Patents

Literature

820results about "Thermoplastic polymer dielectrics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

LED lighting assemblies with thermal overmolding

ActiveUS20070121326A1Thermal conductivityPoint-like light sourceElectric circuit arrangementsEffect lightEngineering

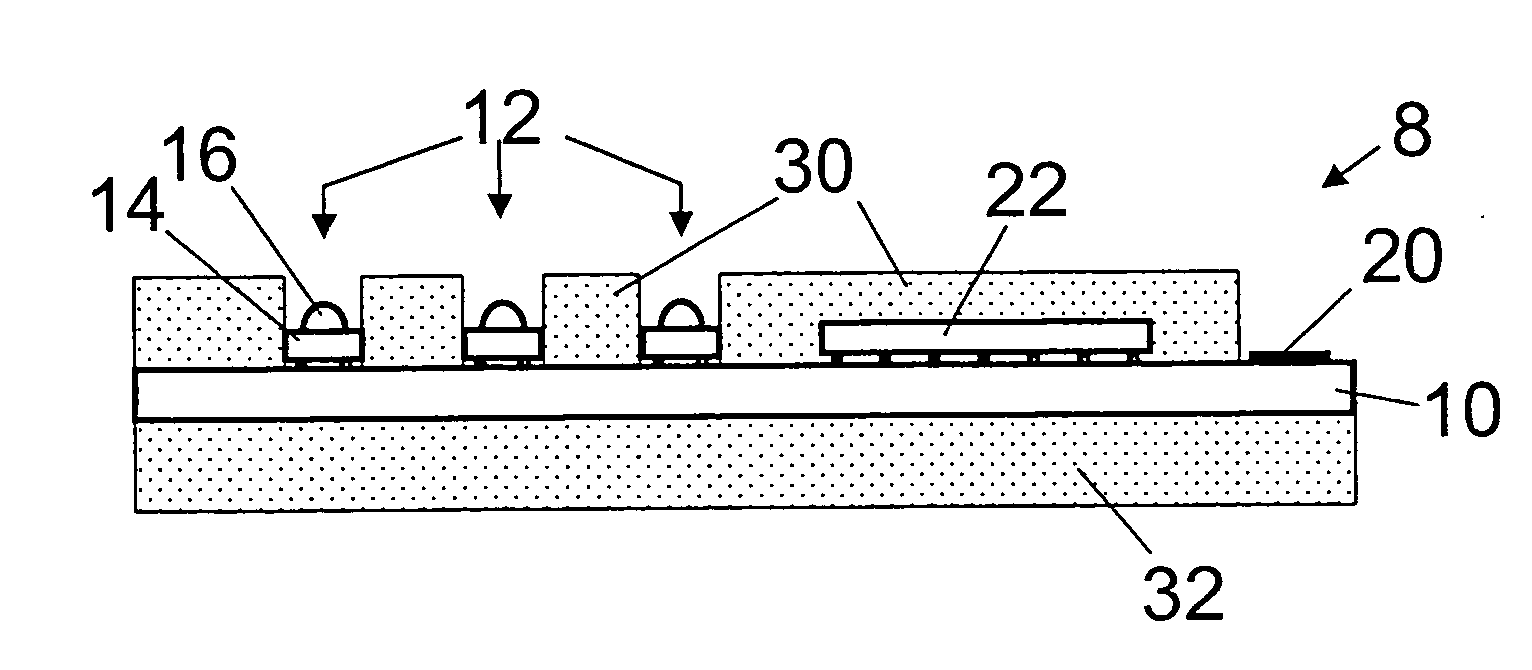

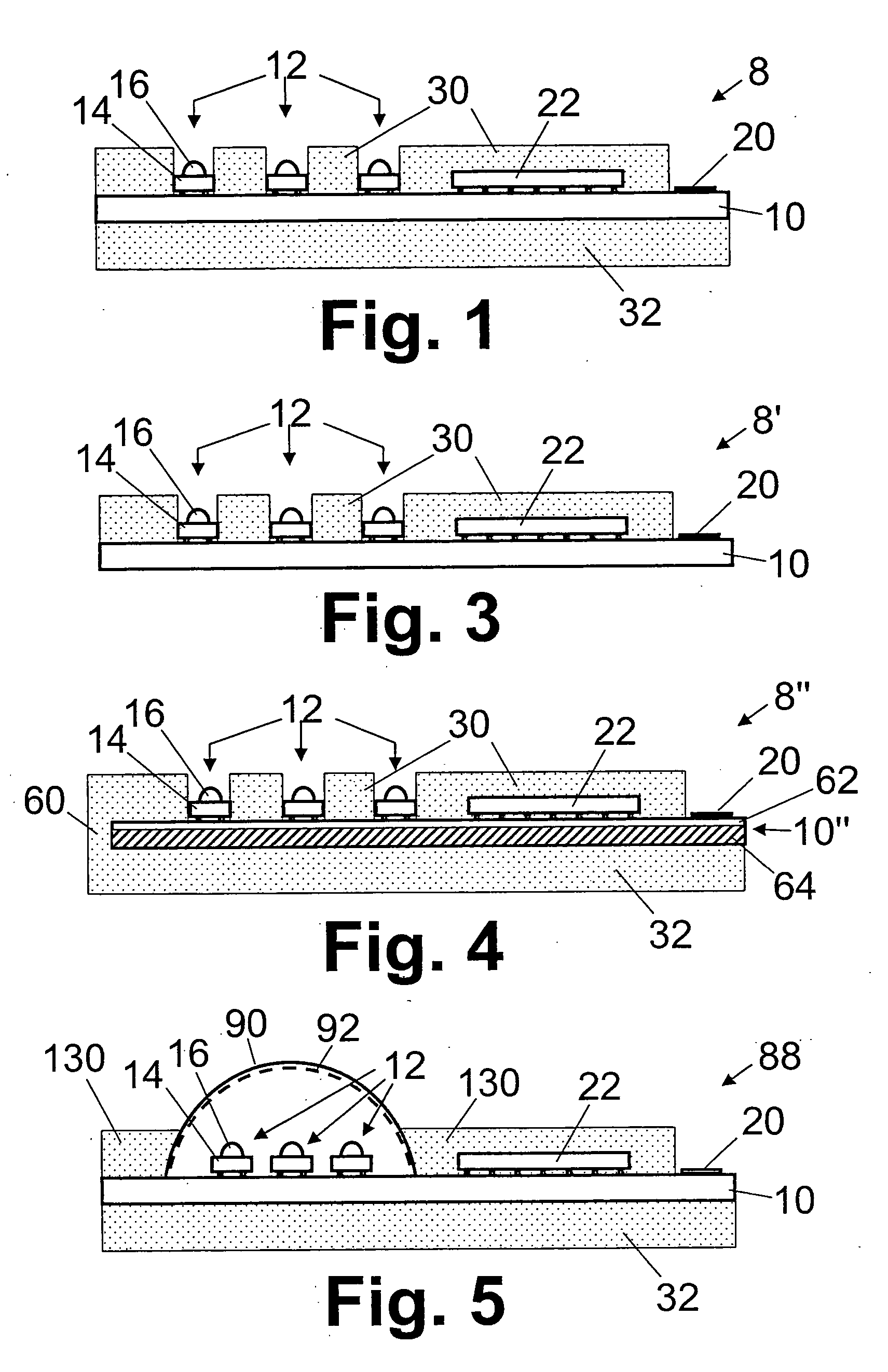

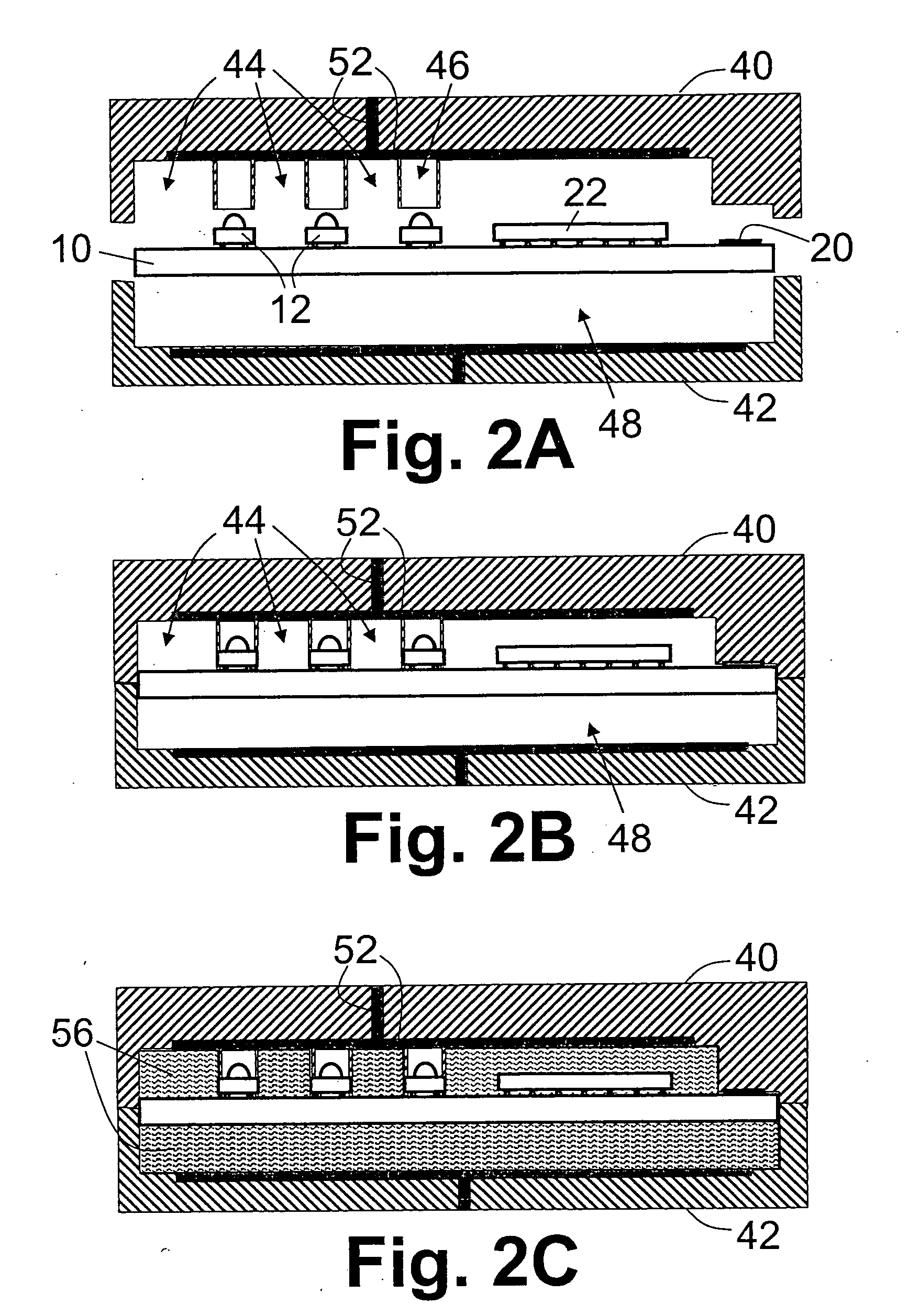

