Patents

Literature

414results about "Soldered/welded connections" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Connector And Coaxial Cable With Molecular Bond Interconnection

ActiveUS20120129391A1Cost-effectiveSimplifying the coaxial connectorElectrically conductive connectionsTwo pole connectionsCoaxial cableElectrical conductor

A coaxial connector in combination with a coaxial cable is provided with an inner conductor supported coaxial within an outer conductor, a polymer jacket surrounding the outer conductor. A unitary connector body with a bore is provided with an overbody surrounding an outer diameter of the connector body. The outer conductor is inserted within the bore. A molecular bond is formed between the outer conductor and the connector body and between the jacket and the overbody. An inner conductor end cap may also be provided coupled to the end of the inner conductor via a molecular bond.

Owner:COMMSCOPE TECH LLC

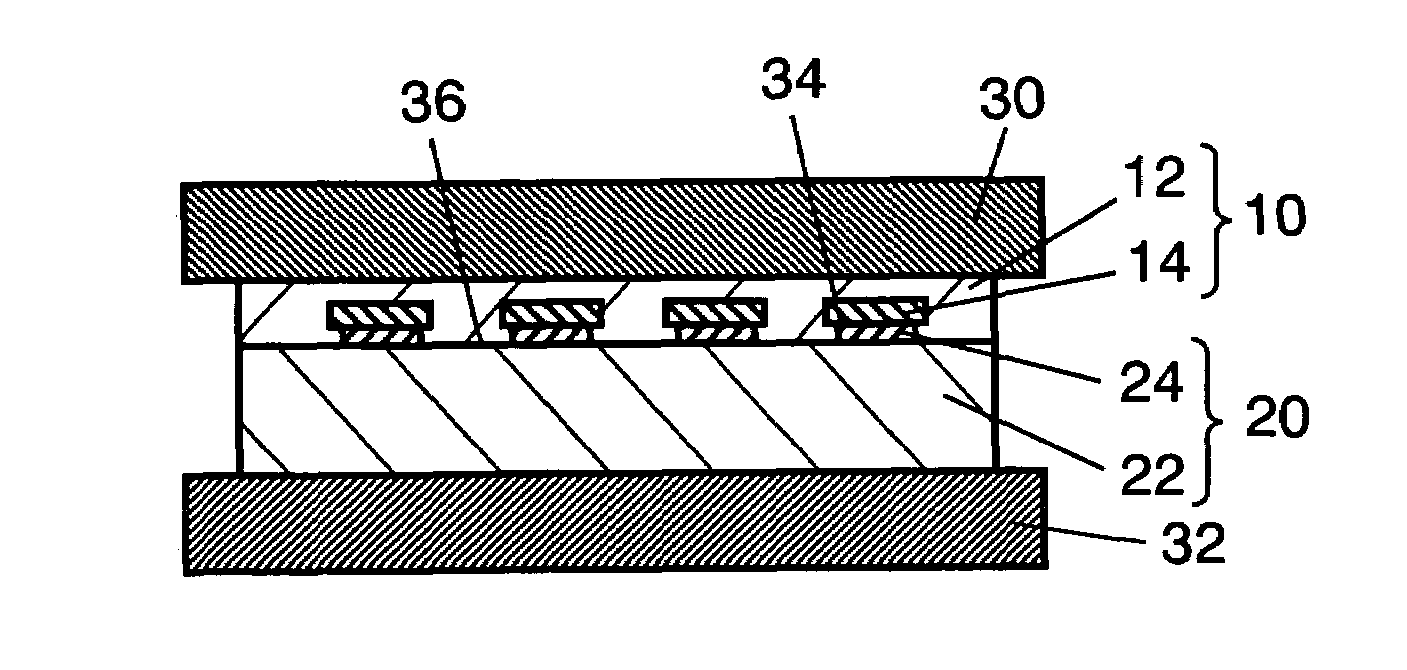

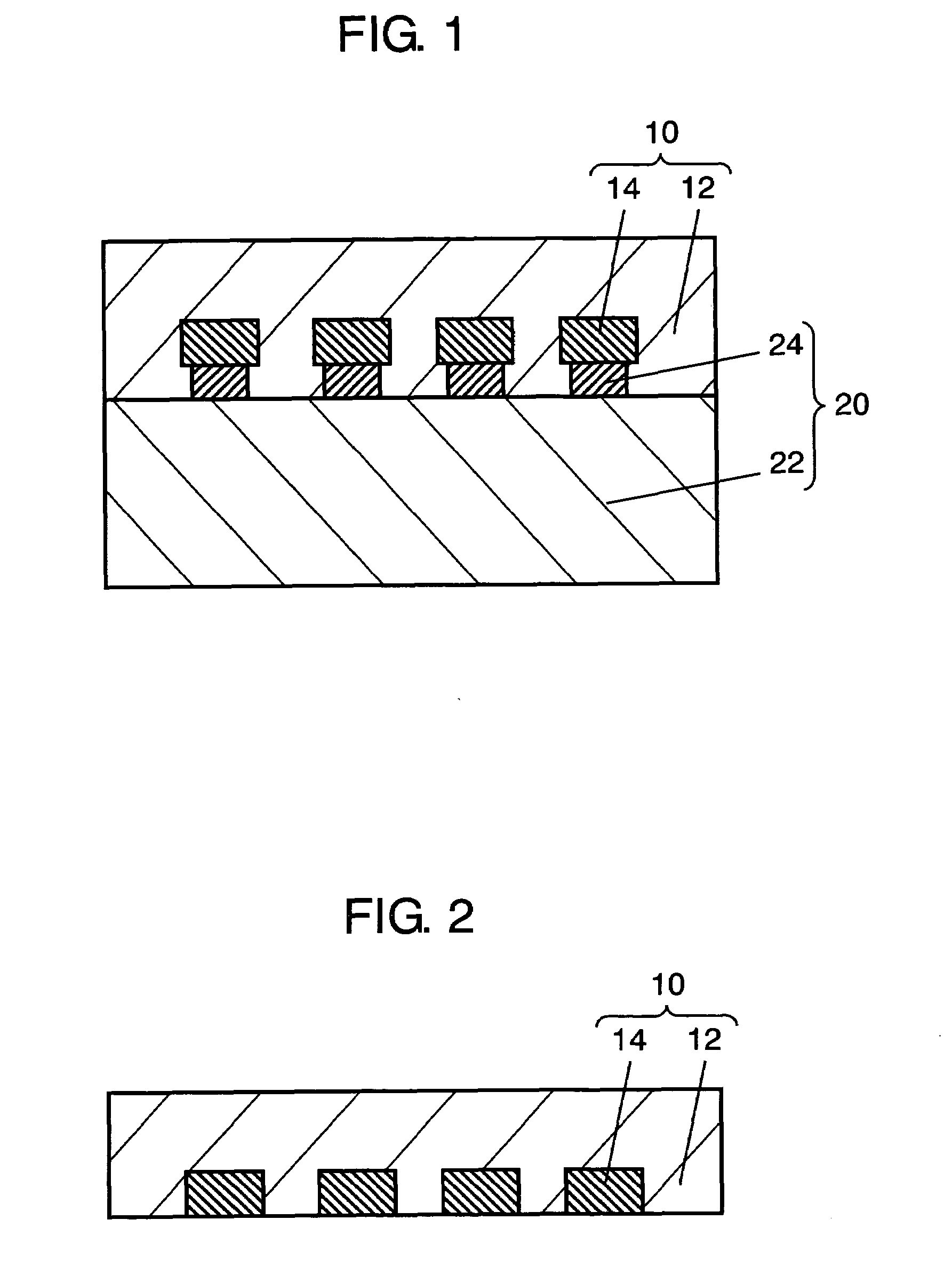

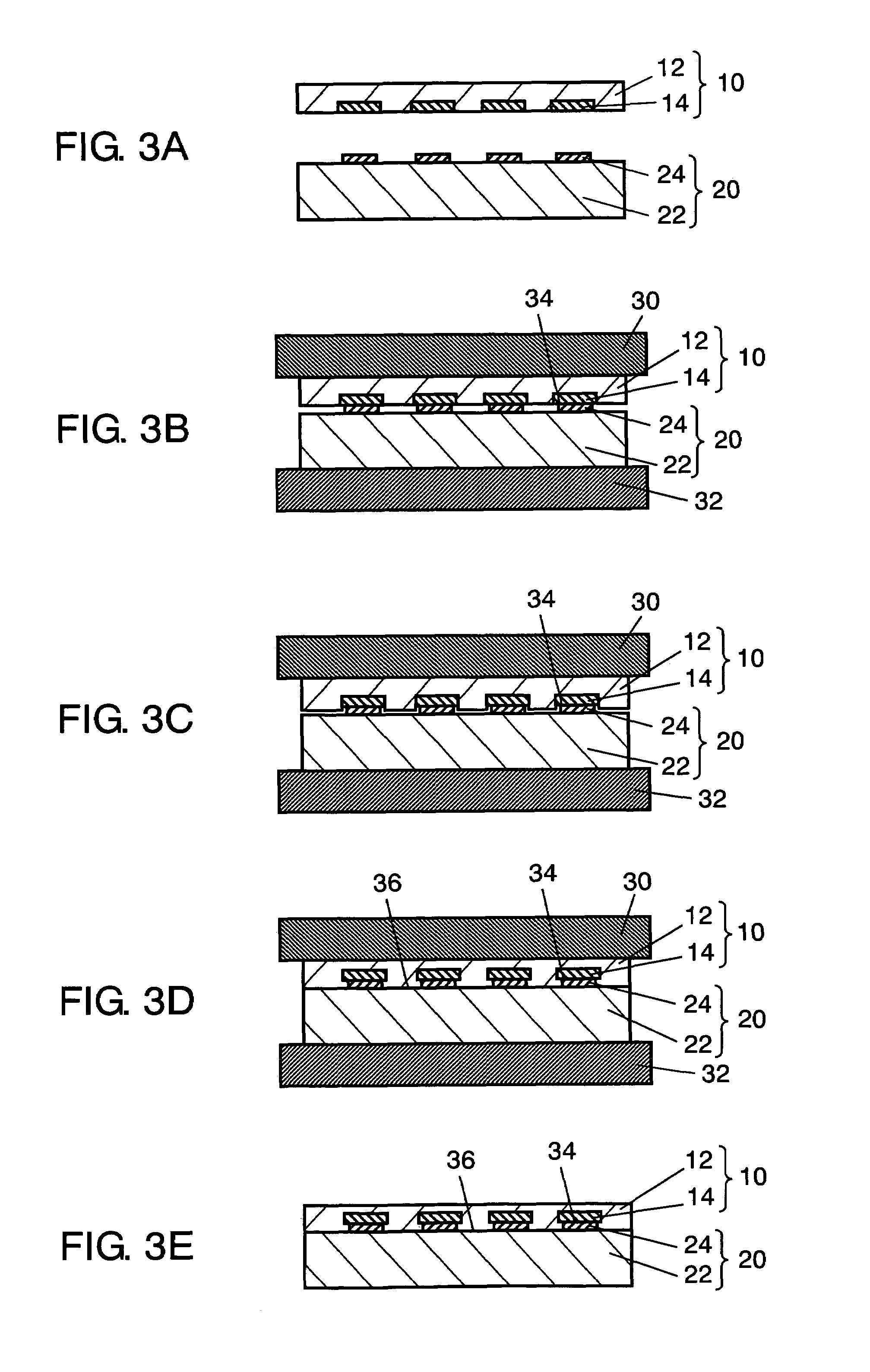

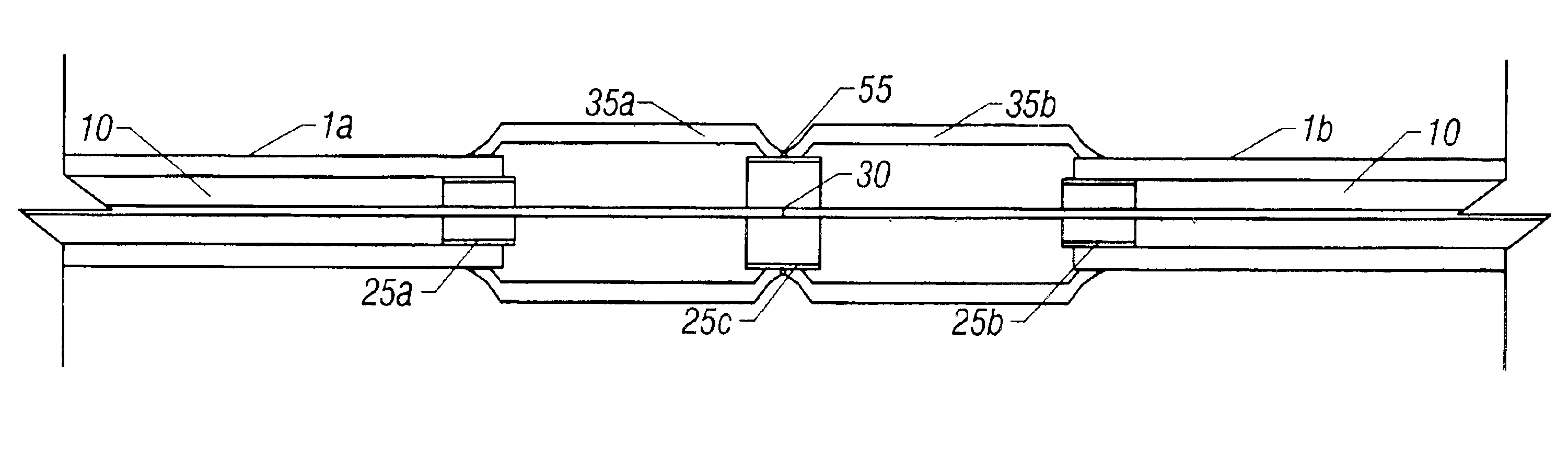

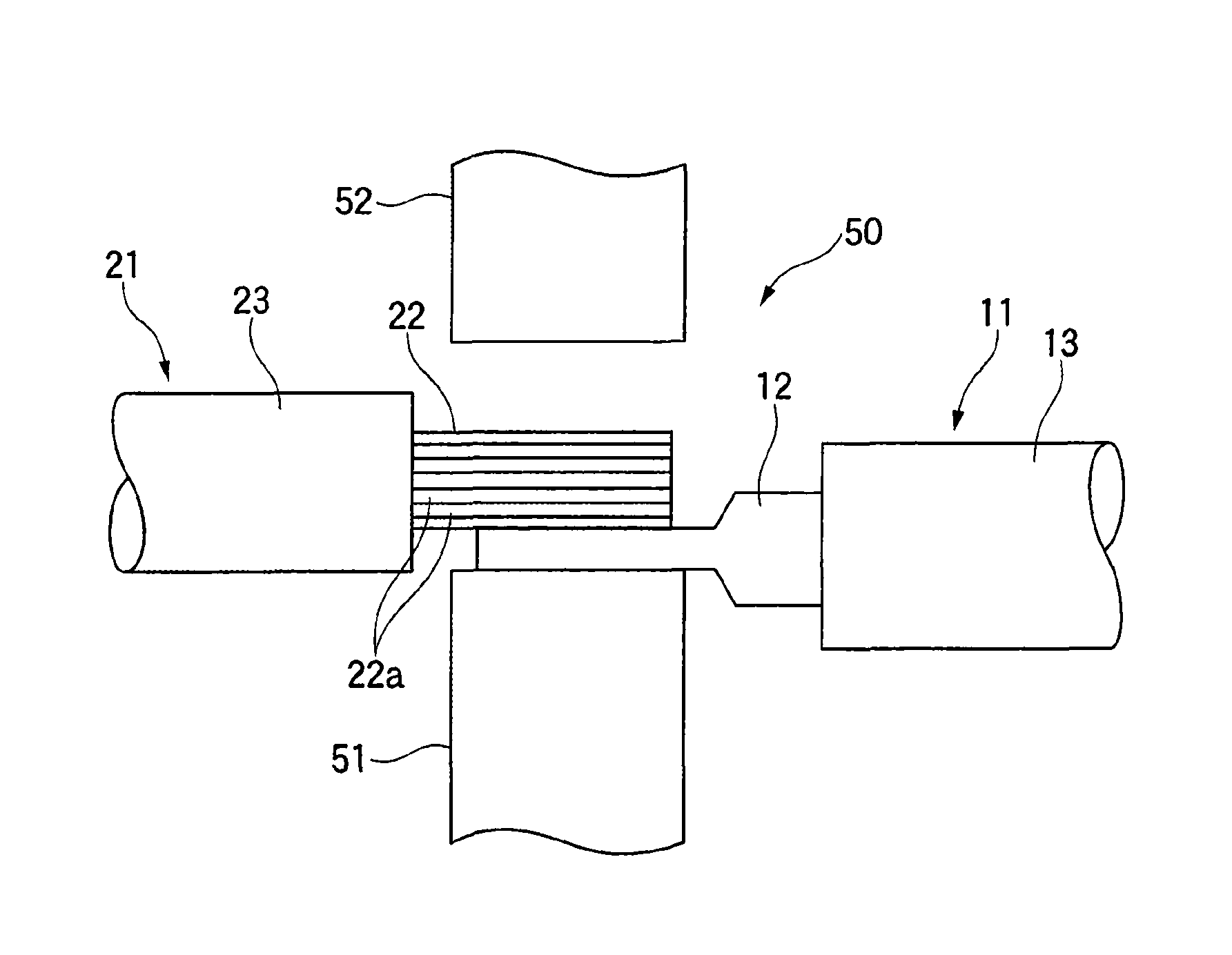

Connecting structure of circuit board and method for manufacturing the same

InactiveUS7229293B2Increase productionReduce connection resistanceSoldered/welded connectionsPrinted circuit manufactureElectrical conductorEngineering

First circuit board 10 including first resin base material 12 which is softened by heating and has a fusing property, and a plurality of first conductor patterns 14 formed on a surface of first resin base material 12, and second circuit board 20 on which a plurality of second conductor patterns 24 are formed with the same pitch as that of first conductor patterns 14 are provided. In the configuration, first conductor patterns 14 and second conductor patterns 24 are brought into mechanical contact with each other to provide electrical conduction; first resin base material 12 covers first conductor patterns 14 and second conductor patterns 24 and is bonded to second resin base material 22 of second circuit board 20, thereby connecting first circuit board 10 and second circuit board 20 to each other.

Owner:PANASONIC CORP

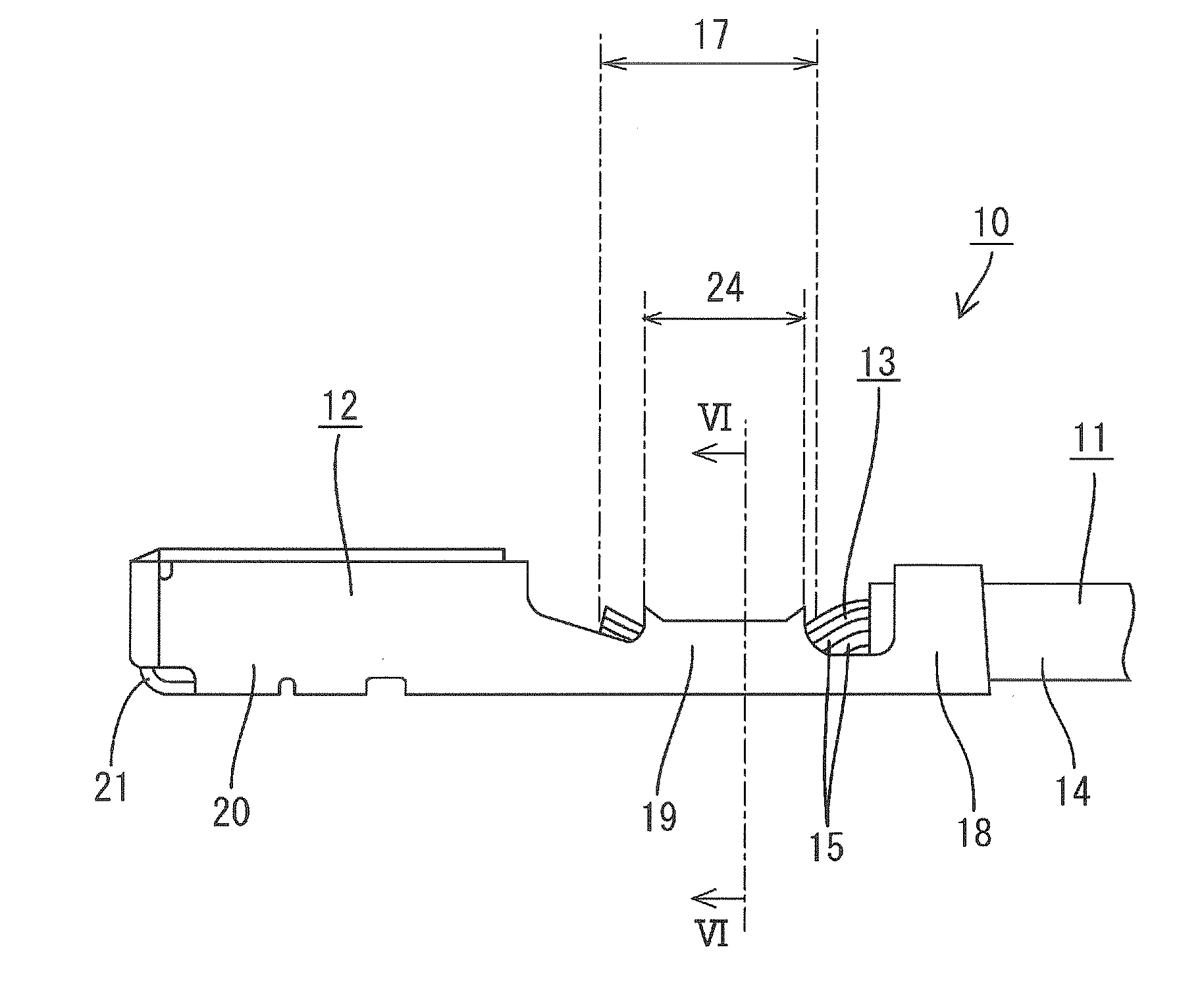

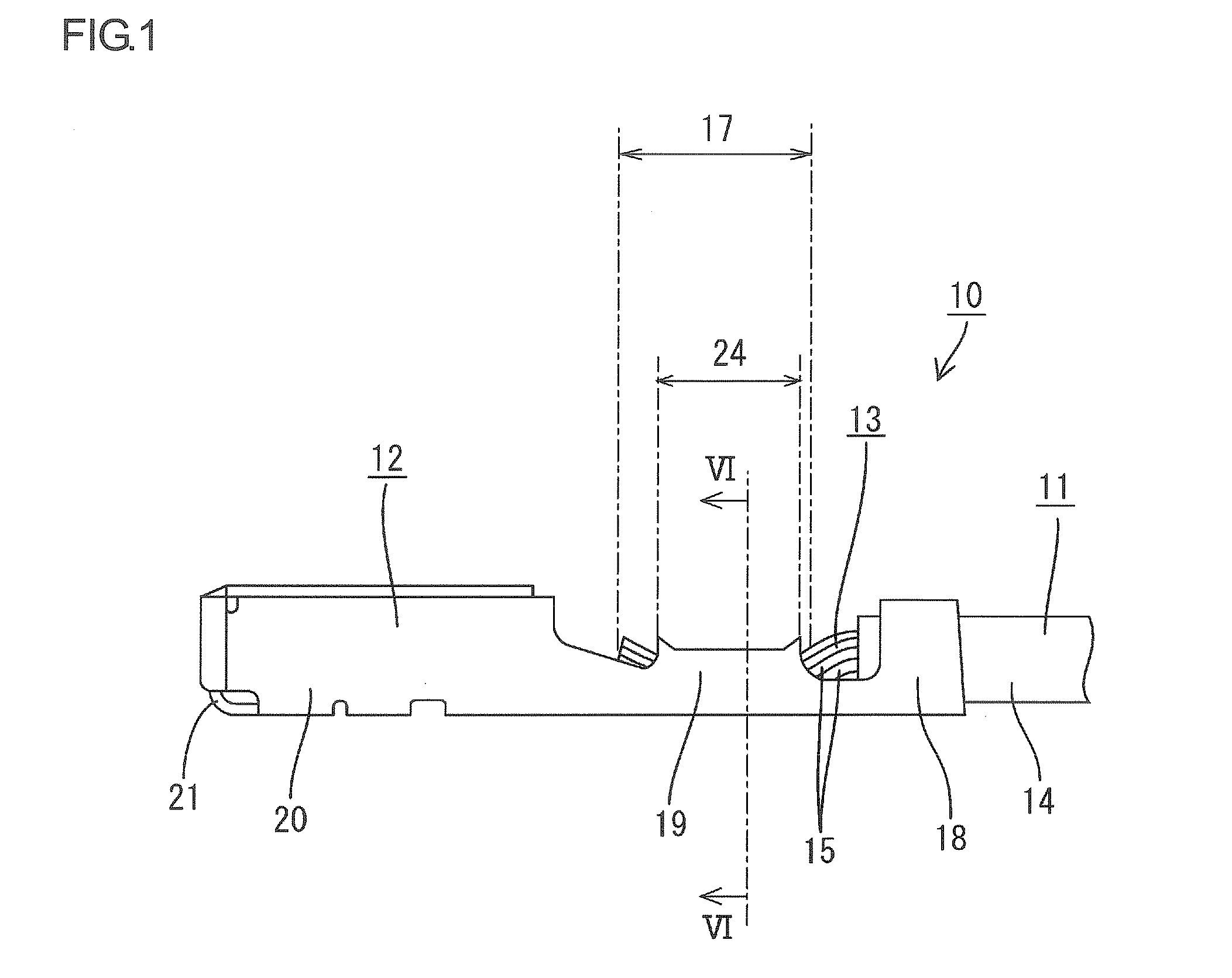

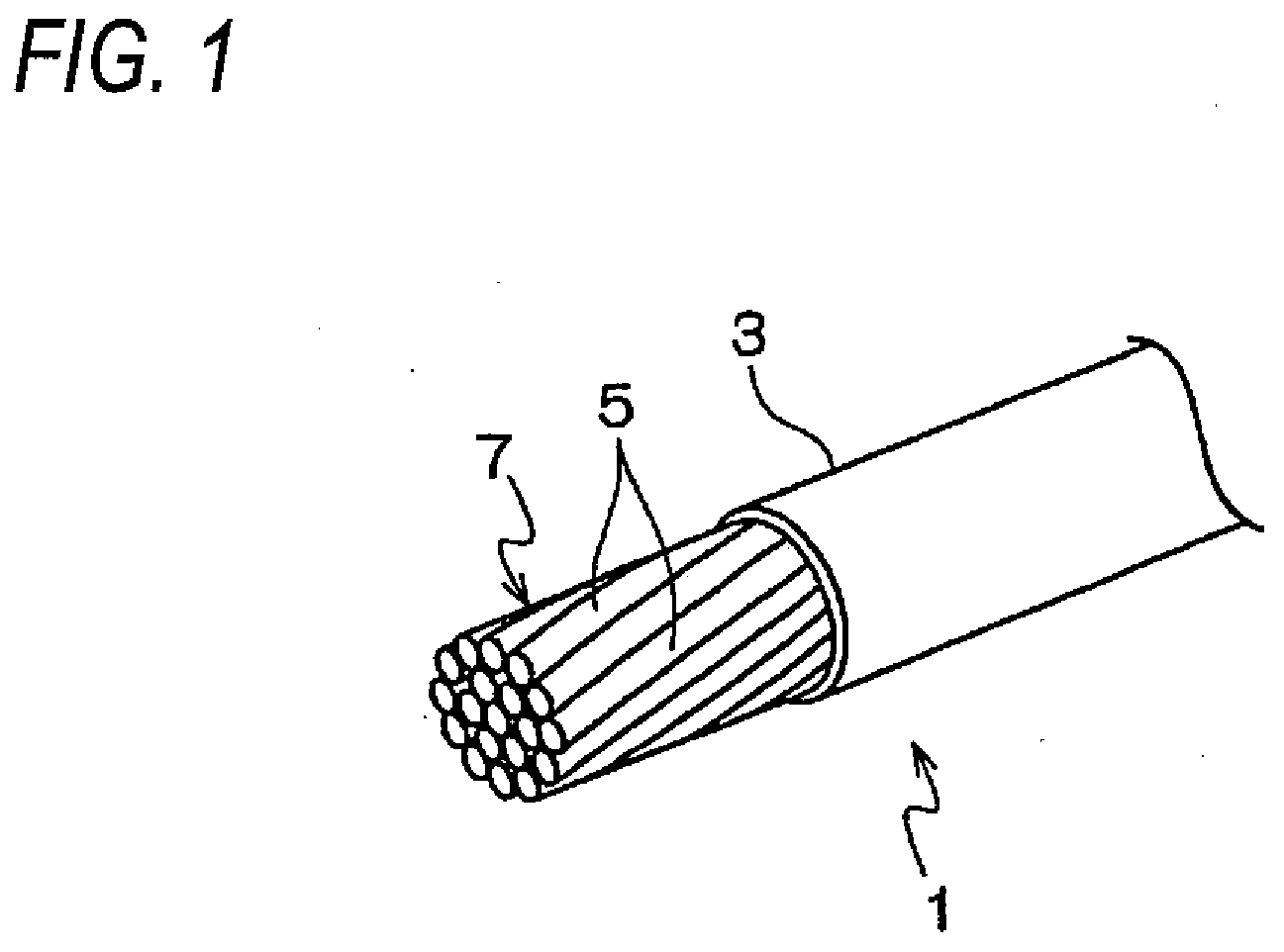

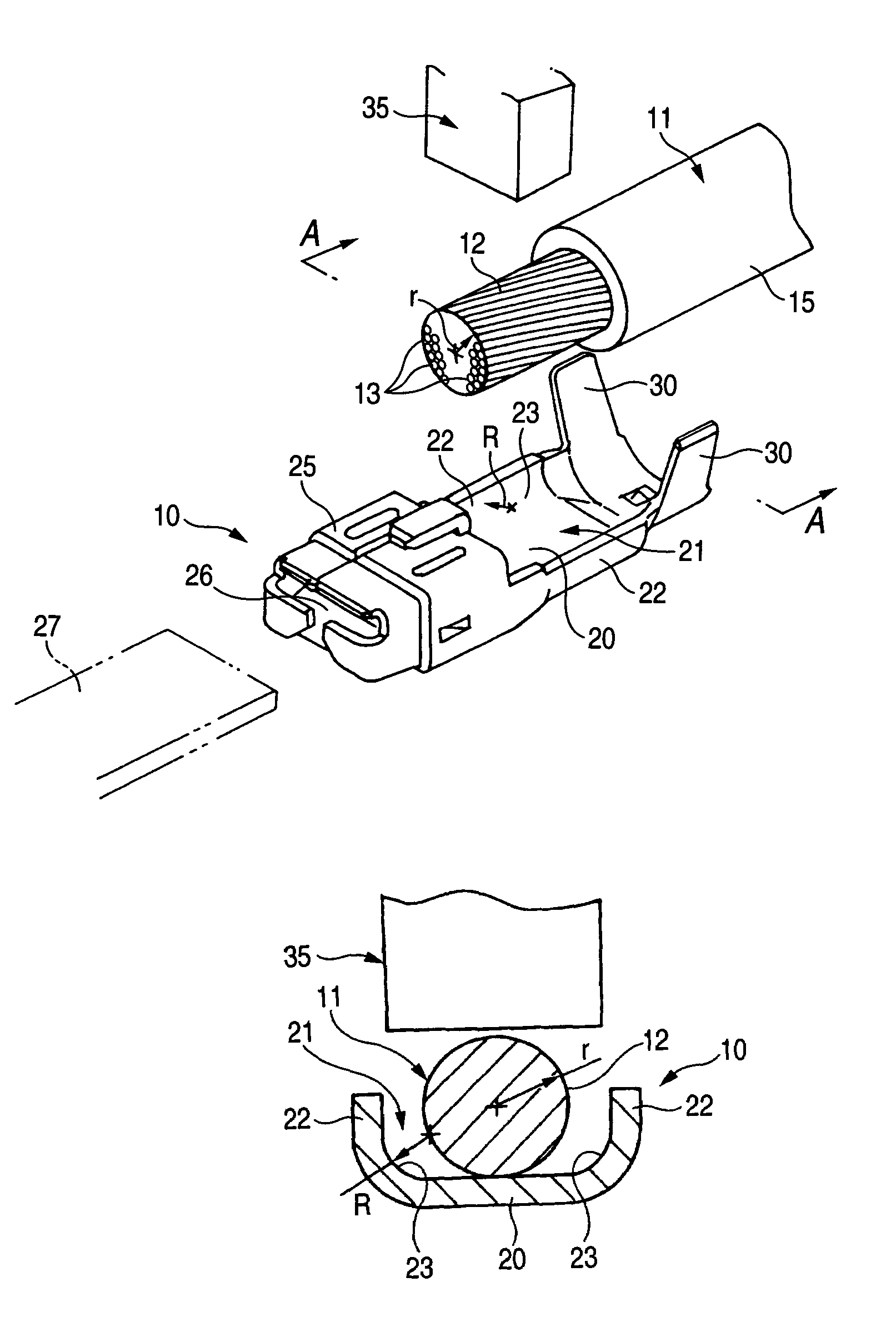

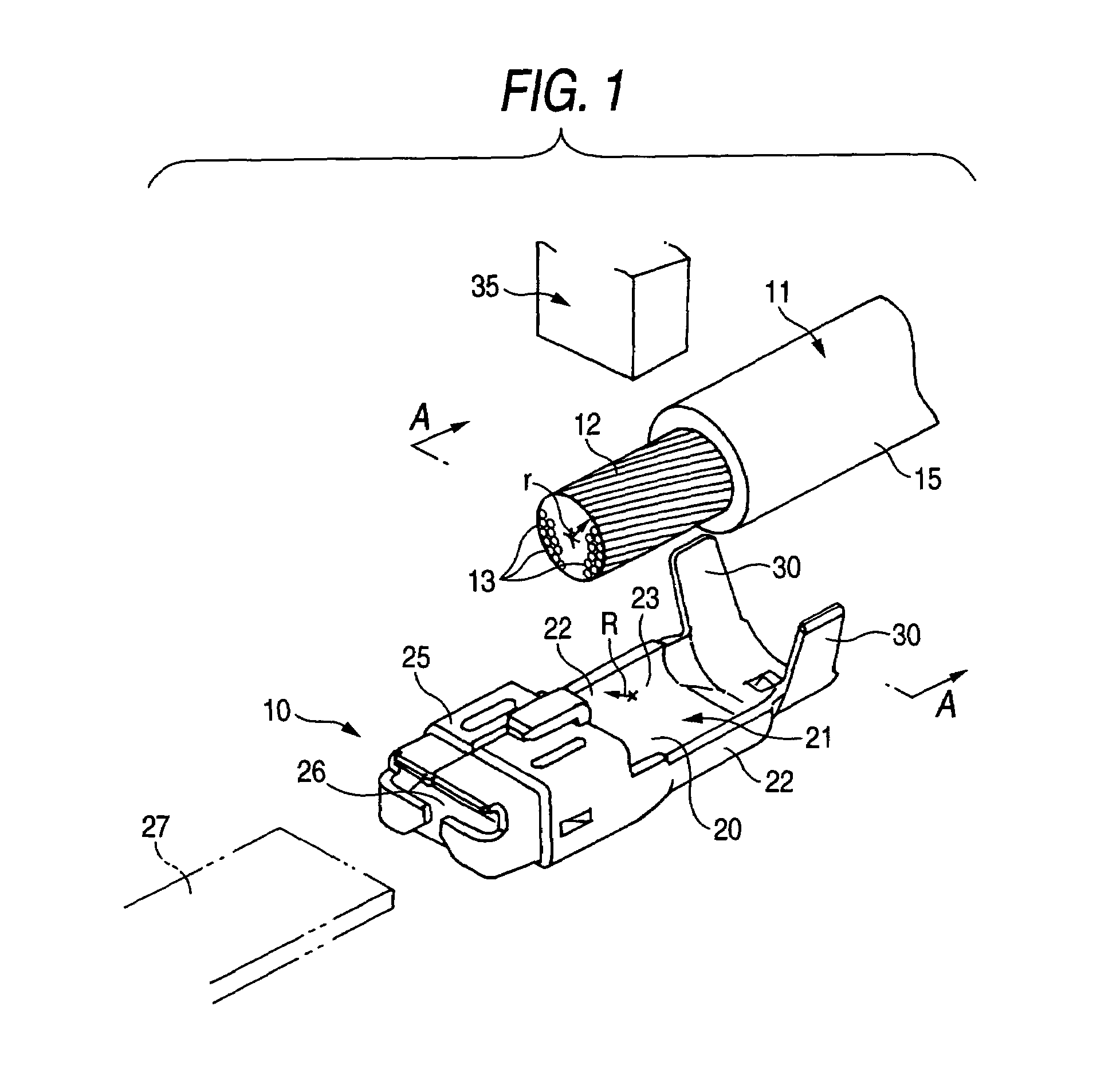

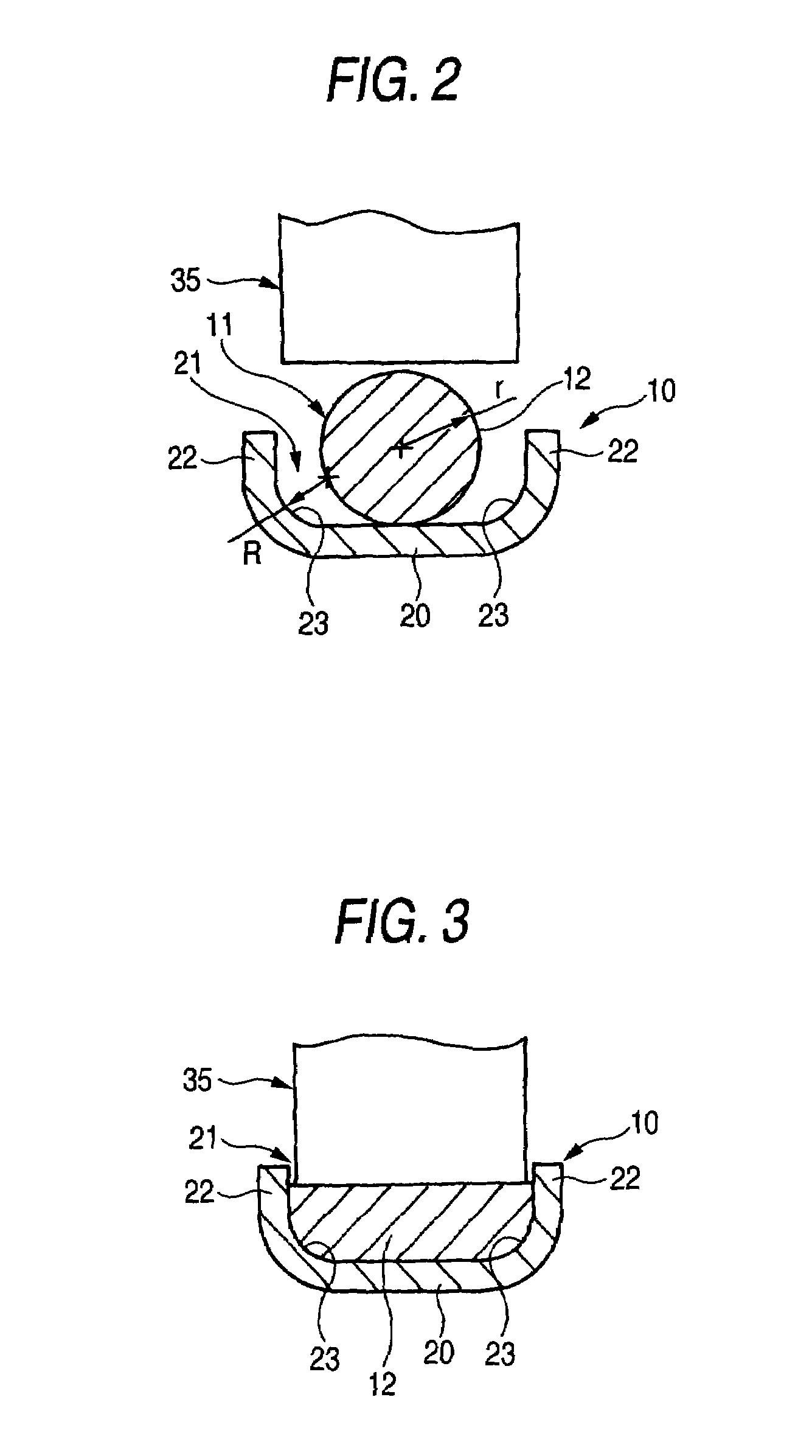

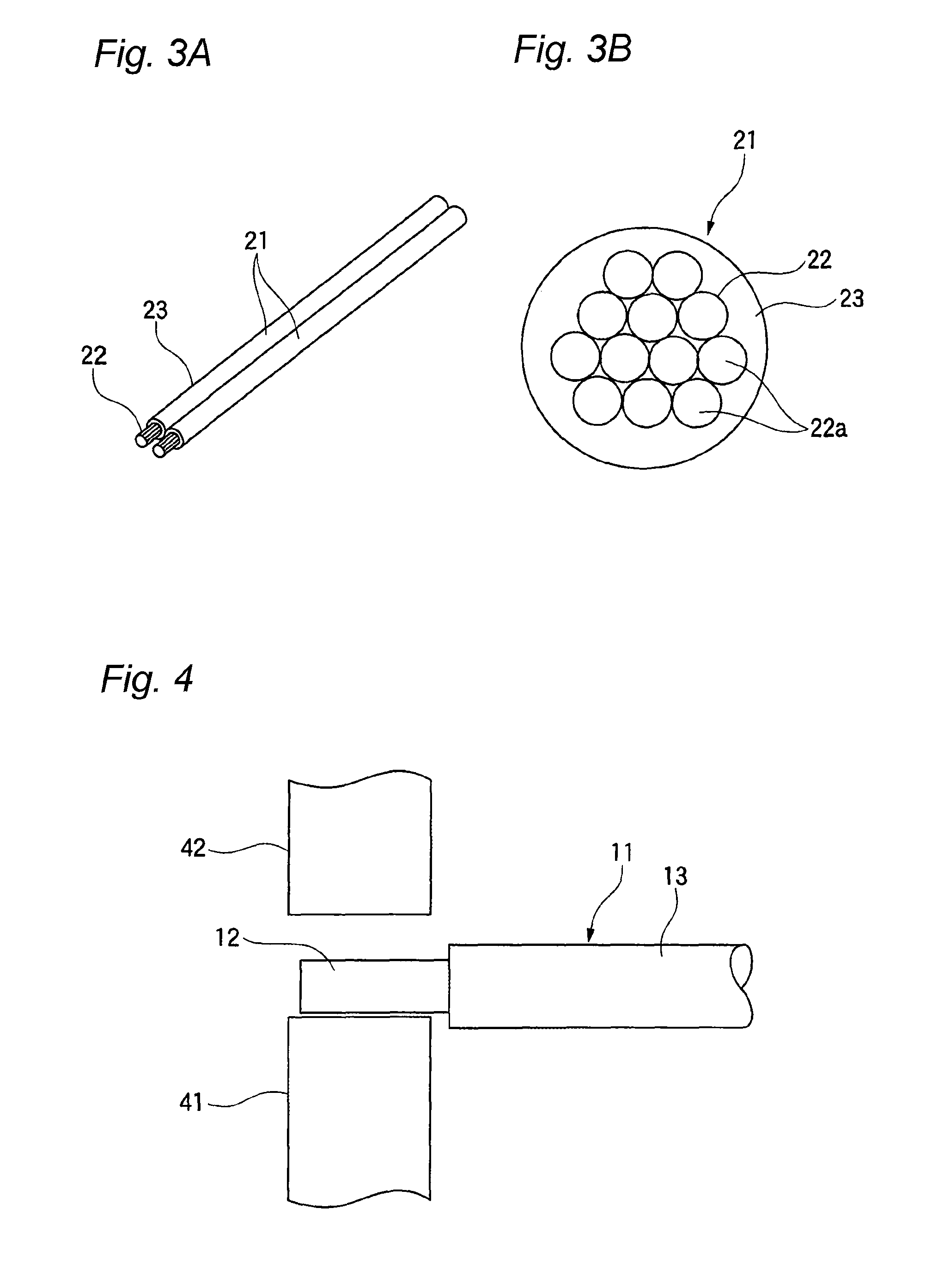

Electric wire with terminal connector and method of manufacturing electric wire with terminal connector

InactiveUS20110094797A1Increase resistanceLower resistanceSoldered/welded connectionsConnections effected by permanent deformationUltrasonic vibrationElectric wire

An electric wire with terminal connector including an electric wire having a core wire including a plurality of wires and a female terminal connector including a wire barrel that is crimped onto the core wire exposed from the electric wire, the following steps are executed. The steps include a step of removing wire insulation covering an outer peripheral surface of the core wire to expose the core wire, a step of holding the exposed core wire with jigs provided in a pair and applying ultrasonic vibration to the core wire via the jigs, and a step of crimping the wire barrel so as to surround a part of the core wire to which the ultrasonic vibration is applied.

