Conductive connecting method for first and second electric conductor

A technology of conductive connection and electric conductor, applied in the field of conductive connection of the first and second electric conductors, can solve the problems of high contact resistance, expensive splicing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

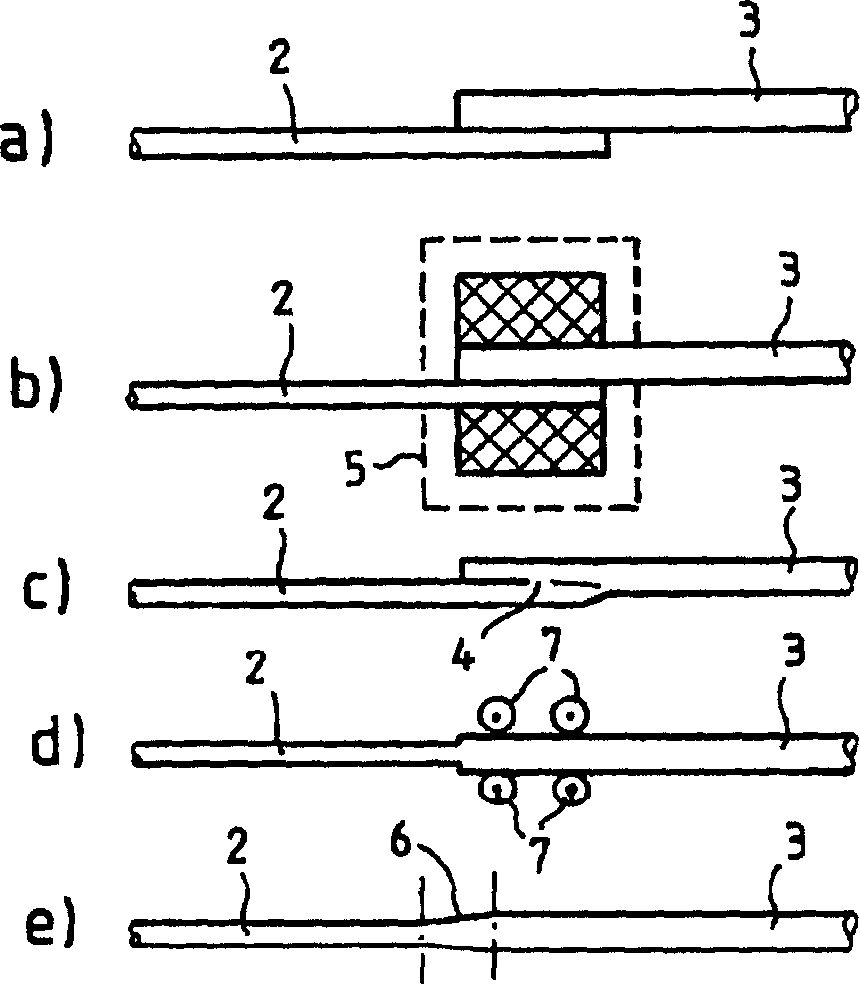

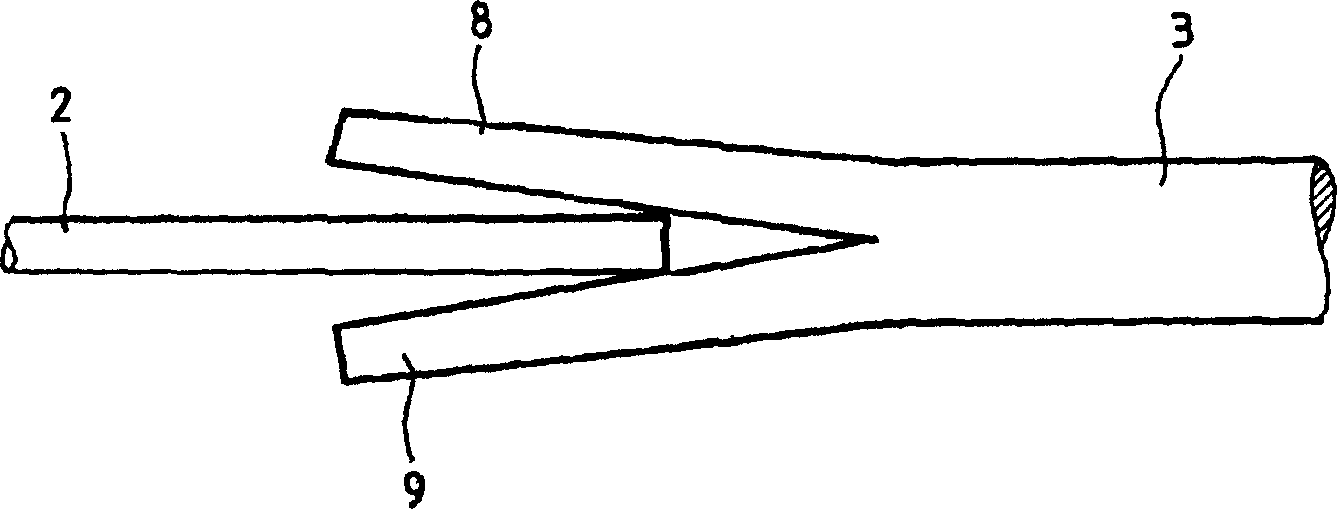

[0038] The first and second embodiments of the method of the invention are explained using ultrasonic welding. But other welding methods without additional welding material, like TIG (tungsten inert gas) welding, laser welding and HF (high frequency) welding are also included.