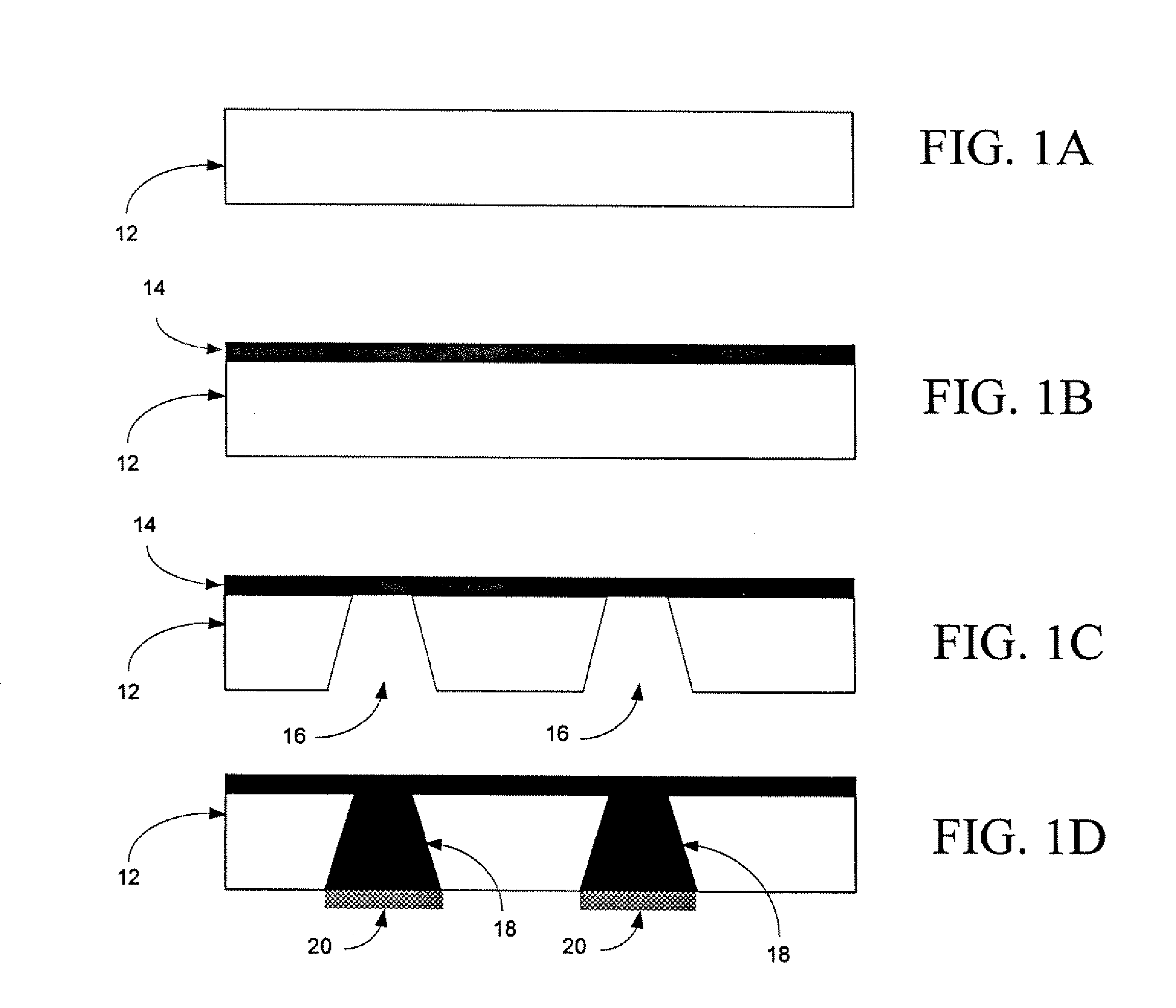

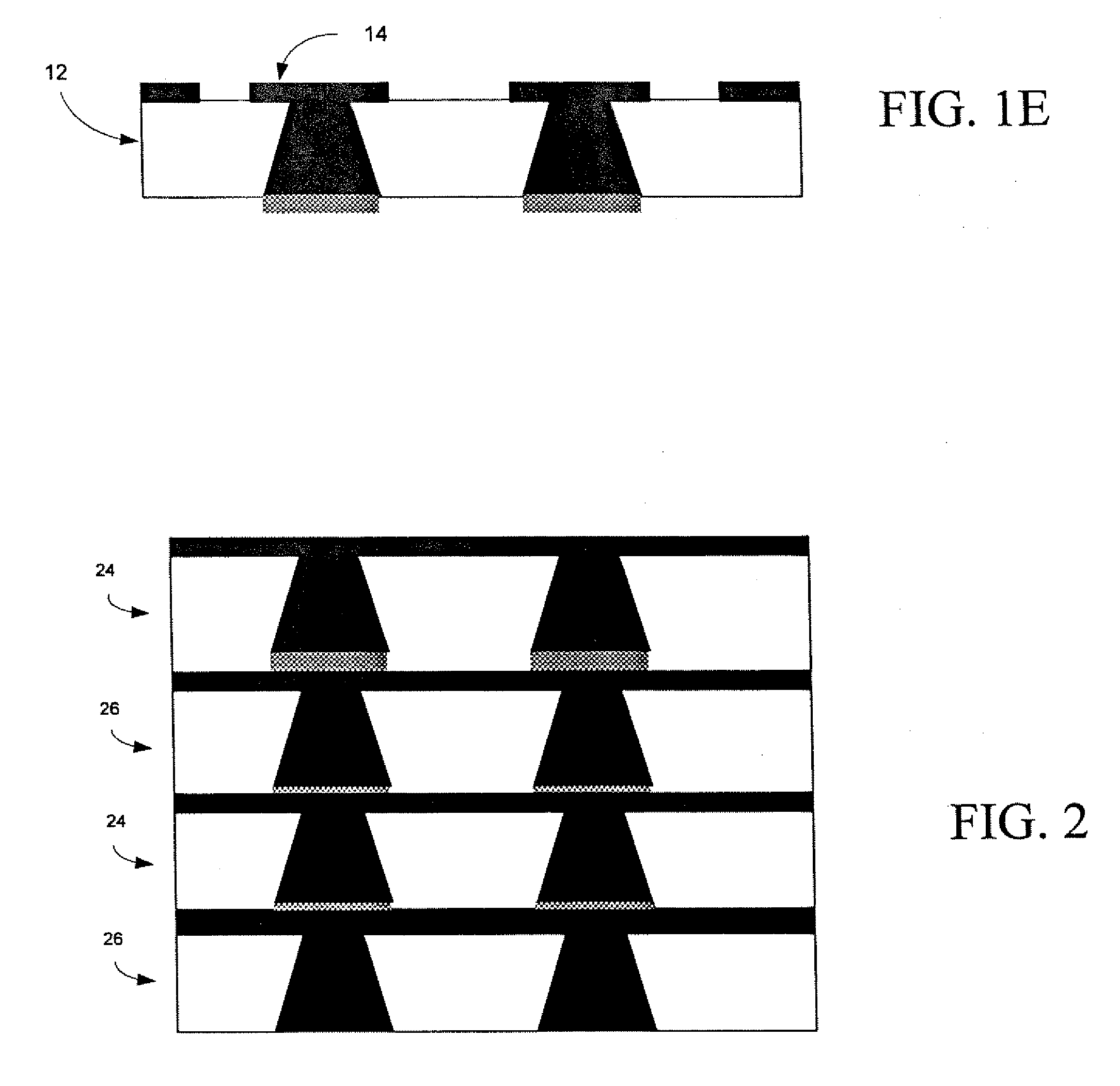

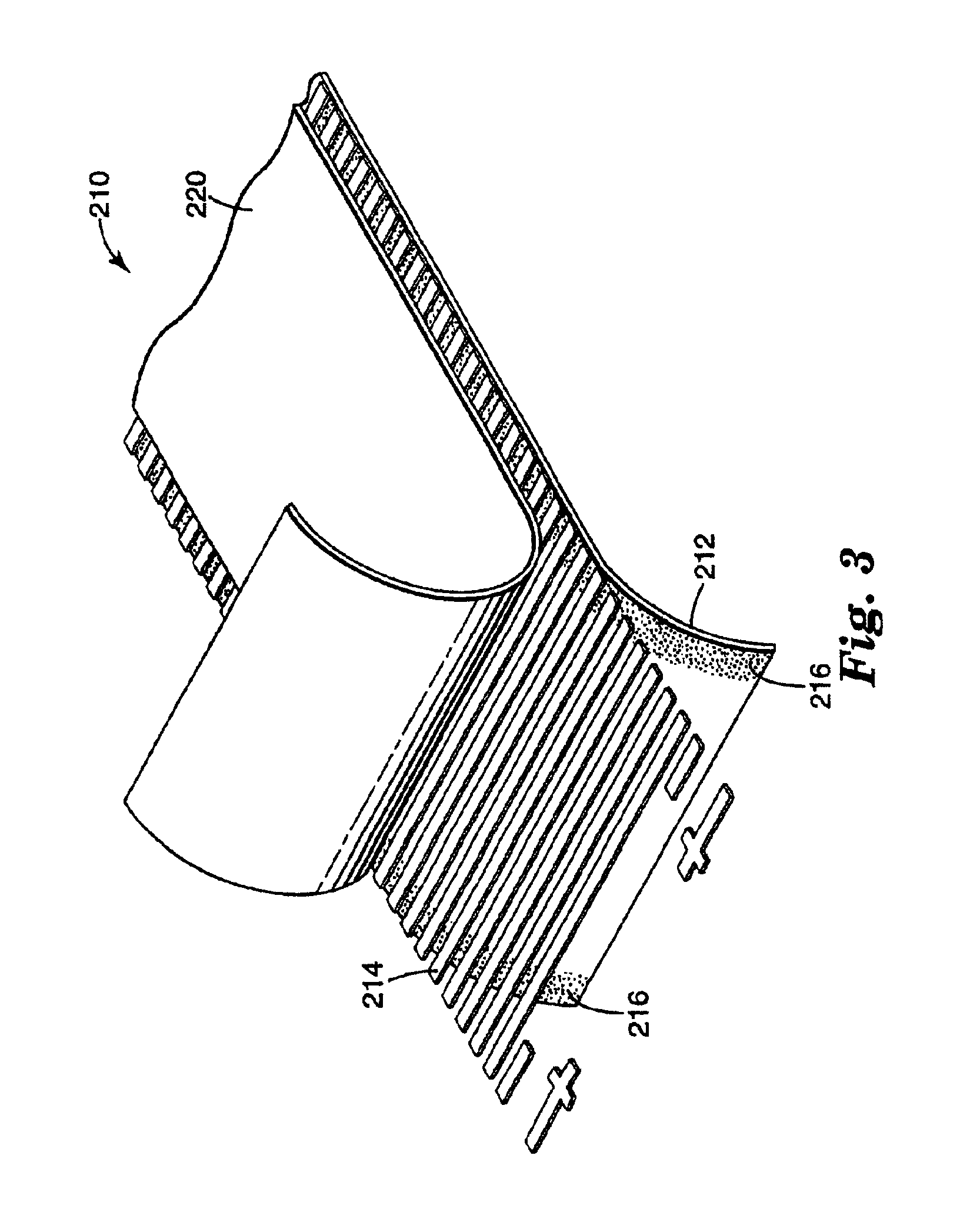

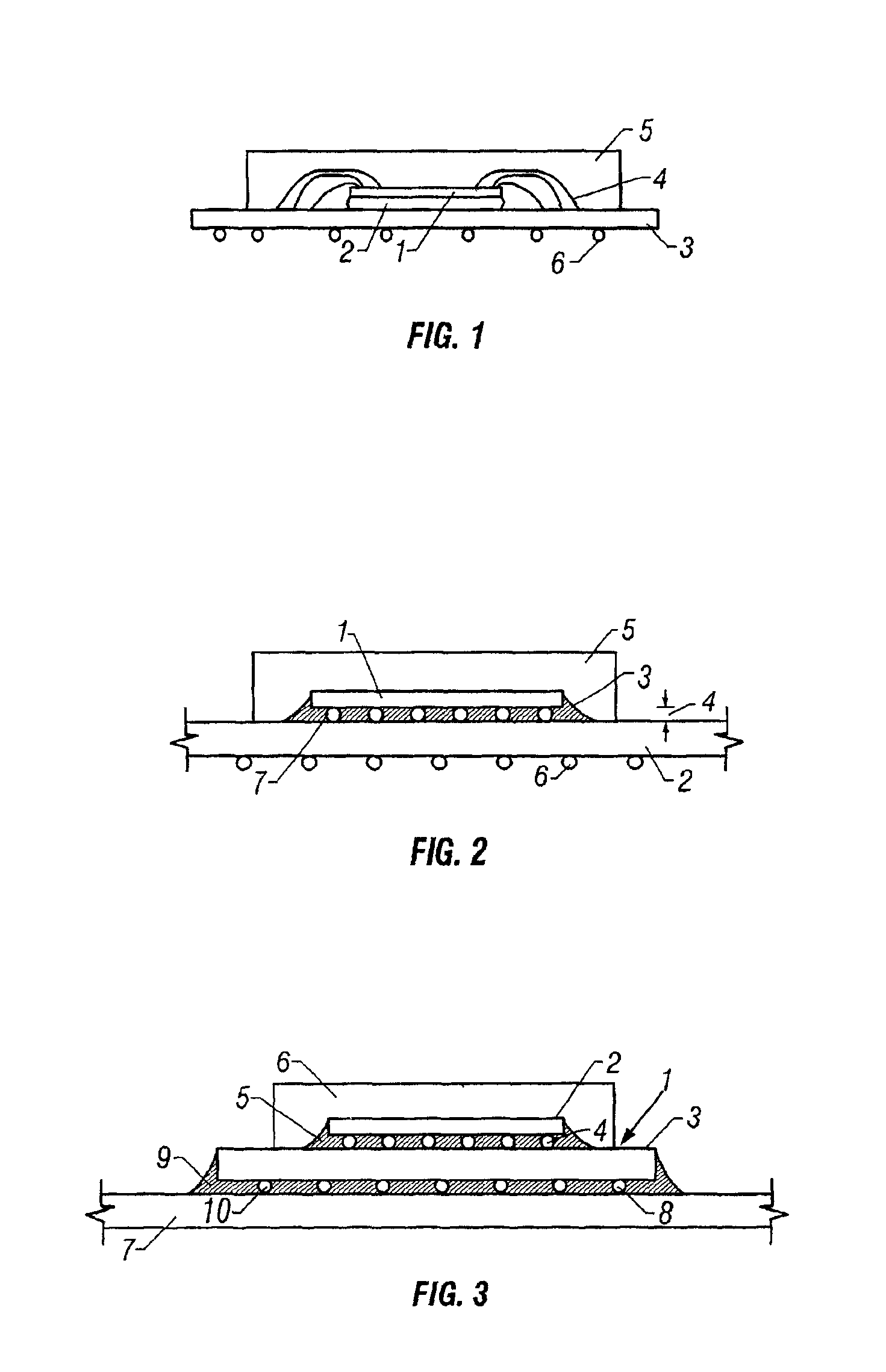

One or more light emitting diode diodes (LEDs) are attached to a printed circuit board. The attached LEDs are connectable with a power source via circuitry of the printed circuit board. An overmolding material is insert molded an over at least portions of the printed circuit board proximate to the LEDs to form a free standing high thermal conductivity material overmolding that covers at least portions of the printed circuit board proximate to the LEDs. The free standing high thermal conductivity material has a melting temperature greater than about 100° C. and has a thermal conductivity greater than or about 1 W / m·K. In some embodiments, the free standing high thermal conductivity material is a thermoplastic material.