Owner:AUTONETWORKS TECH LTD +2

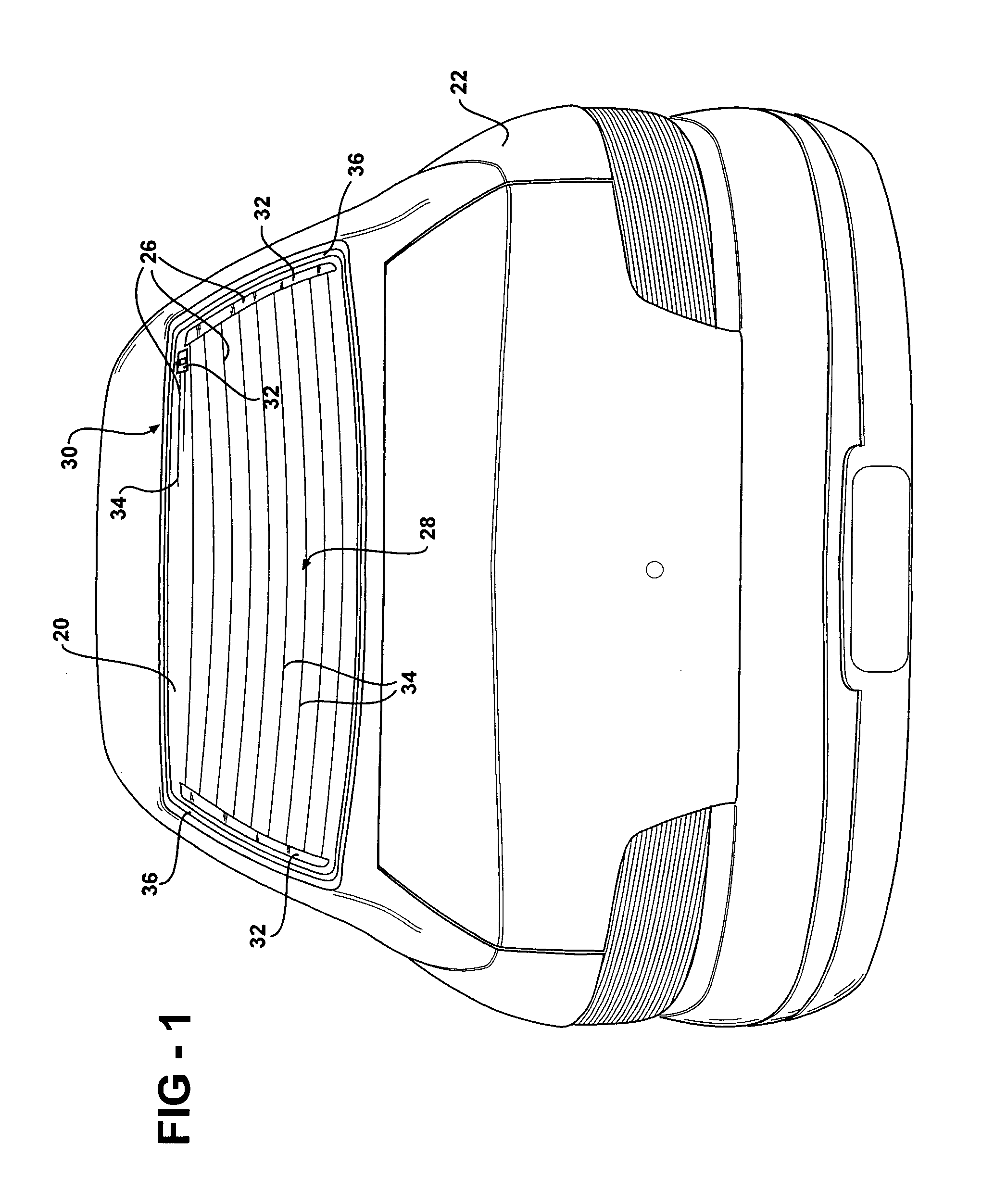

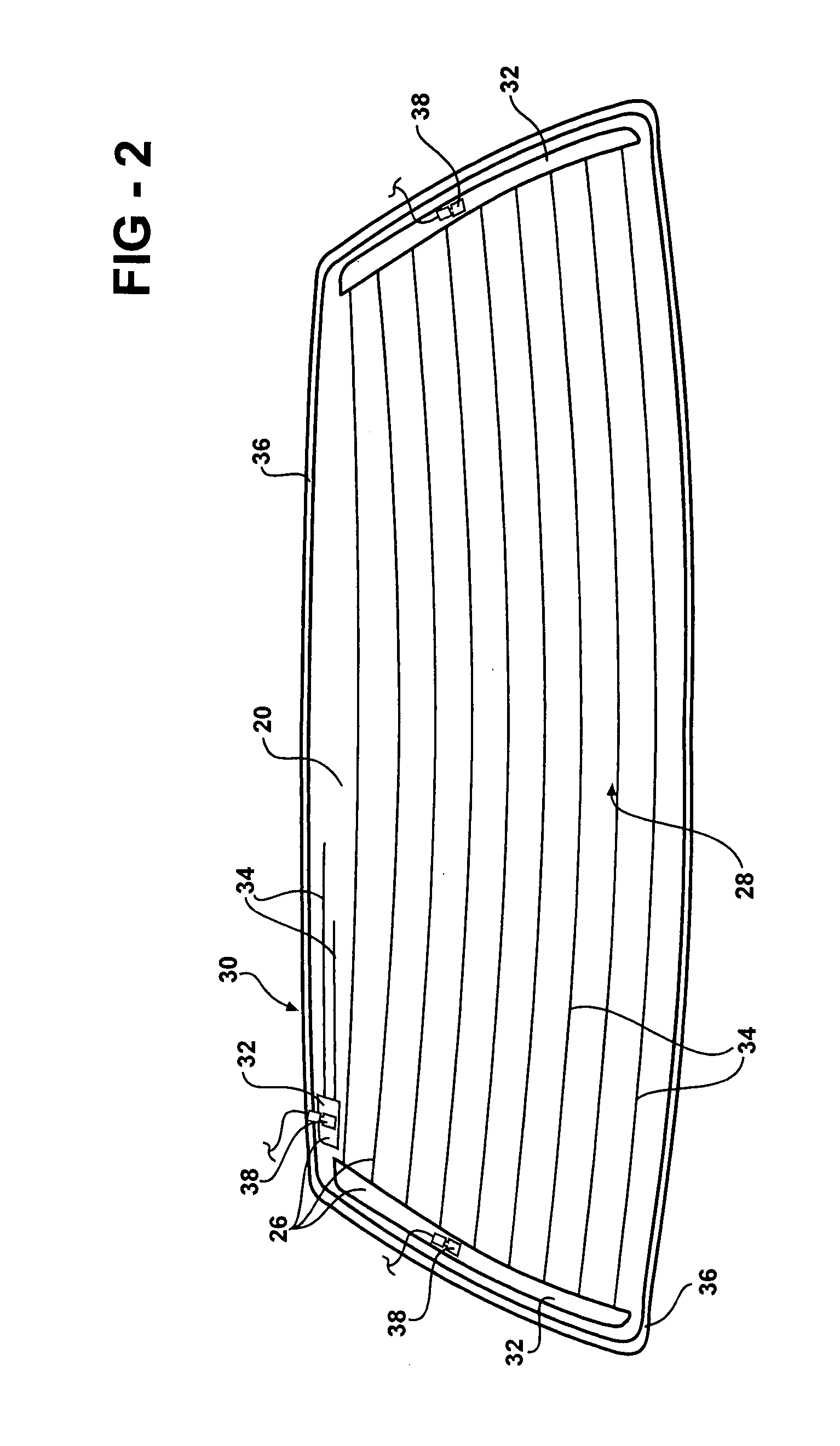

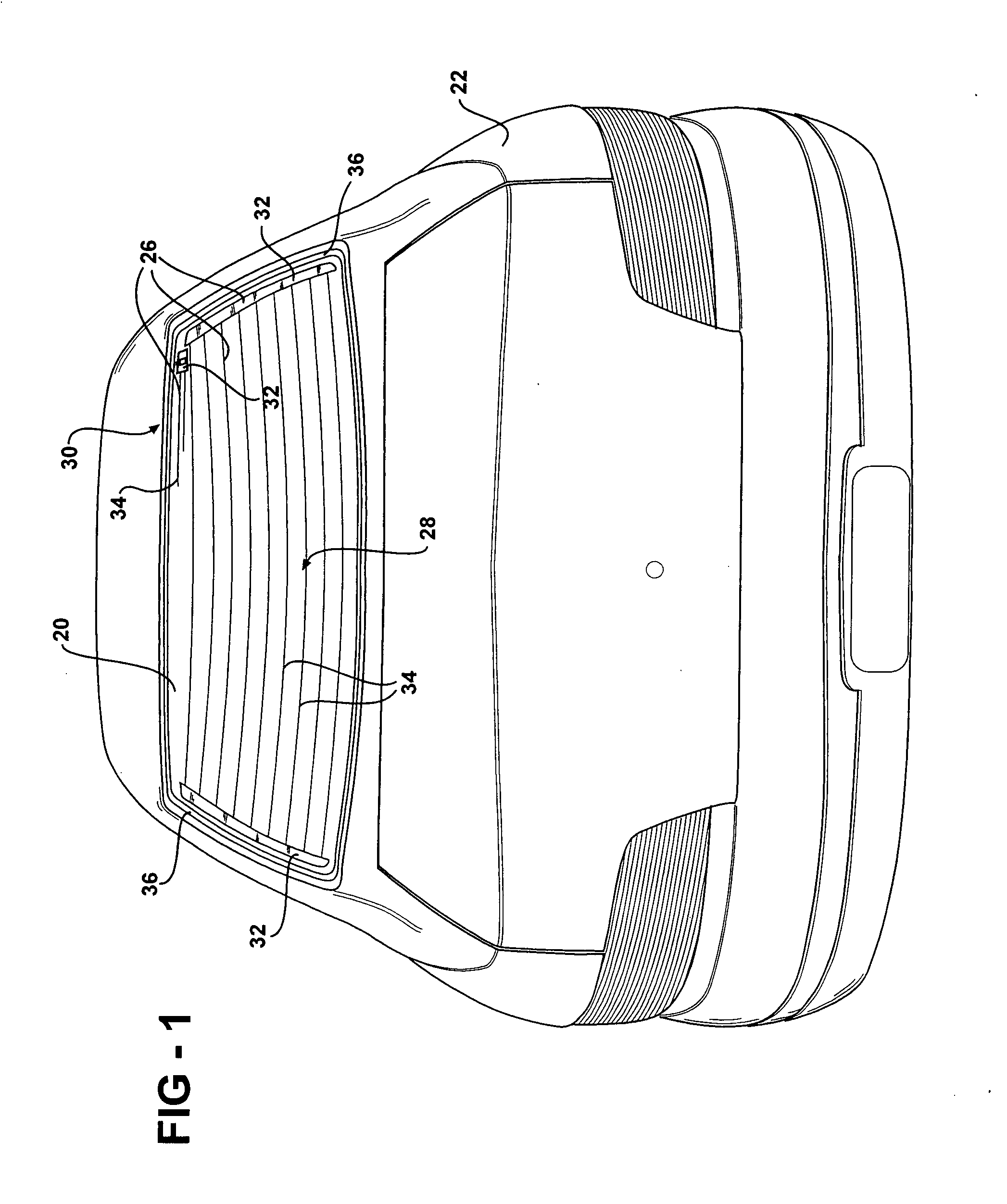

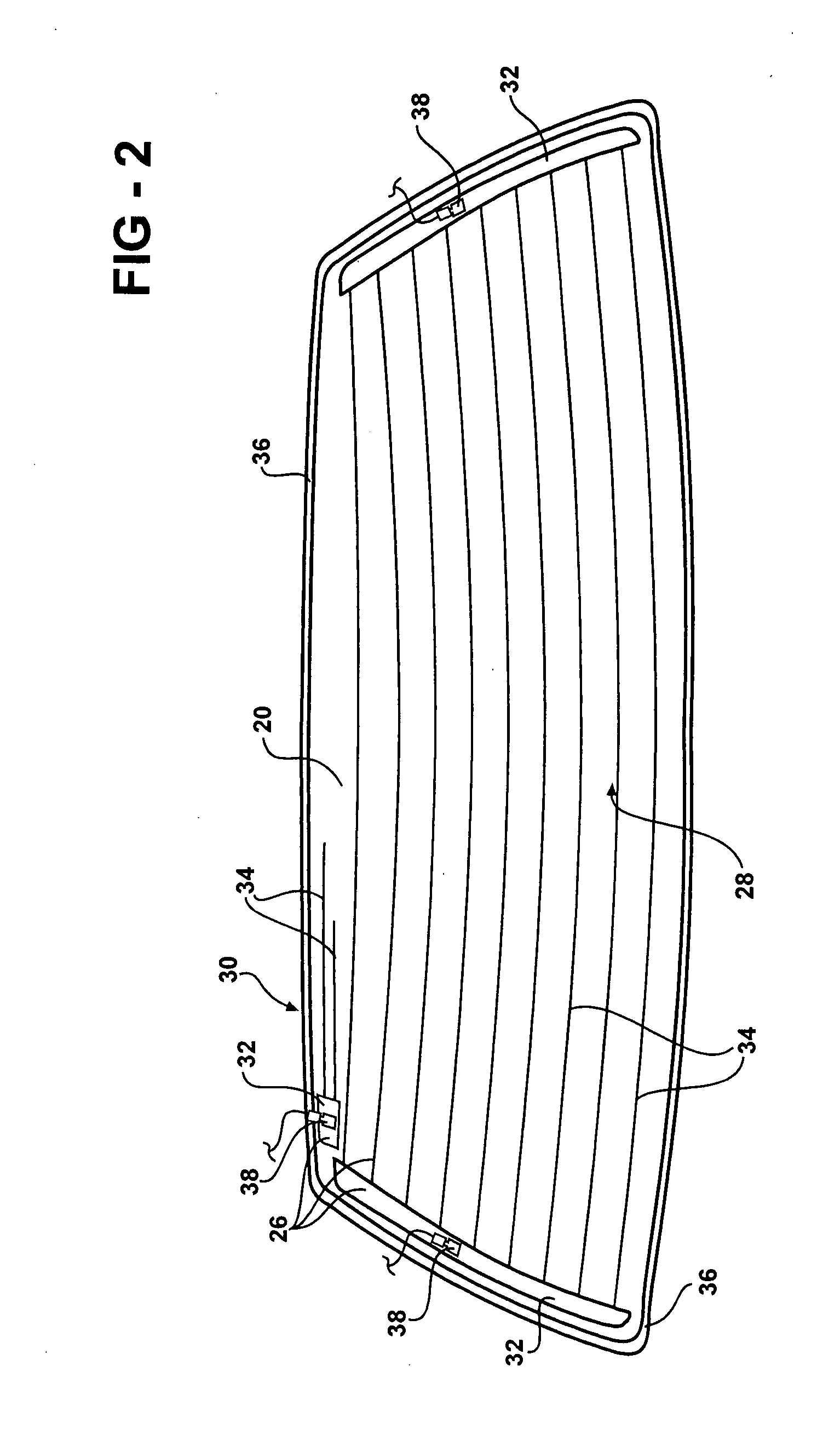

Window pane and a method of bonding a connector to the window pane

InactiveUS7134201B2Eliminate useAvoid defectsVehicle connectorsElectrically conductive connectionsElectrical conductorUltrasonic welding

Owner:AGC AUTOMOTIVE AMERICAS

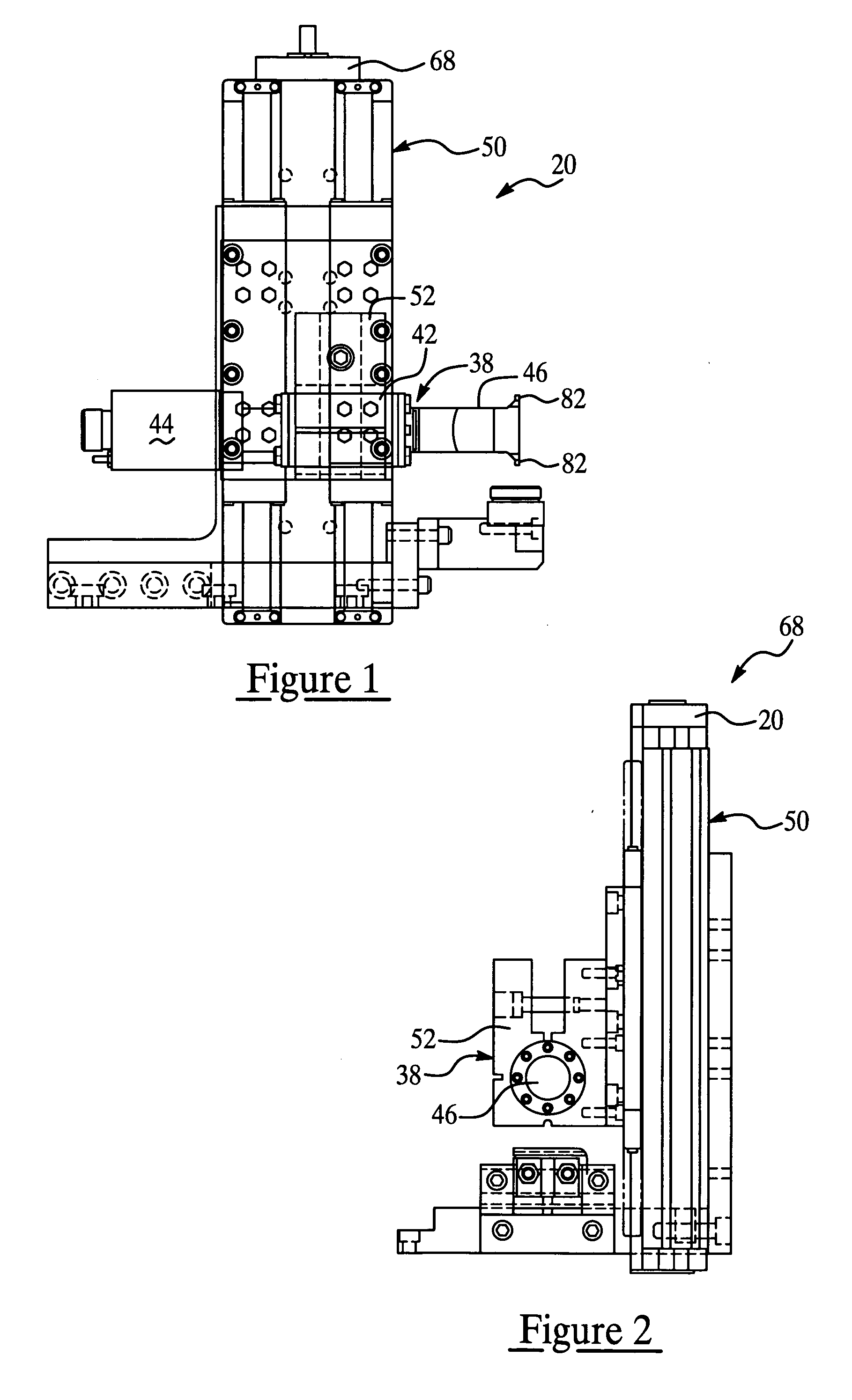

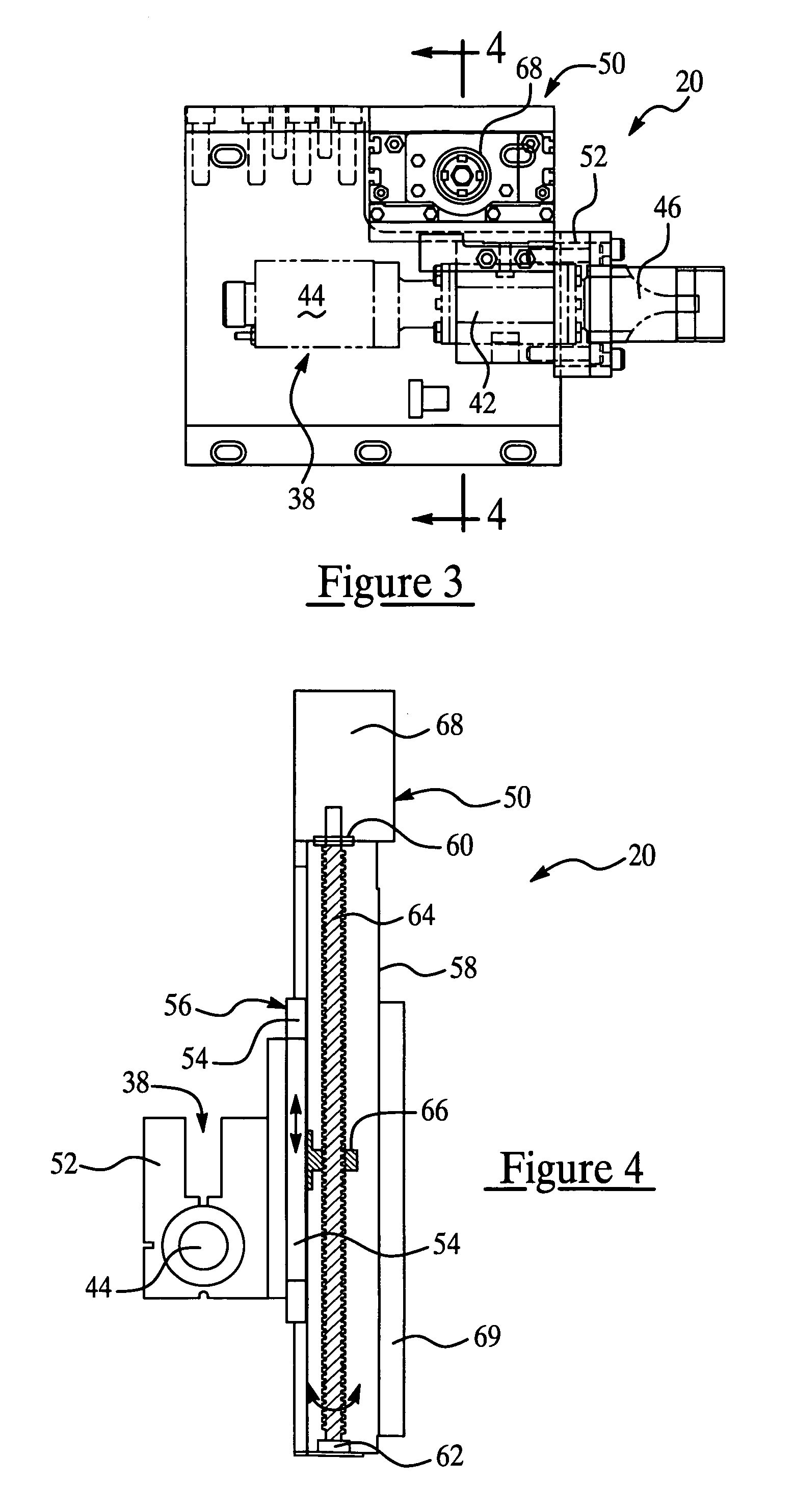

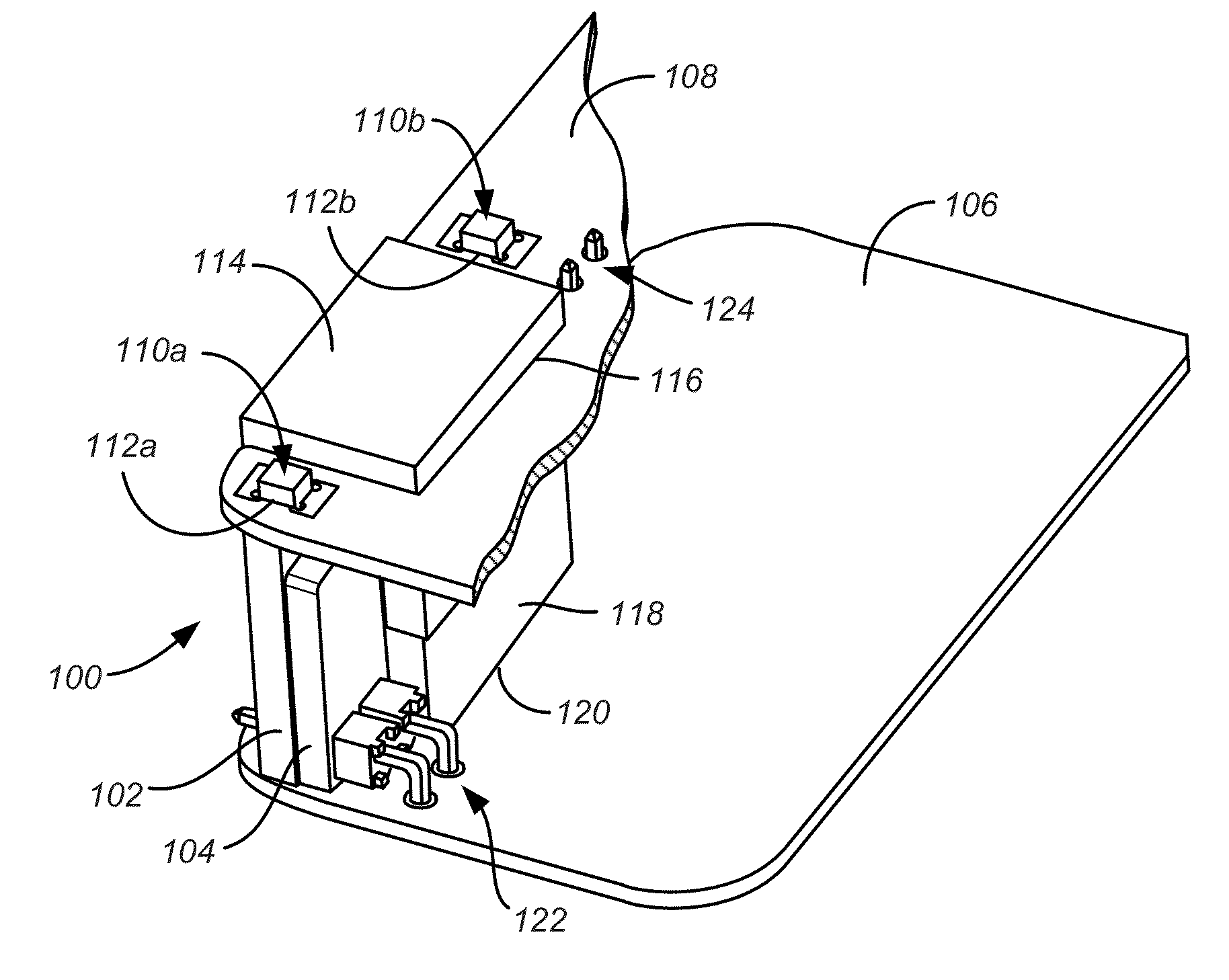

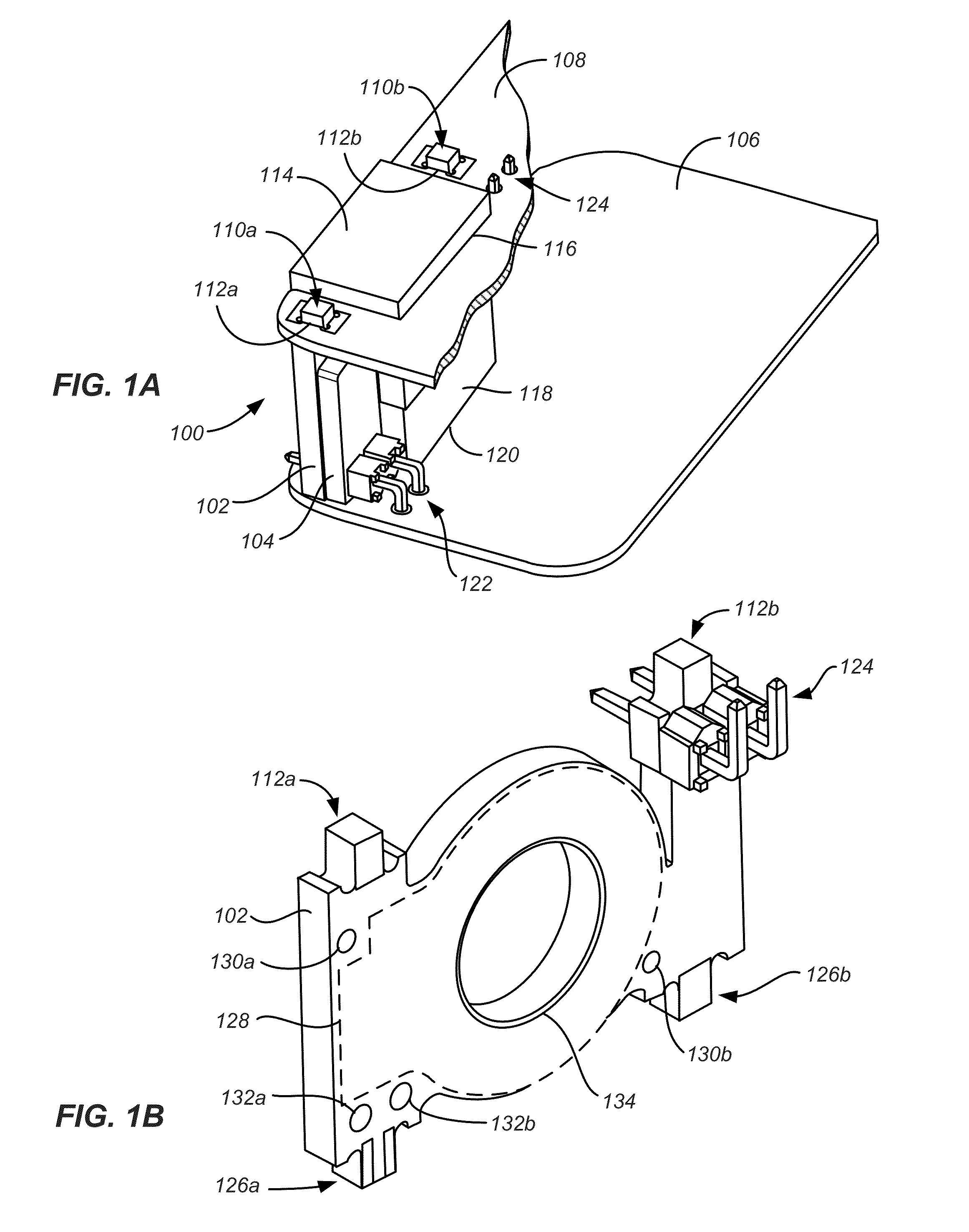

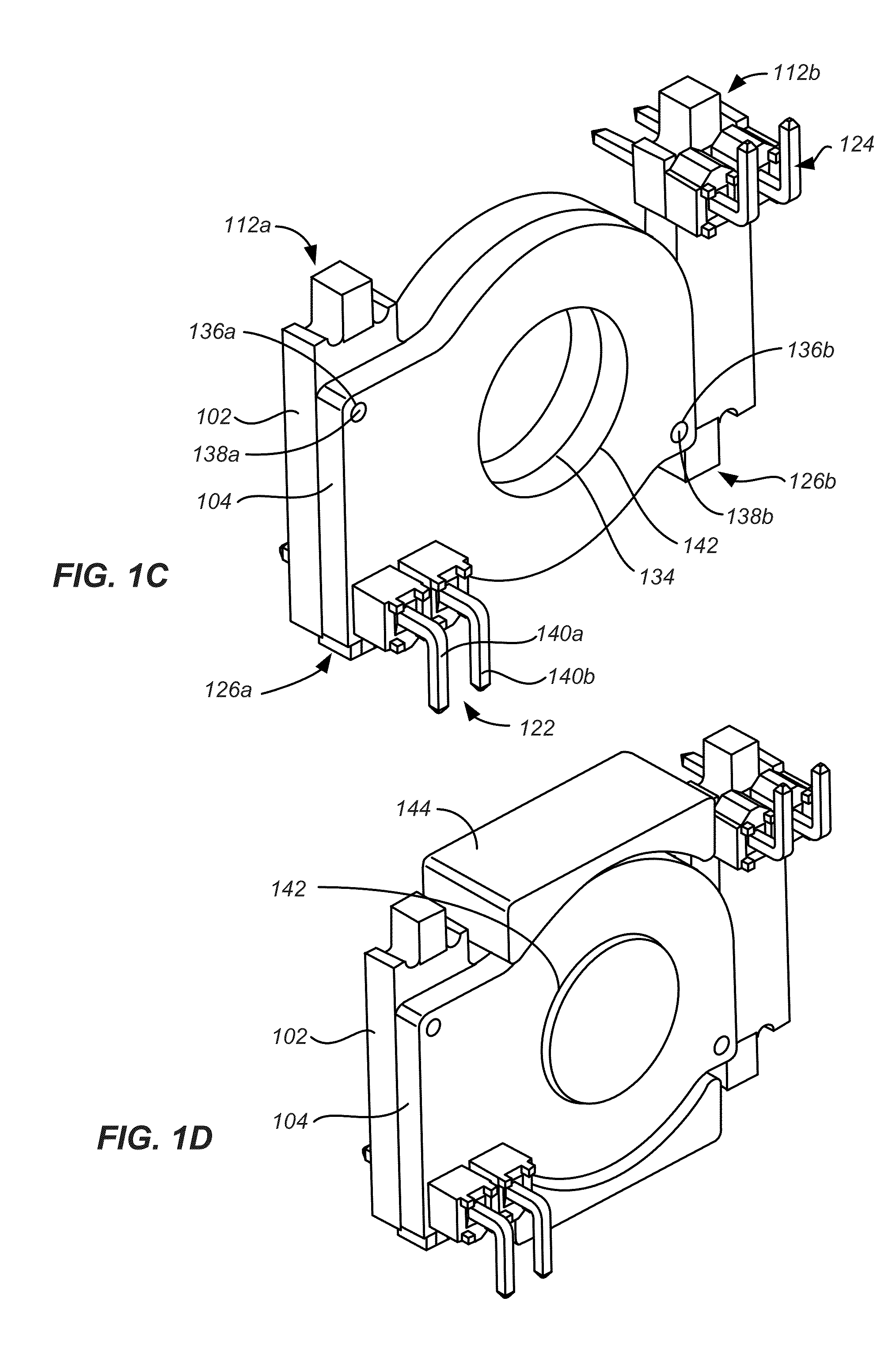

Ultrasonic welding system

InactiveUS20070068991A1Highly versatileRobust systemElectrically conductive connectionsWelding/cutting auxillary devicesUltrasonic weldingTransducer

The present invention is an ultrasonic welding system having an ultrasonic welder integrated with a servo press for galling and ultrasonic welding of a first workpiece to a second workpiece. The first and second workpieces are substantially disposed between a confronting tip and stationary anvil of the ultrasonic welder. Prior to welding, the servo press preferably quickly moves the tip toward and generally against the first workpiece. During welding, a variable speed motor of the servo press preferably slowly moves the tip toward the anvil compressing the workpieces together while a transducer of the ultrasonic welder transmits mechanical vibration to the tip for welding the workpieces together.

