Double-faced milling mechanism

A double-sided milling and milling machine technology, applied in the mechanical field, can solve the problems of reducing the stability of the milling machine mechanism, unable to realize adjustment in time, poor clamping effect, etc., to achieve convenient pattern layout, facilitate mass production, and improve space utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

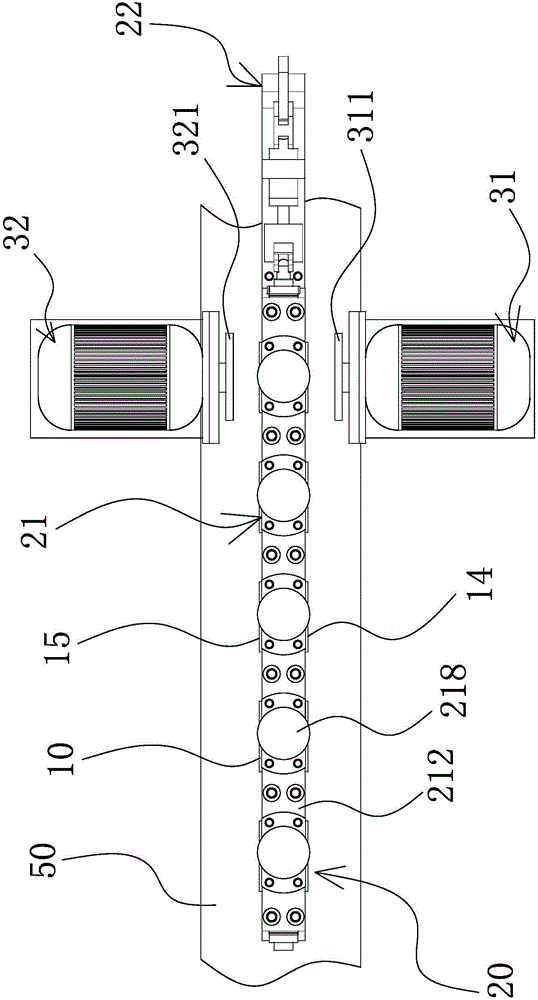

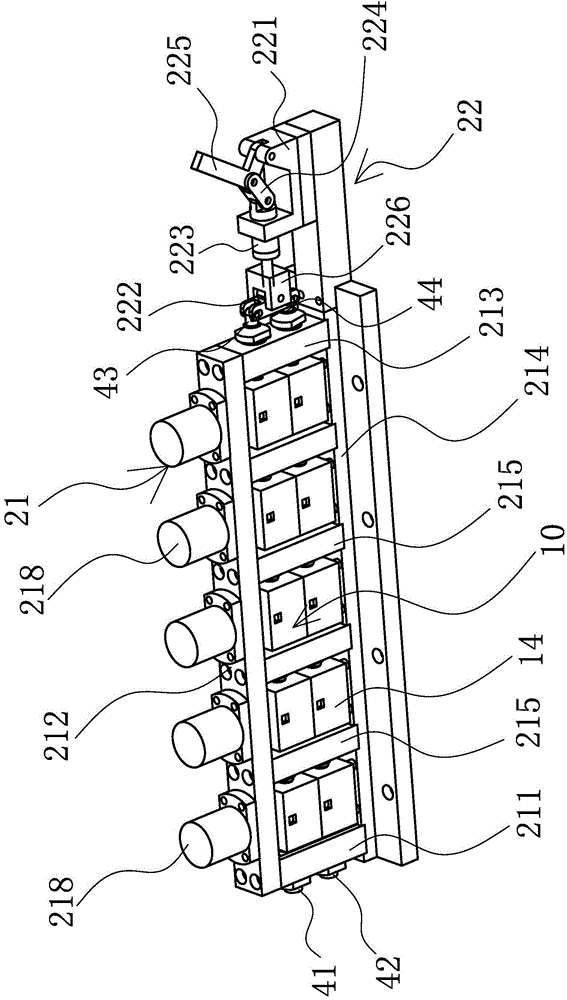

[0035]The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0036] The existing milling machine mechanism for processing blanks such as solenoid valve bodies has a simple structural design, and only one end face of a single valve body blank 10 is milled at a time, and the corresponding blank clamp can only clamp a single valve body blank 10 at a time. The adjustment of the blank fixture is also inconvenient, and the clamping effect is not good, thereby reducing the stability and work efficiency of the milling machine mechanism. Therefore, it is necessary to design a more reasonable double-sided milling mechanism.

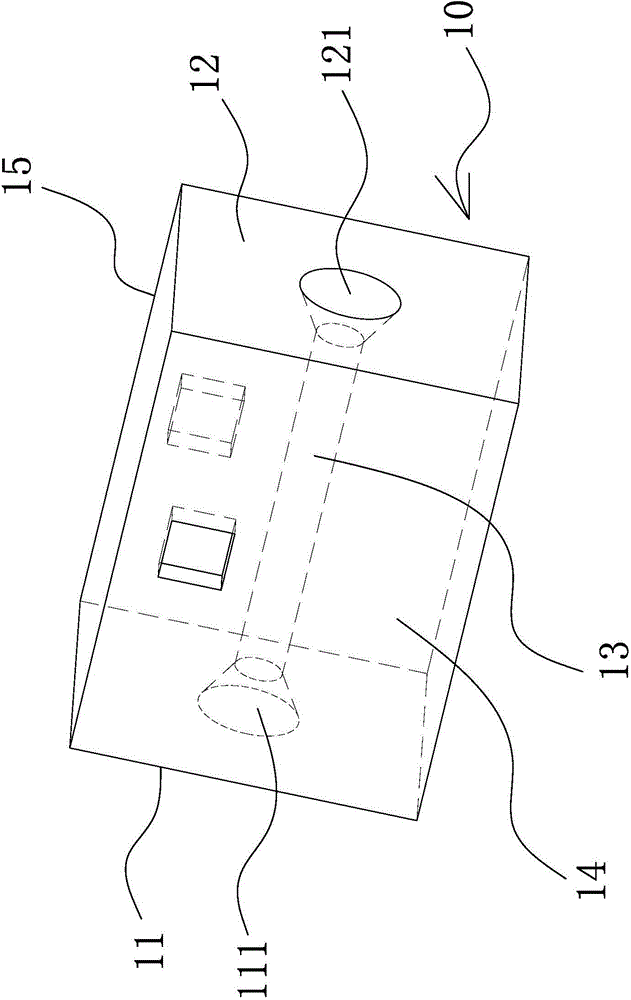

[0037] The invention protects a double-sided milling mechanism, which adopts double-sided milling to simultaneously mill the front 14 and the back 15 of blanks such as so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com