Hydraulic system for thread roller

A technology of hydraulic system and thread rolling machine, which is applied in the directions of fluid pressure actuating system components, mechanical equipment, fluid pressure actuating devices, etc., can solve the problems of unstable size, large error, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings.

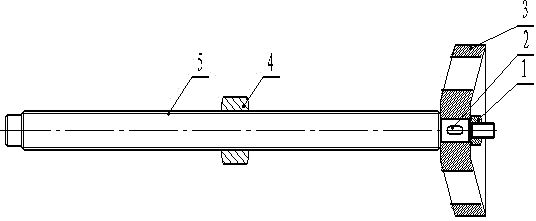

[0012] The thread rolling machine is a very common machine tool used in the machining industry. The following takes the ZA28-12.5 thread rolling machine as an example to introduce. The working principle of the ZA28-12.5 thread rolling machine is as follows:

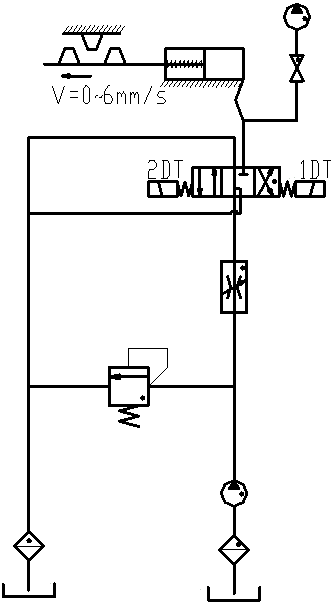

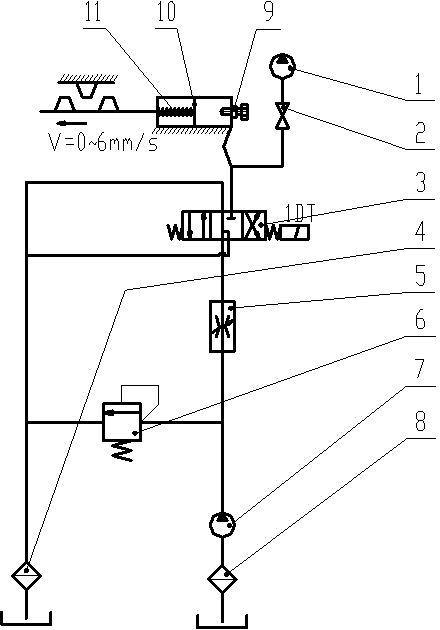

[0013] Such as figure 1 As shown, after the machine tool is started, the three-position four-way reversing valve (1DT) is controlled by the rolling time relay. The hydraulic oil enters the oil cylinder through the oil pipe to move the piston forward to the front dead center, and the pressure is kept until the adjustable time is cut off. After the processing step is completed, another contact point of the rolling time relay controls the reversing valve (2DT) to work, so that the hydraulic oil pressure relief piston moves backwards to the travel switch disconnected by the reaction force of the return spring, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com