Owner:DELPHI TECH INC

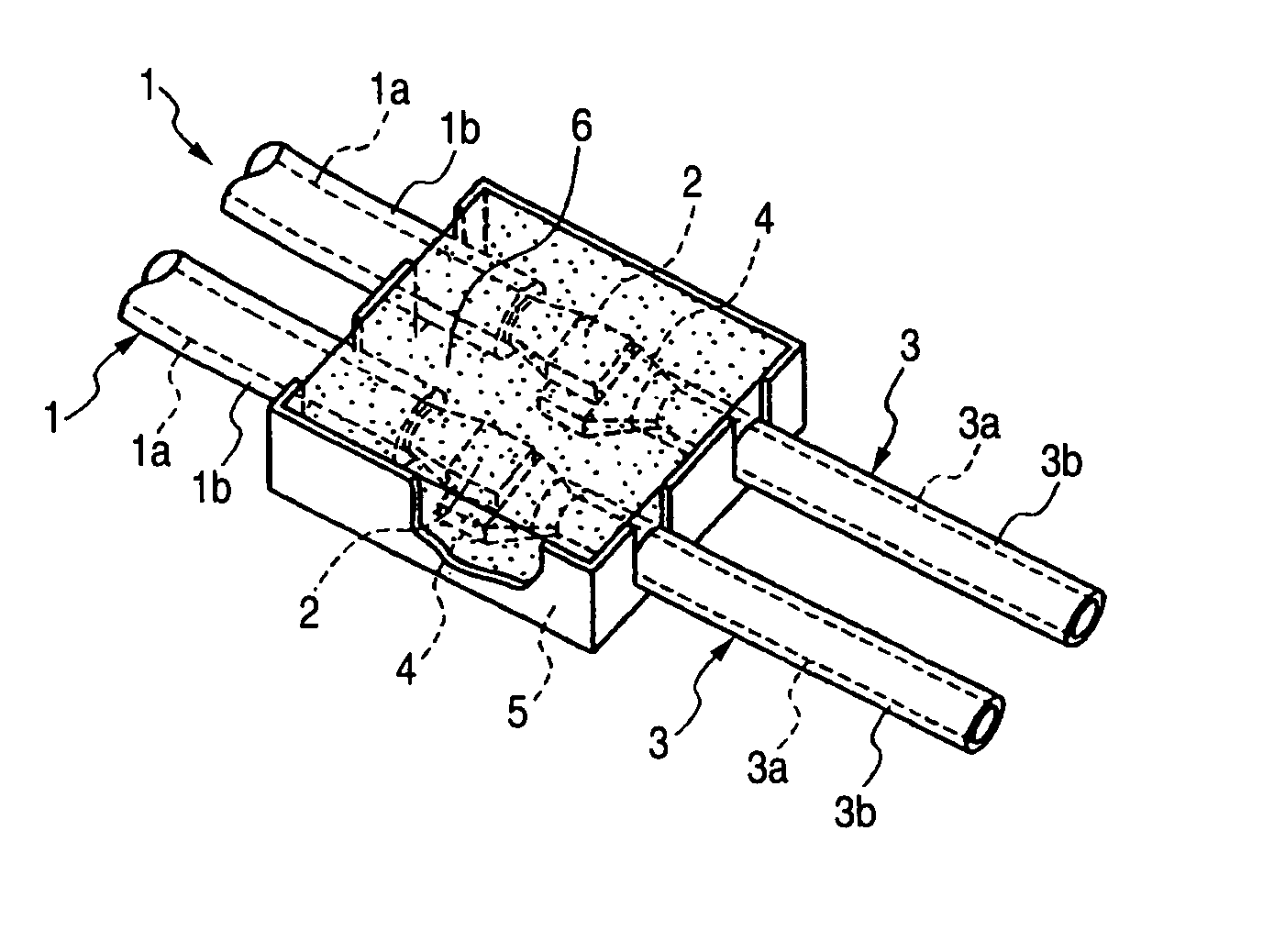

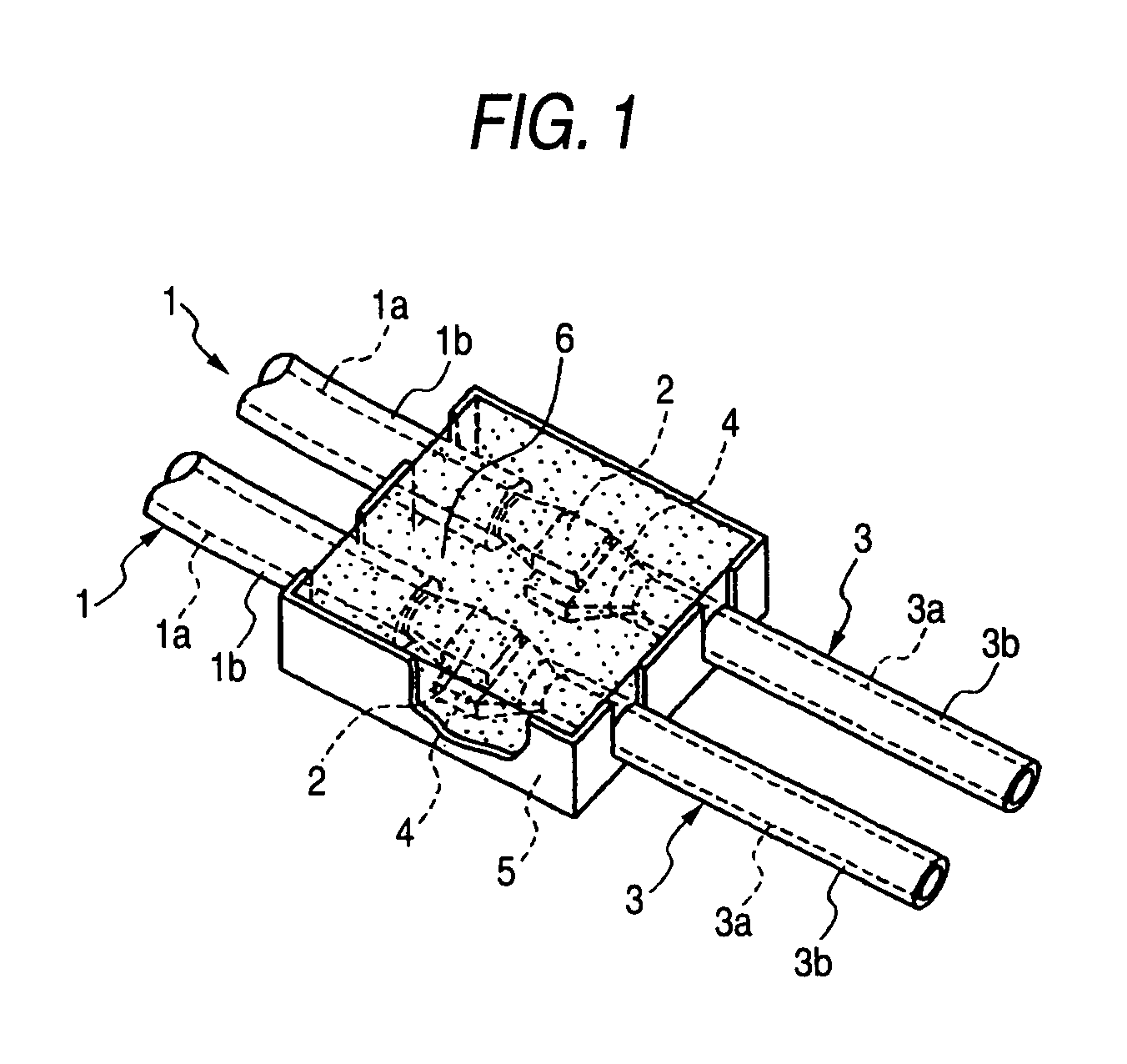

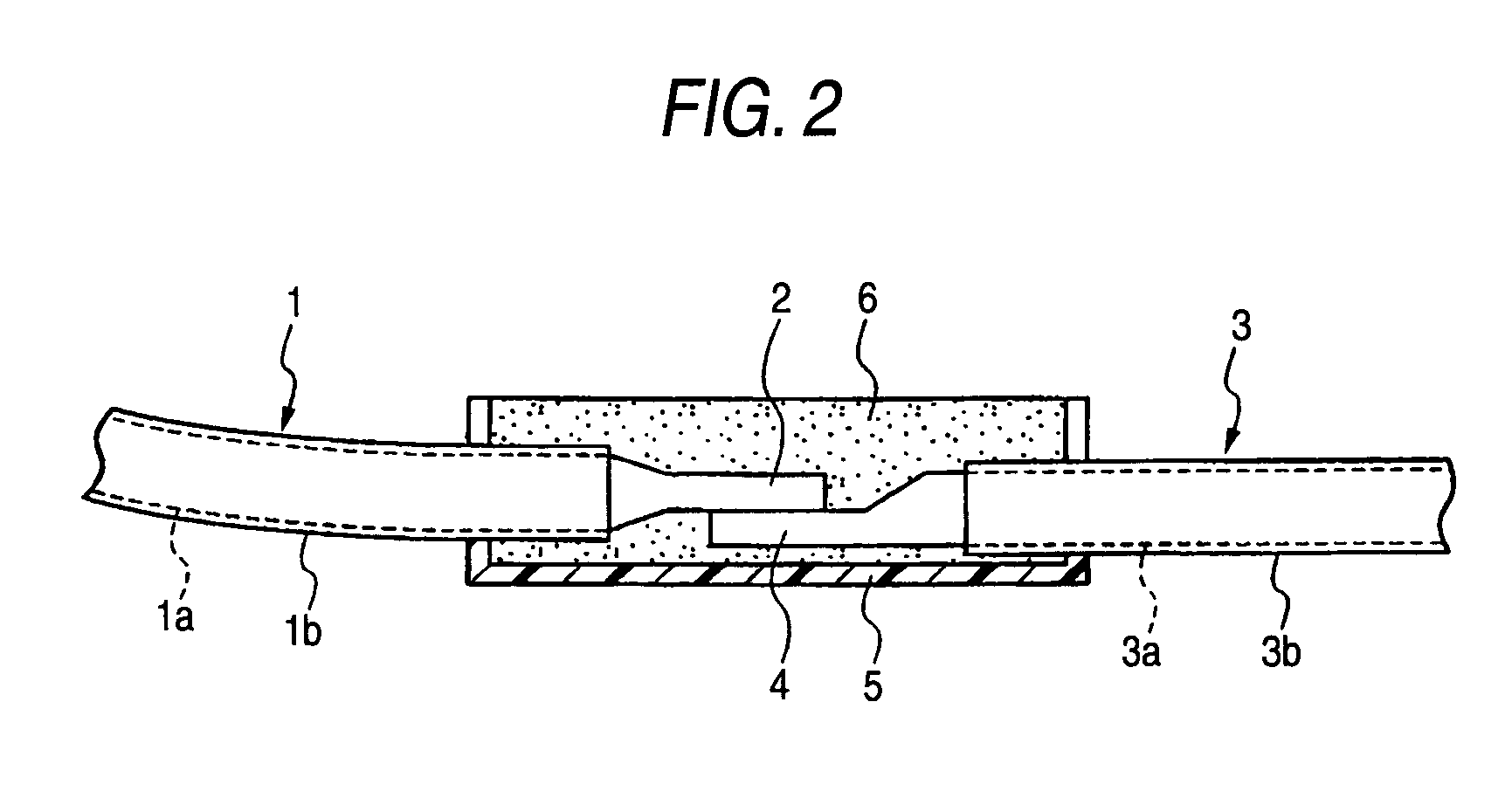

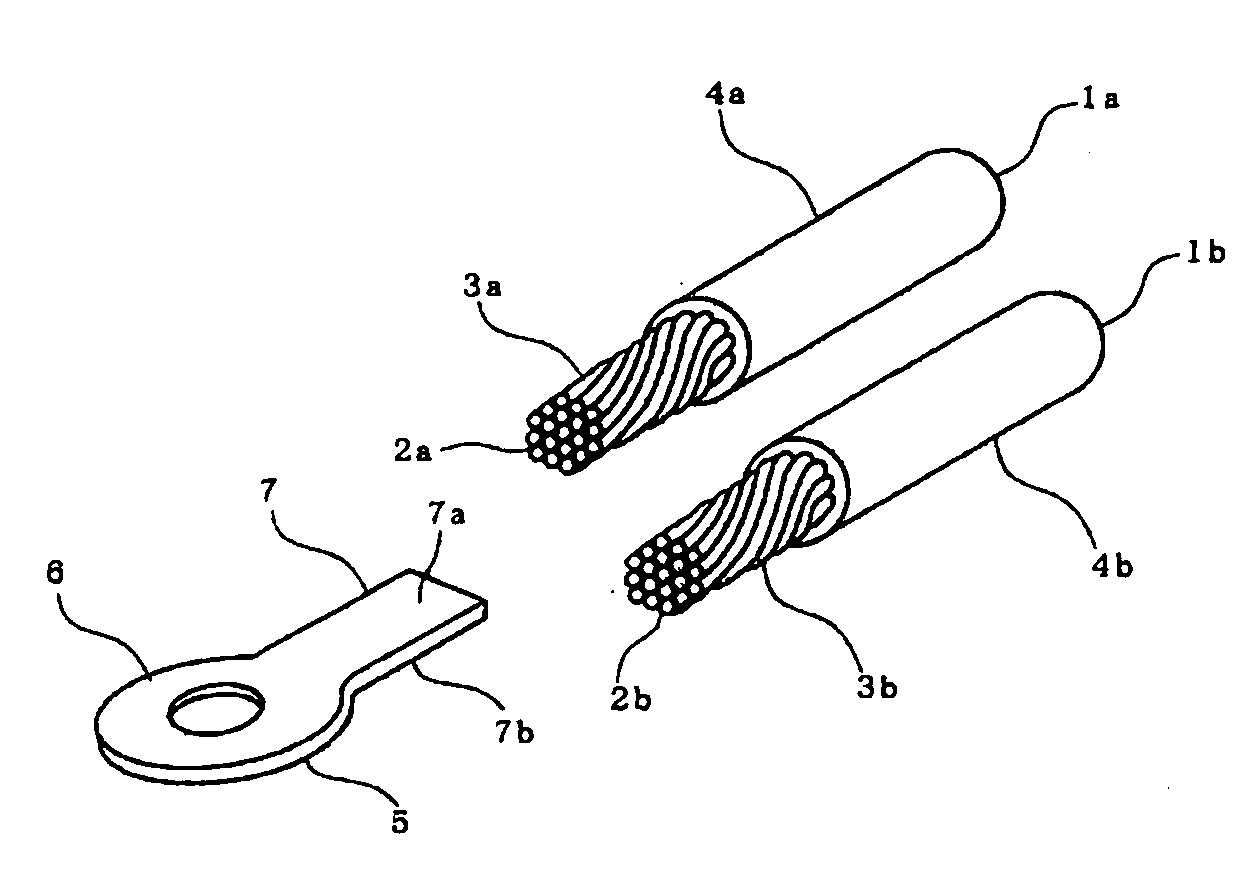

High-voltage wire connecting structure and high-voltage wire connecting method

InactiveUS20060121773A1Fast curingCouplings bases/casesSoldered/welded connectionsElectrical conductorEngineering

A portion of a conductor 1a of each high-voltage wire, exposed by removing an insulating sheath 1b, is formed into a flat plate-like terminal 2 of an integral construction. A portion of a conductor 3a of each of the other high-voltage wires 3, exposed from an insulating sheath 3b, is formed into a flat plate-like terminal 4. Each mating pair of flat plate-like terminals 2 and 4 are connected together by welding or melt adhesion, and are received within an insulating casing 5, and are sealed by a hot-melt adhesive 6 filled in the insulating casing 5.

Owner:YAZAKI CORP

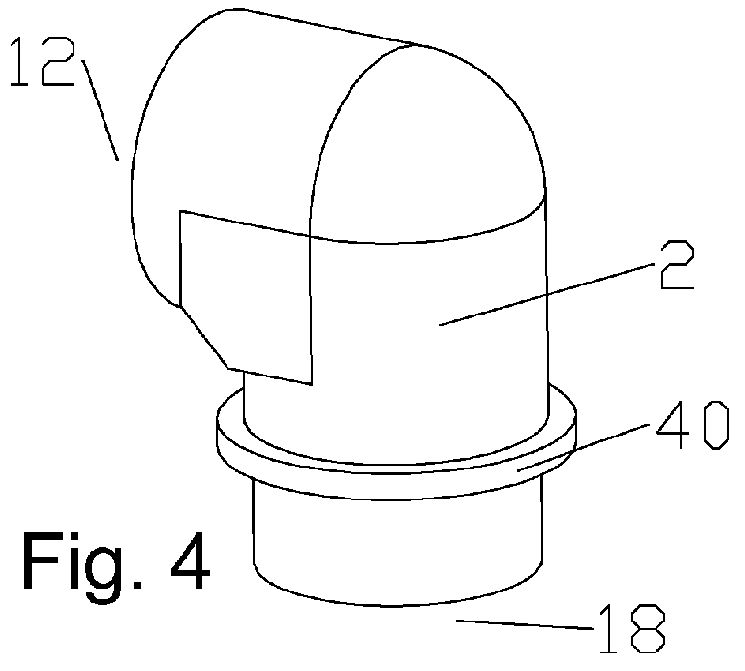

Field weldable connections

The present invention provides a field weldable connection. In one embodiment, the field weldable connection is a downhole connector assembly for sealingly attaching a first and a second segment of a control line. The control line has an outer housing that encapsulates a polymeric secondary housing. A communication line runs therethrough the secondary housing. The connector further comprises a weld coupling welded to the outer housing of the first and second segments of the control line. To protect the communication line from the thermal radiation and heat generated during the welding process, at least one reflective sleeve replaces a portion of the secondary housing at a location intermediate the communication line and the welds of the coupling.

Owner:SCHLUMBERGER TECH CORP

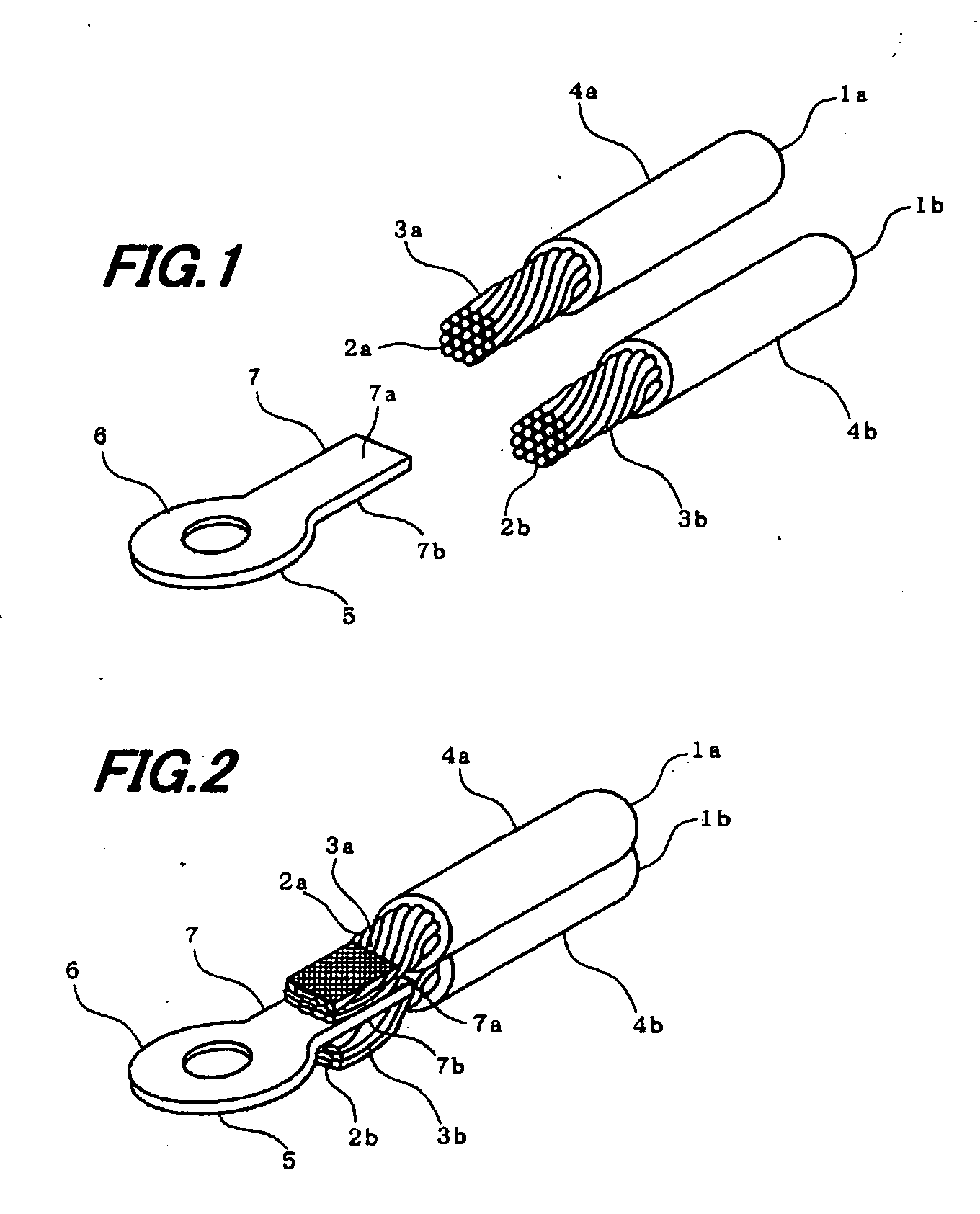

Electric wire with terminal and method of manufacturing the same

ActiveUS20110198122A1Soldered/welded conductive connectionsSoldered/welded connectionsElectrical conductorElectrical devices

An electric wire with a terminal including a conductor, and the terminal connected to an end portion of the conductor. The terminal includes a first connecting portion connected to an electrical equipment and a second connecting portion connected to the conductor. The second connecting portion includes a first connection surface and a second connection surface opposite to the first connection surface. The conductor includes a first conductor and a second conductor that are connected to the first connection surface and the second connection surface, respectively, by ultrasonic bonding. A total cross-sectional area of the first conductor and the second conductor is not less than 20 mm2.

Owner:HITACHI METALS LTD

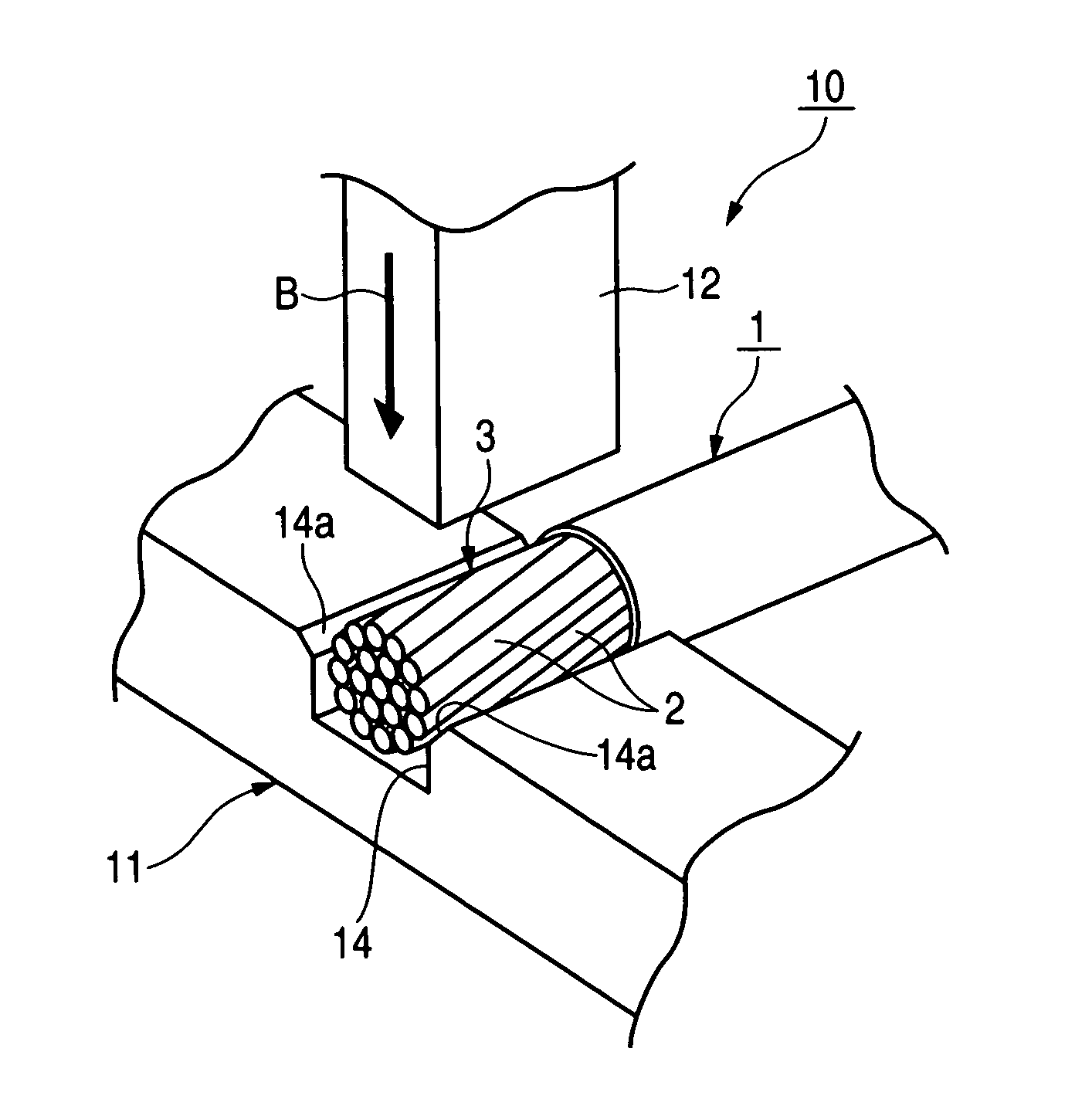

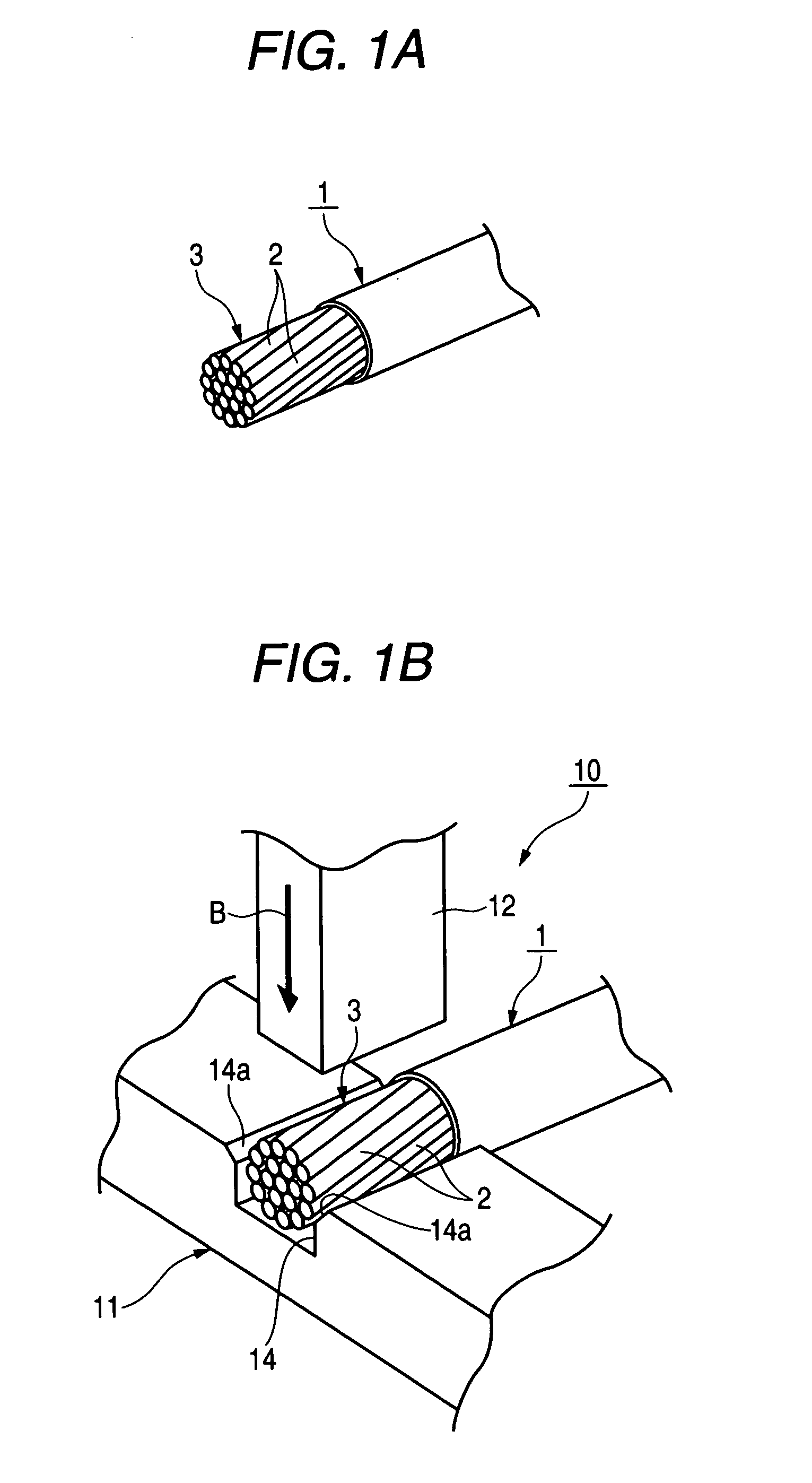

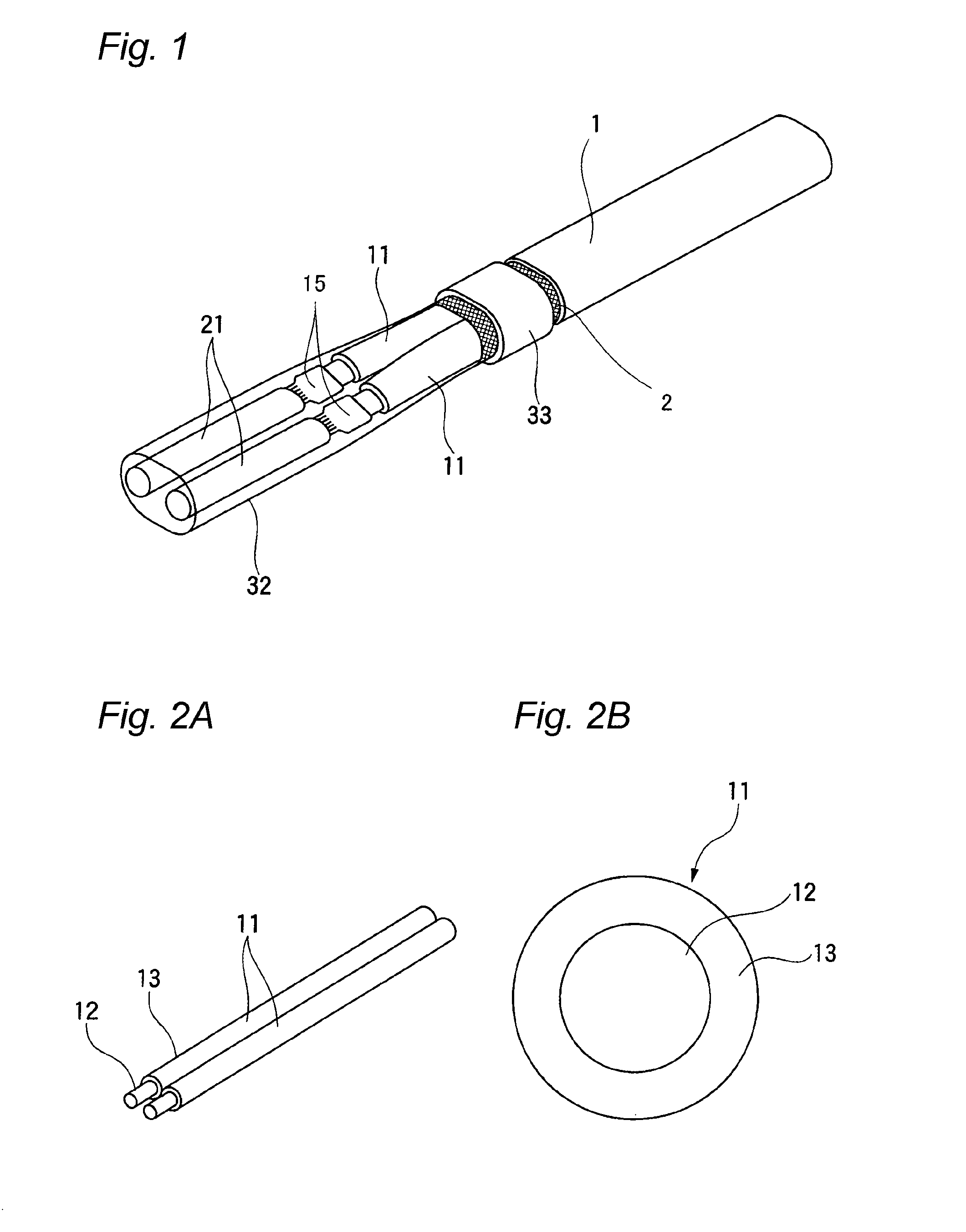

Ultrasonic bonding method of electric wire

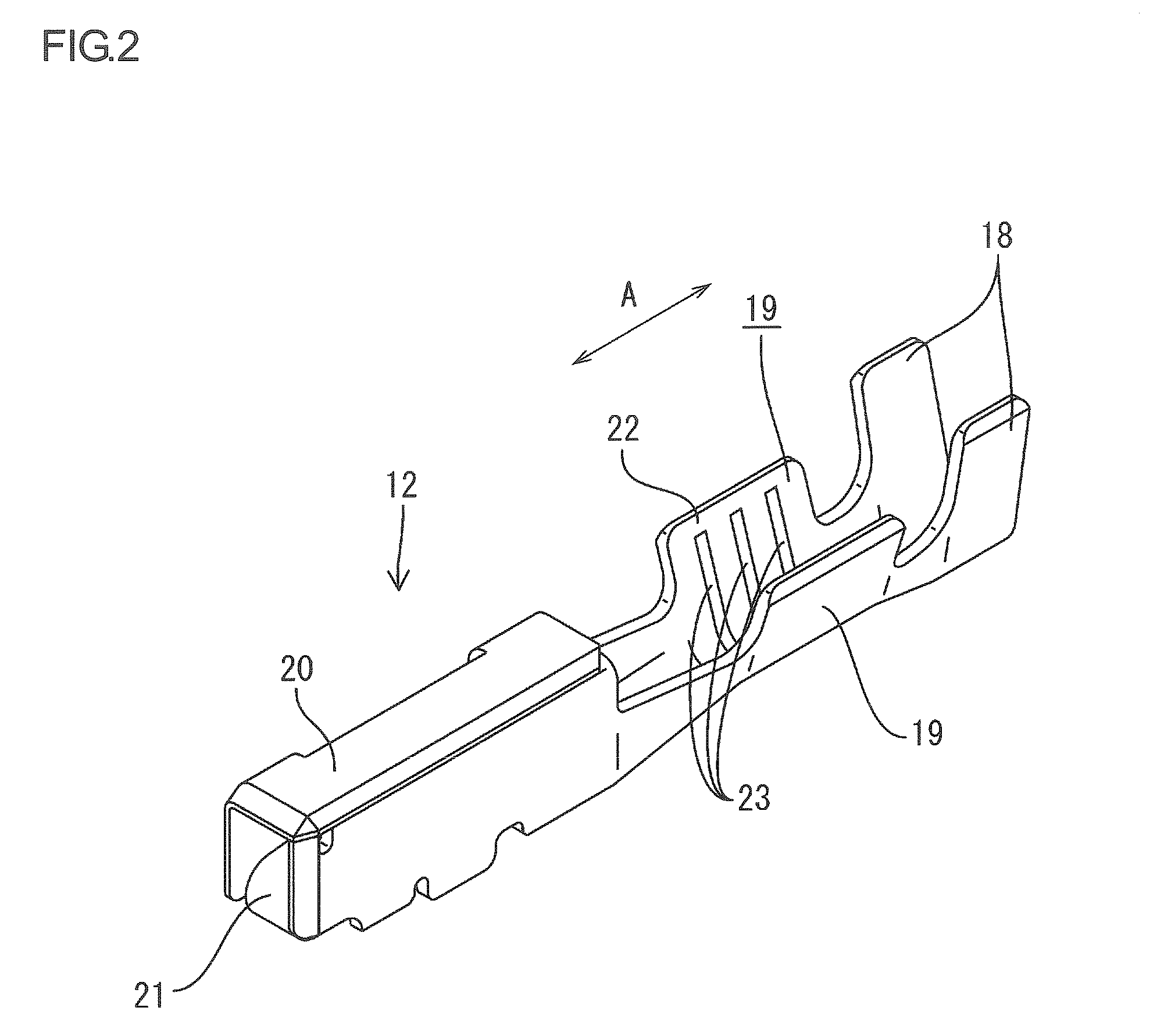

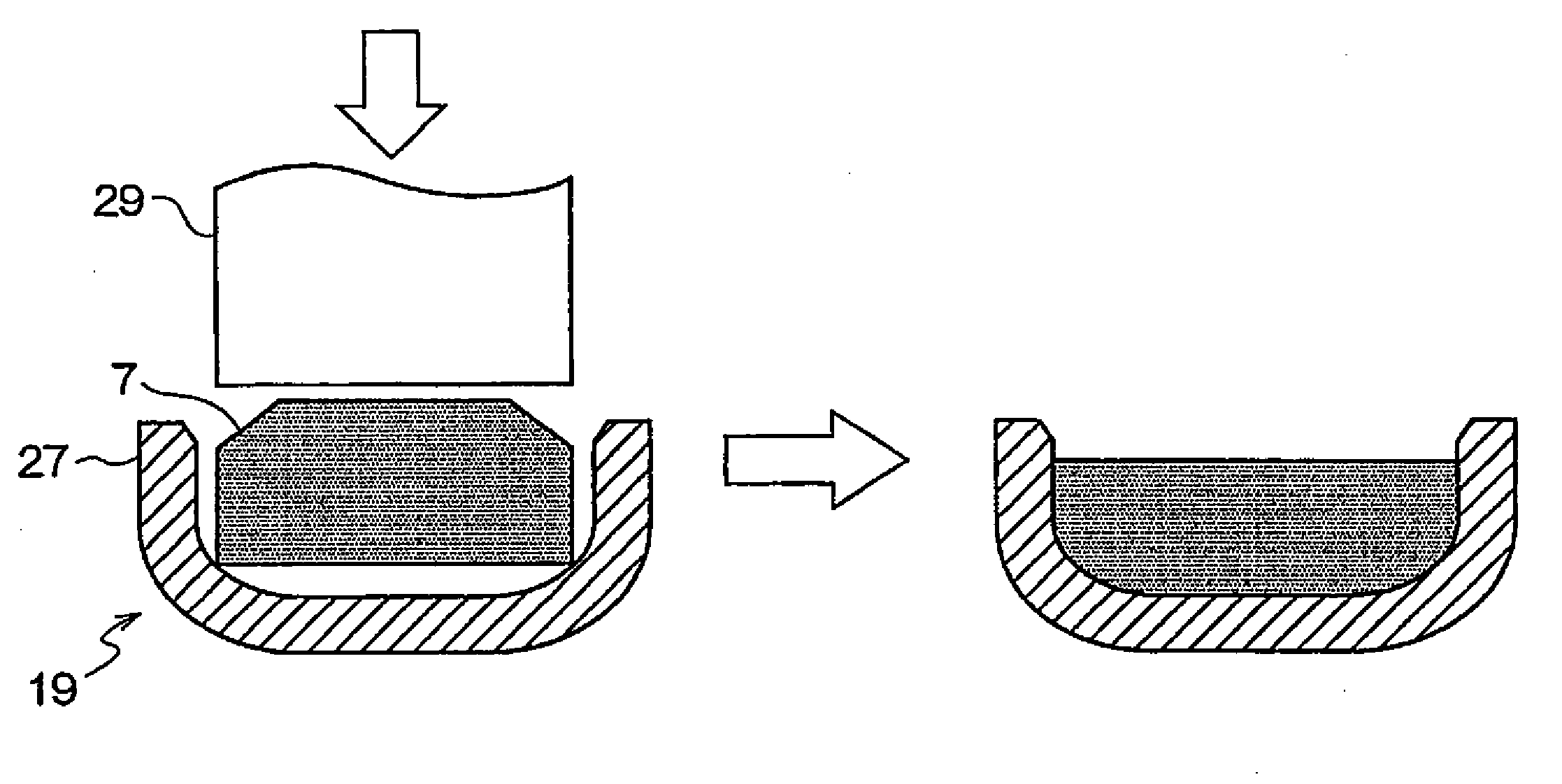

ActiveUS20110062218A1Thin thicknessSwelling can be suppressedElectrically conductive connectionsSoldering apparatusElectrical conductorEngineering

In an ultrasonic bonding method of an electric wire in which the electric wire 1 in which a conductor end 7 made of plural core wires is exposed and a metallic connection terminal 19 formed by erecting two side walls 27 from a bottom surface are prepared and the conductor end is bonded to the connection terminal by applying ultrasonic vibration while the conductor end of the electric wire is positioned in the bottom surface between the two side walls of the connection terminal and is pushed, a cross section of the conductor end of the electric wire is made by being molded by press so that a thickness of a width direction between the side walls becomes thin toward at least one of the side positioned in the bottom surface of the connection terminal and the side to which the ultrasonic vibration is applied.