Owner:GE LIGHTING SOLUTIONS LLC

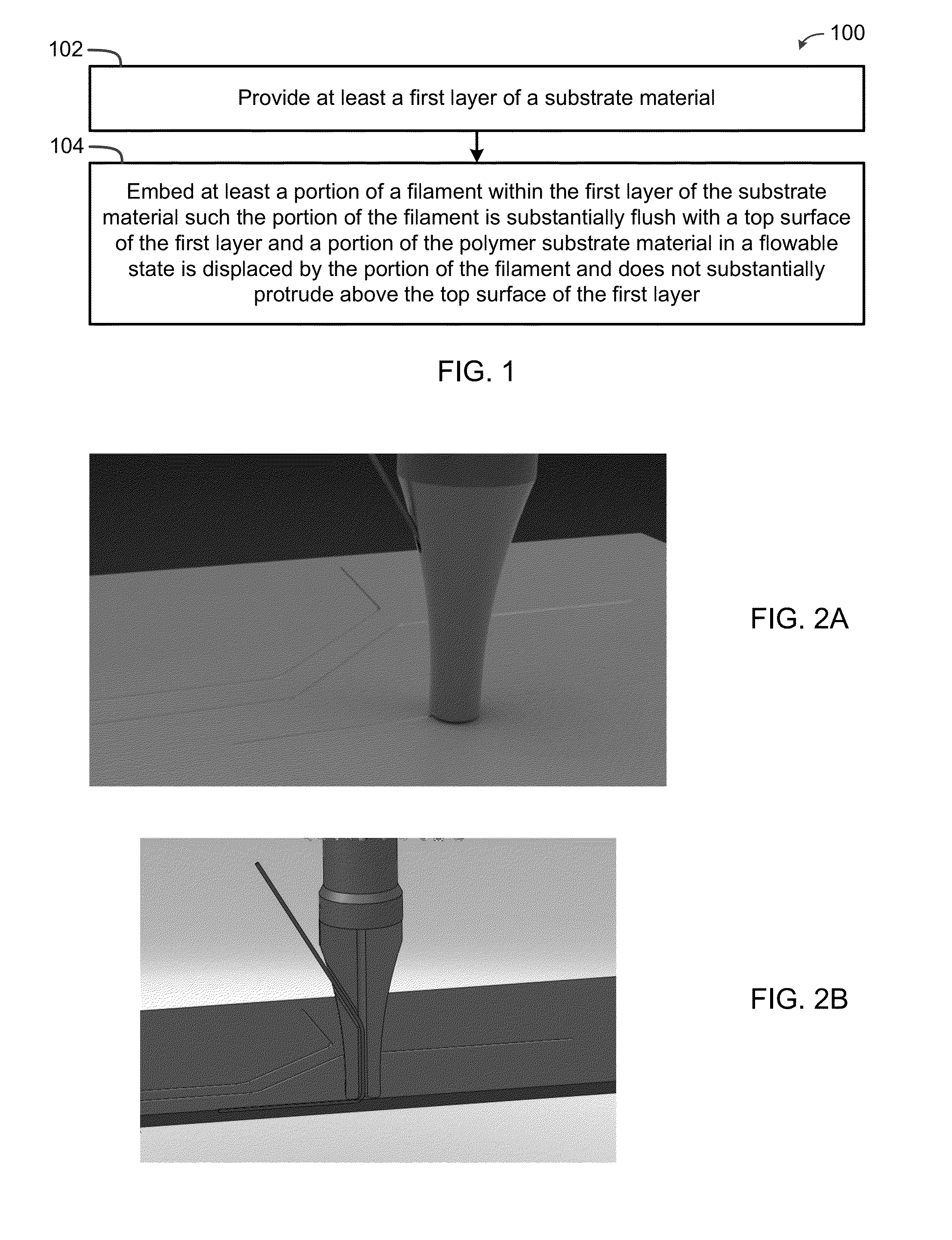

