Five-axis machine tool with tool magazine arranged in stand column

A column and tool magazine technology, used in positioning devices, metal processing machinery parts, clamping and other directions, can solve the problems of unstable processing size, unreliable clamping positioning, poor rigidity of the manipulator, etc., to achieve compact structure, good rigidity, Machining dimensionally stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

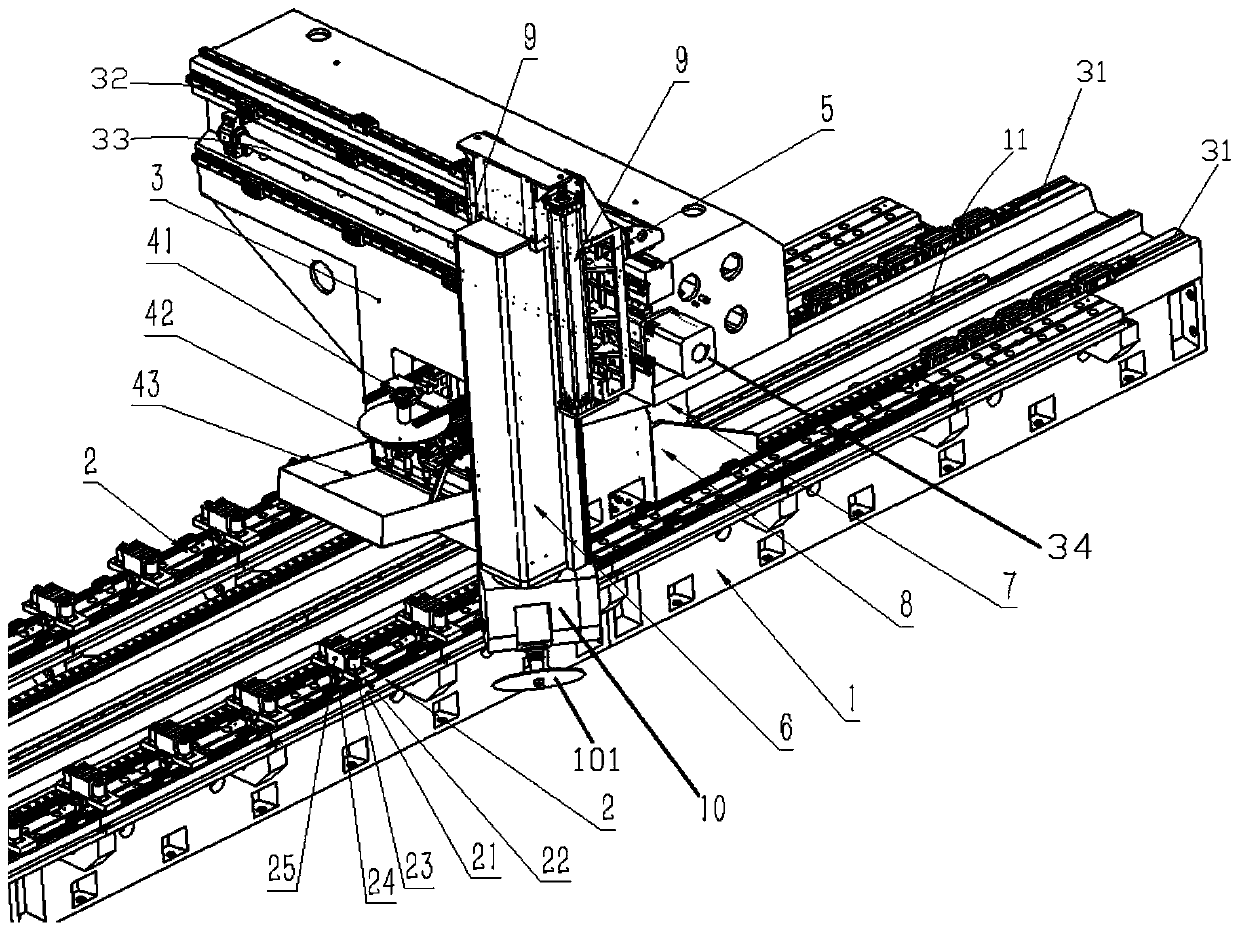

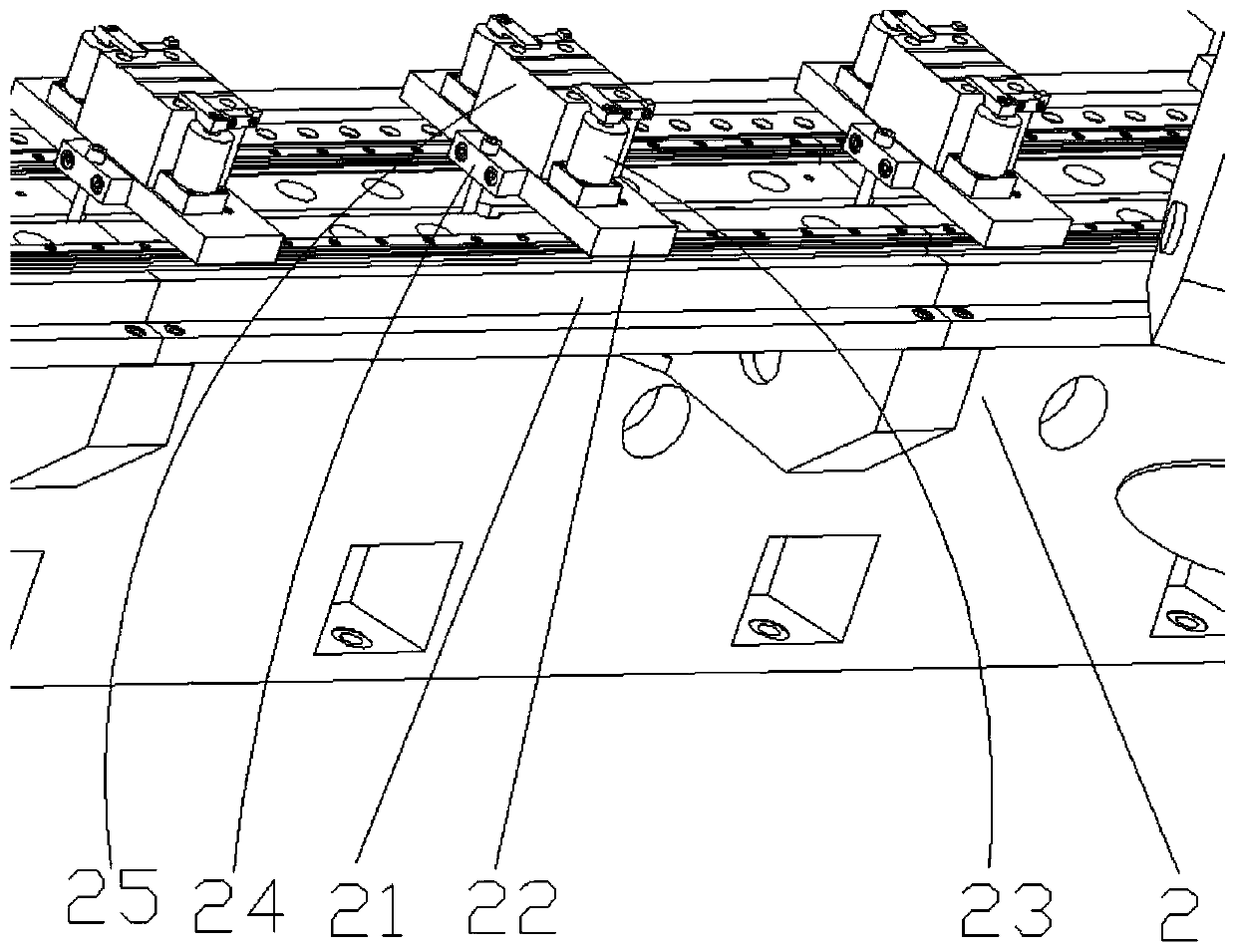

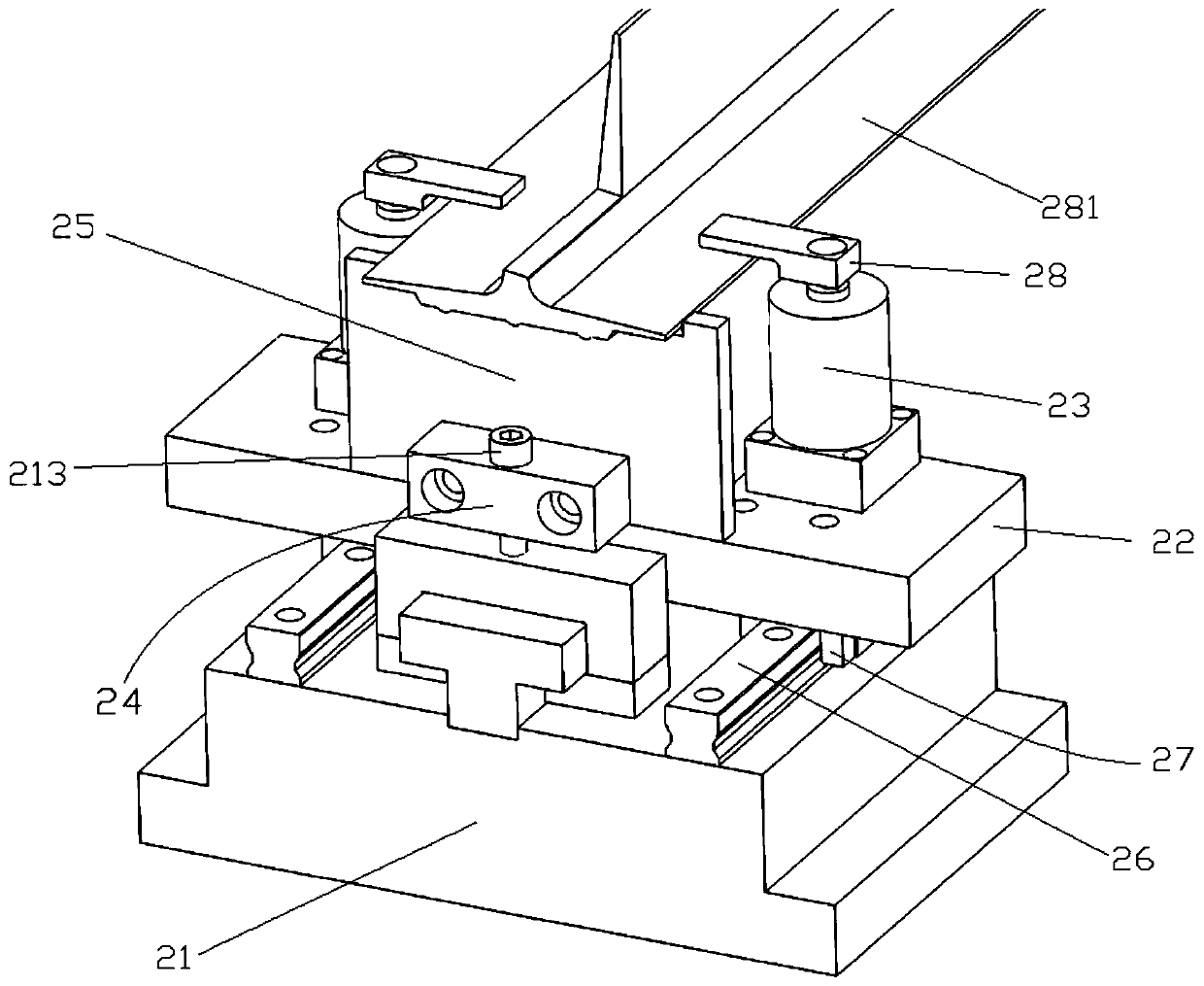

[0024] Such as Figure 1-7 As shown, a five-axis machine tool with a built-in tool magazine in the column includes a bed 1, and two parallel column guide rail pairs 31 are arranged in the middle of the bed 1, and a column 3 is slidably connected to the column guide rail pairs 31. , the column 3 moves back and forth on the column guide rail pair 31 through the rack and pinion pair, the rack and pinion pair includes the gear 71 at the bottom of the anti-backlash gearbox 7 and the rack 11 fixed on the bed 1, the The back side of the column 3 is connected with a mounting bracket 8, the anti-backlash gear box 7 is arranged on the mounting bracket 8, the first motor 72 is connected to the anti-backlash gear box 7, and the first motor 72 rotates to drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com