Owner:YAZAKI CORP

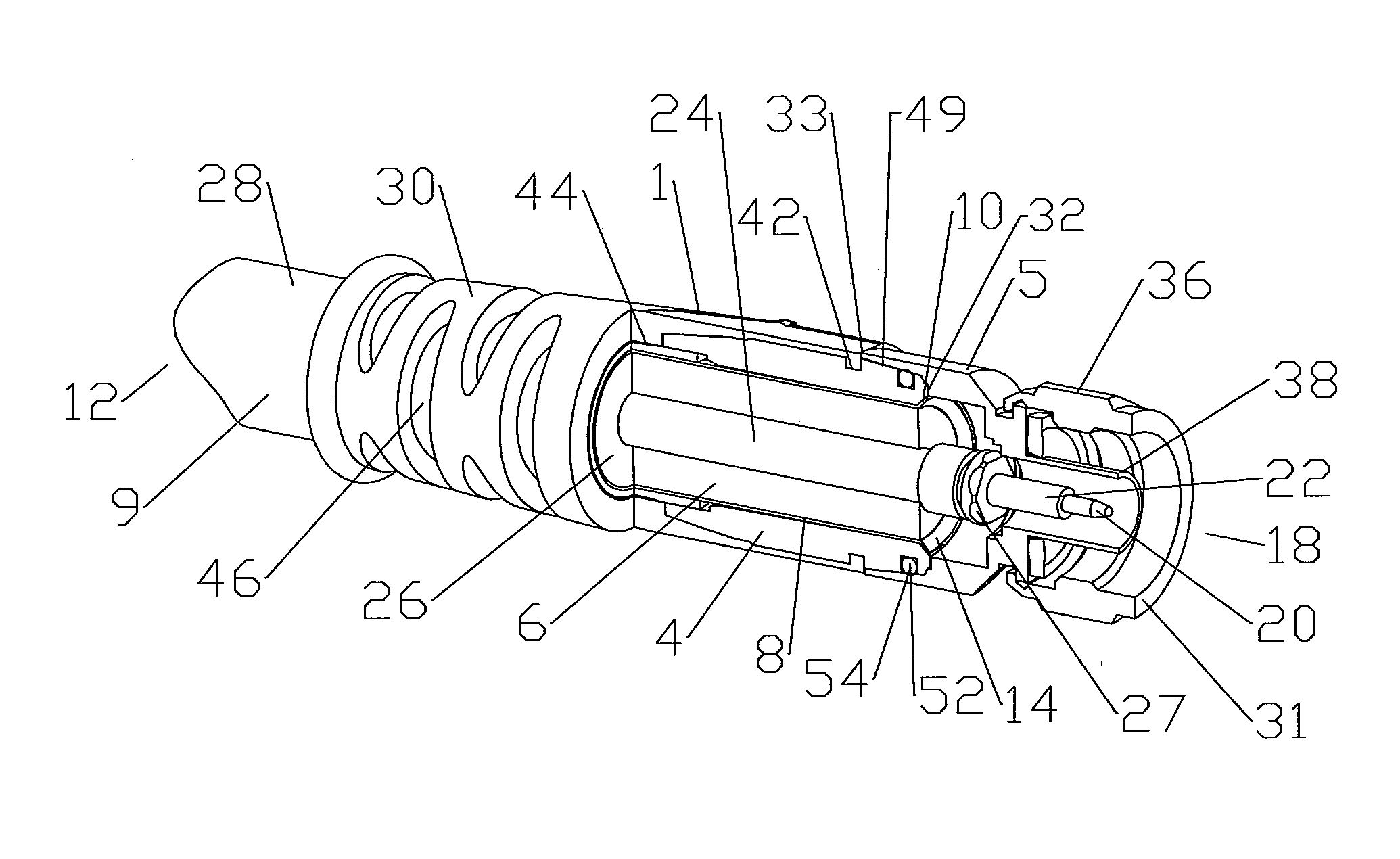

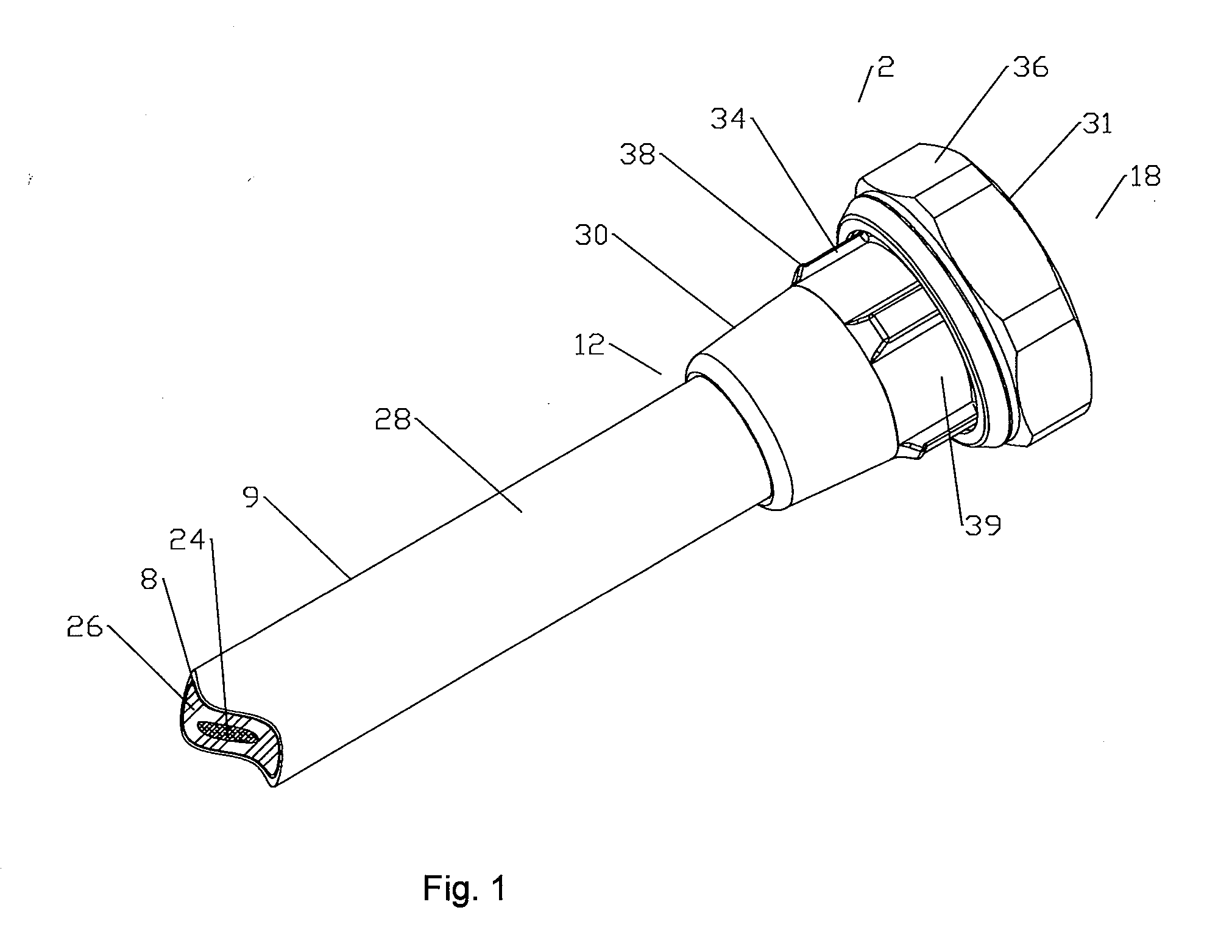

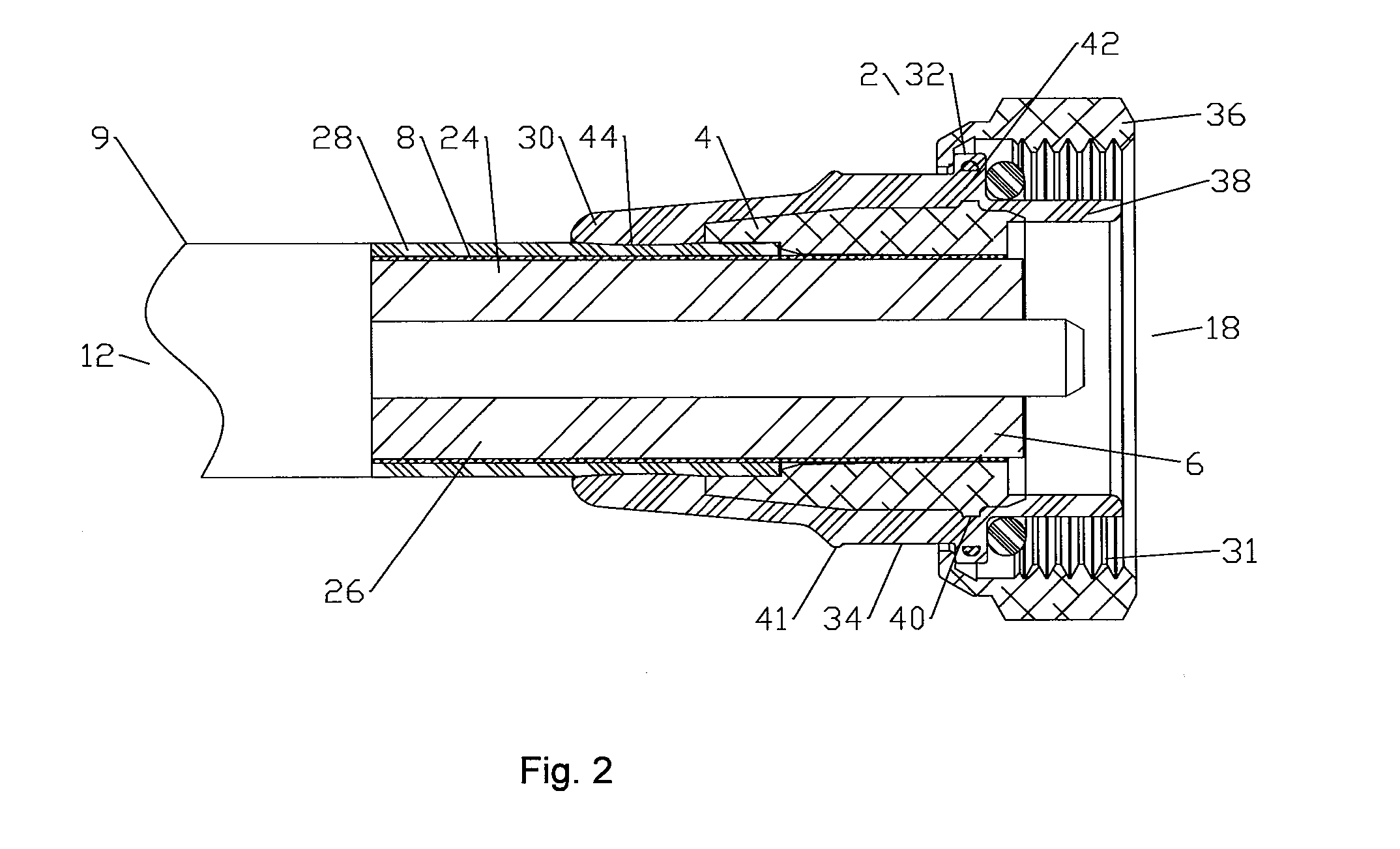

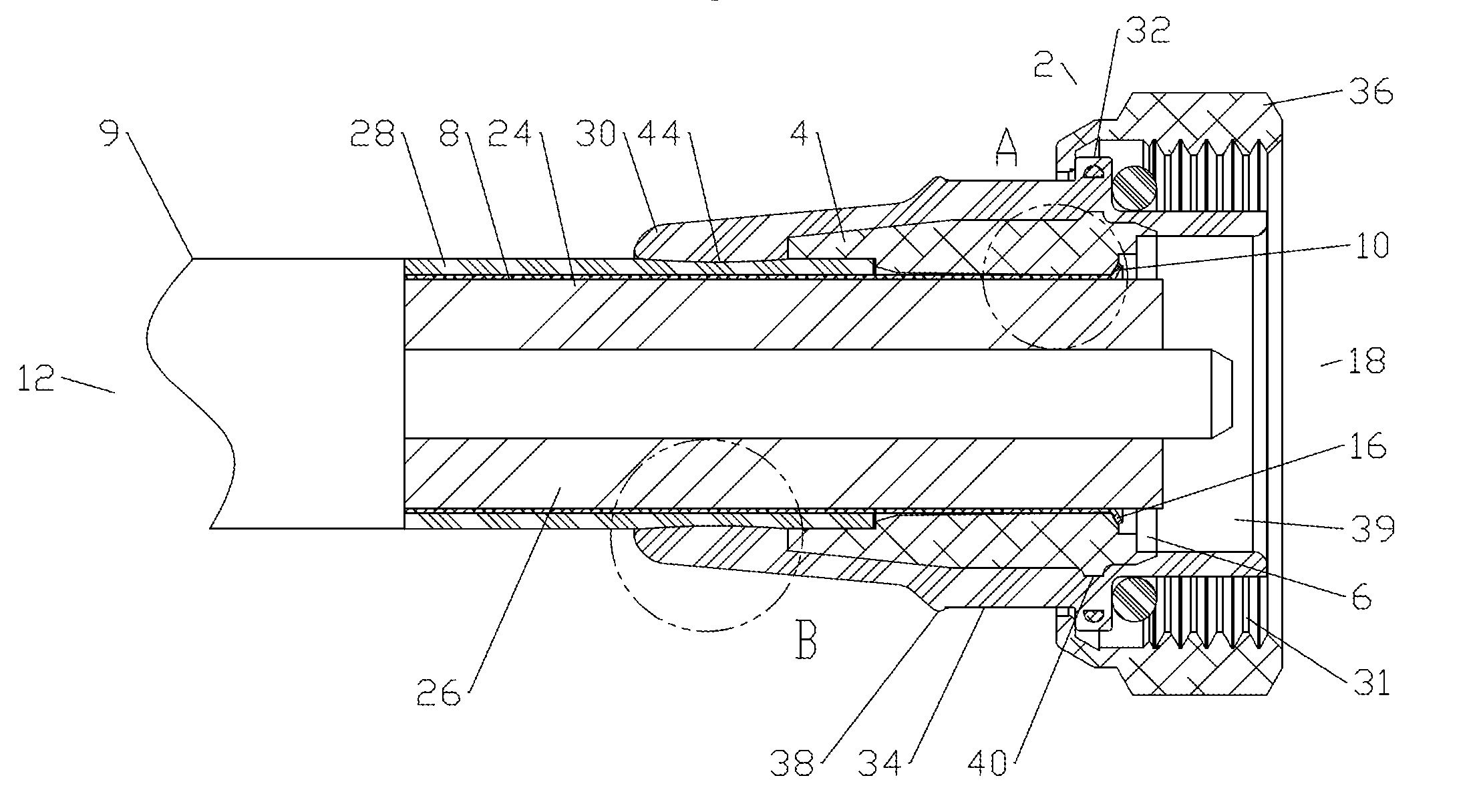

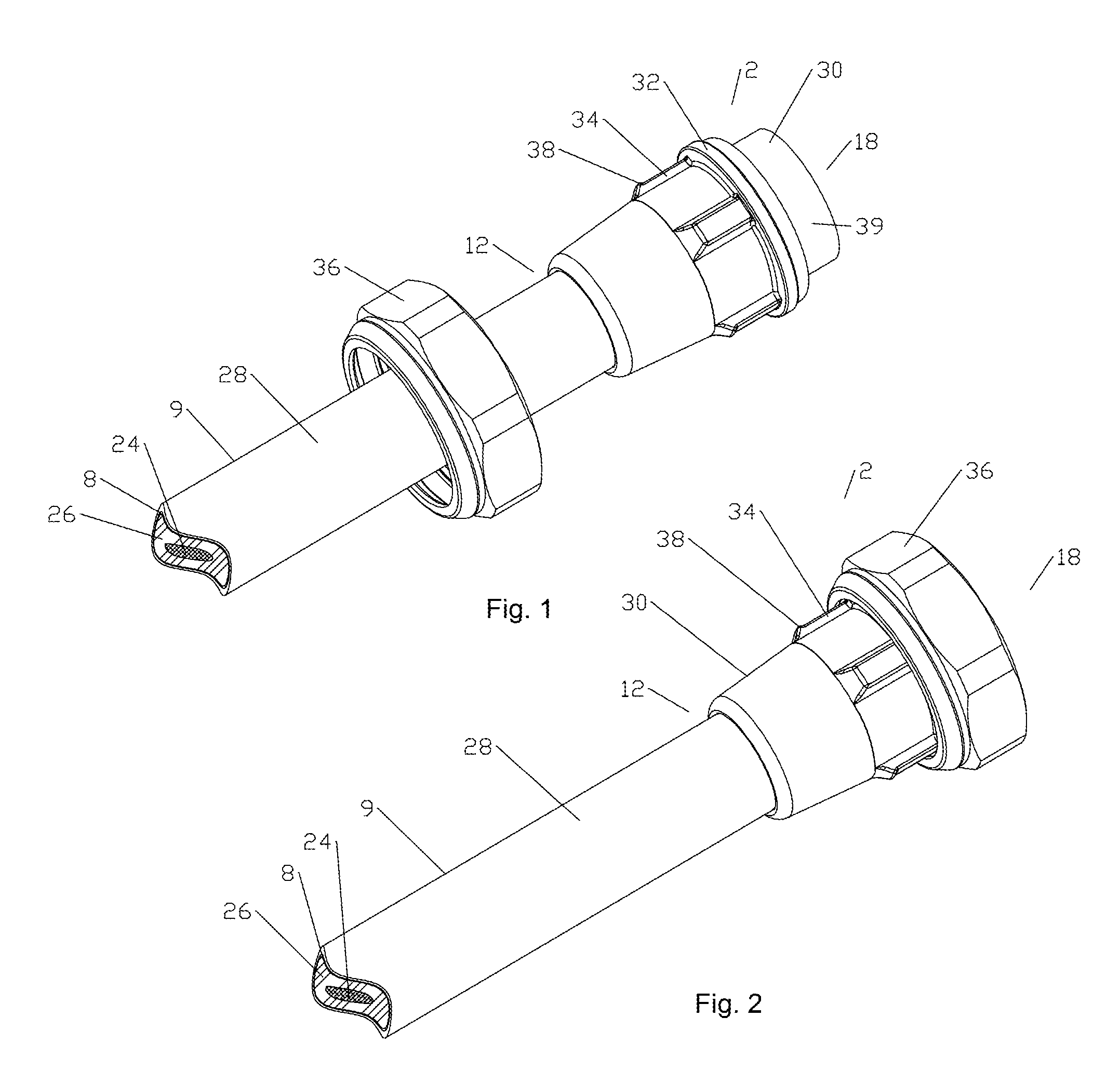

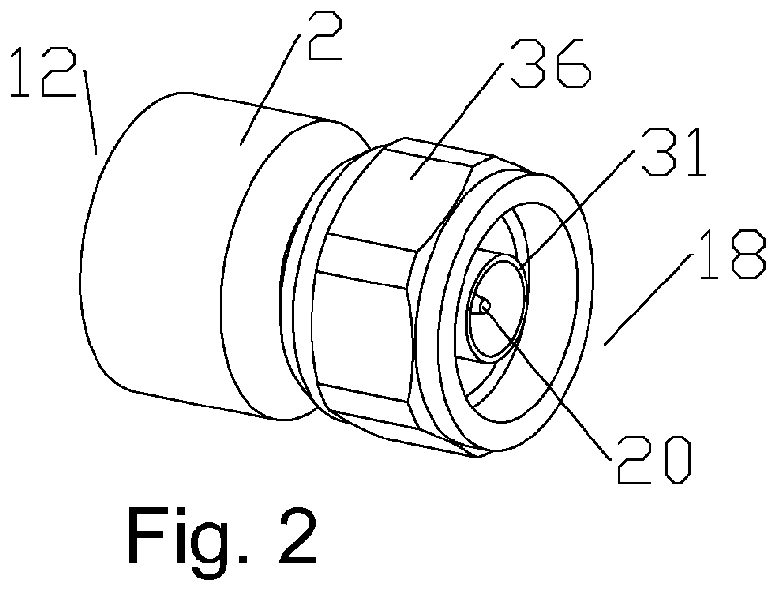

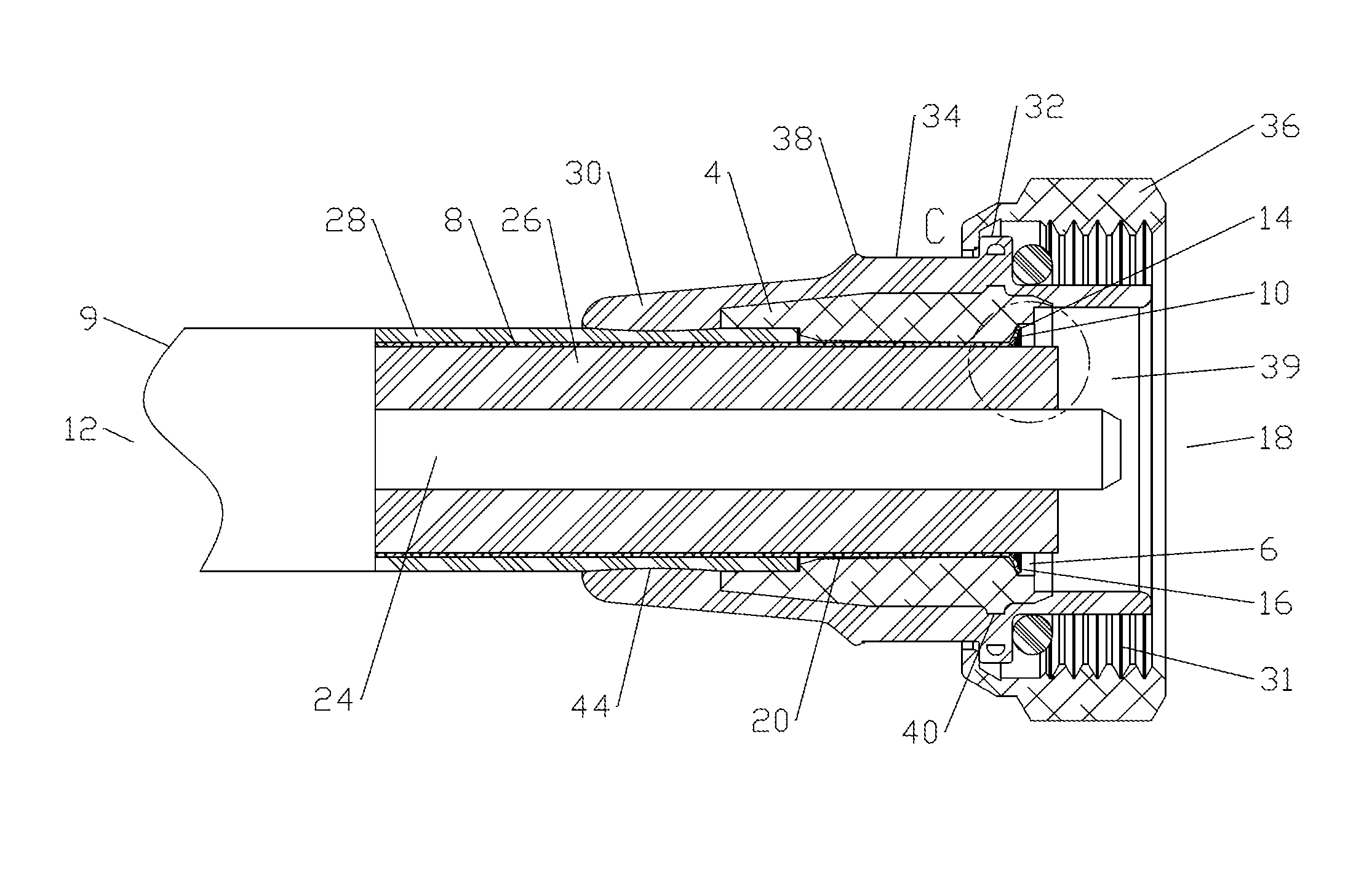

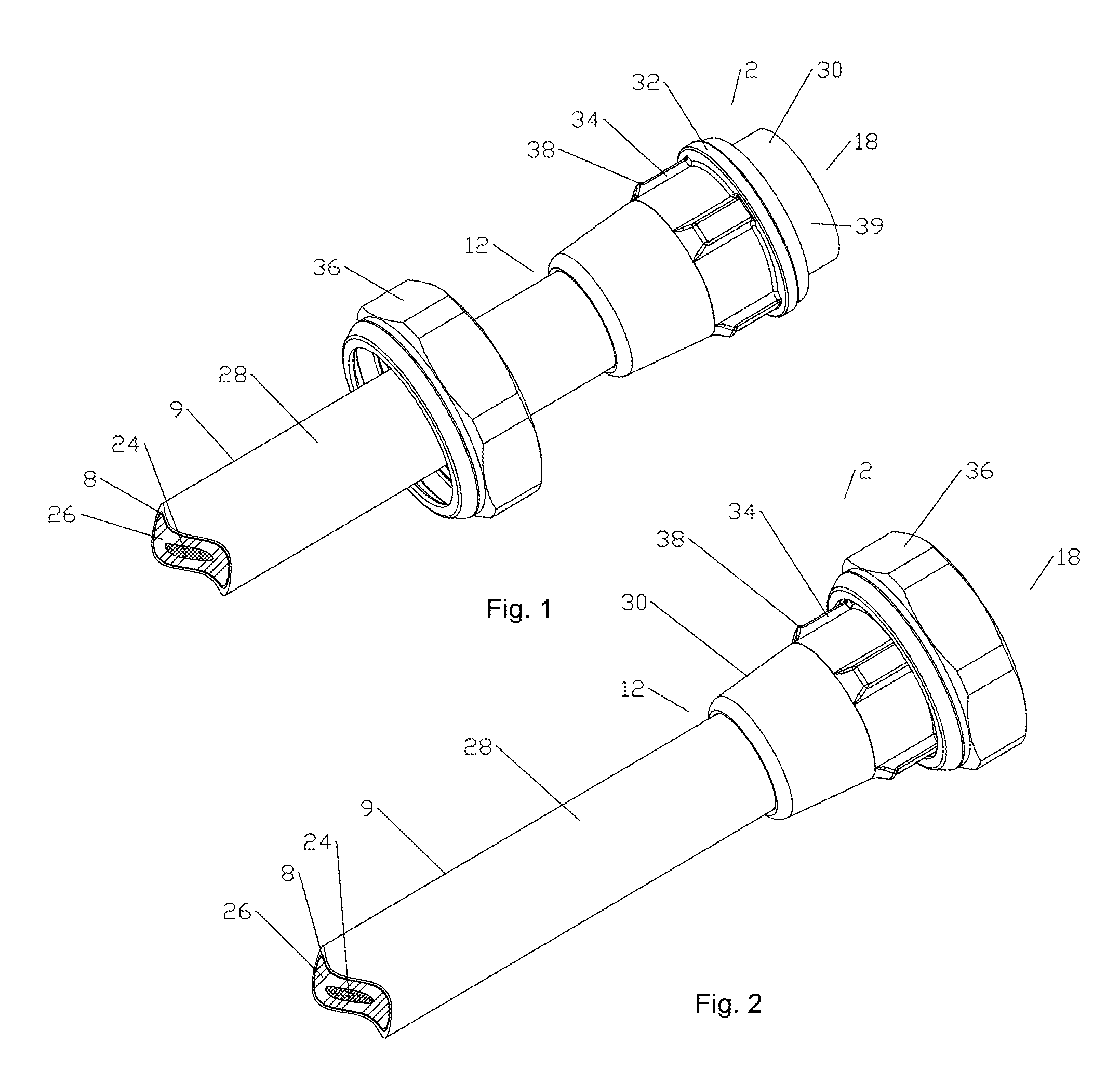

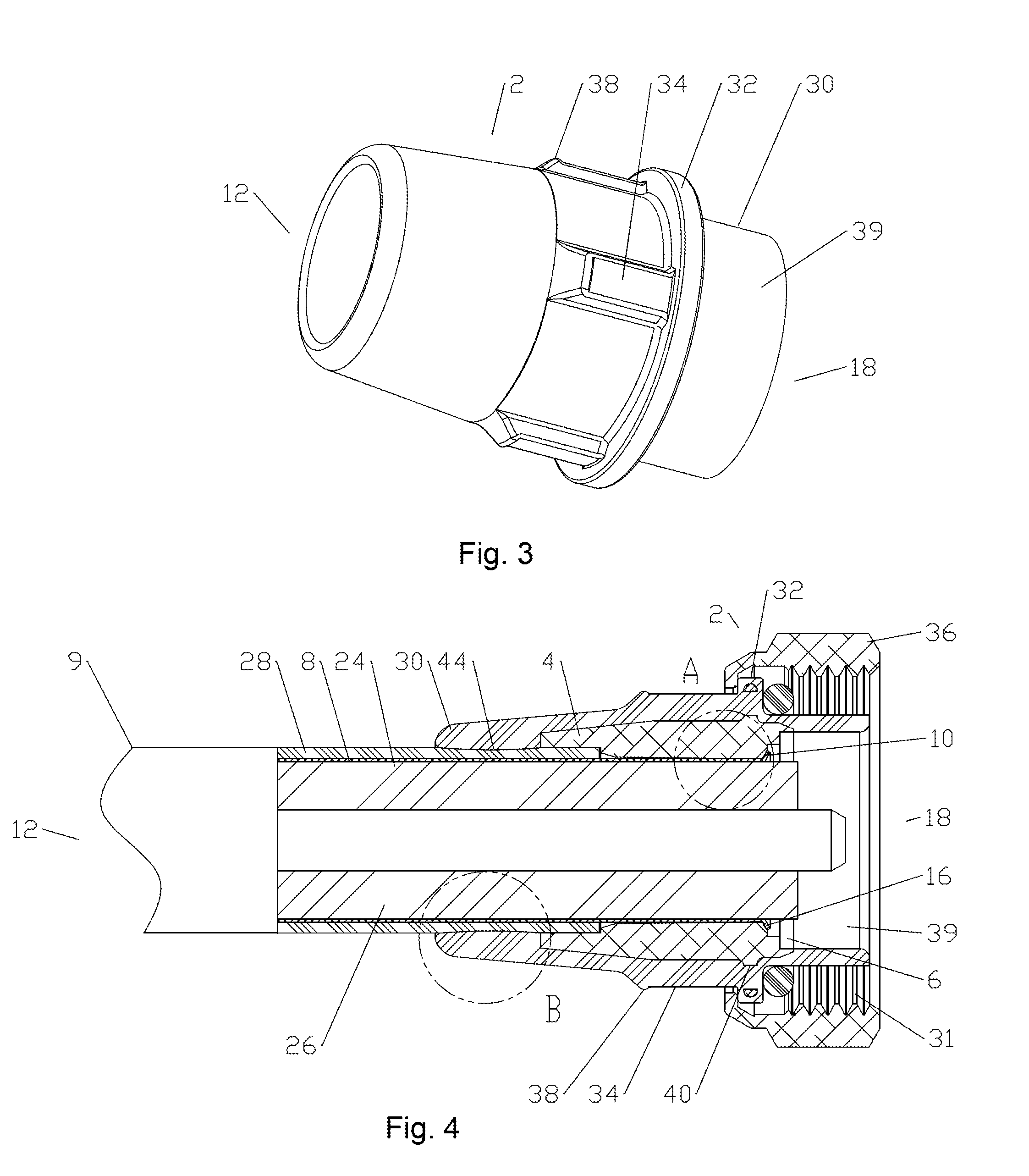

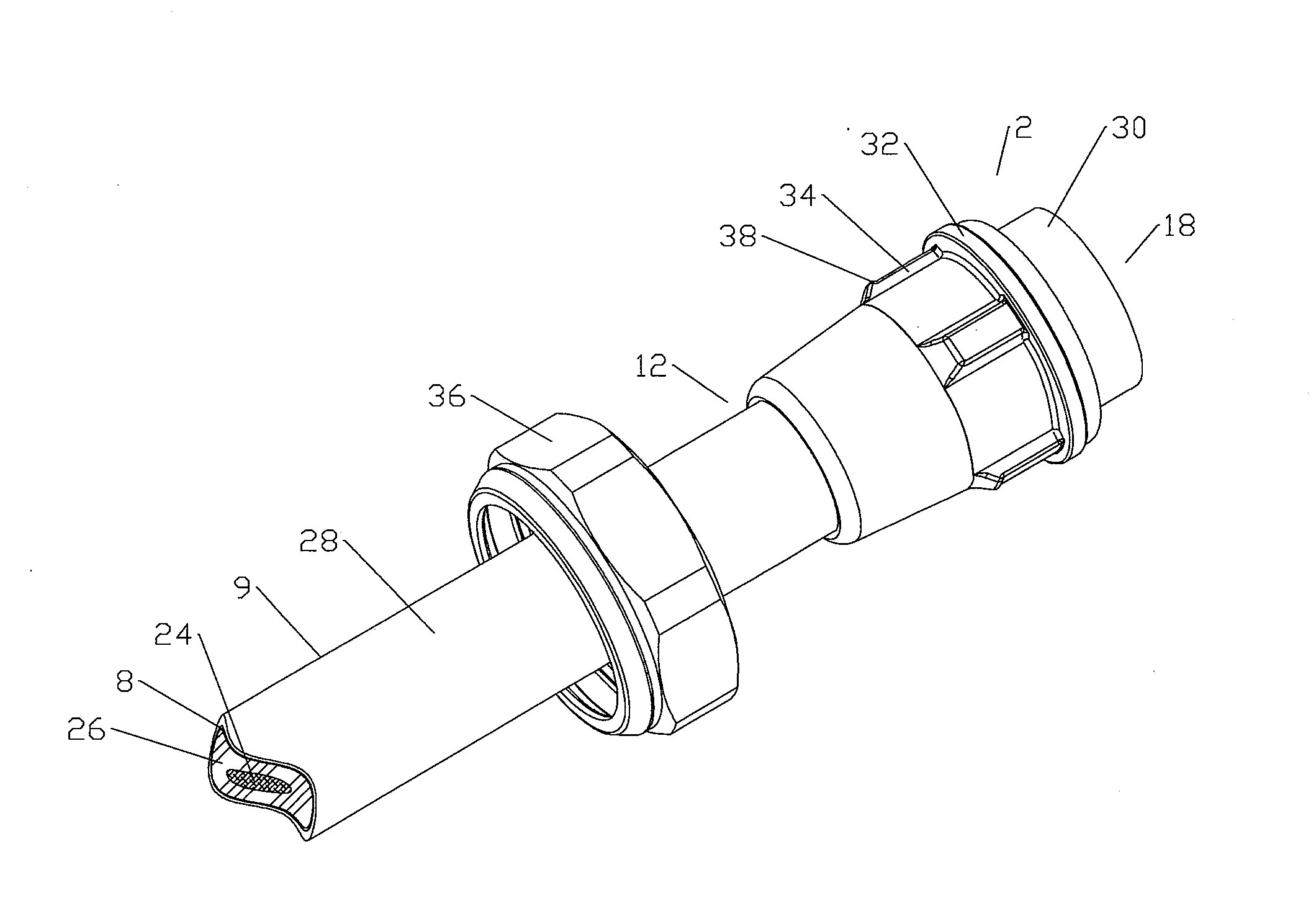

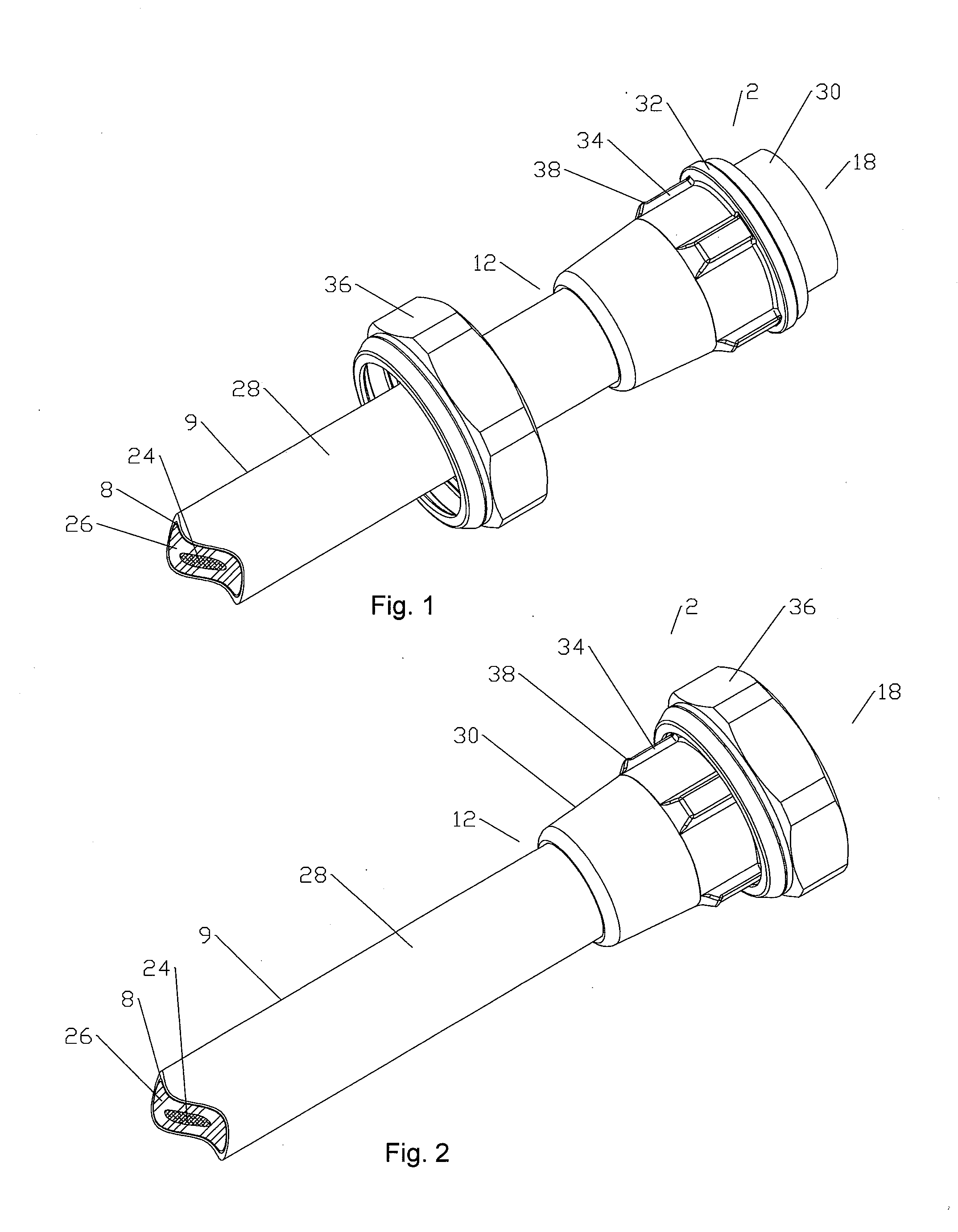

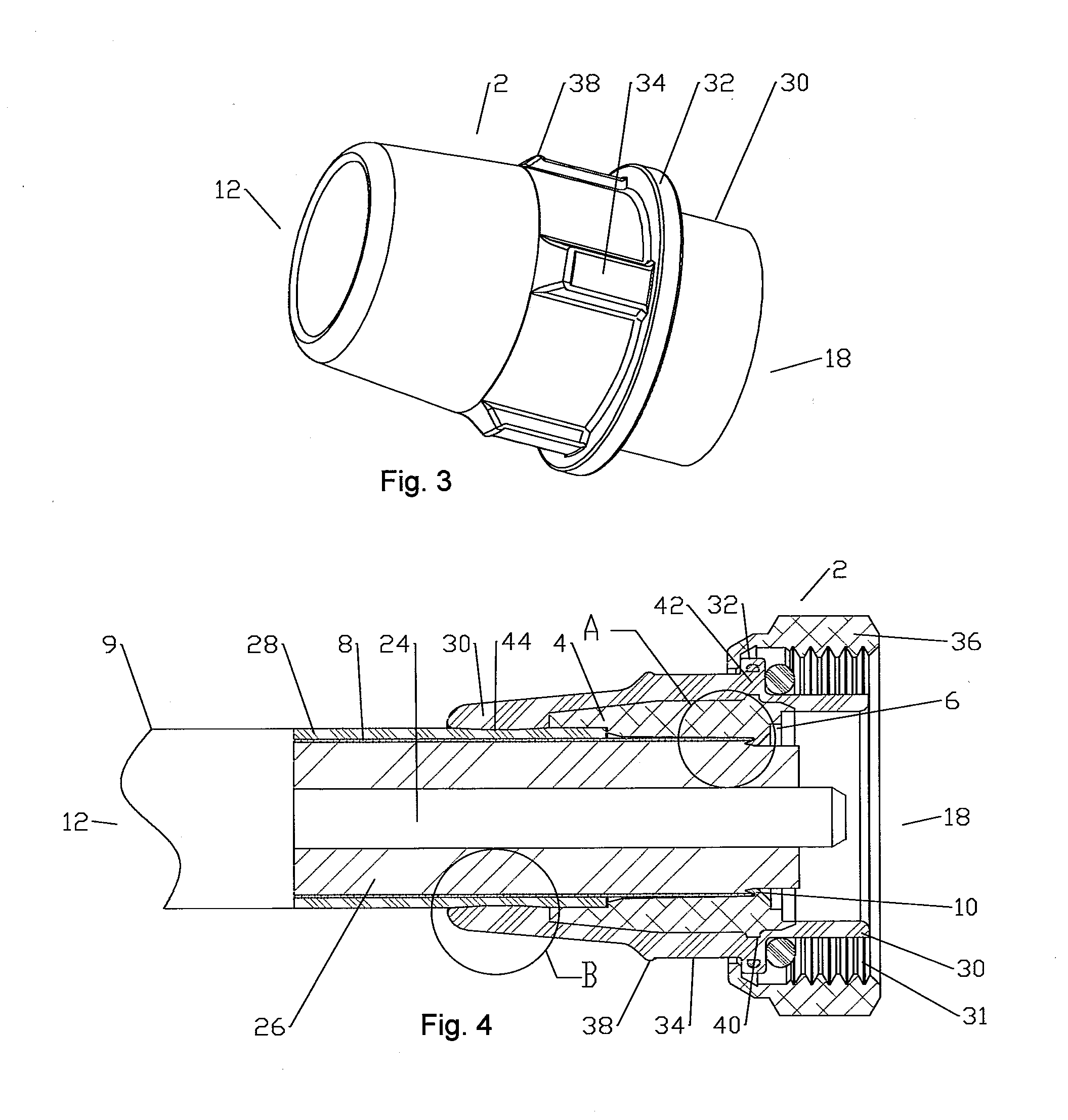

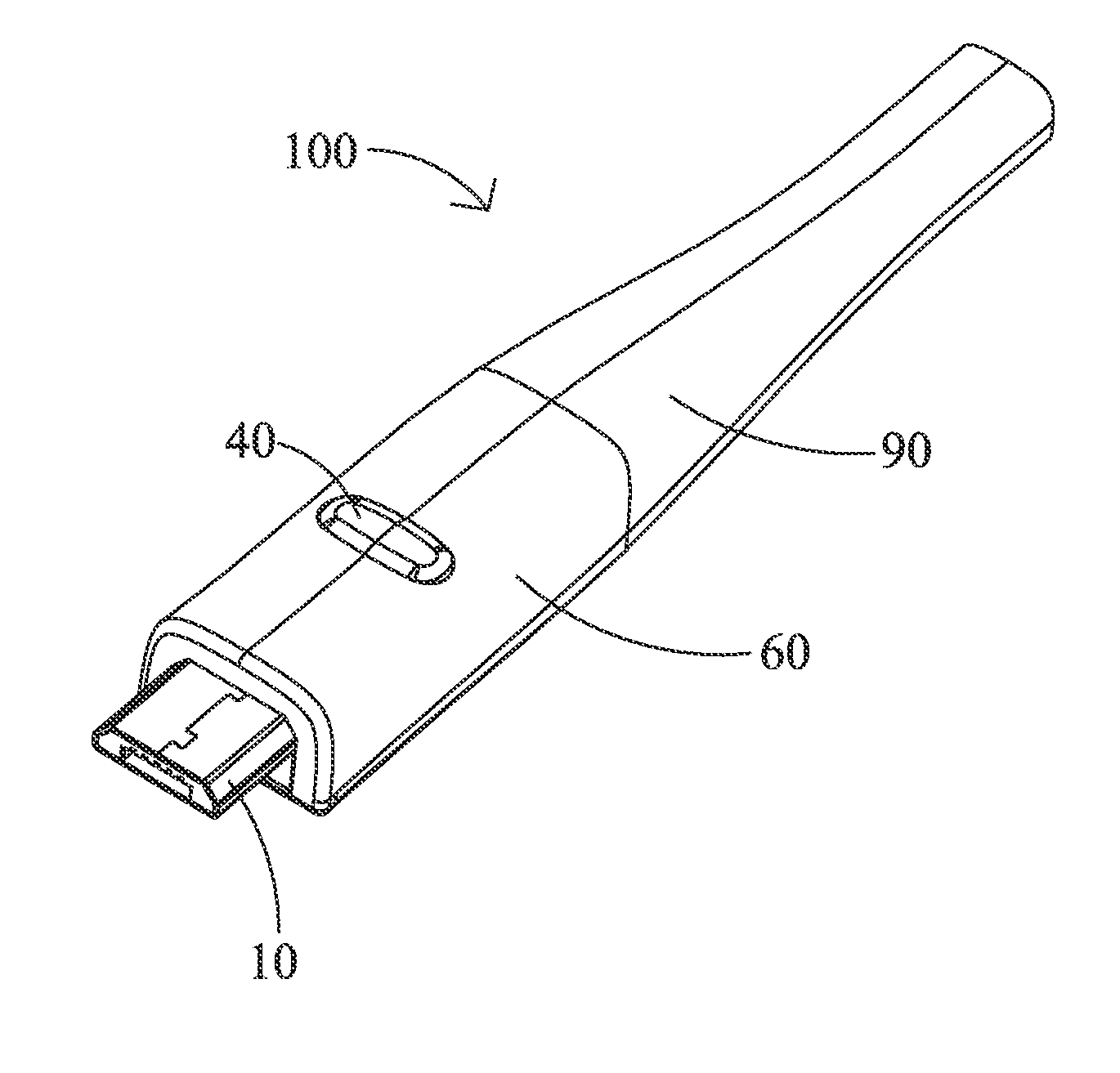

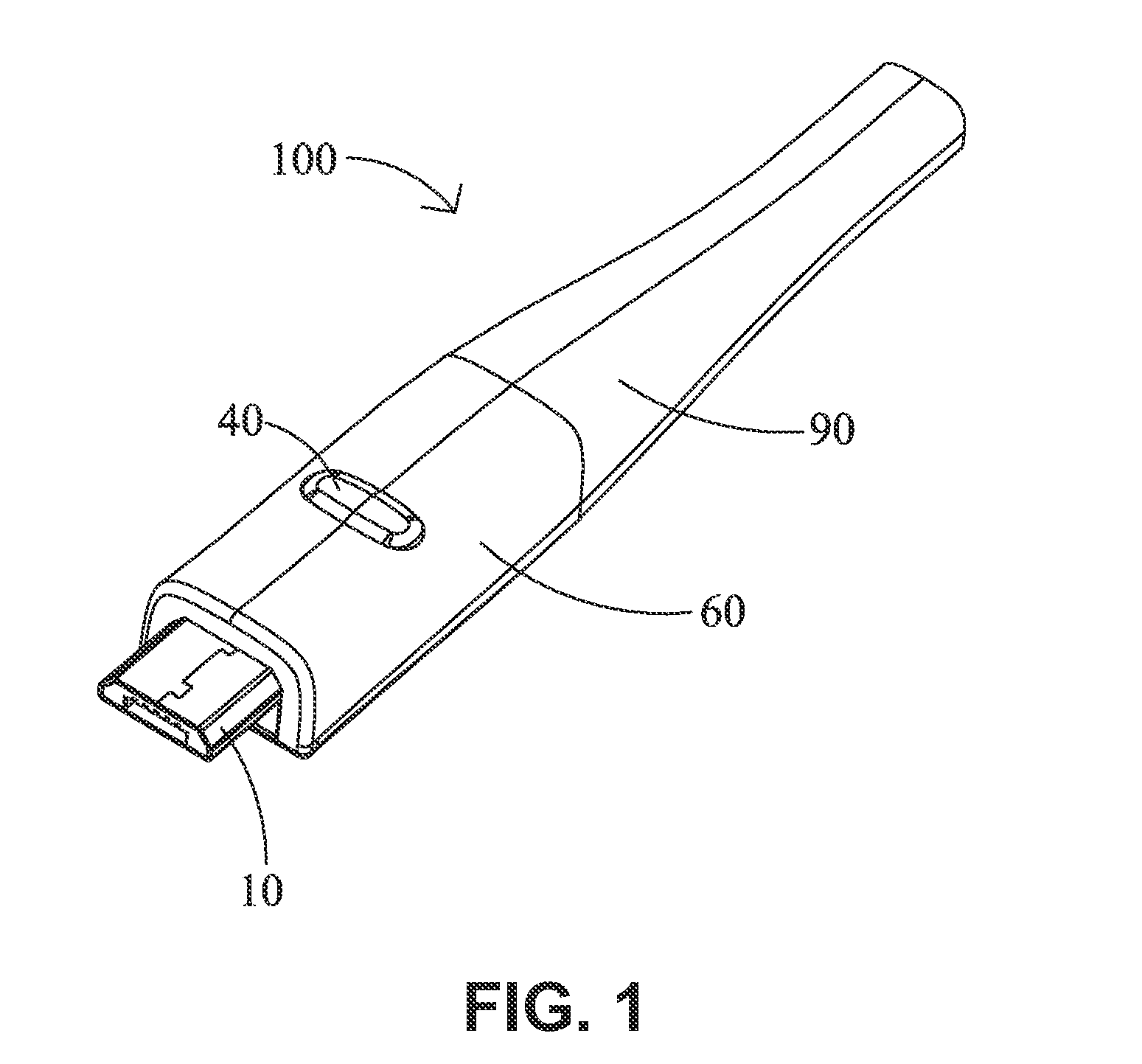

Ultrasonic weld coaxial connector and interconnection method

InactiveUS20120129390A1Cost-effectiveSignificant material cost efficiencyElectrically conductive connectionsContact member assembly/disassemblyCoaxial cableElectrical conductor

A coaxial connector for interconnection with a coaxial cable with a solid outer conductor by ultrasonic welding is provided with a monolithic connector body with a bore. An annular flare seat is