Notching machine

A technology of notching machine and indexing mechanism, applied in metal processing equipment, grinding device, grinding/polishing equipment, etc., can solve the problems of low processing efficiency, cumbersome installation and restoration, etc., and achieve fast cutting speed and stable processing size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

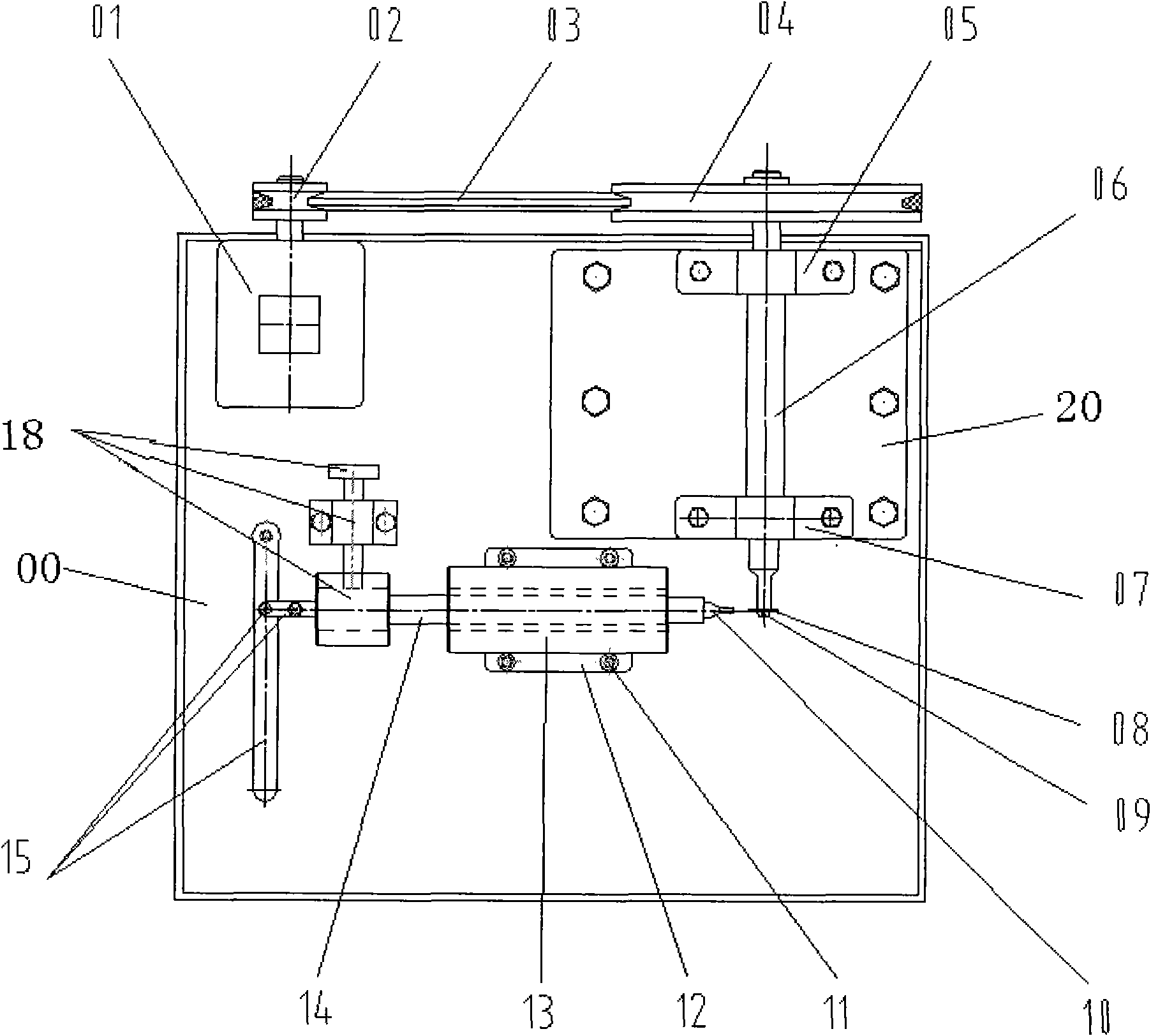

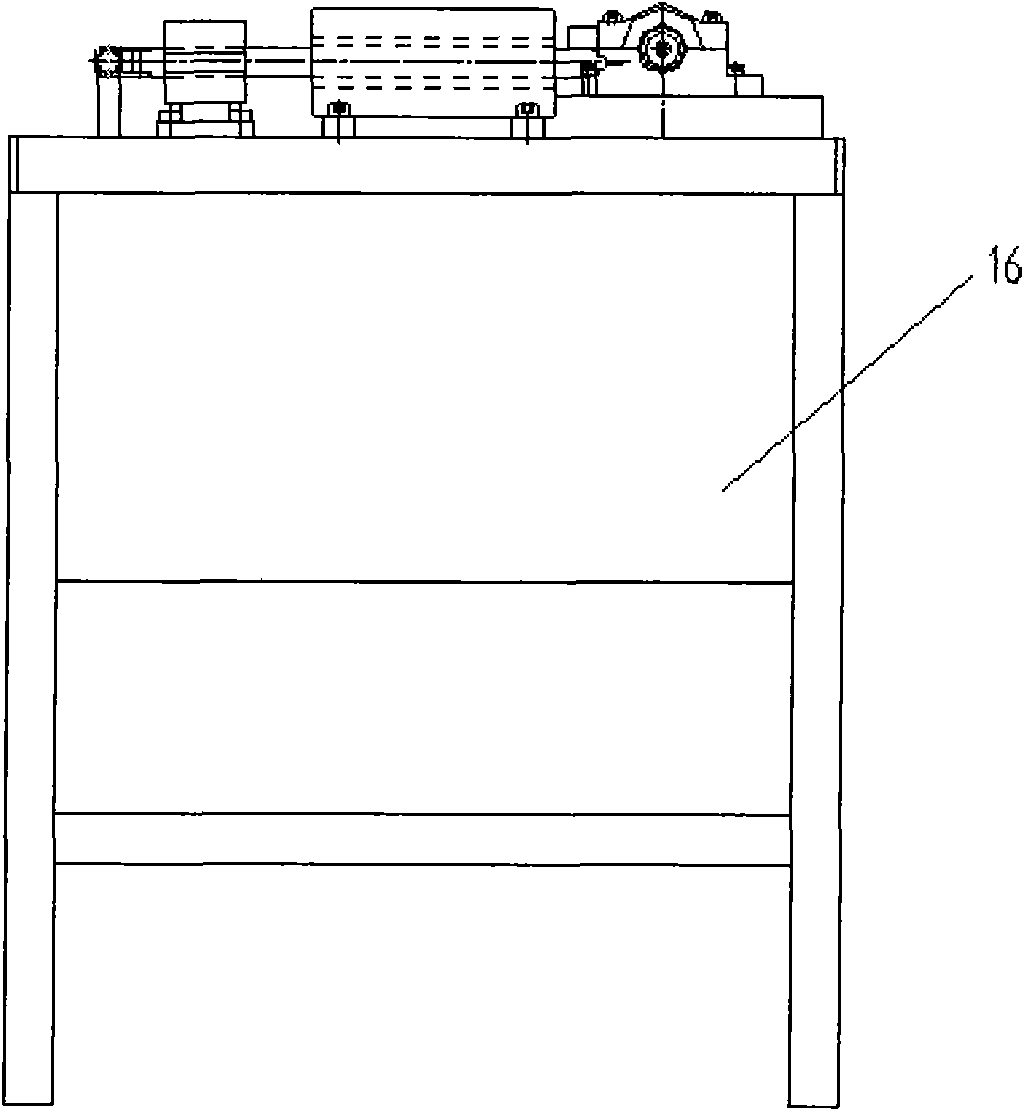

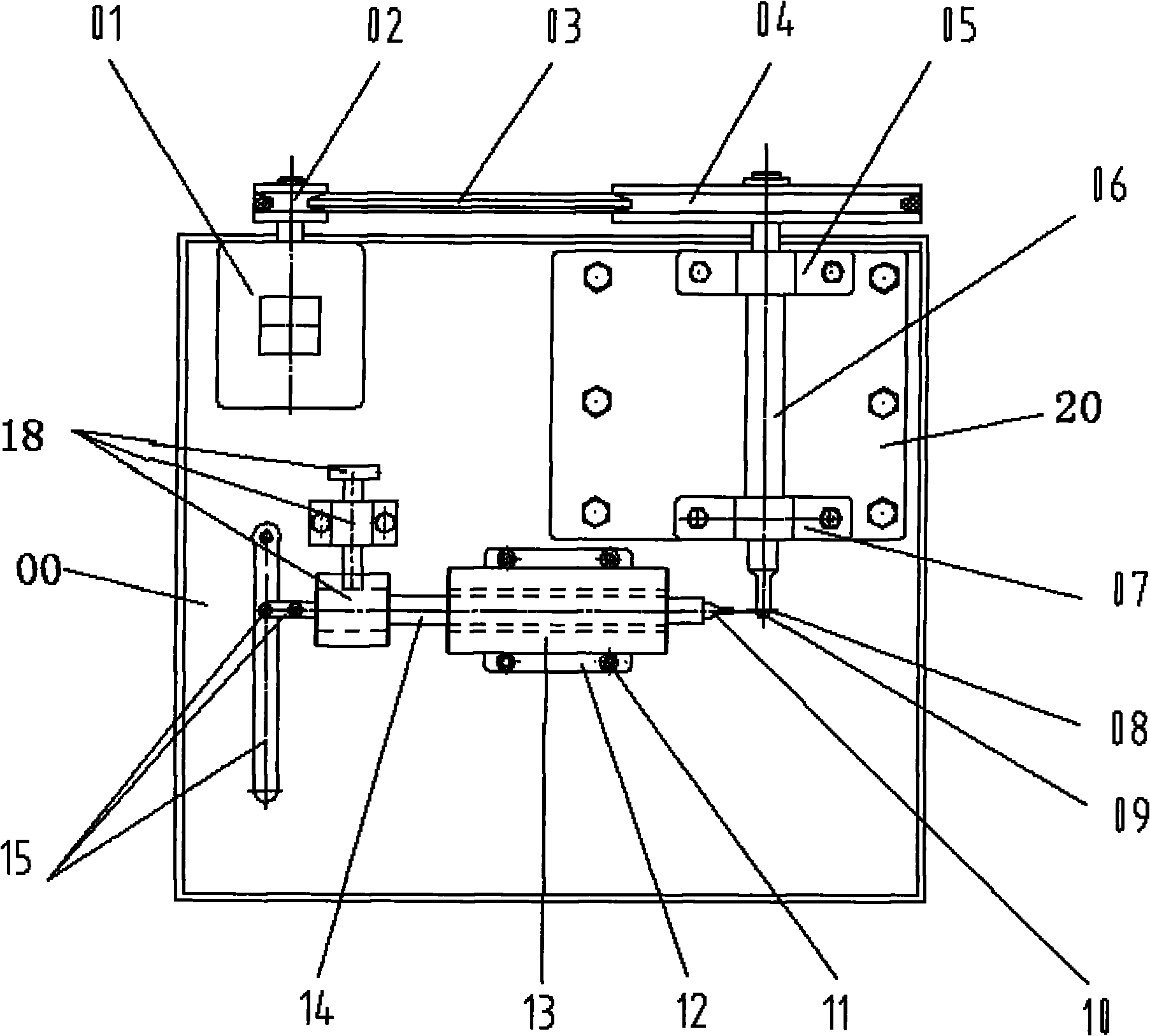

[0012] Such as figure 1 As shown, the present invention includes a base 00, a motor 01, a small pulley 02, a belt 03, a large pulley 04, a rear bearing and a support seat 05, a saw blade shaft 06, a front bearing and a support seat 07, a saw blade 08, and a lock nut 09 , workpiece connecting shaft 10, locking screw 11, connecting plate 12, guide sleeve 13, workpiece spindle 14, lever feed mechanism 15, ejector rod indexing mechanism 18, motor 01 is connected with base 00 through connecting plate, and set on motor 01 There is a small pulley 02, the small pulley 02 drives the large pulley 04 through the belt 03, the large pulley 04 is fixed on the base 00 through the rear bearing and the bearing seat 05, the saw blade shaft 06 is coaxially fixed with the large pulley 04, and the front end of the saw blade shaft 06 is fixed by The front bearing and support seat 07 are fixed, and the rear end is fixed by the rear bearing and bearing seat 05; the saw blade 08 is set on the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com