Clamp for machining inside diameters and outer diameters of fixed ball races

A bead ring and fixture technology, used in clamping, positioning devices, manufacturing tools, etc., can solve the problems of thin bead ring thickness, large size, low work efficiency, etc., and achieve stable processing dimensions, good concentricity, and improved Ergonomics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

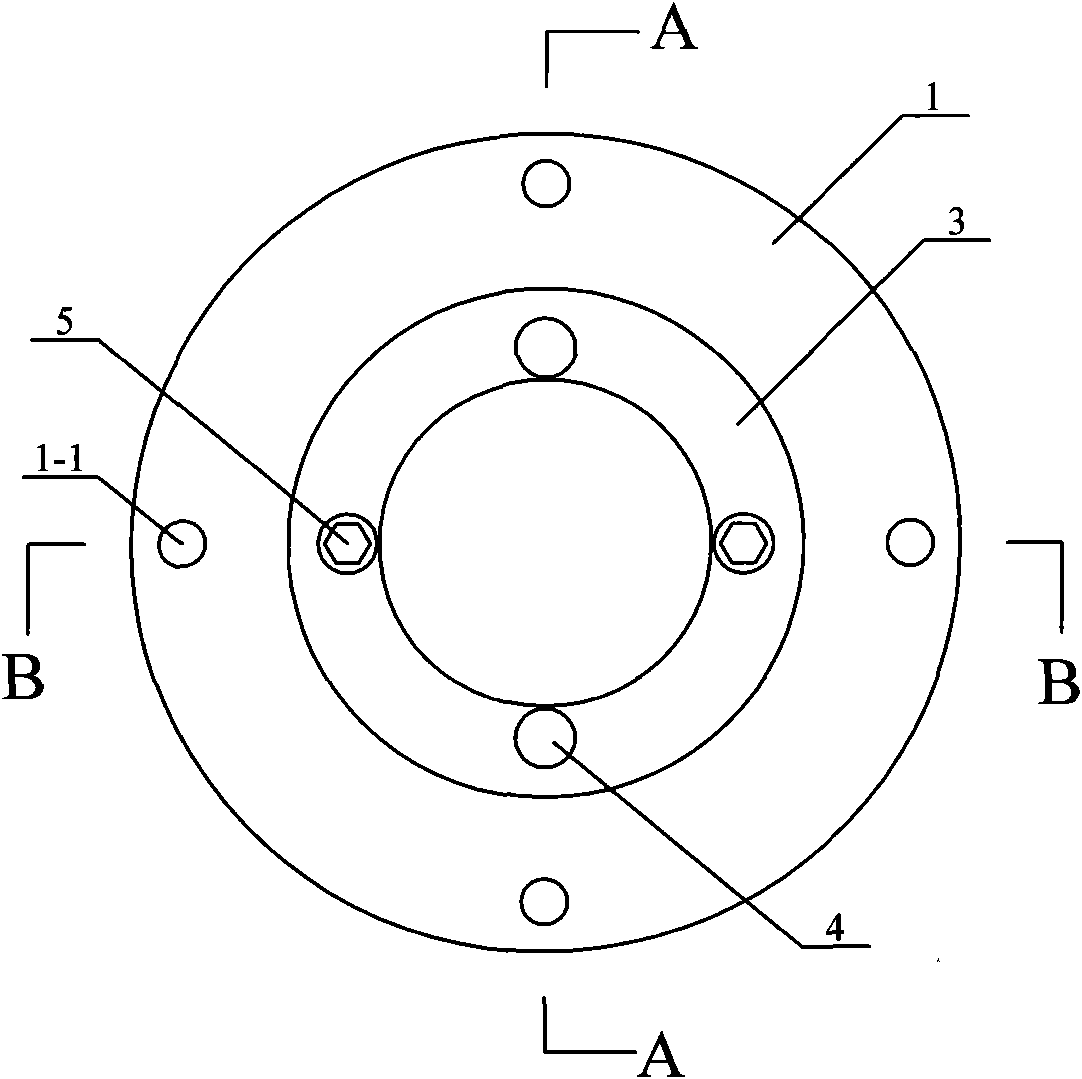

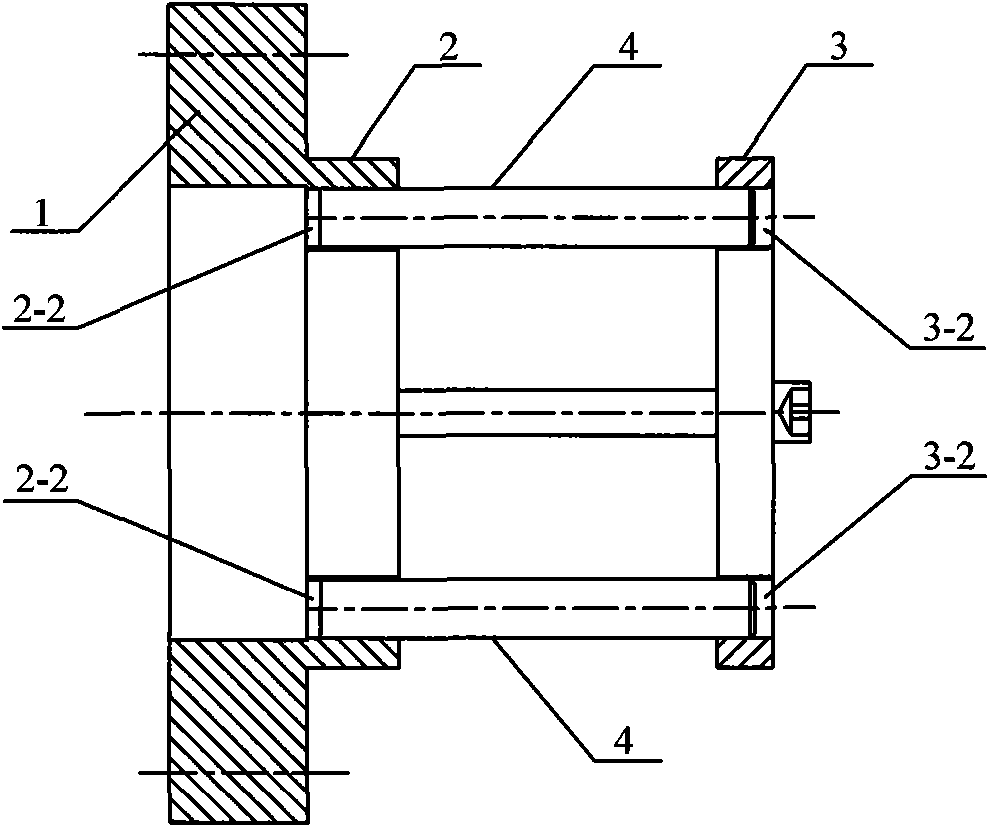

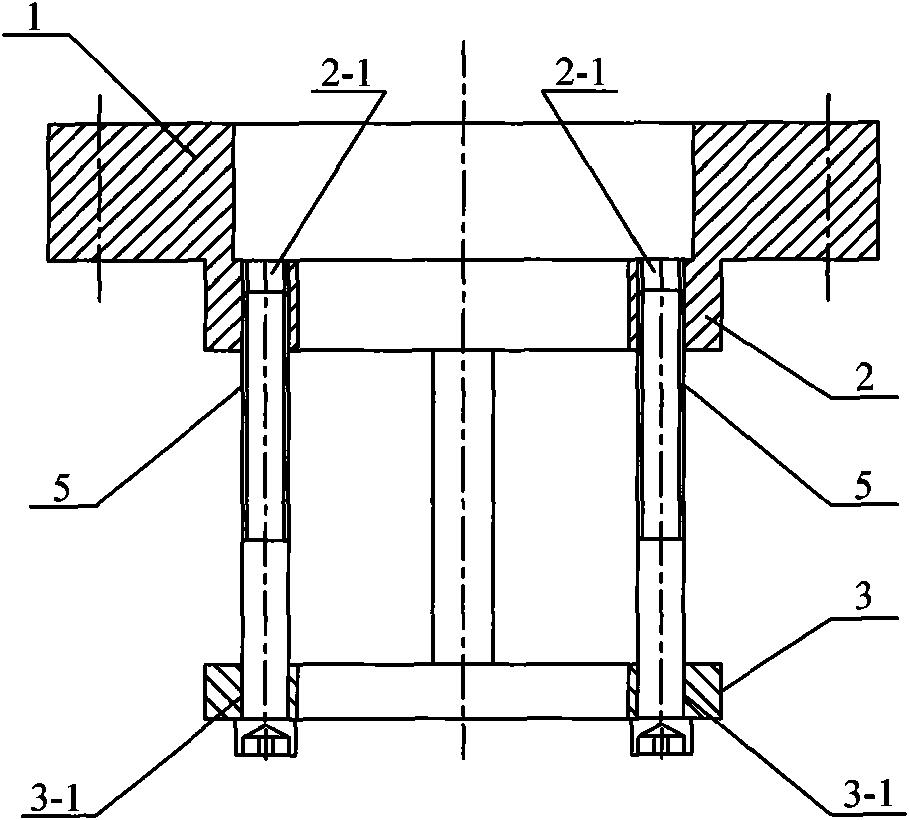

[0013] Such as figure 1 , figure 2 and image 3 As shown, the fixture in this embodiment includes a chassis 1, a connecting block 2, a pressing block 3, two positioning pins 4 and two connecting bolts 5; .

[0014] The connection block 2 is concentric with the chassis 1 and the inner diameter of the connection block 2 is smaller than the inner diameter of the chassis 1 . A part of the connection block 2 is connected to the surface of the chassis 1 . Two threaded holes 2-1 and two positioning pin mounting holes 2-2 are set on another part of the connecting block 2 . The center line of the two threaded holes 2-1 passes through the center of the connection block 2, the center line of the two positioning pin mounting holes 2-2 passes through the center of the connection block 2, and the center line of the two threaded holes 2-1 The center line and the center line of the two positioning pin mounting holes 2-2 are perpendicular to each other.

[0015] Two bolt connection hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com