angled radially outward from the bore toward a connector end of the connector; the annular flare seat open to the connector end of the connector. The flare seat may be provided with an annular flare seat corrugation.

Owner:COMMSCOPE TECH LLC

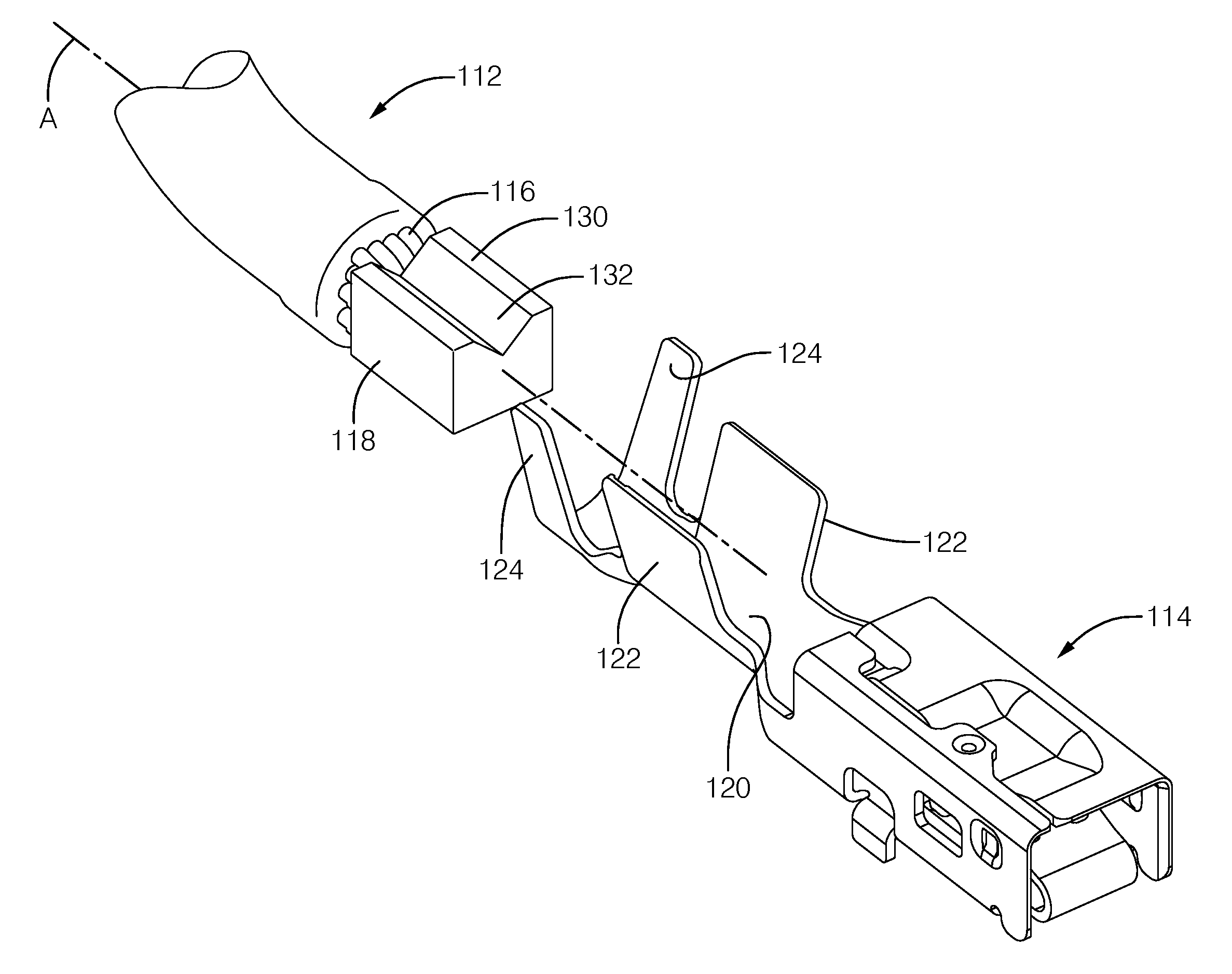

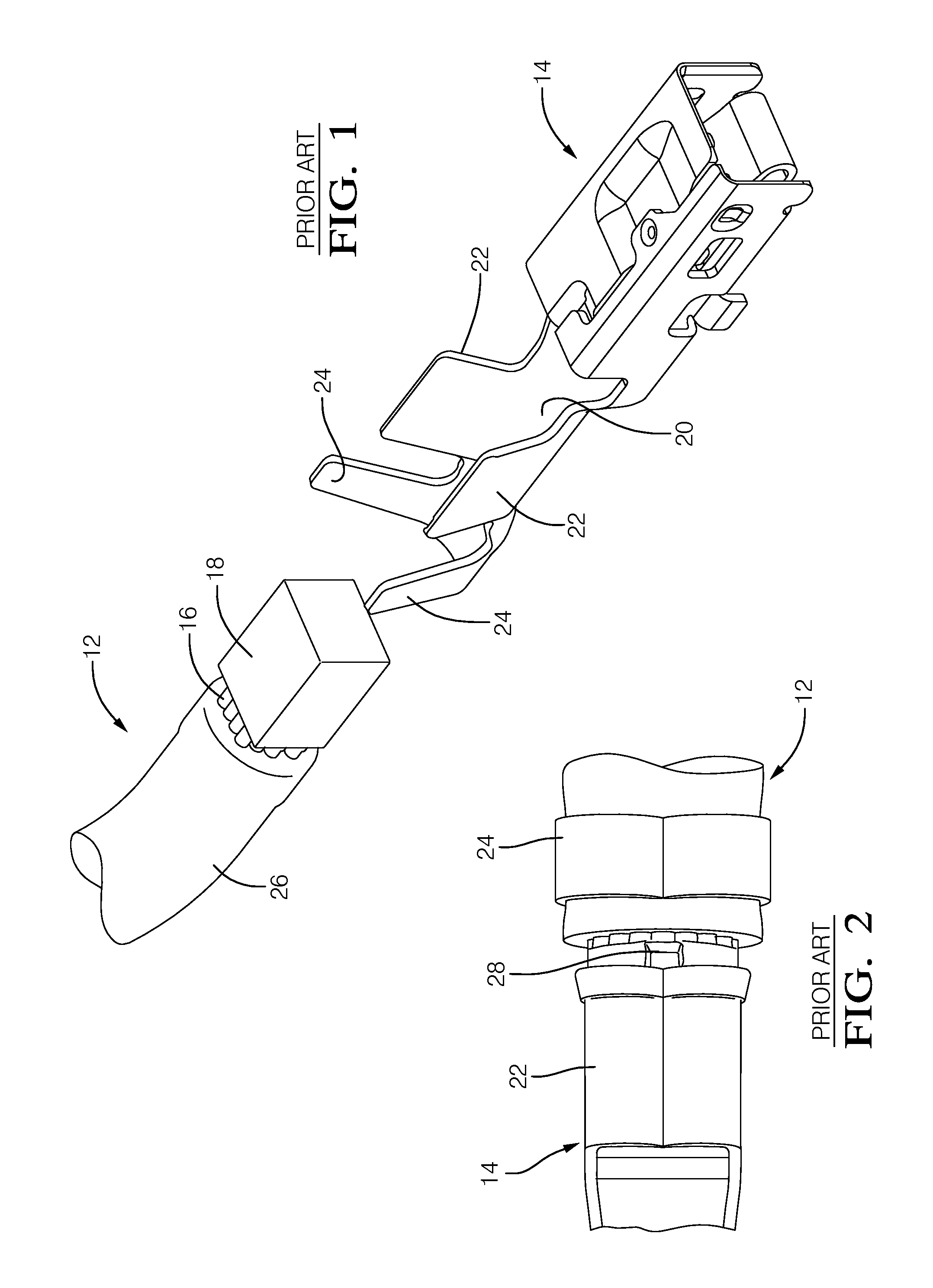

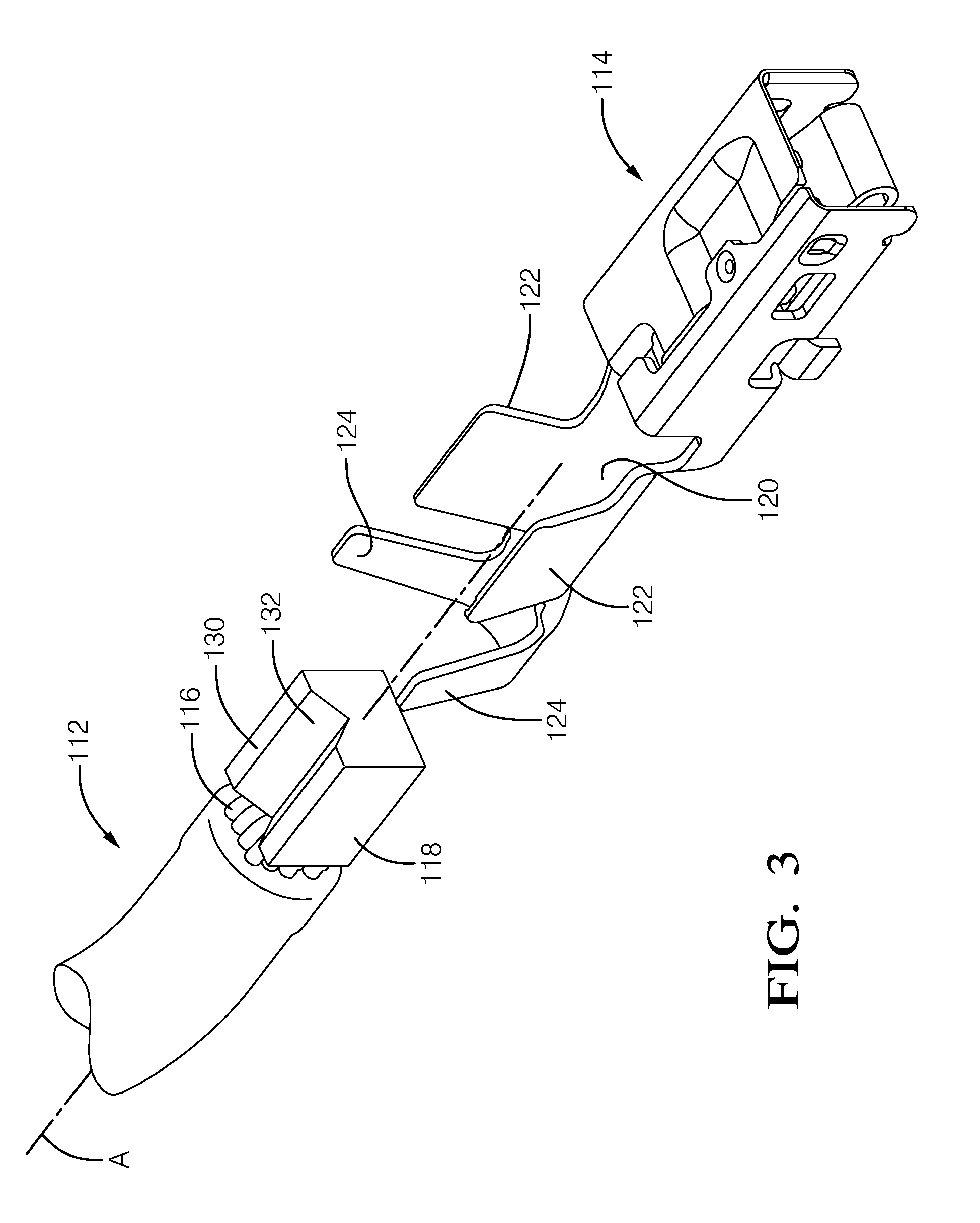

Connector for use with light-weight metal conductors

InactiveUS7828610B2Vehicle connectorsSoldered/welded conductive connectionsMobile vehicleElectrical conductor

Connecting elements and methods for the electrical connection between a light-weight metal conductor and an electrical contact, in particular for use in motor vehicles are disclosed. A metal sleeve is cold welded to the conductor. A contact element is connected to the metal sleeve in an electrically conductive manner and can be connected to the contact. A hardenable liquid seals, in a gas-tight manner, a contact element-side opening in the metal sleeve cold welded to the light-weight metal conductor.

