A cold heading sleeve processing technology

A processing technology and cold heading technology, which is applied in the field of cold heading sleeve processing technology, can solve the problems of unstable size of blank assembly, large blank allowance, irregular shape, etc., and achieve stable size and less processing allowance. , the effect of saving processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so that the protection scope of the present invention can be more clearly defined.

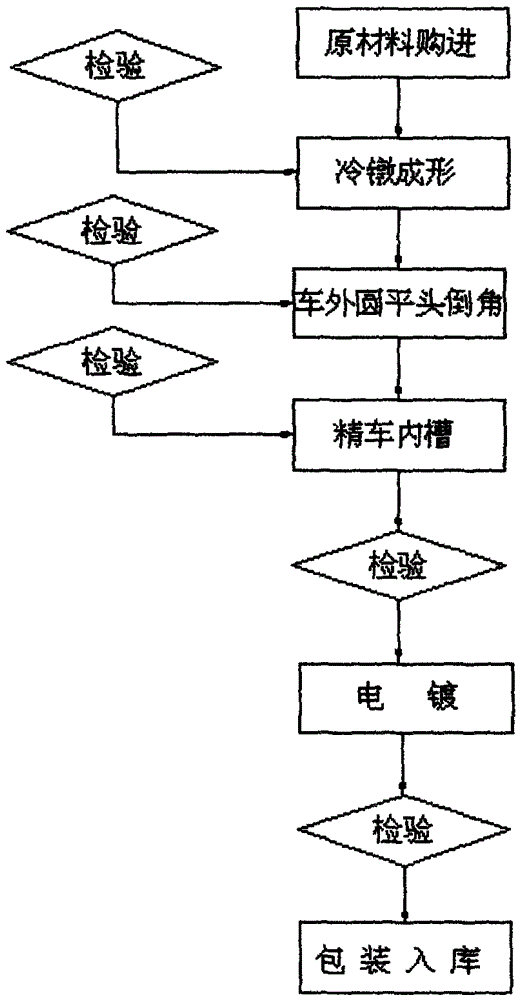

[0019] Such as figure 1 As shown, the process for processing a cold-heading sleeve of the present invention, the specific steps are as follows:

[0020] (1). Screen and inspect the blank materials. According to the specific requirements of the product, carry out corresponding incoming inspections on the blanks and select the appropriate size blank materials. The blank is a round bar with a diameter of 39mm and a weight of 390g ;

[0021] (2) Choose a multi-station cold heading machine to directly cold head the shape, and process it into the required product size through four cold heading;

[0022] (3) The outer round flat head chamfer of the turnin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com