[0039] Furthermore, the method is explained with the connection of resistive conductors and copper conductors.

[0040] However, other conductors made of different materials, such as alloys, are also included.

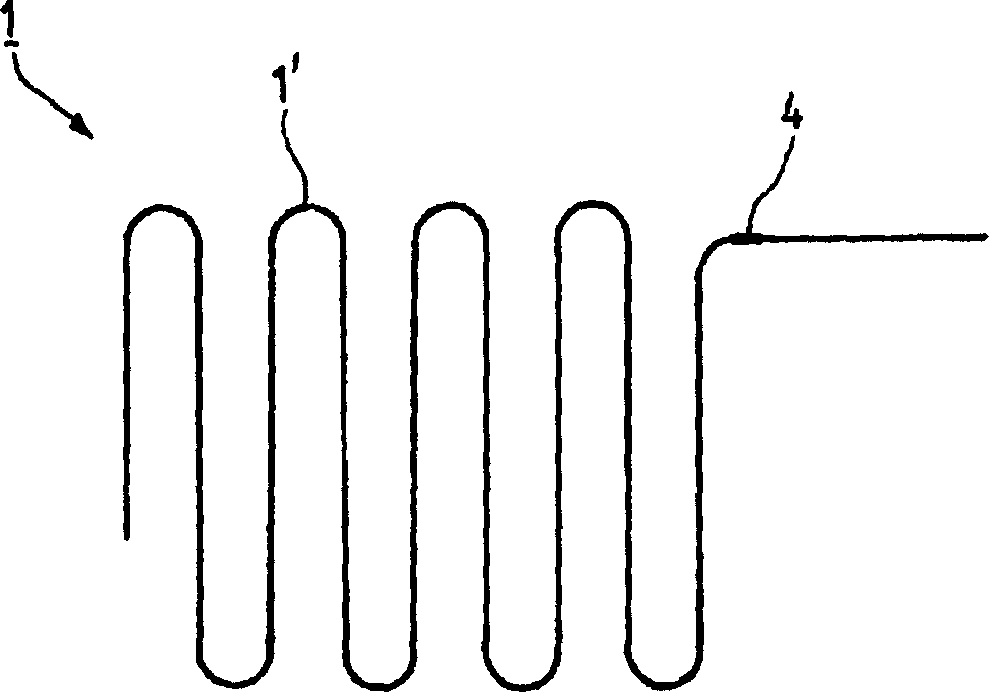

[0041] figure 1 A heating wire 1 is schematically shown, which is installed in the floor of a building (not shown) in a meandering shape. The heating wire 1 comprises a resistance conductor and a copper conductor (not visible), which are connected to each other at a splicing area 4 .

[0042] The conductors are enclosed in a sheath 1' of insulating material applied by an extrusion line (not shown). By way of example only, the diameter of the resistive conductor is smaller than that of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com