Owner:LISA DRAXLMAIER GMBH

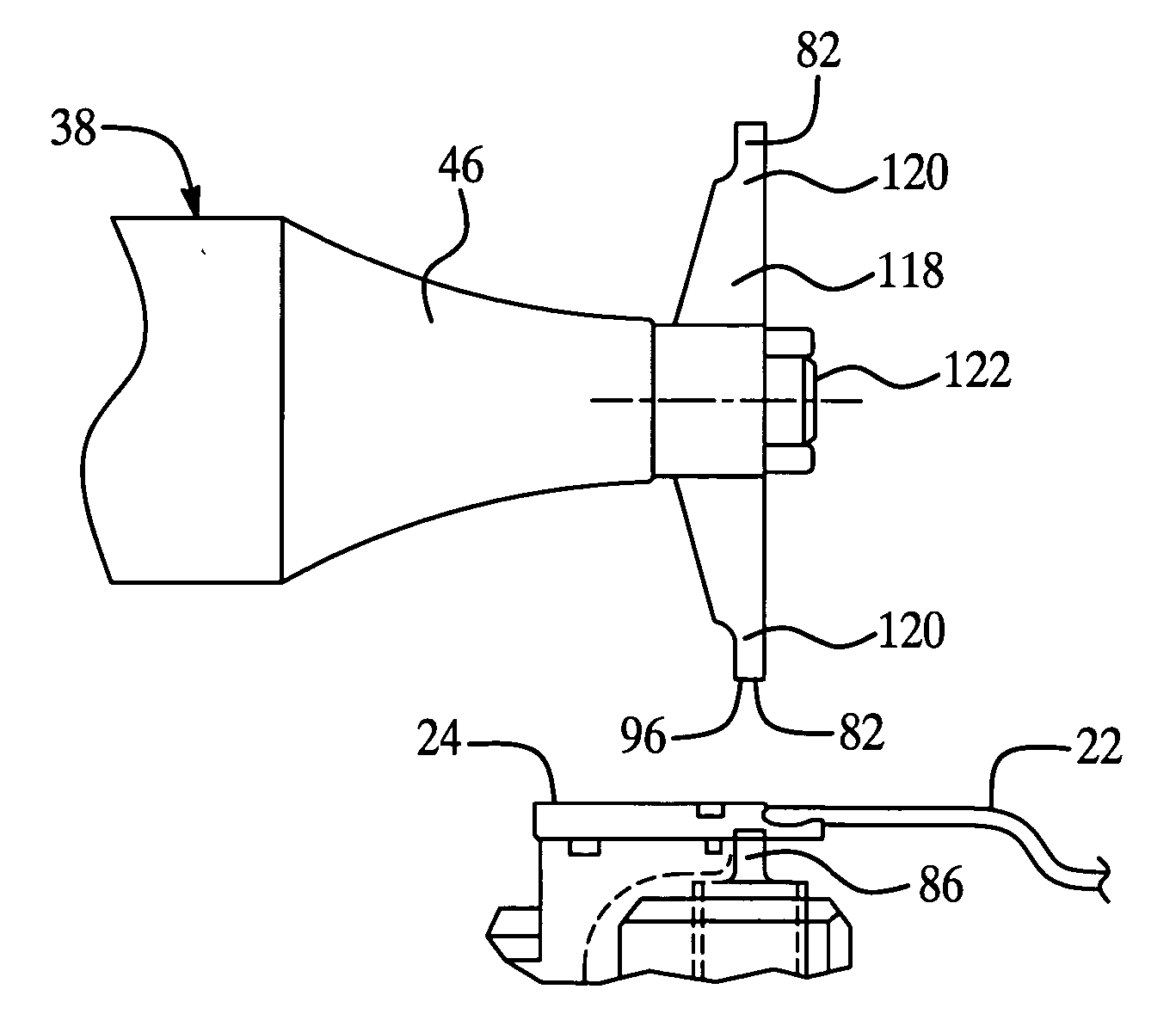

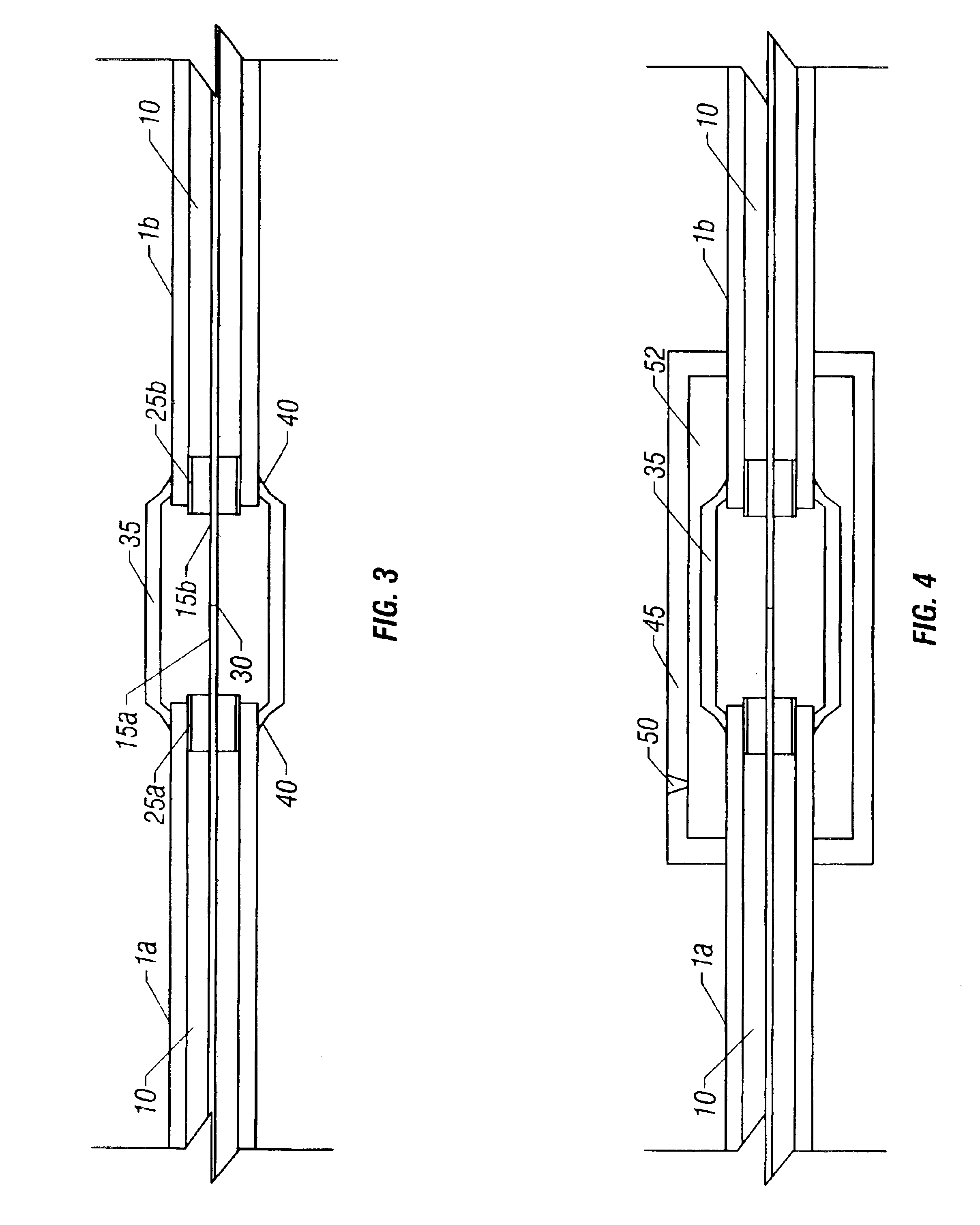

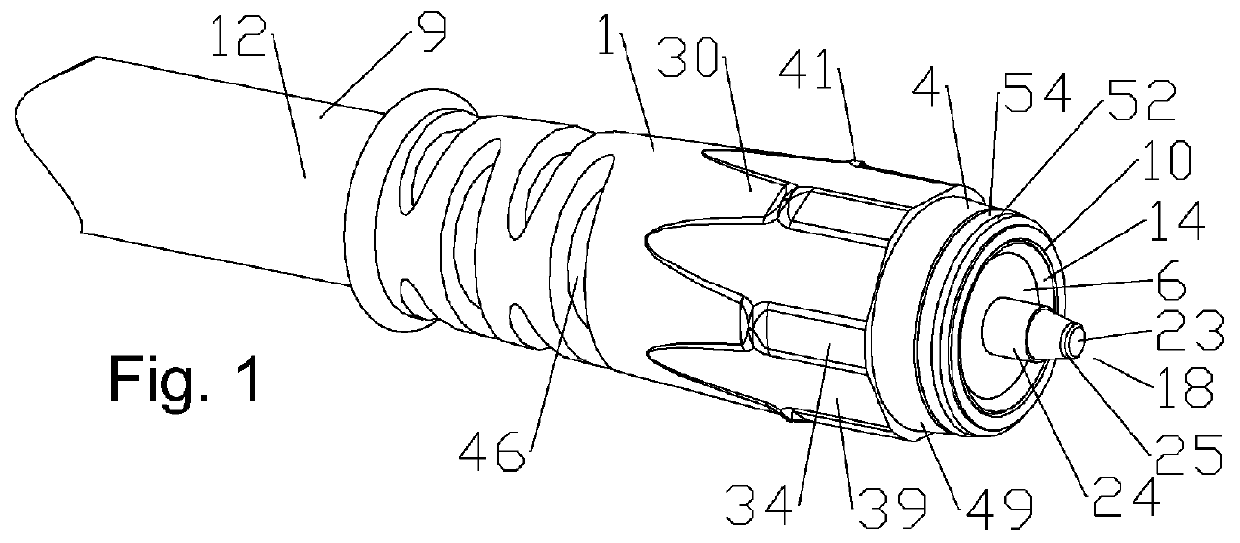

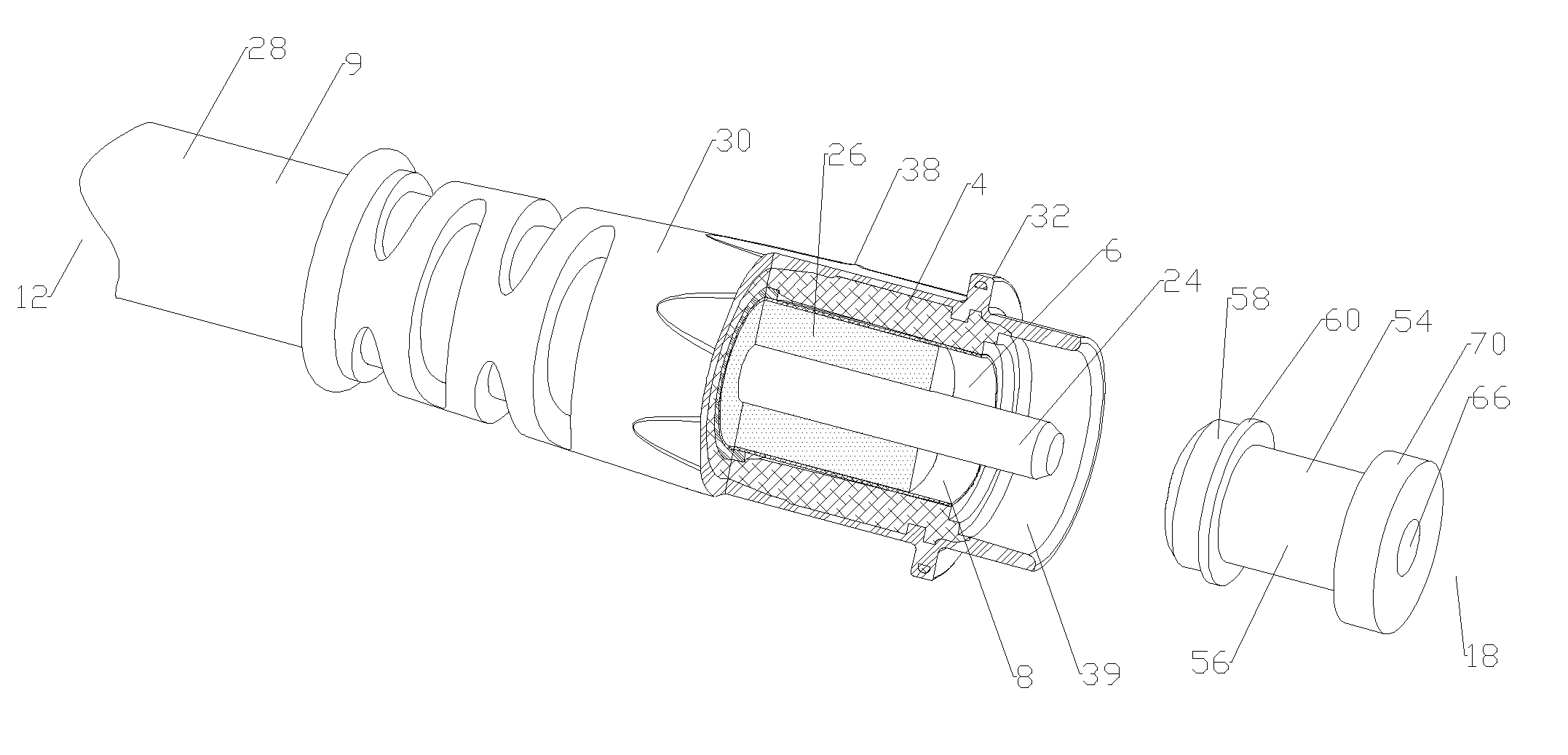

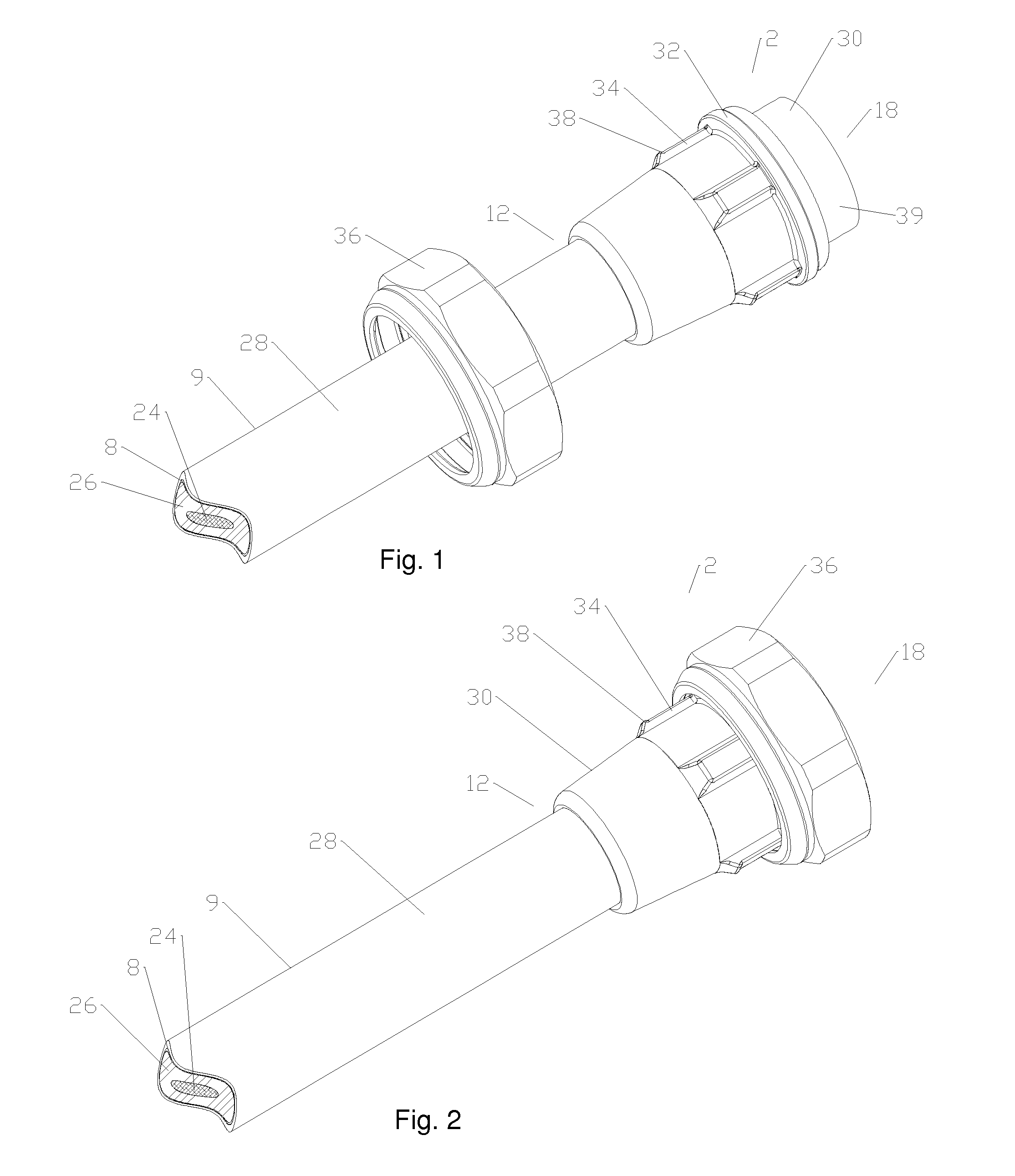

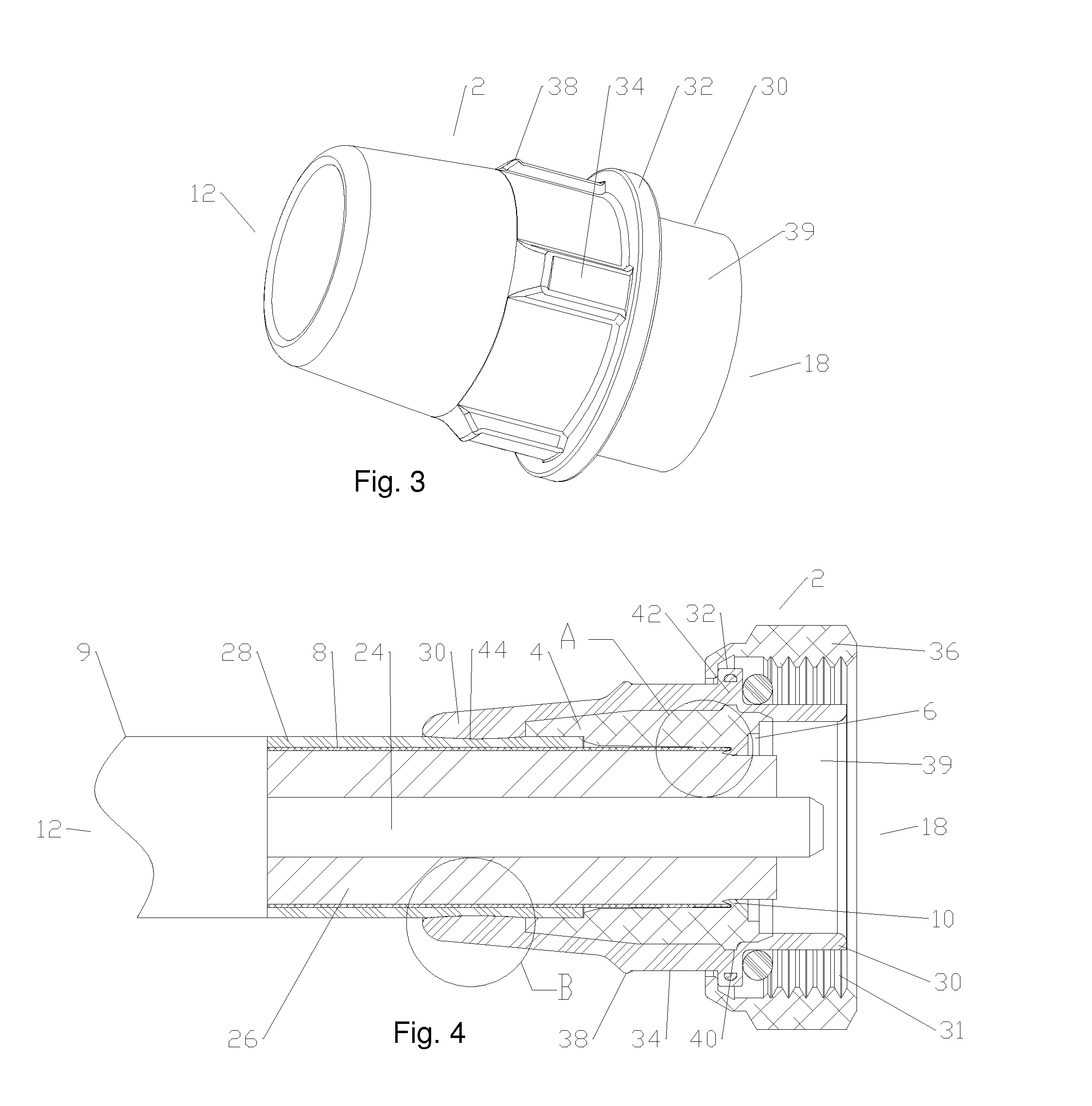

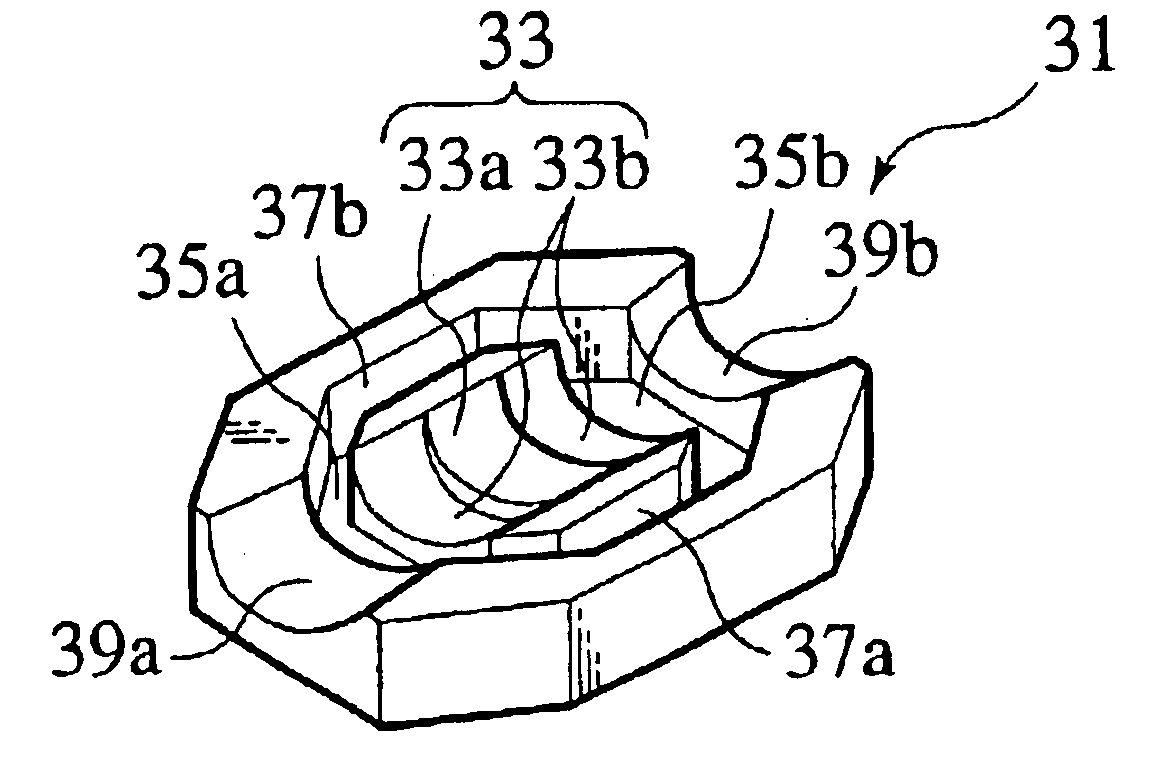

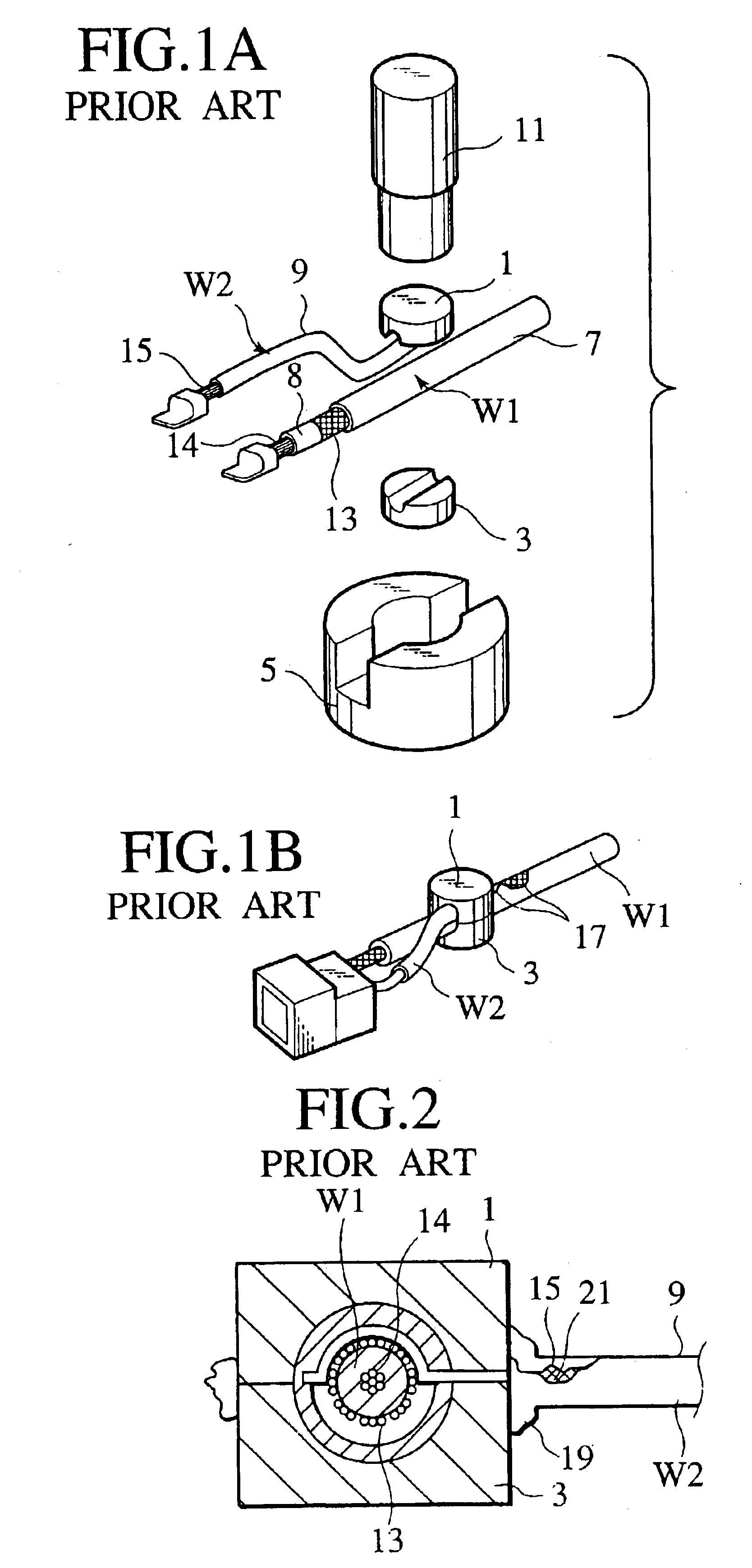

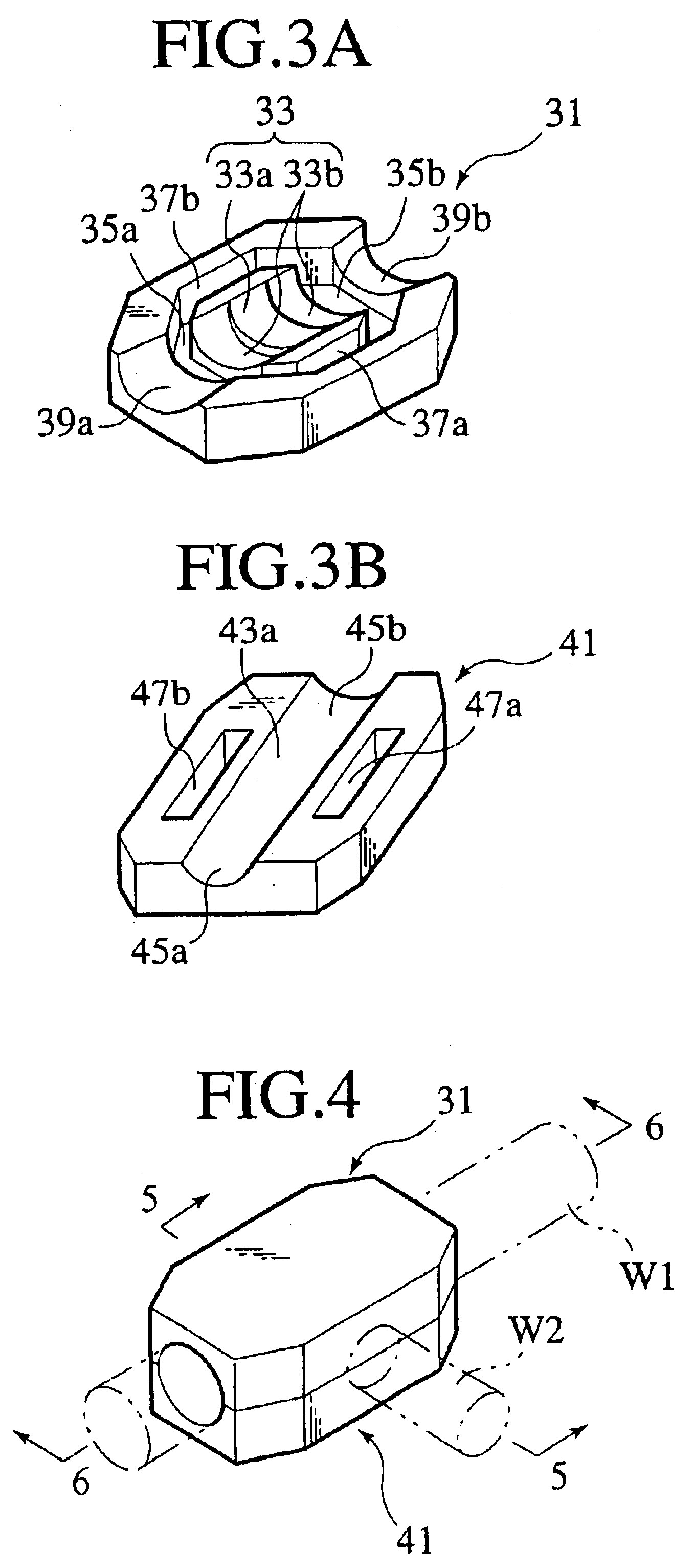

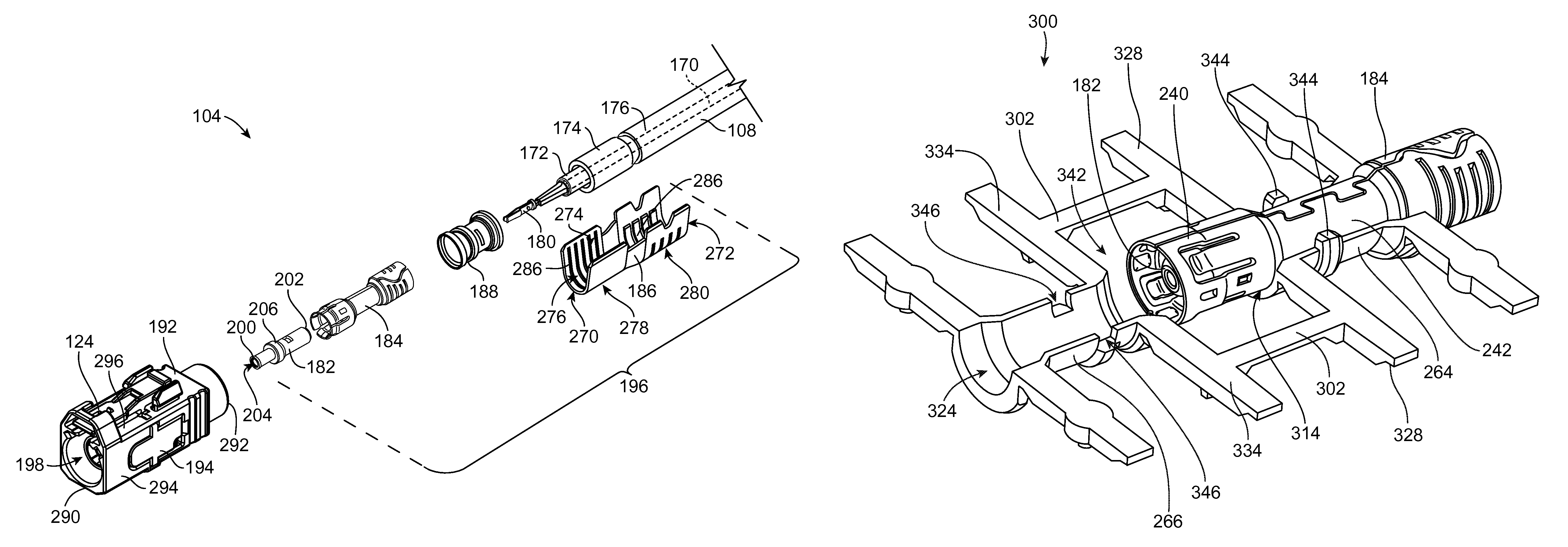

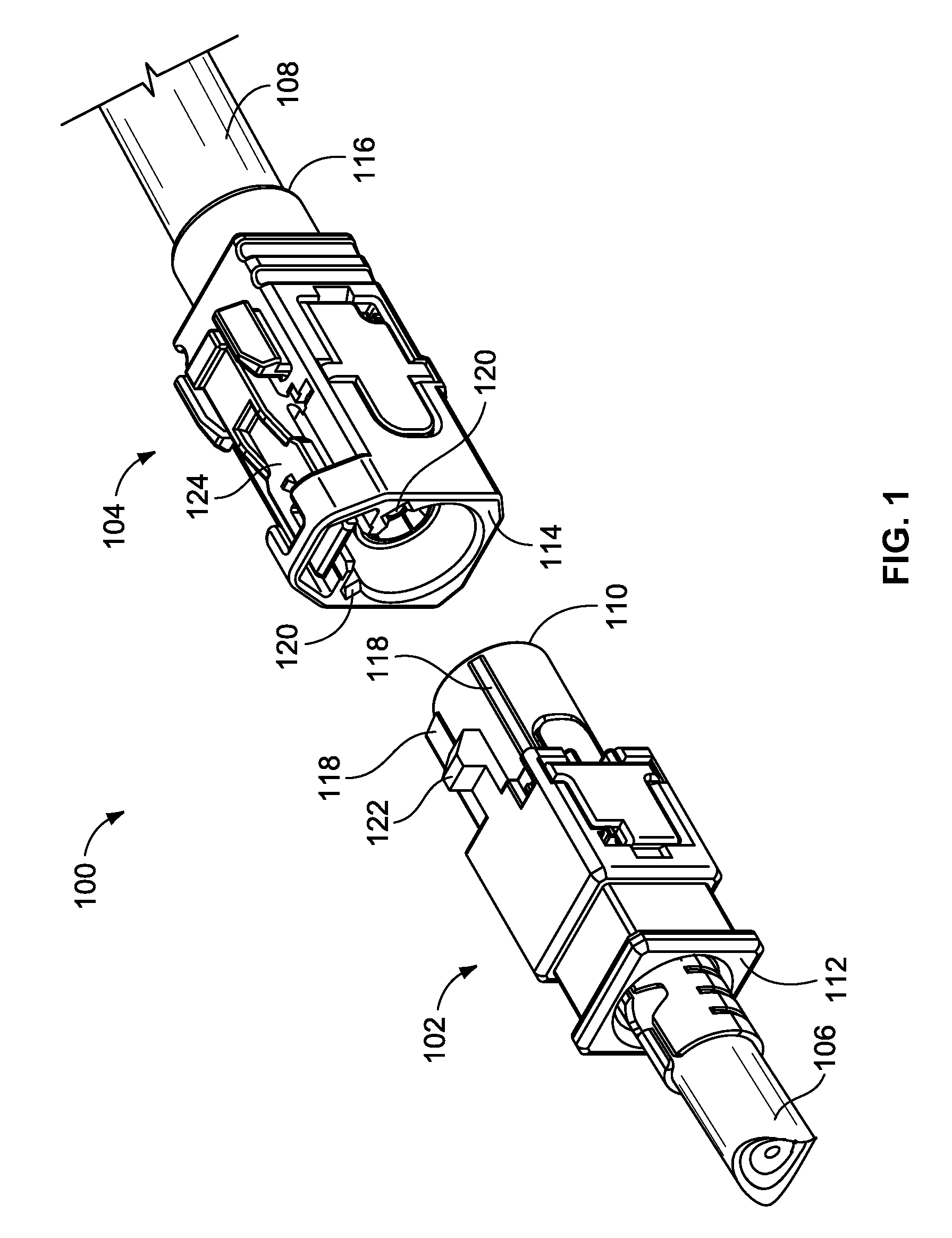

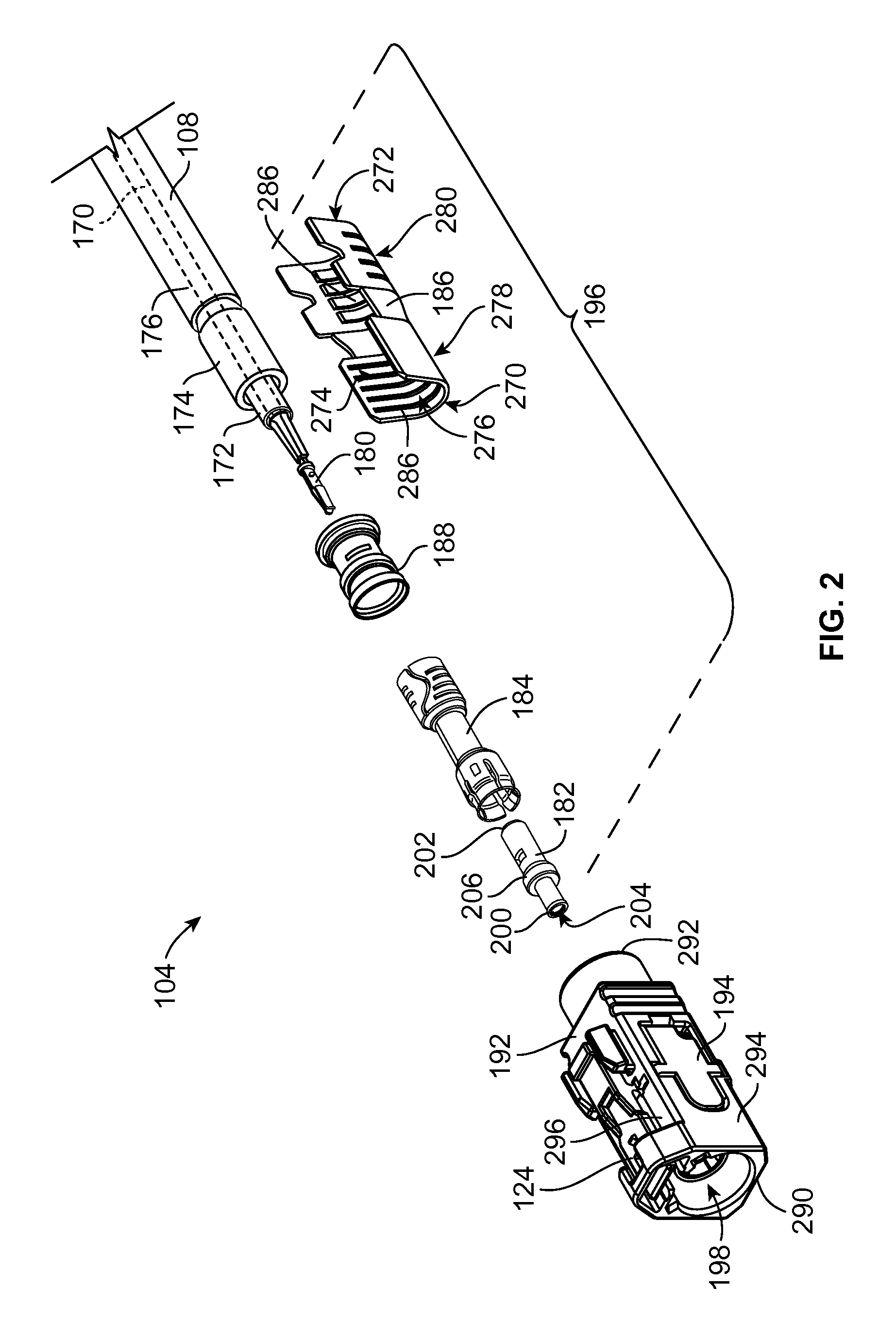

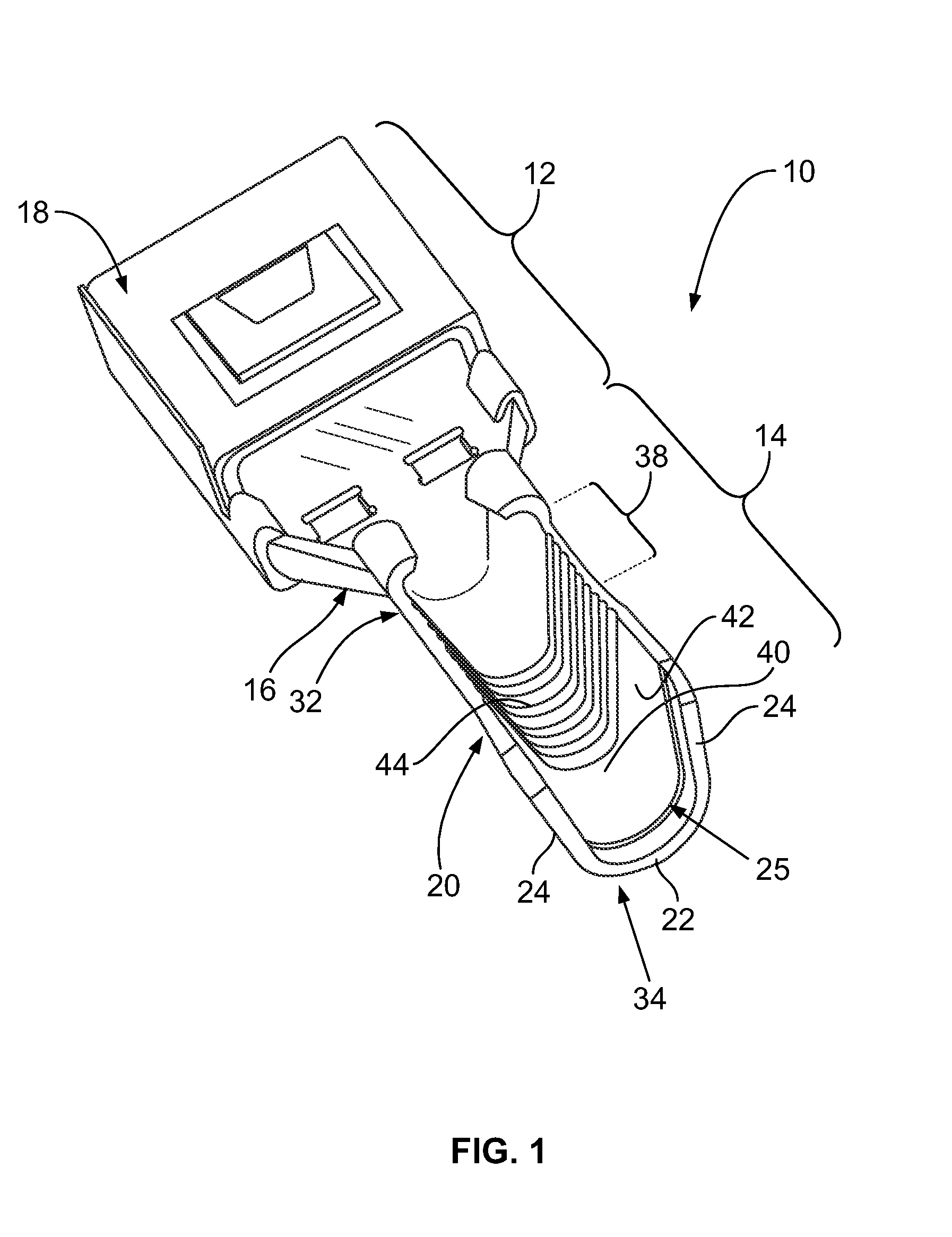

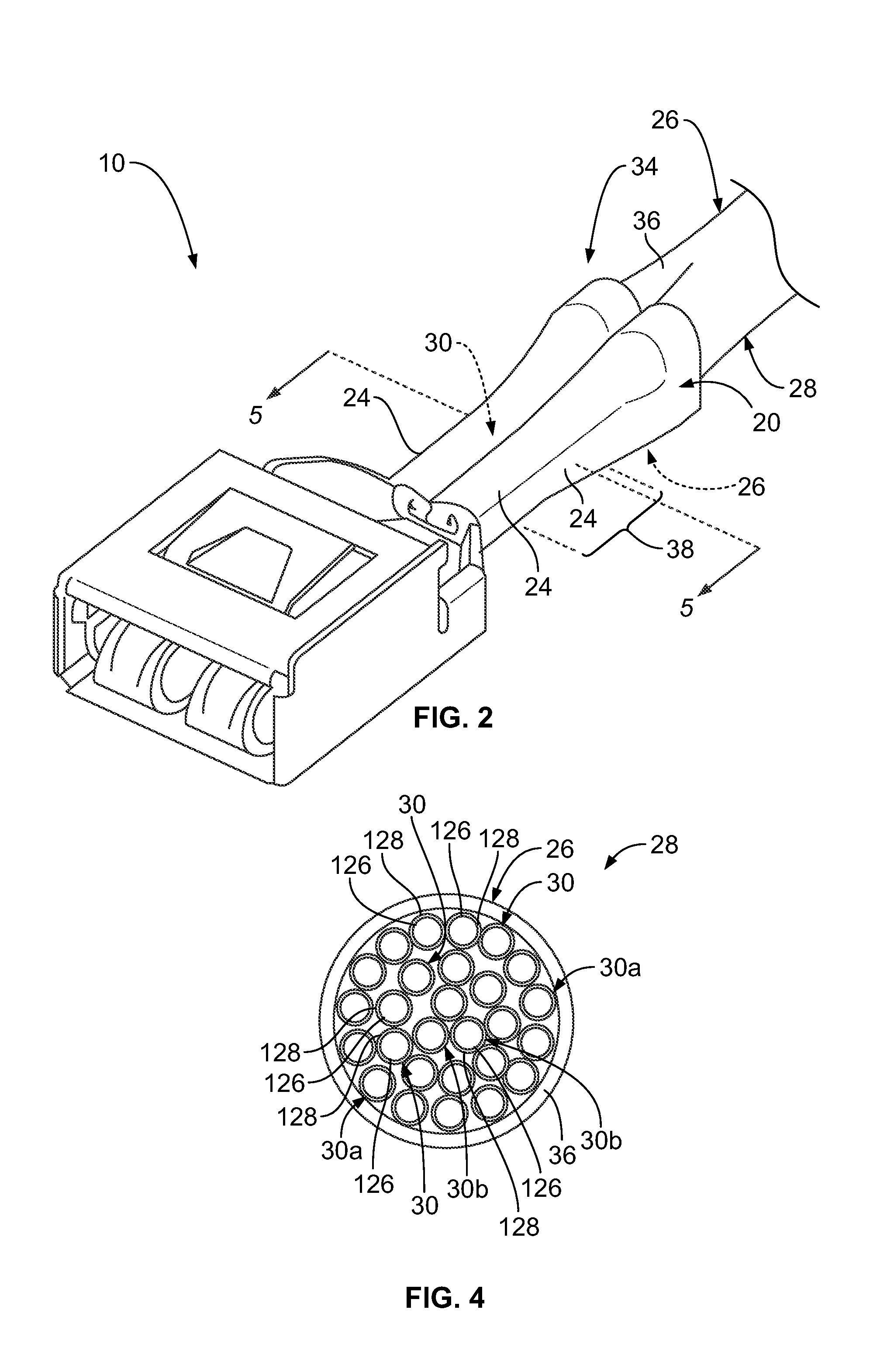

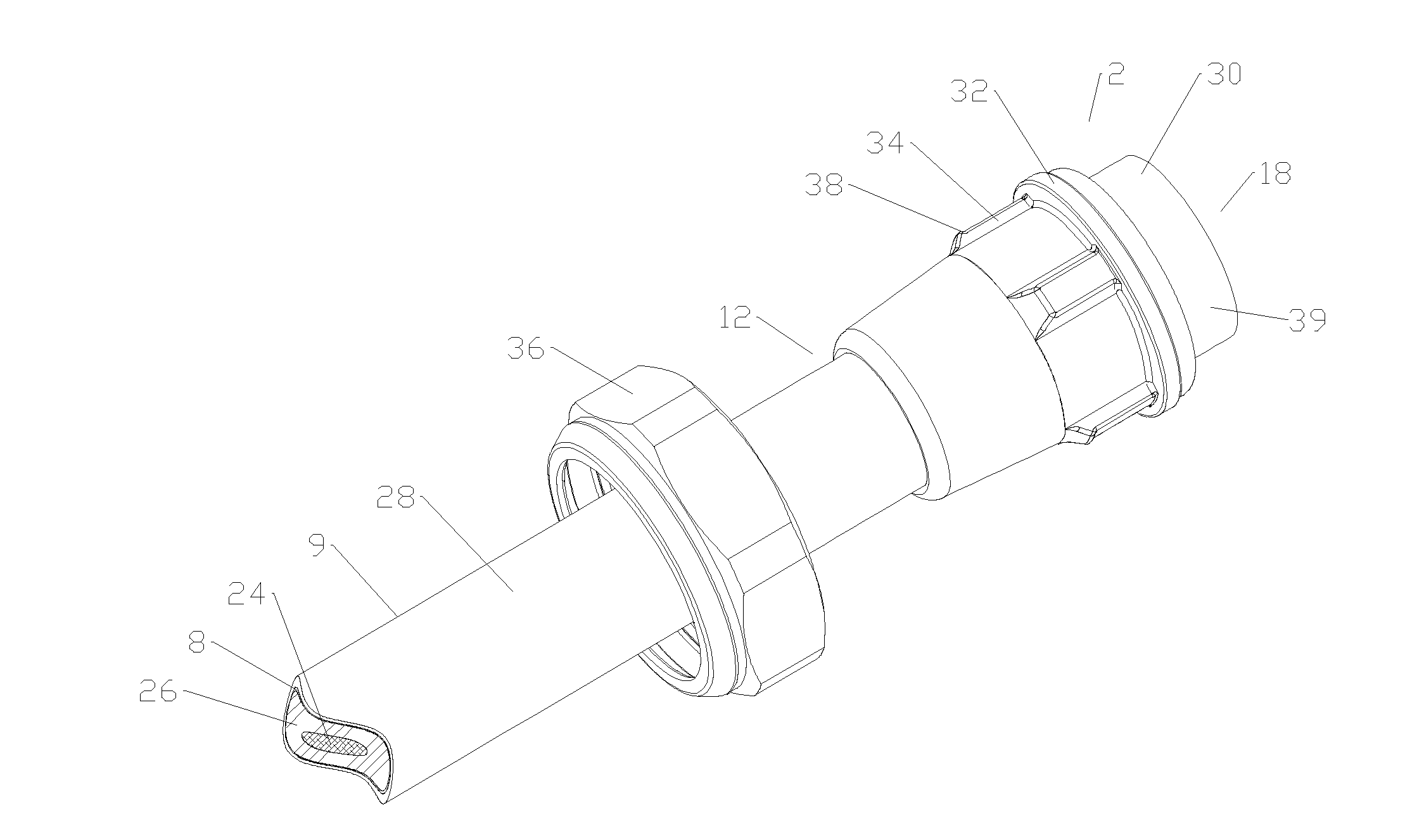

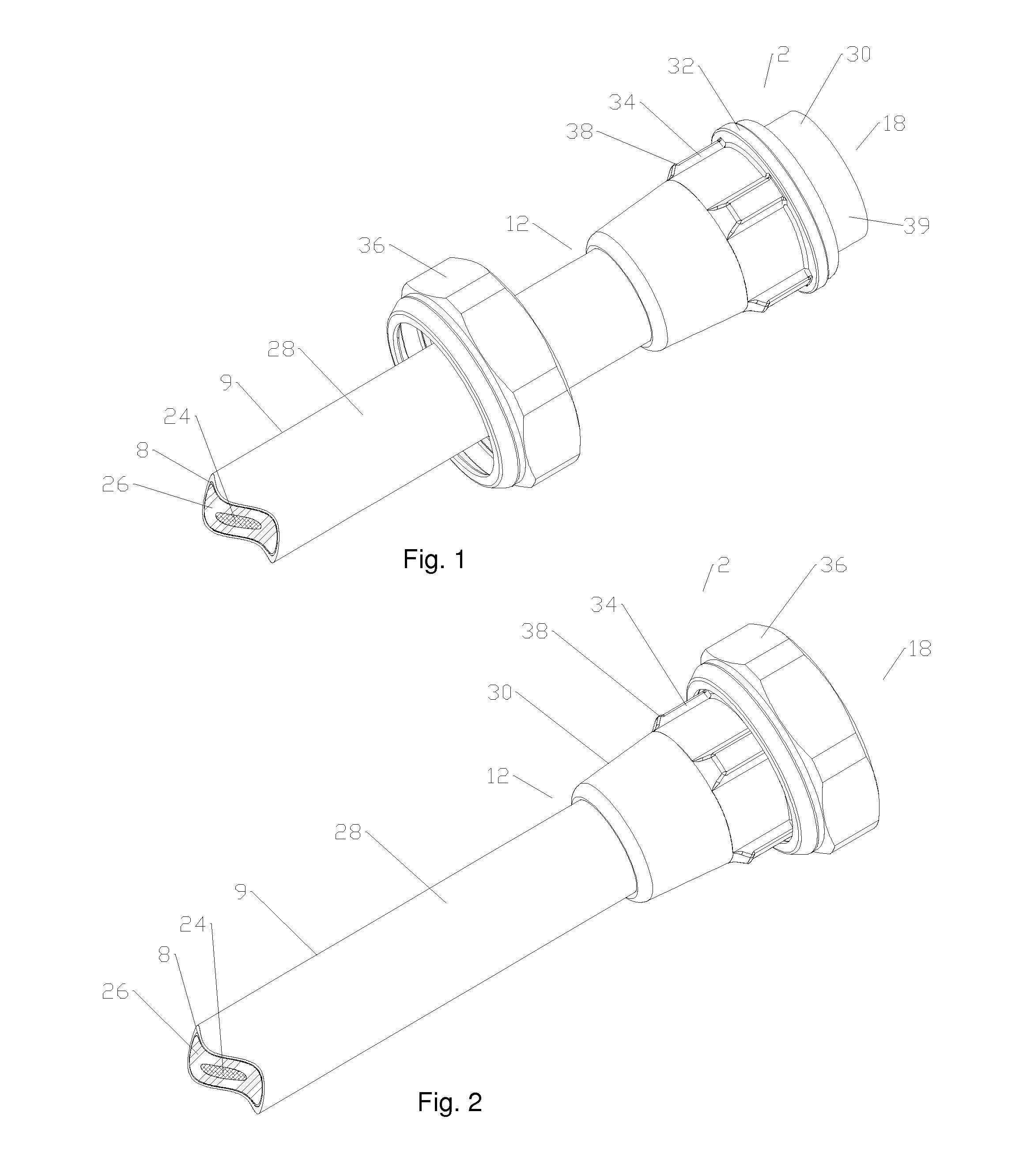

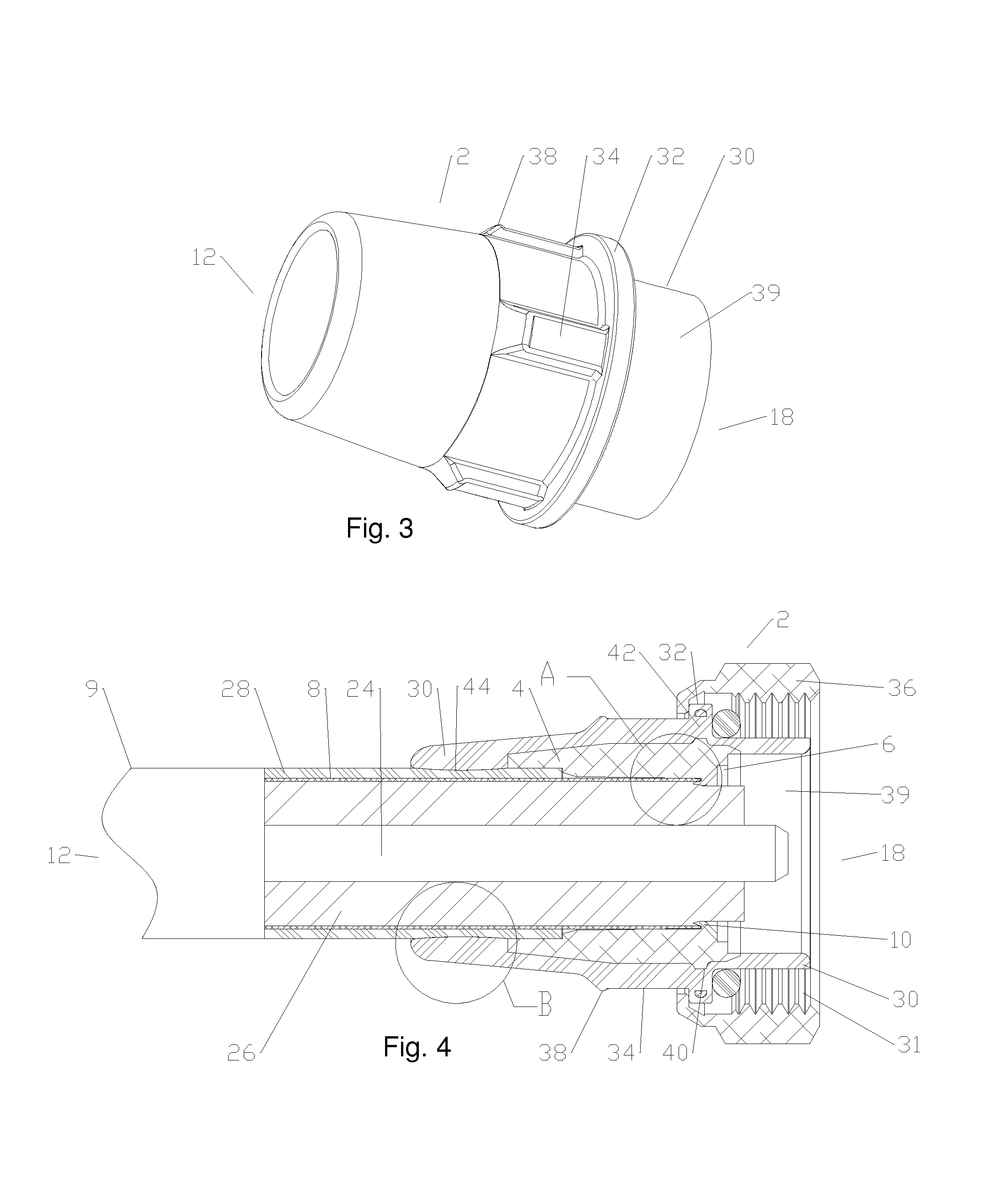

Method and aparatus for radial ultrasonic welding interconnected coaxial connector

ActiveUS20120129384A1Cost-effectiveLower potentialContact member manufacturingElectrically conductive connectionsCoaxial cableElectrical conductor

A coaxial connector assembly for interconnection with a coaxial cable with a solid outer conductor is provided with a monolithic connector body with a bore. A mating surface with a decreasing diameter toward a connector end is provided on an outer diameter of the connector body proximate the connector end. An overbody may be provided overmolded upon a cable end of the connector body. An interface end may be seated upon the mating surface, the interface end provided with a desired connection interface. The interface end may be permanently coupled to the mating surface by a molecular bond interconnection. In a method of interconnection, the interface end is coupled to the mating surface by application of radial ultrasonic welding.

Owner:COMMSCOPE TECH LLC

Welding terminal and welding apparatus for welding the same

InactiveUS7033233B2Improve welding strengthReliable electrical connectionLine/current collector detailsSoldered/welded conductive connectionsEngineeringElectrical conductor

A welding terminal for electrically connecting a conductor portion of a wire includes a terminal base plate portion, on which the conductor portion is placed for welding and a pair of side walls, formed on opposite side edges of the terminal base plate portion so as to stand perpendicularly. The wire has a plurality of conductors covered with a insulating sheath. Each corner portion formed by the each side wall and terminal base plate portion has a rounded shape in cross section.

Owner:YAZAKI CORP

Testing method for non-destructive testing of a welded connector, a testing device and an ultrasonic welding apparatus having such a device

InactiveUS6393924B1Soldered/welded conductive connectionsMaterial strength using steady bending forcesNon destructiveElectrical conductor

In testing a method for non-destructive testing of a welded assembly which includes a plurality of strands of electrical conductors which are joined together into a bundle by ultrasonic welding, a defined testing force is introduced into two or more shell surface segments of the welded assembly in directions oriented substantially towards each other or substantially to a comon intersection. For carrying out the testing method, a testing device and a welding machine which constitute such a testing device are provided.

