Thermal treatment process for thin-wall aluminum alloy component

A technology for processing aluminum alloy parts and parts, which is applied in the field of mechanical processing and can solve problems such as stress and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

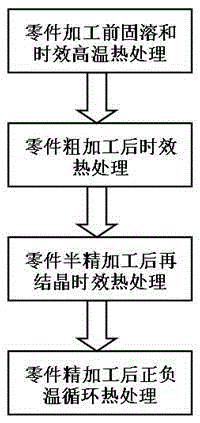

[0018] The specific processing method is as follows:

[0019] a) Solution and aging high-temperature heat treatment before part processing, using 460 ° C, 100 min solution + aging heat treatment, through discontinuous recrystallization to form fine grains, and change the grain morphology and composition phase distribution, to improve the short transverse direction The purpose of improving the plasticity and toughness of aluminum alloy parts, thereby improving the machinability of the material structure of aluminum alloy parts.

[0020] b) Aging heat treatment after rough machining of parts. Due to the large machining allowance and fast tool wear in the rough machining stage of the part, the machining stress of the part is the largest and the structure is unstable. Therefore, after the rough machining of the part removes the large cutting allowance , for the second time 170 ℃, 8h aging heat treatment to eliminate processing stress, increase the service life of the tool, and imp...

Embodiment 2

[0024] The specific processing method is as follows:

[0025] a) Solution and aging high-temperature heat treatment before parts processing, using 470 ° C, 90 min solution + aging heat treatment, through discontinuous recrystallization to form fine grains, and change the grain morphology and composition phase distribution, to improve the short transverse direction The purpose of improving the plasticity and toughness of aluminum alloy parts, thereby improving the machinability of the material structure of aluminum alloy parts.

[0026] b) Aging heat treatment after rough machining of parts. Due to the large machining allowance and fast tool wear in the rough machining stage of the part, the machining stress of the part is the largest and the structure is unstable. Therefore, after the rough machining of the part removes the large cutting allowance , for the second 180 ℃, 7h aging heat treatment to eliminate processing stress, increase the service life of the tool, and improve ...

Embodiment 3

[0030] The specific processing method is as follows:

[0031] a) Solution and aging high-temperature heat treatment before part processing, using 480 ° C, 80 min solution + aging heat treatment, through discontinuous recrystallization to form fine grains, and change the grain morphology and composition phase distribution, to improve the short transverse direction The purpose of improving the plasticity and toughness of aluminum alloy parts, thereby improving the machinability of the material structure of aluminum alloy parts.

[0032] b) Aging heat treatment after rough machining of parts. Due to the large machining allowance and fast tool wear in the rough machining stage of the part, the machining stress of the part is the largest and the structure is unstable. Therefore, after the rough machining of the part removes the large cutting allowance , for the second 190 ℃, 6h aging heat treatment to eliminate processing stress, increase tool life, improve the quality of surface p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com