-station two-way extruders and one set of thickening extrusion dies and five sets of forming extrusion dies for the production of North American axle products. After repeated trial production and test verification, the material used for making the dies was finally selected as UNIMAX special die steel. This steel has high Hardness and excellent toughness, with excellent polishing performance, suitable for coating and nitriding treatment. After multiple quenching and tempering and nitriding treatment, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com