Owner:SCHUNK ULTRASCHALLTECHN

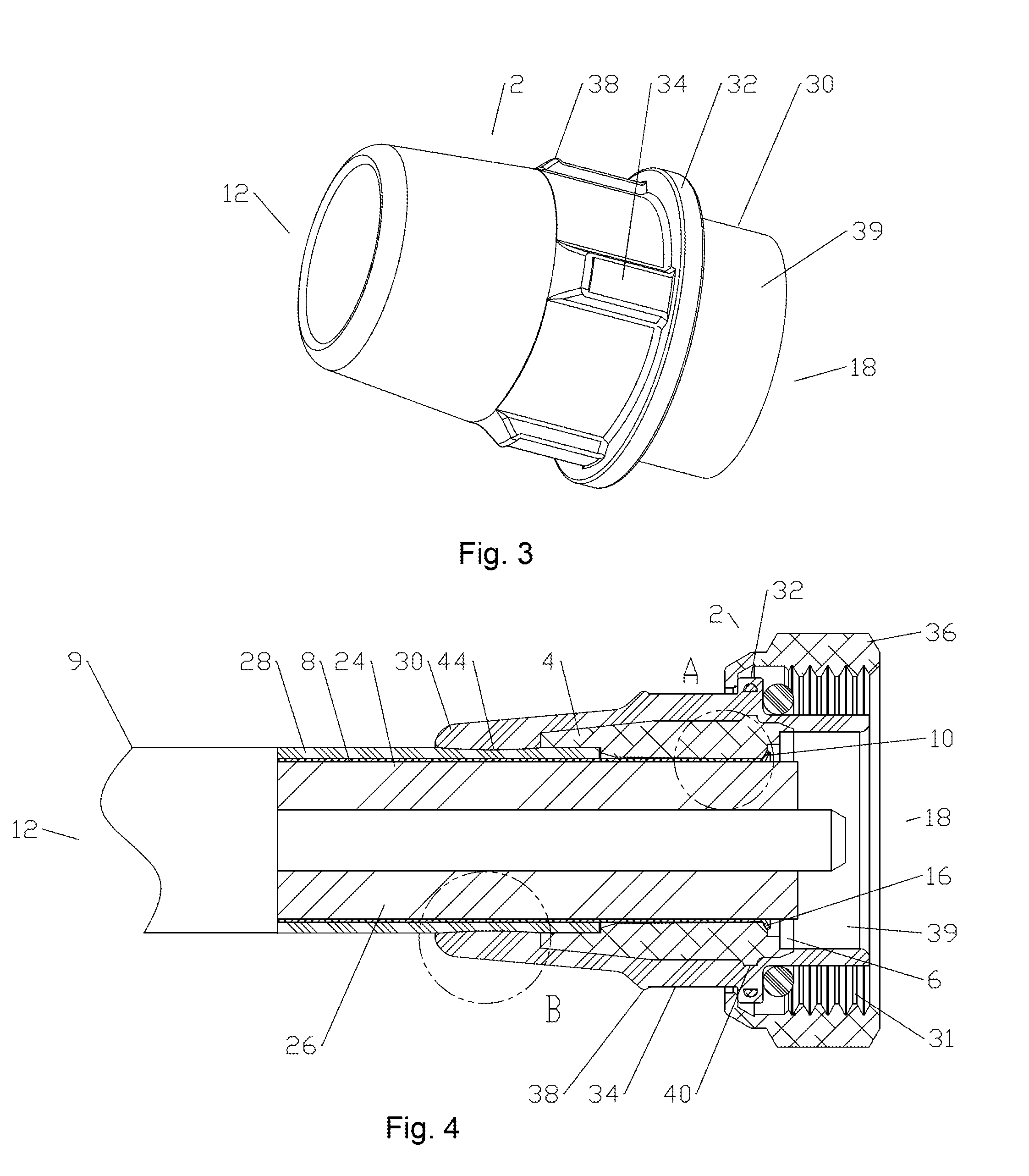

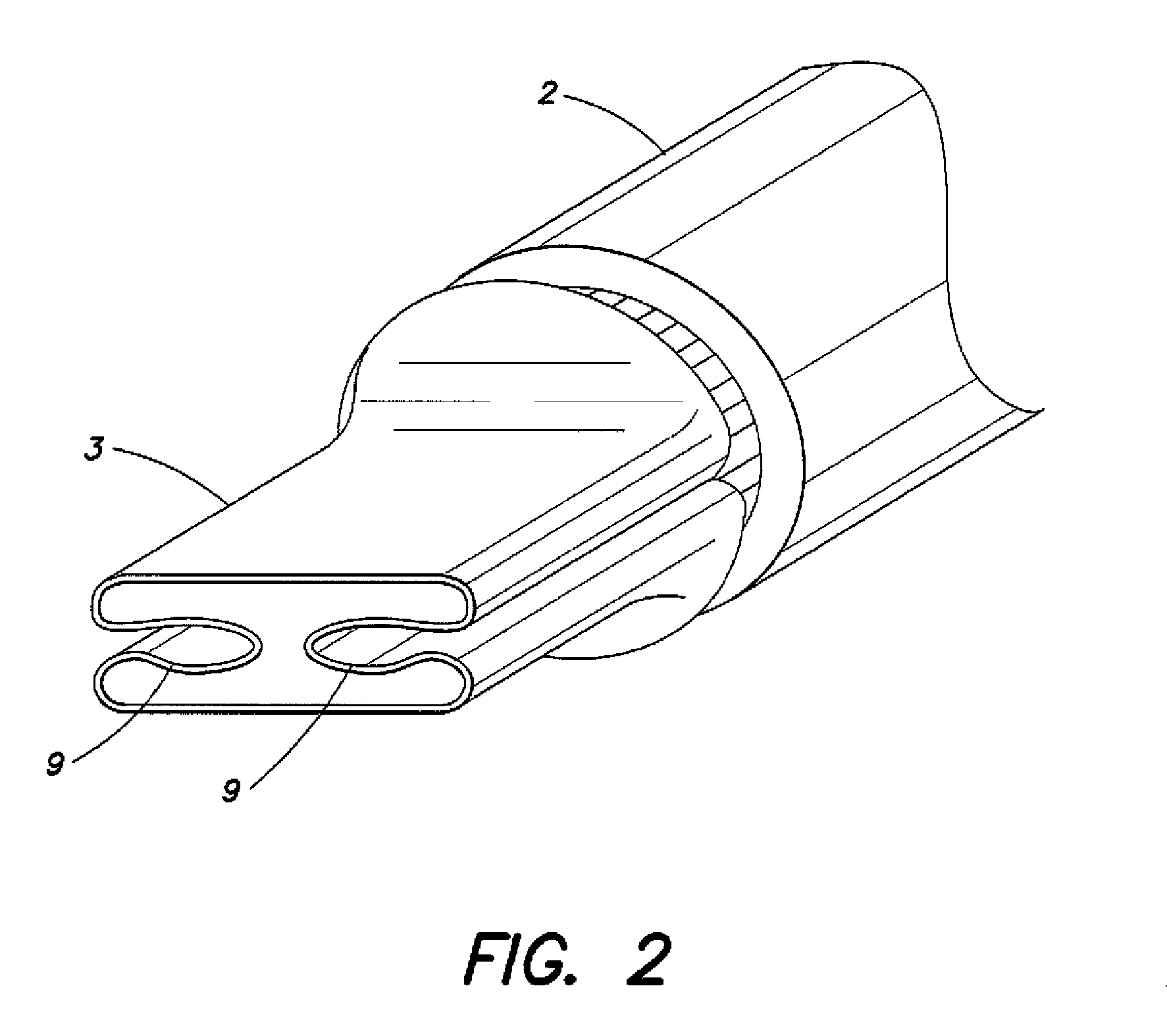

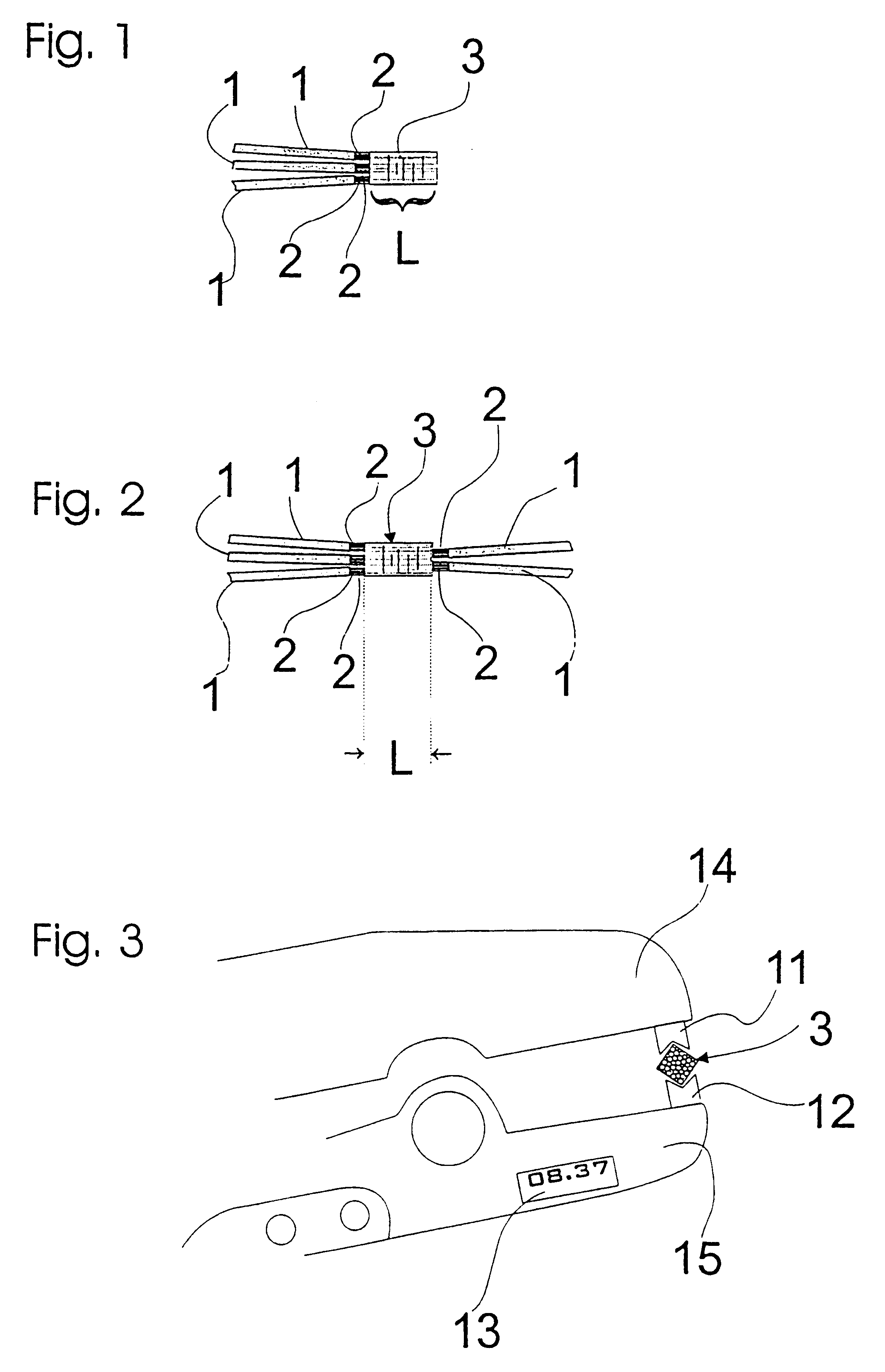

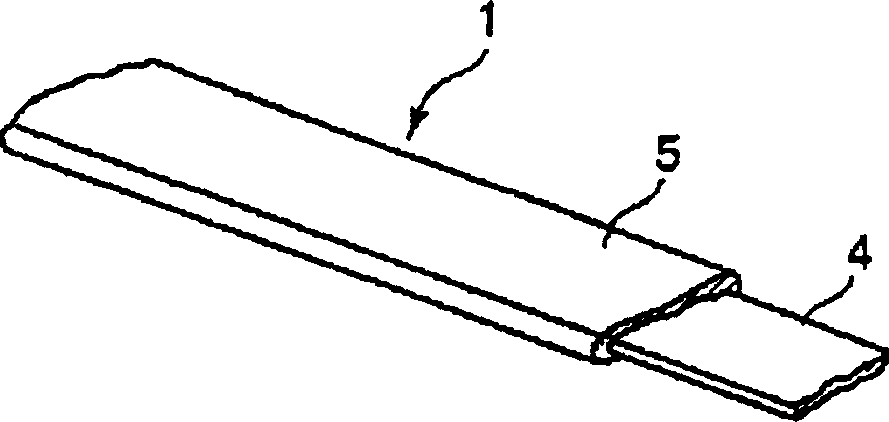

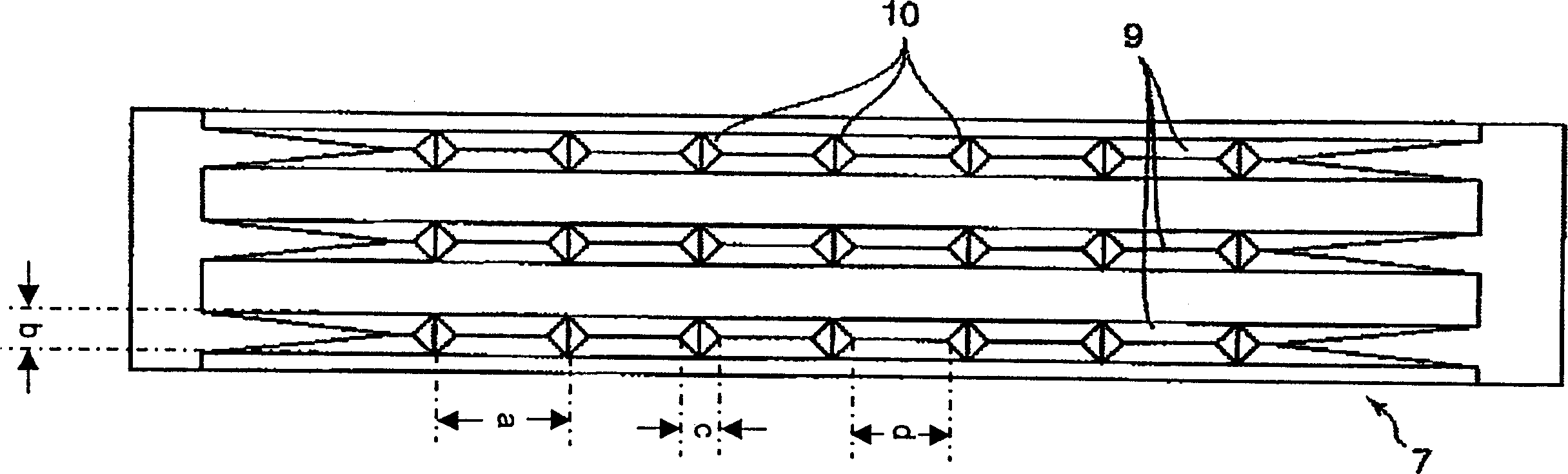

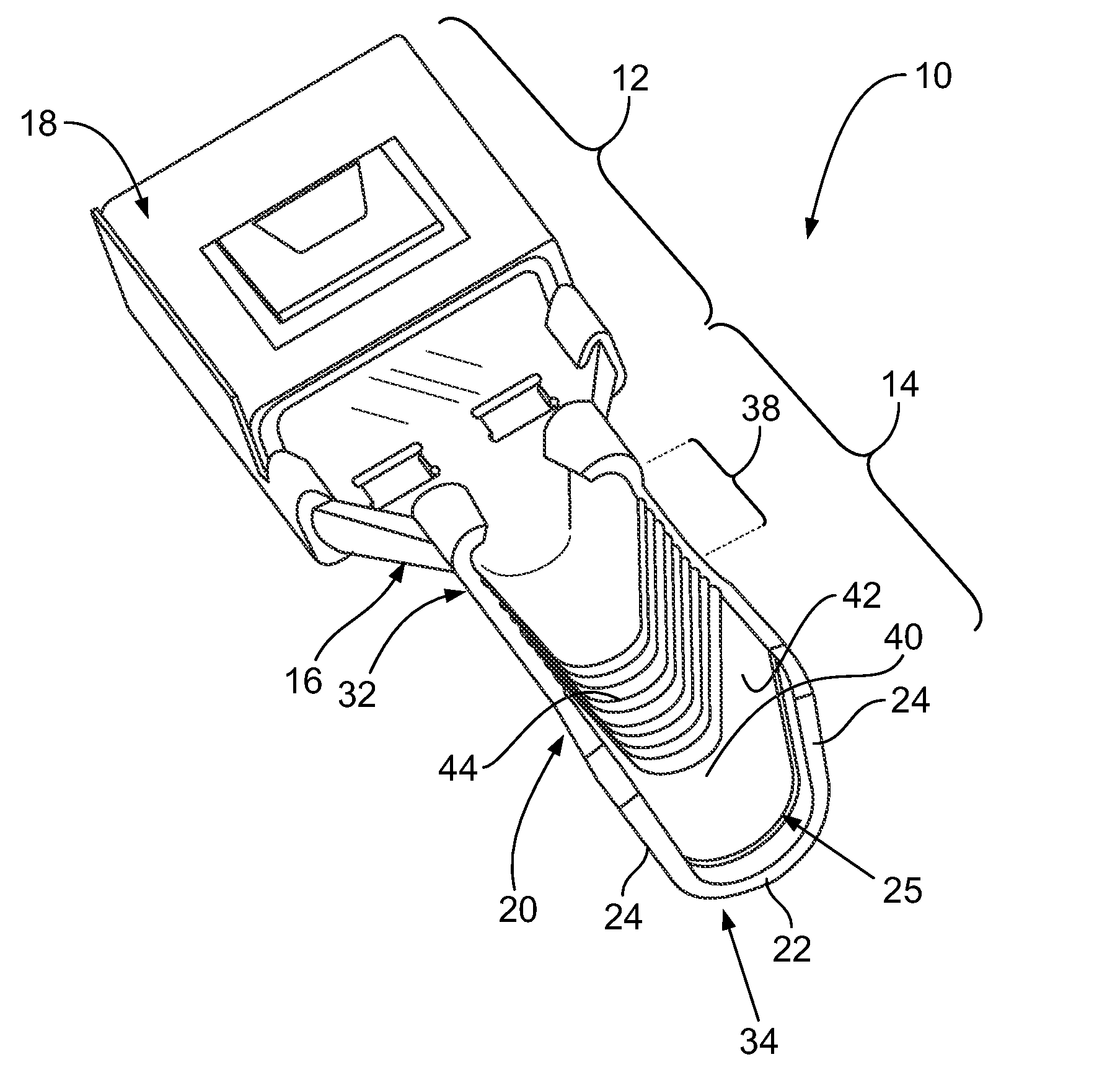

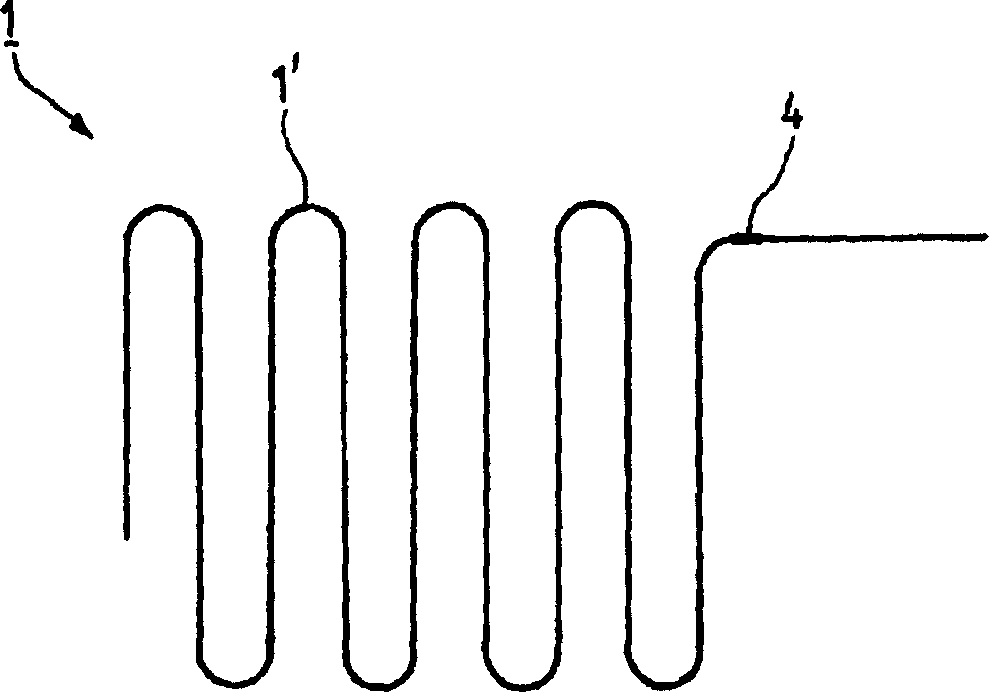

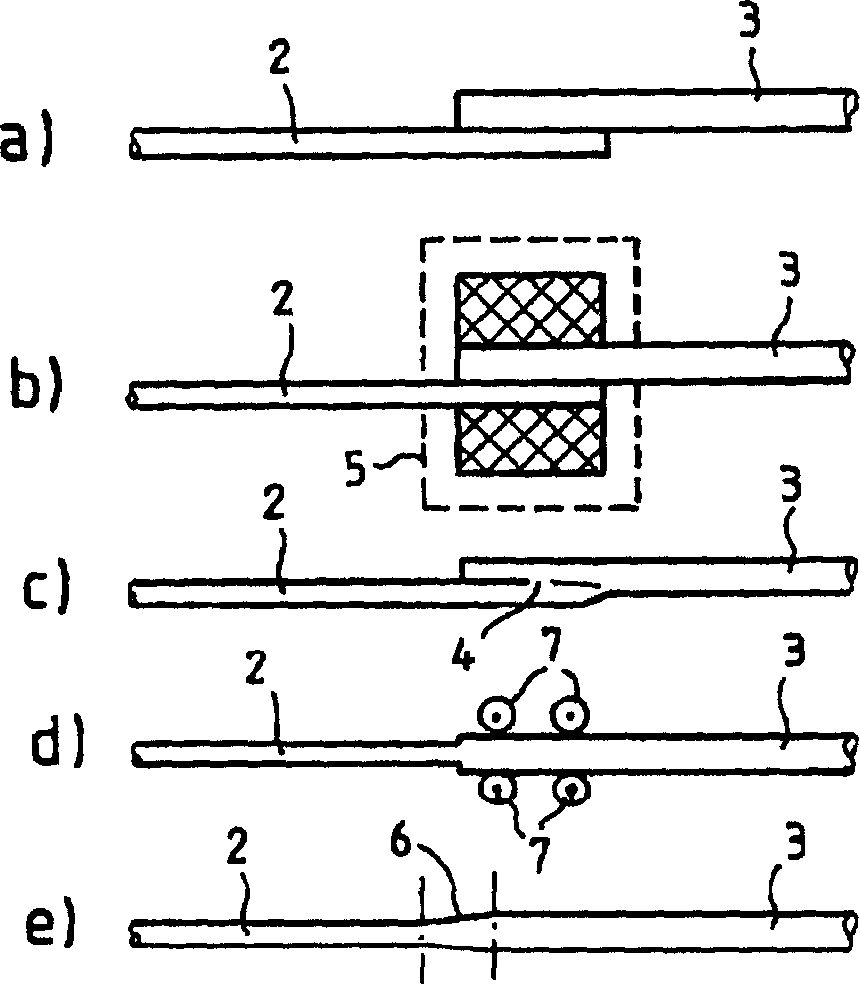

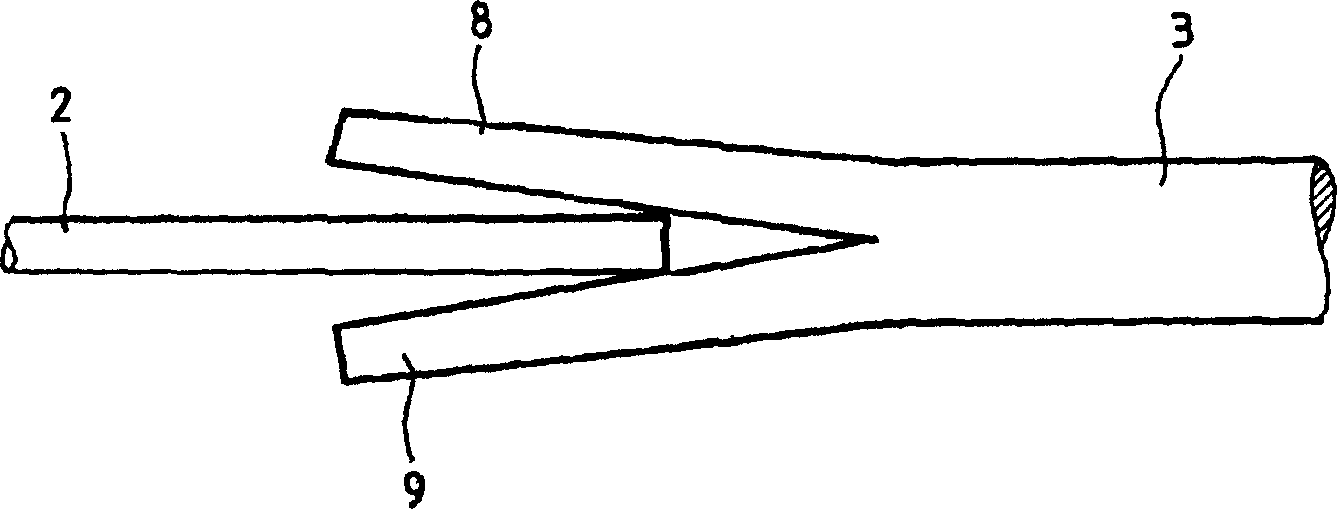

Flexible flat cable connecting method and boom structure of ultrasonic bonding machine

A flexible flat cable connecting method includes stripping an insulation coating (5) surface of a flexible flat cable (1) to be connected with a busbar (2) to expose a conductive element (4). The method continues by introducing the flexible flat cable (1) and the busbar (2) between a horn (7) and an anvil (6) of an ultrasonic welding machine (3), and then transmitting an ultrasonic vibration to the horn (7). The horn (7) has a plurality of elongated projections (9) of tapered cross-section pressed in contact with the insulation coating (5) of the flexible flat cable (1). Thus, the elongated projections (9) bite into the insulation coating (5) to weld the conductive element (4) ultrasonically into the busbar (2)

Owner:SUMITOMO WIRING SYST LTD

Friction weld coaxial connector and interconnection method

InactiveUS8479383B2Cost-effectiveSignificant material cost efficiencyContact member manufacturingContact member assembly/disassemblyInterference fitFriction welding

A coaxial connector for interconnection with a coaxial cable with a solid outer conductor by friction welding is provided with a monolithic connector body with a bore dimensioned for an interference fit with an outer diameter of the outer conductor. A friction groove may be formed around the leading end of the outer conductor by application of a friction weld support against the inner diameter and leading end of the outer conductor. The friction groove may include a material chamber formed between a radial friction protrusion of the bore and a bottom of the friction groove. The friction weld support may be provided with ceramic surfaces contacting the outer conductor, a stop shoulder dimensioned to abut a cable end of the bore and / or an elastic insert seated within an inner conductor bore.

Owner:COMMSCOPE TECH LLC

Recessed resin tips used in a connecting method

InactiveUS6844499B2High strengthSoldered/welded conductive connectionsSoldered/welded connectionsEngineeringMechanical engineering

Owner:YAZAKI CORP

Method of interconnecting a coaxial connector to a coaxial cable via ultrasonic welding

InactiveUS8453320B2Cost-effectiveSignificant material cost efficiencyElectrically conductive connectionsContact member assembly/disassemblyCoaxial cableElectrical conductor

Owner:COMMSCOPE TECH LLC

Friction weld coaxial connector and interconnection method

ActiveUS20120129389A1Cost-effectiveSmall sizeElectrically conductive connectionsContact member assembly/disassemblyFriction weldingElectrical conductor

A coaxial connector for interconnection with a coaxial cable with a solid outer conductor by friction welding is provided with a monolithic connector body with a bore. A sidewall of the bore is provided with an inward annular projection angled toward a cable end of the bore. A sidewall of the inward annular projection and the sidewall of the bore form an annular friction groove open to a cable end of the bore. The annular friction groove is dimensioned with a taper at a connector end of the friction groove less than a thickness of a leading end of the outer conductor. The taper provides an annular material chamber between the leading end of the outer conductor, when seated in the friction groove, and the connector end of the friction groove.

Owner:COMMSCOPE TECH LLC

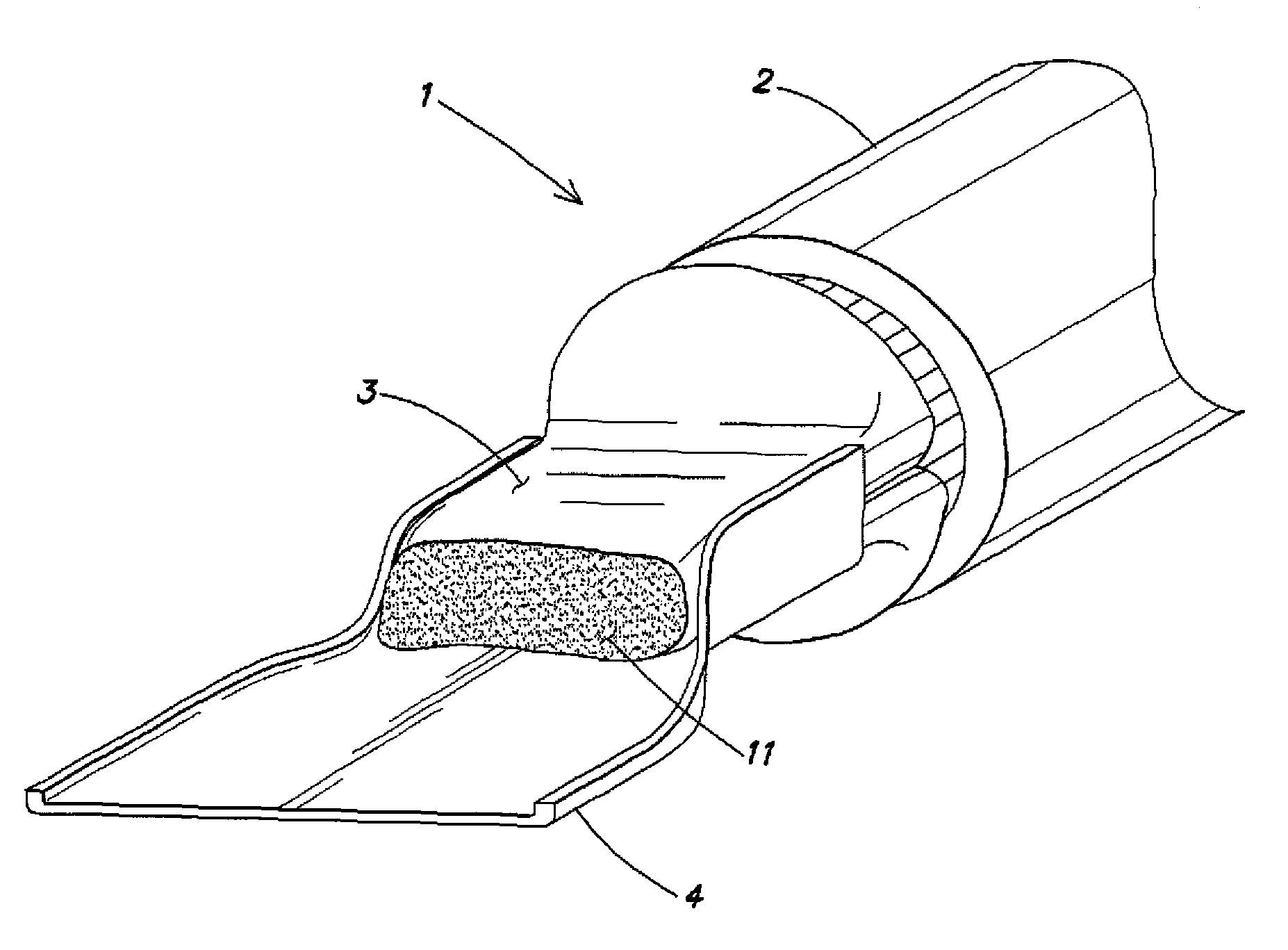

Method of attaching a wire cable terminal to a multi-strand wire cable, wire cable formed during said method, and apparatus for forming said wire cable

A wire cable configured to be attached to a wire cable terminal. An uninsulated end of the wire cable is formed into a nugget having a shape that generally defines a rectangular cuboid or rectangular prism. The nugget includes one face that defines a longitudinal concavity, indentation, or channel, which is oriented generally parallel to the longitudinal axis of the wire cable. The nugget may be formed by ultrasonically welding the wire strands together. The concavity reduces the occurrence of fracturing the nugget when it is attached to the terminal by wire crimping wings. The wire cable may be formed of aluminum-based material. An apparatus for forming an end of a wire cable into a nugget shape having a longitudinal concavity and a method of attaching a wire cable having an end formed into a nugget shape having a longitudinal concavity to a terminal is also presented.

Owner:APTIV TECH LTD

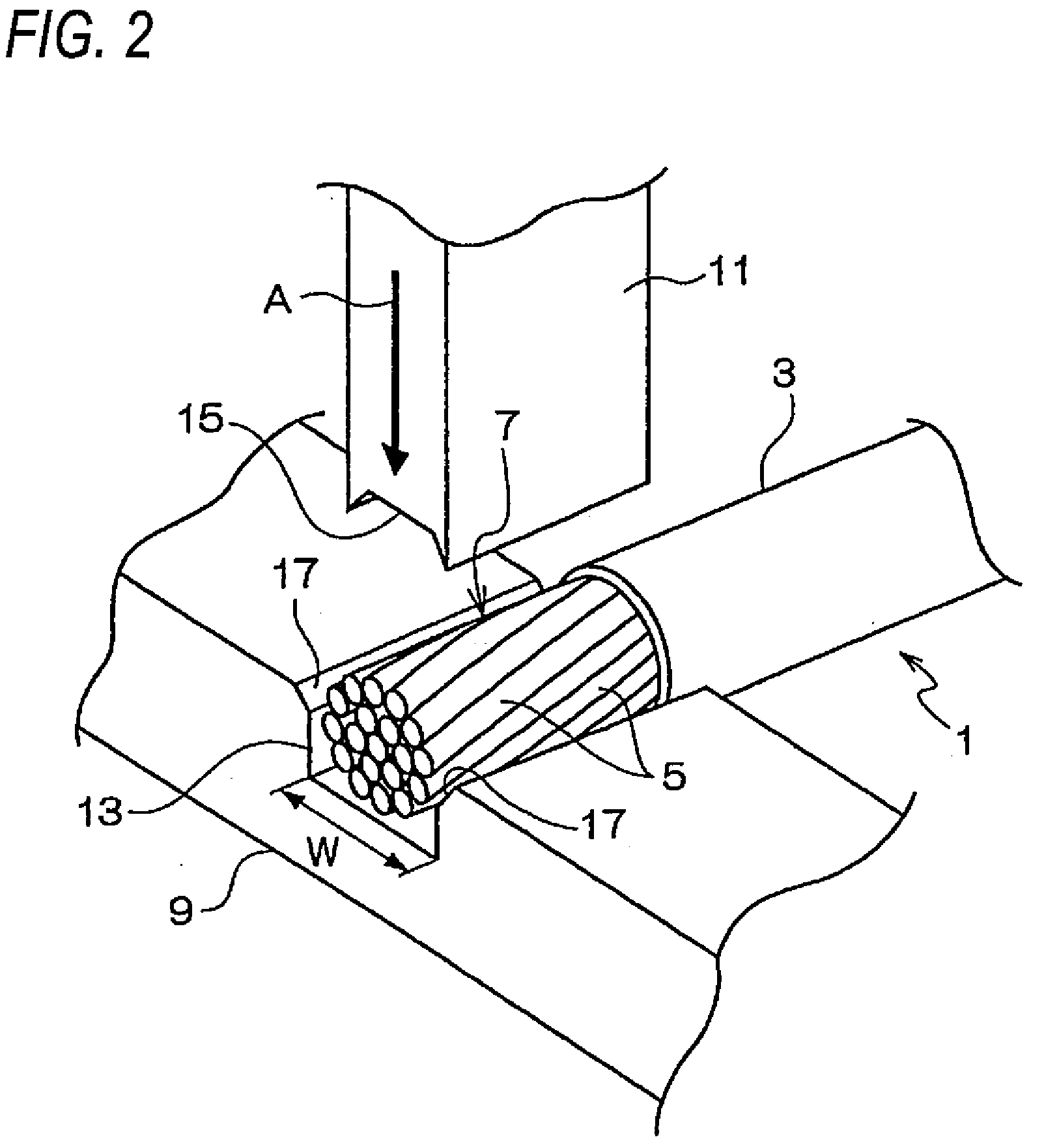

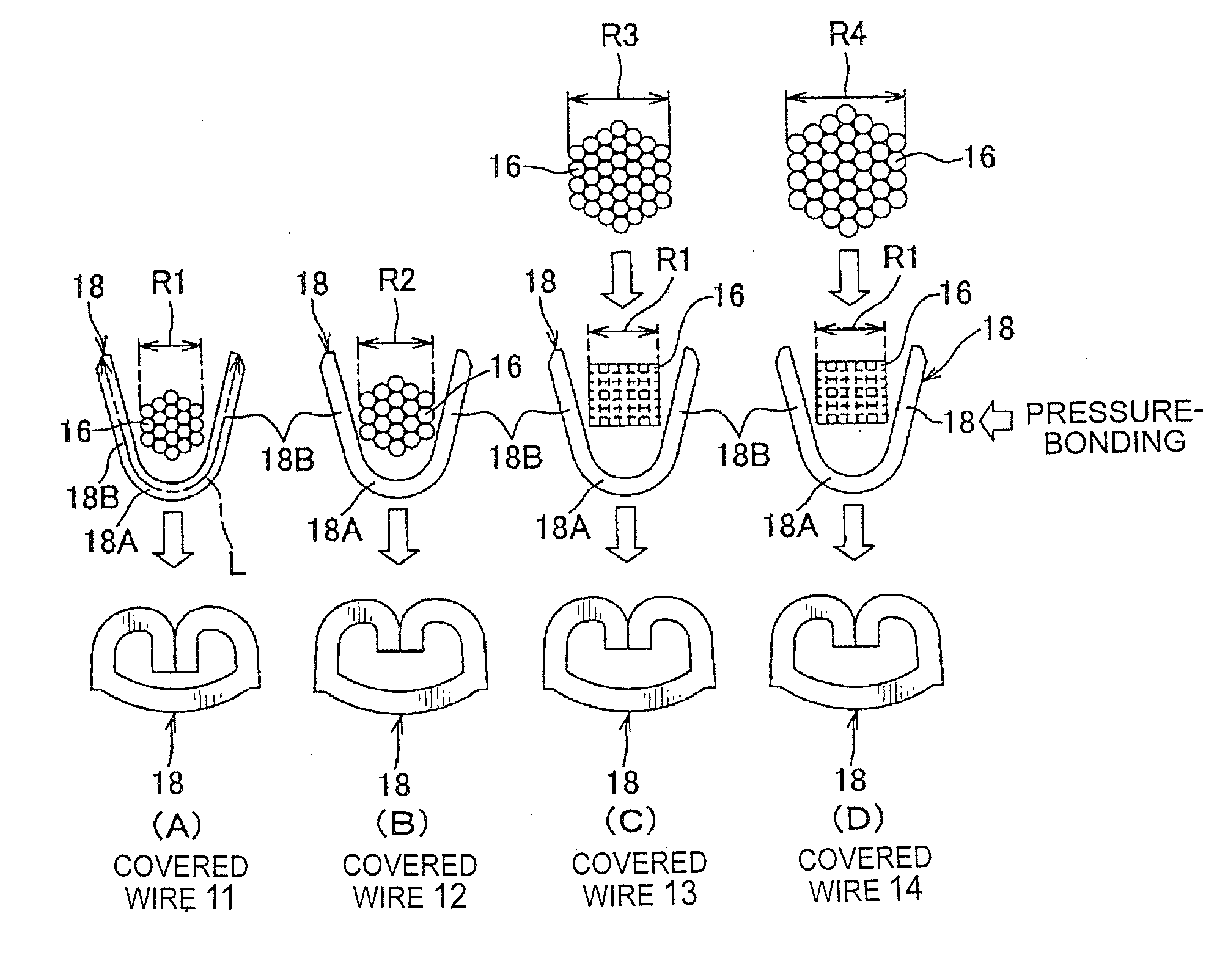

Wire ultrasonic bonding method and wire ultrasonic bonding apparatus

InactiveUS20060169742A1Improve adhesionAvoid attenuationWelding/cutting auxillary devicesElectric connection structural associationsEngineeringUltrasonic vibration

A conductive portion of a wire, composed of a plurality of core wires, is inserted and fitted into a groove in a pressing die, thereby restricting the conductive portion to a bonding width of a terminal, and in this condition with the use of a press forming machine, the conductive portion is pressed in a thickness direction thereof to be formed into a flat shape. Thereafter, the conductive portion is inserted and fitted into the terminal, and then the conductive portion, while pressed by a pressing vibration horn, is bonded to the terminal by ultrasonic vibrations applied from the pressing vibration horn.

Owner:YAZAKI CORP

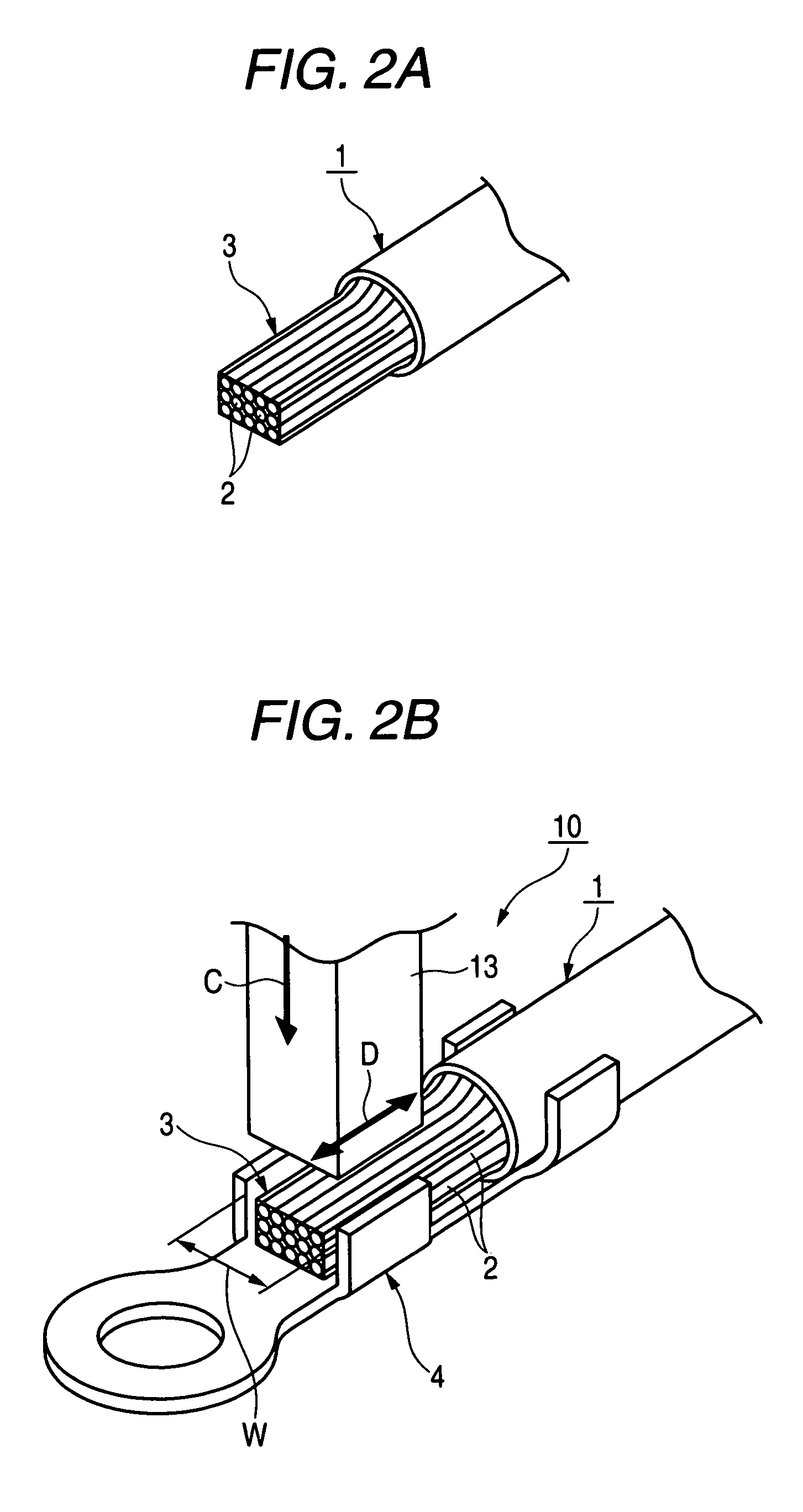

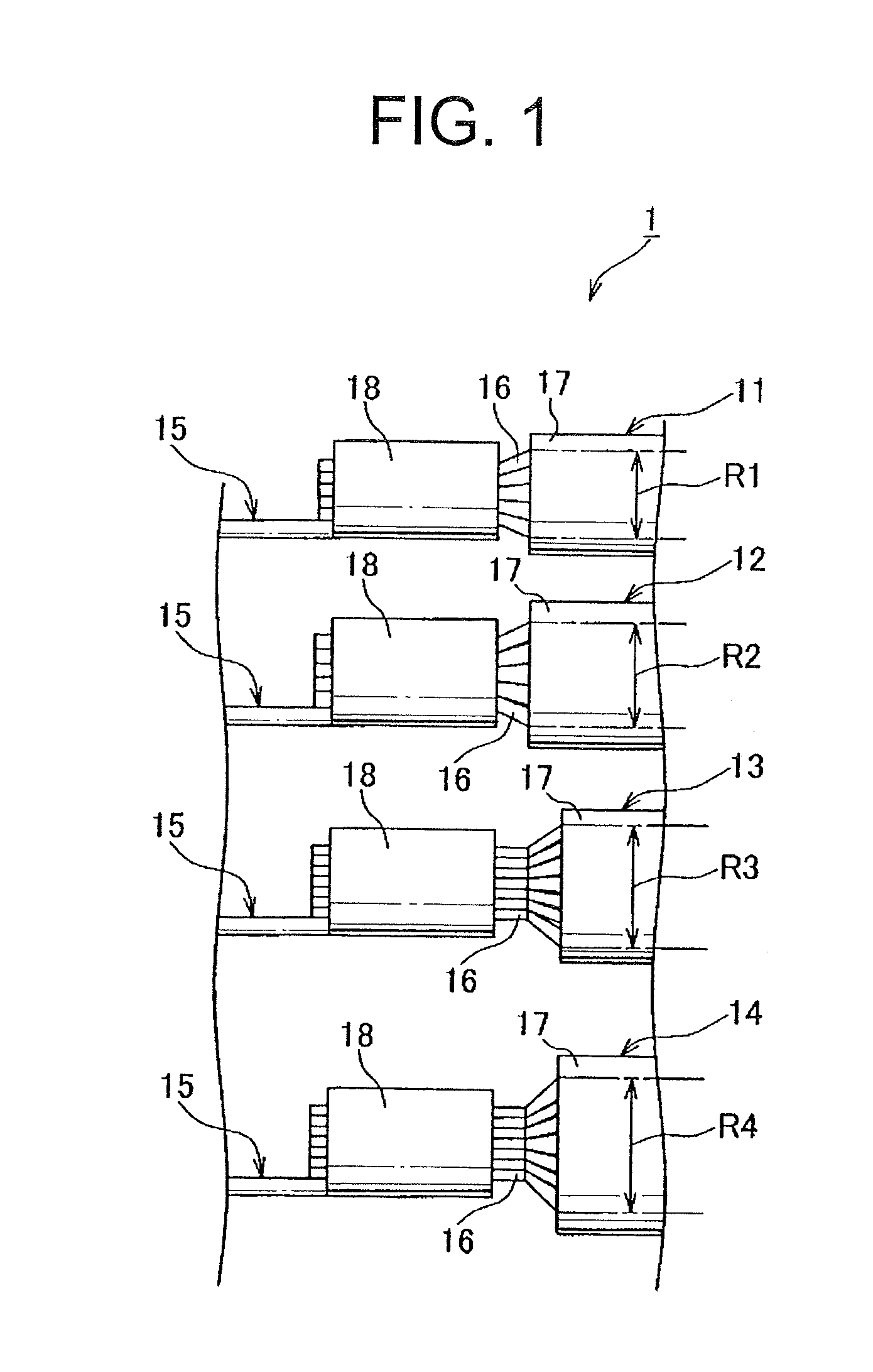

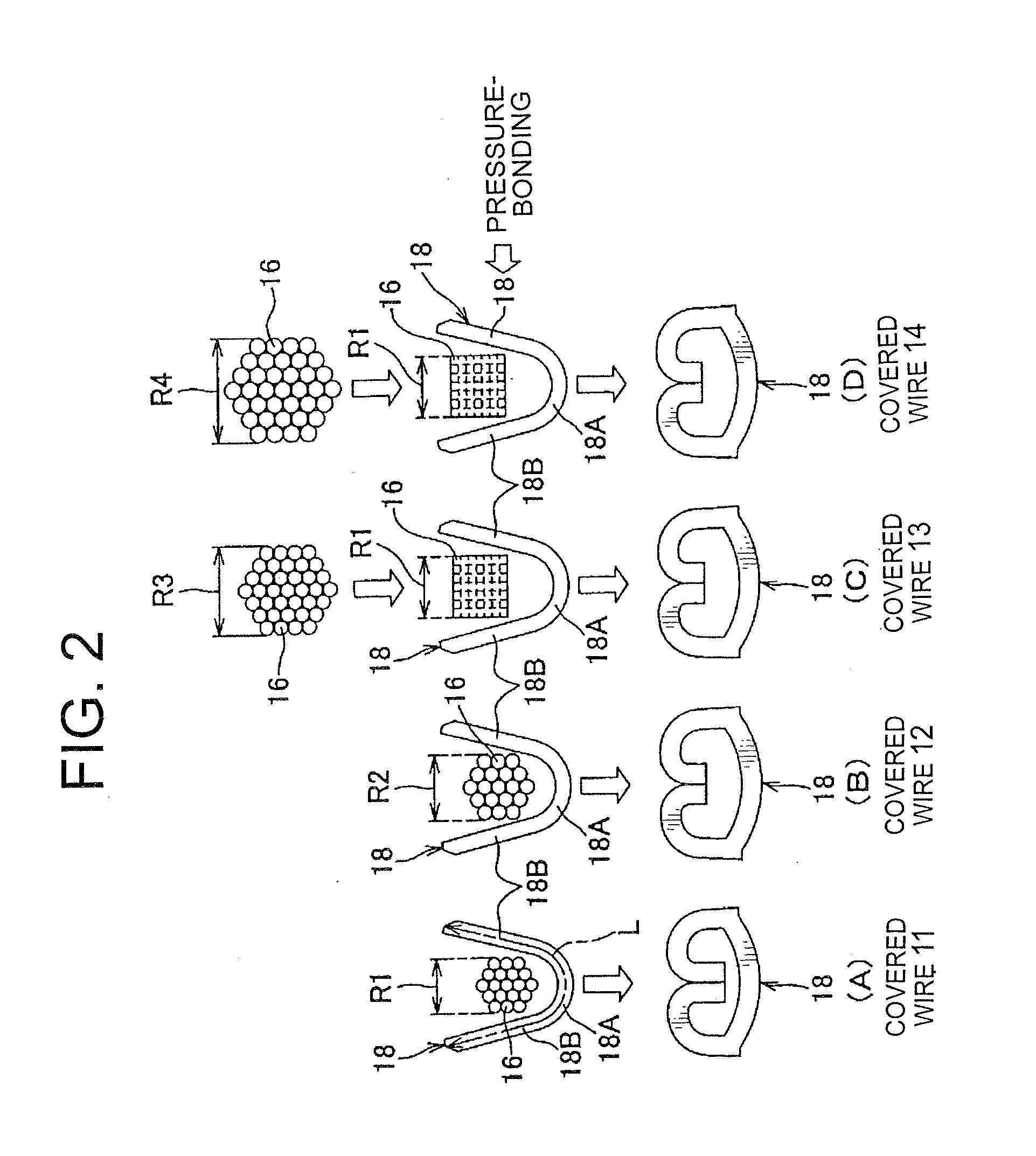

Wire connecting method and wiring harness

InactiveUS20130025935A1Low costLimit size of wireSoldered/welded connectionsConnections effected by permanent deformationEngineeringCable harness

[Technical Problem]An object of the present invention is to provide a wire connecting method and a wiring harness allowed to reduce the number of types of terminals for reducing cost by increasing the number of core wire sizes able to be crimped or press-connected with respect to one terminal.[Solution to Problem]Regarding covered wires 13, 14 of which core wire diameter is larger than the core wire diameter allowed to be crimped with a wire barrel 18, an ultrasonic processing in which while pressure is applied to a core wire 16, ultrasonic energy is applied to the core wire 16 is performed. Thereby, the core wire diameter is reduced to be allowed to be crimped to the wire barrel 18, and the core wire 16 of the covered wire 13, 14 is crimped or press-connected between a pair of crimping pieces 18B of the terminal 15. Regarding covered wires 11, 12 of which core wire diameter is allowed to be crimped to the wire barrel 18, the ultrasonic processing is not performed, and the core wire 16 of the covered wire 13, 14 is directly crimped between the pair of crimping pieces 18B of the terminal 15.

Owner:YAZAKI CORP

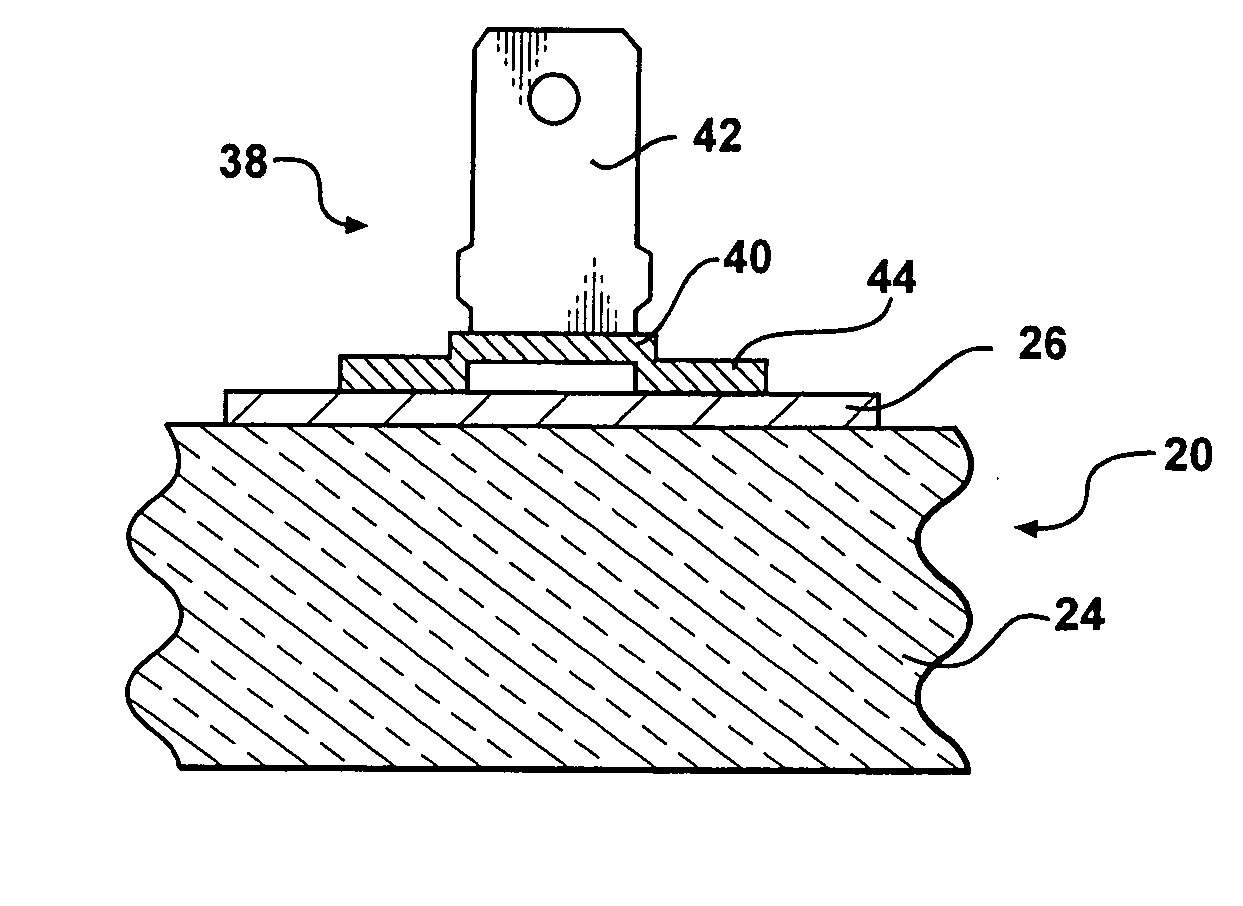

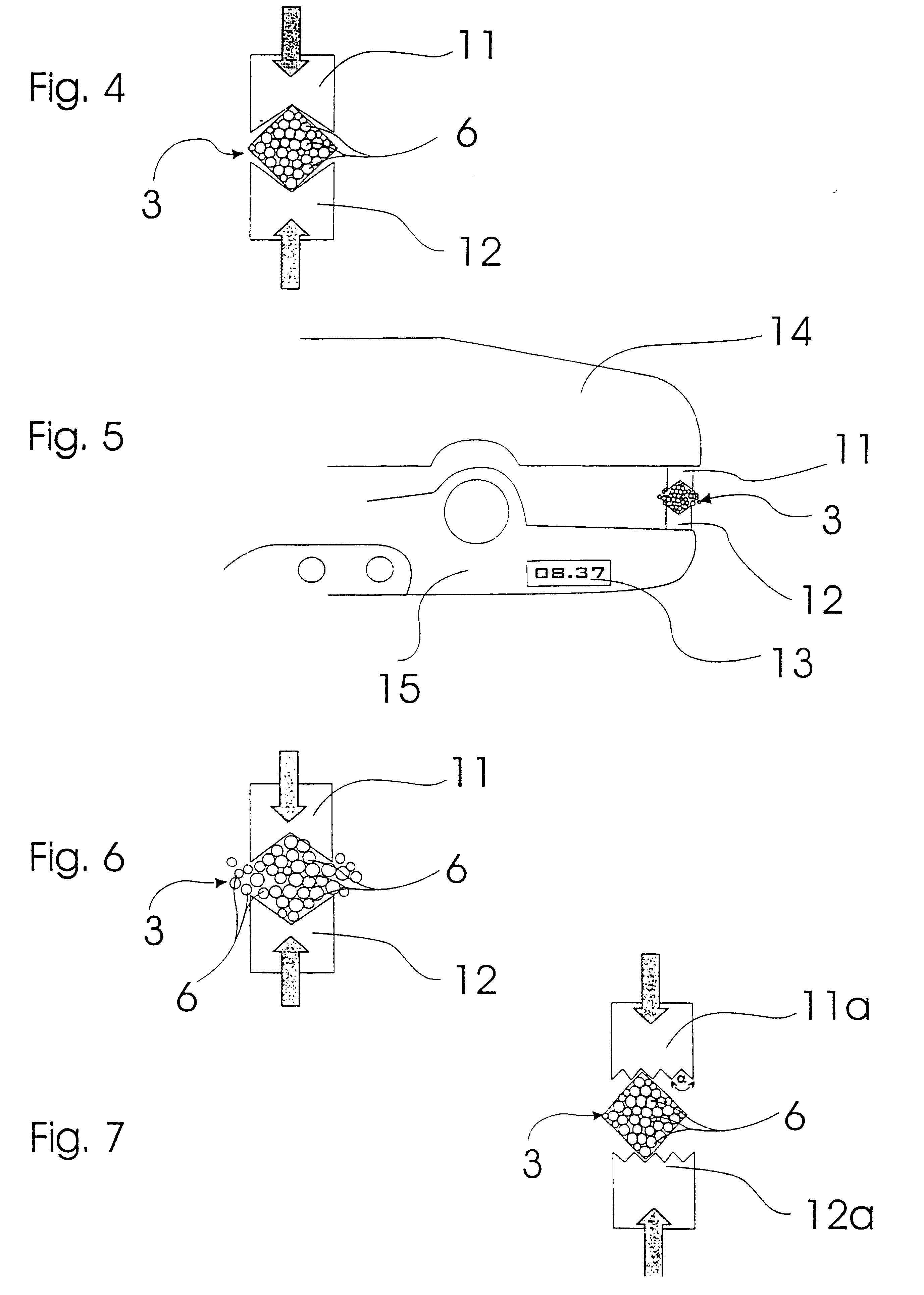

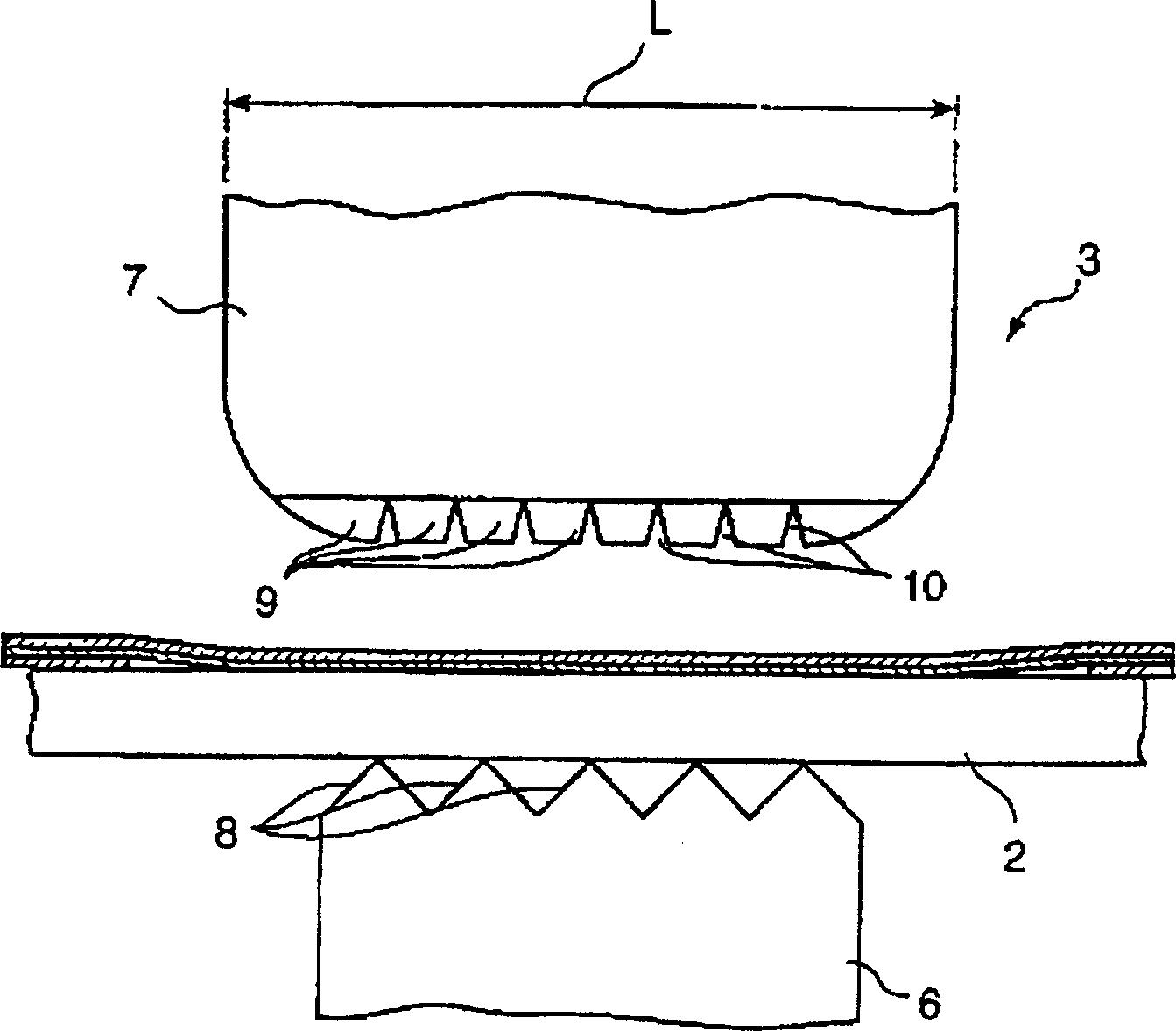

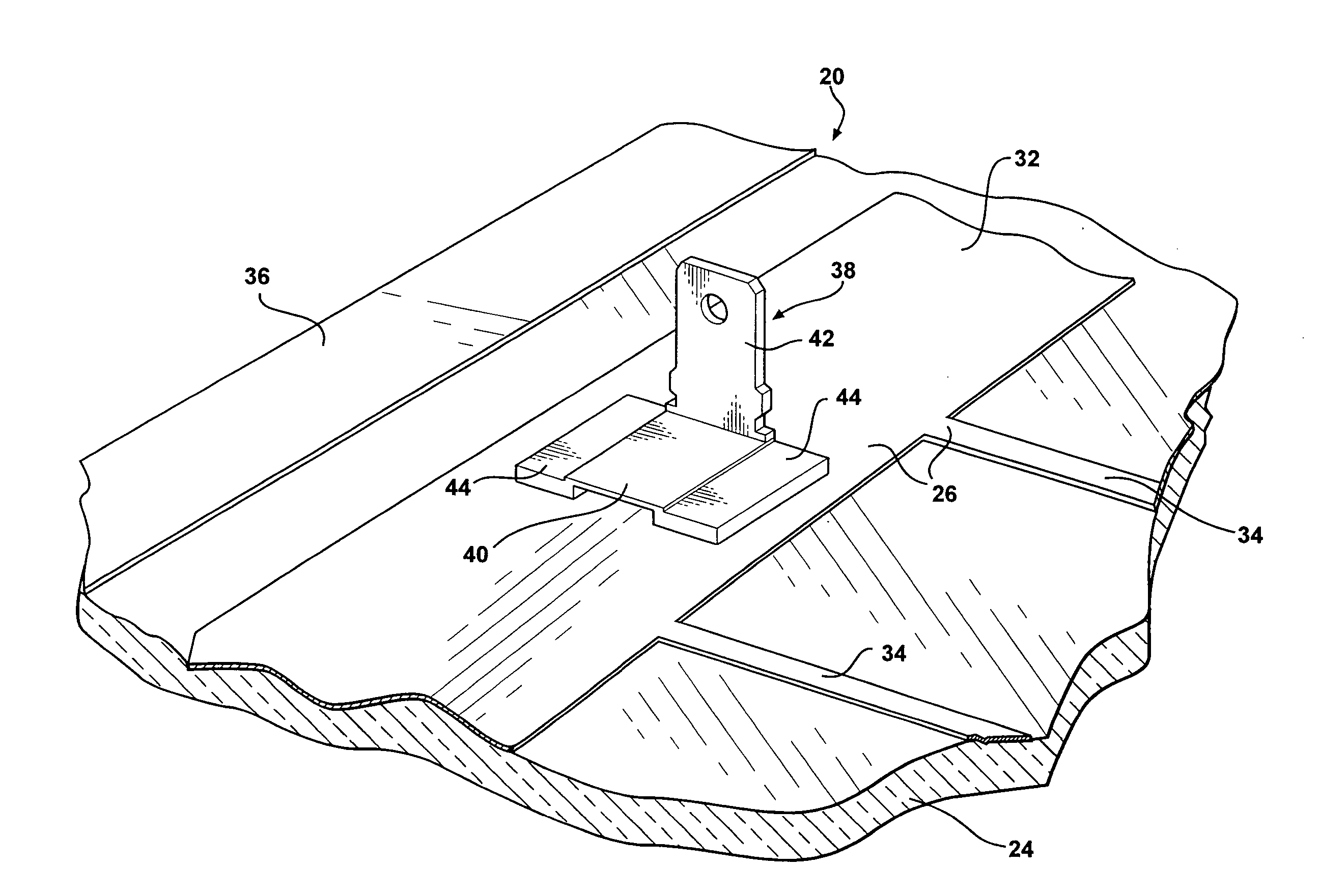

Window pane and a method of bonding a connector to the window pane

InactiveUS20060105589A1Eliminate useAvoid defectsVehicle connectorsElectrically conductive connectionsElectrical conductorUltrasonic welding

A method of bonding a connector to an electrical conductor. The conductor is applied to a glass substrate and the connector is placed over the conductor. An ultrasonic welding apparatus is used to oscillate the connector relative to the conductor to bond the connector to the conductor while maintaining the temperatures of the connector and conductor below the predefined melting points and without damaging the glass substrate. In addition, an electrically conductive foil can be disposed between the connector and the conductor for ensuring electrical communication between the connector and the conductor.

Owner:AGC AUTOMOTIVE AMERICAS

Power adapter components, housing and methods of assembly

ActiveUS20150093924A1Provide supportTransformers/inductances casingsTransformers/inductances coils/windings/connectionsUltrasonic weldingTransformer

A dual-purpose transformer may be oriented in a plane perpendicular to planes in which printed circuit boards connected thereto are oriented, thereby providing structural support for a framework that can include a dense arrangement of internal power adapter components, in addition to stepping down voltage. Methods for ultrasonic welding are also provided and may be used to concurrently assemble, join and press-fit power adapter housing components. A ground lug is also provided that is shaped and located within a cover piece of a power adapter housing to allow for blind mating with a printed circuit board during an assembly process.

Owner:APPLE INC

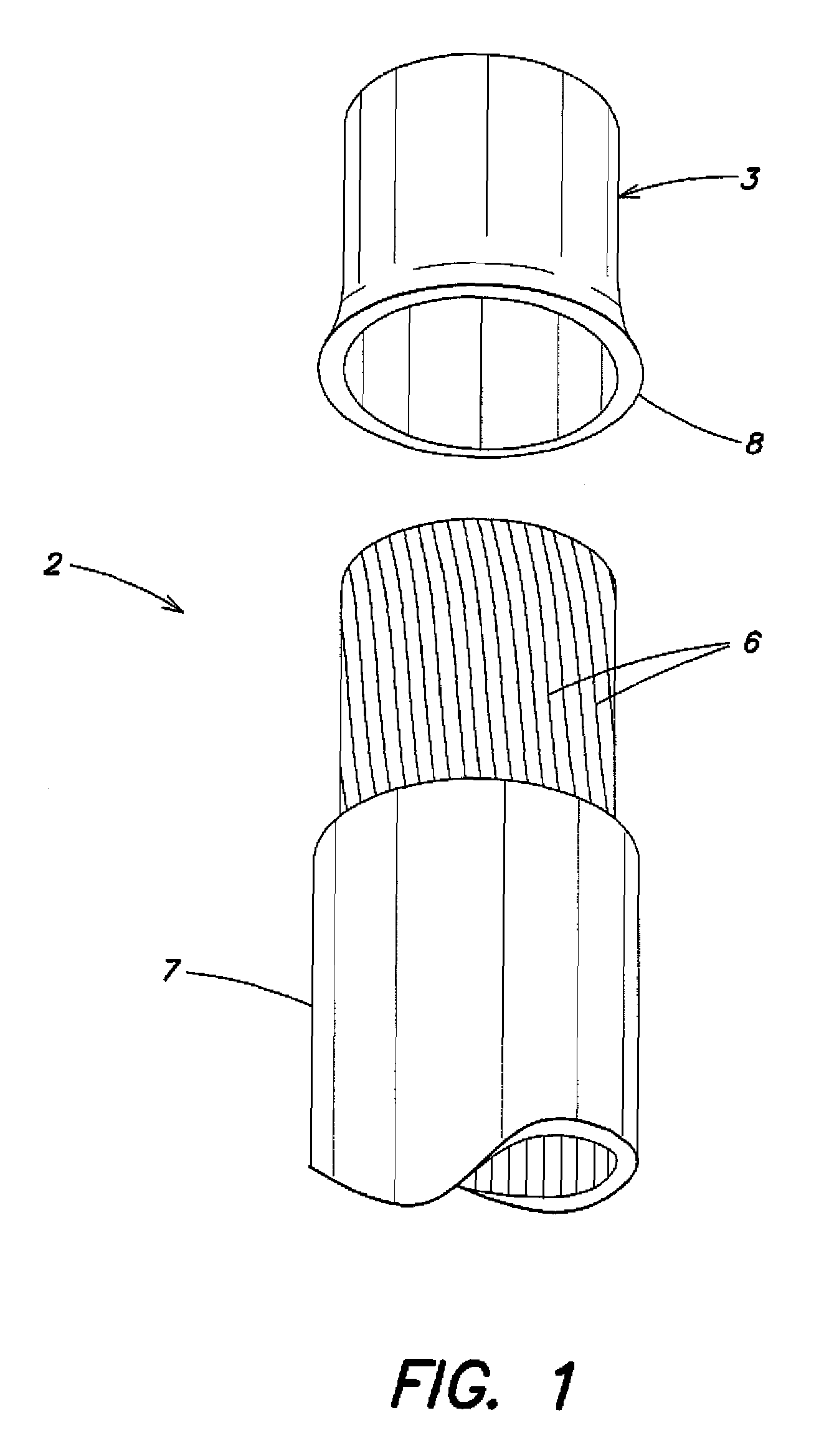

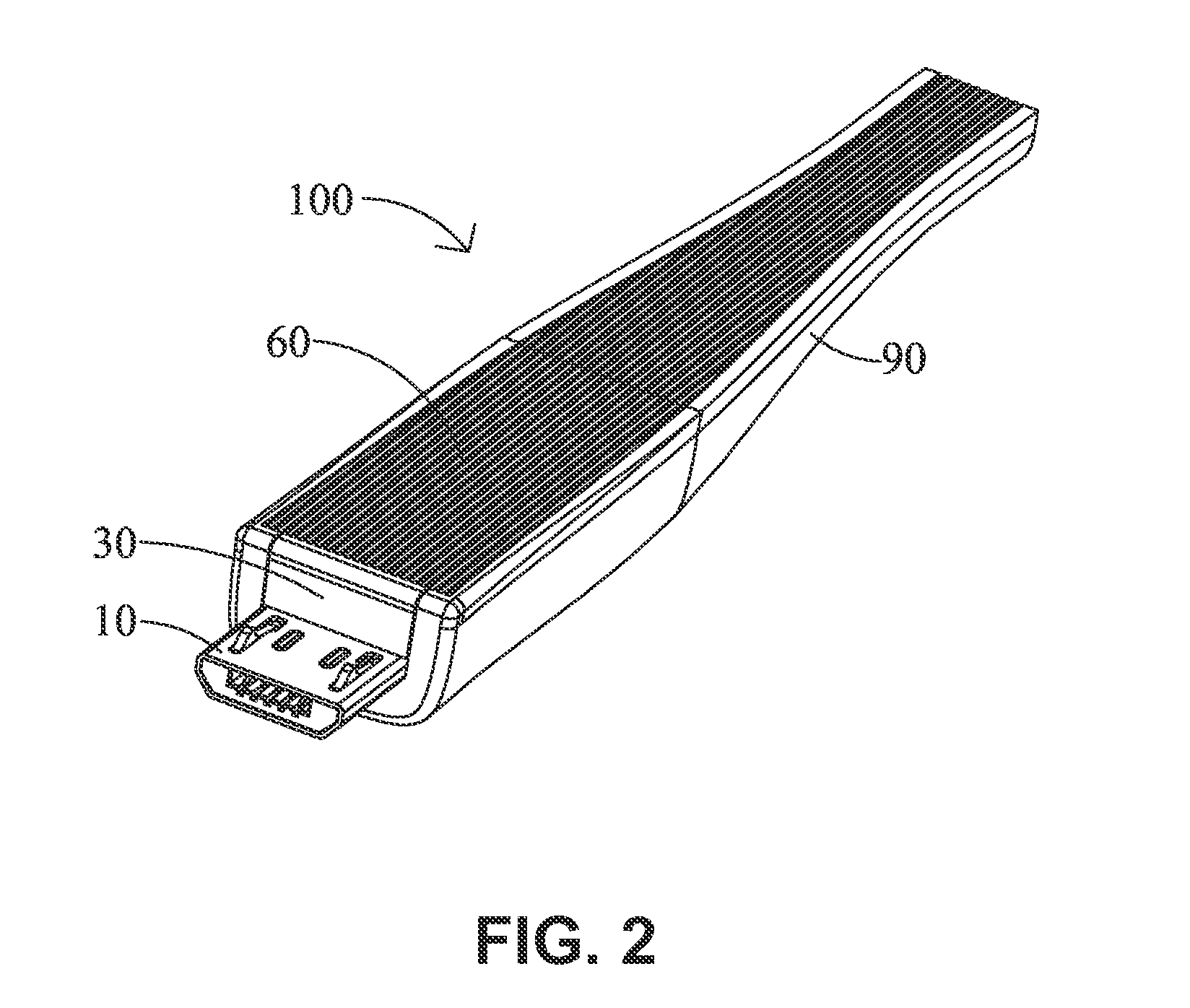

Connector assembly

ActiveUS9537231B2Electrically conductive connectionsTwo pole connectionsDielectricElectrical conductor

A connector assembly includes a center contact configured to be terminated to a center conductor of a cable. A dielectric holds the center contact. An outer contact surrounds the dielectric and the center contact. The outer contact has a mating segment extending from a mating end, a terminating segment extending from a cable end, and a middle segment between the mating and terminating segments. The terminating segment is configured to be terminated to a braid of the cable. The middle segment has a diameter that is less than the respective diameters of the mating and terminating segments. A cavity insert surrounds the middle segment of the outer contact. The cavity insert includes a receiving shell and a closing shell that are joined together at an interface.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

Method and apparatus for crimping an electrical terminal to an electrical wire

ActiveUS20140317922A1Coupling device detailsConnections effected by explosionElectrical conductorElectric wire

A method is provided for crimping an electrical terminal to an electrical wire having electrical conductors. The method includes positioning the electrical wire and the electrical terminal between opposing crimp tooling members of a crimp tool. The method also includes pressing a crimp barrel of the electrical terminal against the electrical conductors of the electrical wire using the crimp tooling members such that the electrical conductors are mechanically and electrically connected to the crimp barrel. The crimp barrel is pressed against the electrical conductors such that at least some contact portions of metallic surfaces of at least some of the electrical conductors melt and form hot weld bonds with one or more contact portions of the metallic surface of one or more adjacent electrical conductors.

Owner:TE CONNECTIVITY GERMANY GMBH +1

Electric wire connecting method

InactiveUS8931685B2Soldered/welded conductive connectionsSoldering apparatusElectrical conductorEngineering

An electric wire connecting method for connecting together a wire having a conductor and a stranded wire having a plurality of strands which are twisted, the electric wire connecting method is provided. The electric wire connecting method includes a forming step and a welding step. In the forming step, the conductor is formed into a plate element by pressing the conductor. In the welding step, the strands are welded to the plate element in a state where the strands are superposed on the plate element.

Owner:YAZAKI CORP

Electrical connector assembly with a light guide member

InactiveUS9461417B2Engagement/disengagement of coupling partsElectrically conductive connectionsLight guideComputer module

An electrical connector assembly includes a connector, an inner printed circuit board, and a light guide member made of transparent or semitransparent material. The connector comprising an insulative housing and a plurality of contacts received in the insulative housing, and each contact has a contacting portion and a soldering portion. The inner printed circuit board is welding with the soldering portions of the contacts and defines an LED. The light guide member is neighboring to the LED and exposed out of the electrical connector assembly. The inner printed circuit board defines a control module thereon for controlling the LED on or off and a touch switch arranged in front of the control module, the LED is electrically connected with the control module and the touch switch.

Owner:DONGGUAN XUNTAO ELECTRONICS CO LTD

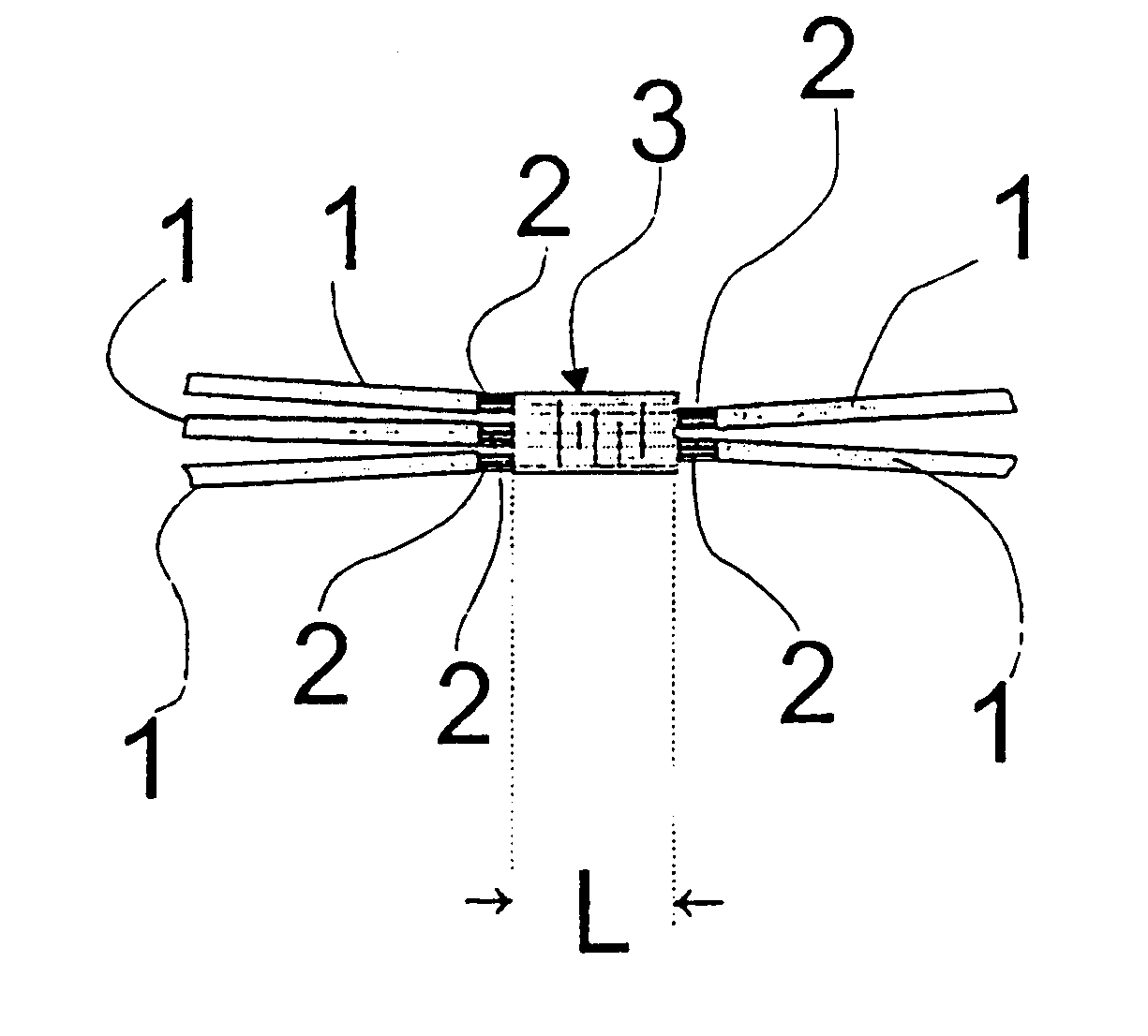

Conductive connecting method for first and second electric conductor

InactiveCN1510784AImprove conductivityEasy to guideSoldered/welded conductive connectionsArc welding apparatusElectrical conductorEngineering

A method for conductively connecting first and second electrical conductors (2, 3) is described which consist of different materials. In carrying out the method the ends of the first and second conductors are brought into mechanical contact with each other in an overlapping position. The first and second conductors (2, 3) then are connected to each other by welding without feeding of additional welding material. Finally the overlapping area (4) is formed mechanically to achieve a smooth width transition between the first and second conductors (2, 3).

Owner:NEXANS

Friction weld coaxial connector and interconnection method

InactiveUS20130025121A1Cost-effectiveSignificant material cost efficiencyContact member manufacturingWave amplification devicesFriction weldingInterference fit

A coaxial connector for interconnection with a coaxial cable with a solid outer conductor by friction welding is provided with a monolithic connector body with a bore dimensioned for an interference fit with an outer diameter of the outer conductor. A friction groove may be formed around the leading end of the outer conductor by application of a friction weld support against the inner diameter and leading end of the outer conductor. The friction groove may include a material chamber formed between a radial friction protrusion of the bore and a bottom of the friction groove. The friction weld support may be provided with ceramic surfaces contacting the outer conductor, a stop shoulder dimensioned to abut a cable end of the bore and / or an elastic insert seated within an inner conductor bore.

Owner:COMMSCOPE TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com