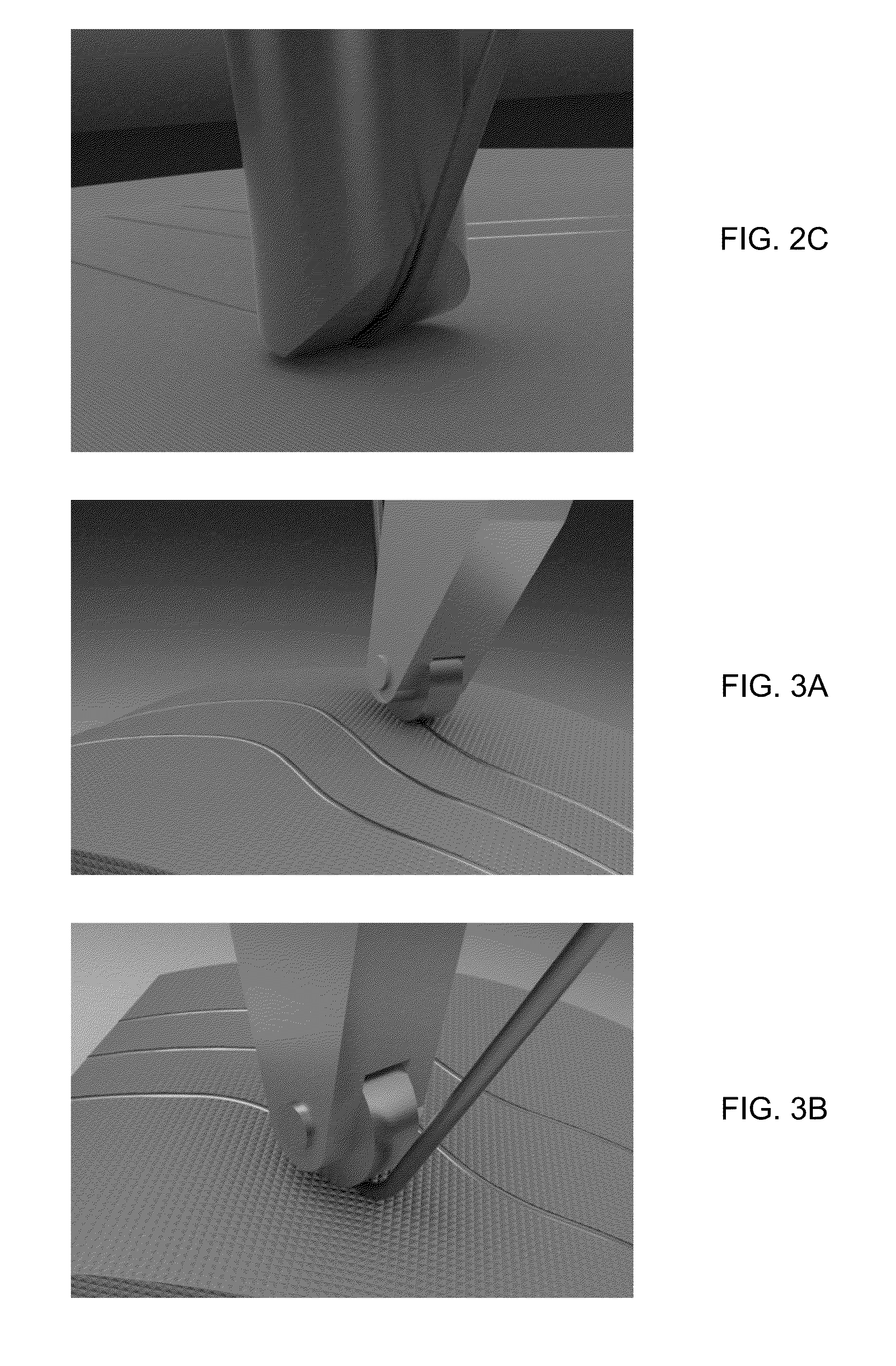

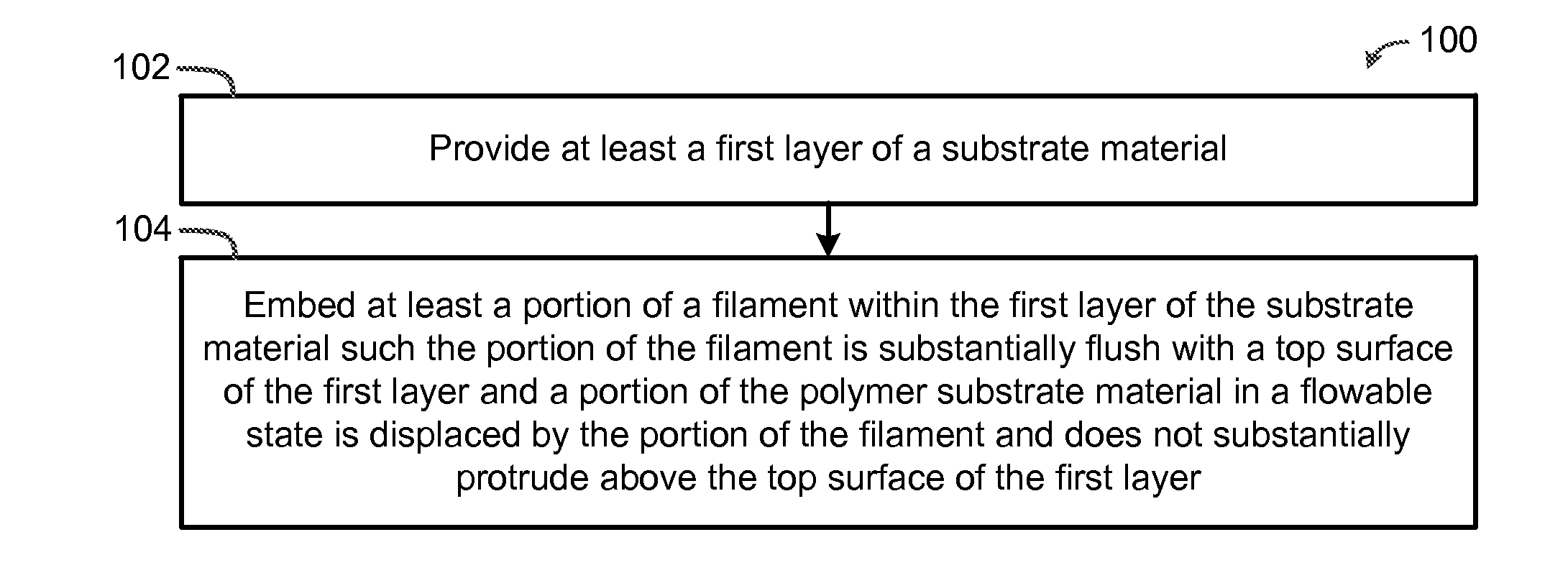

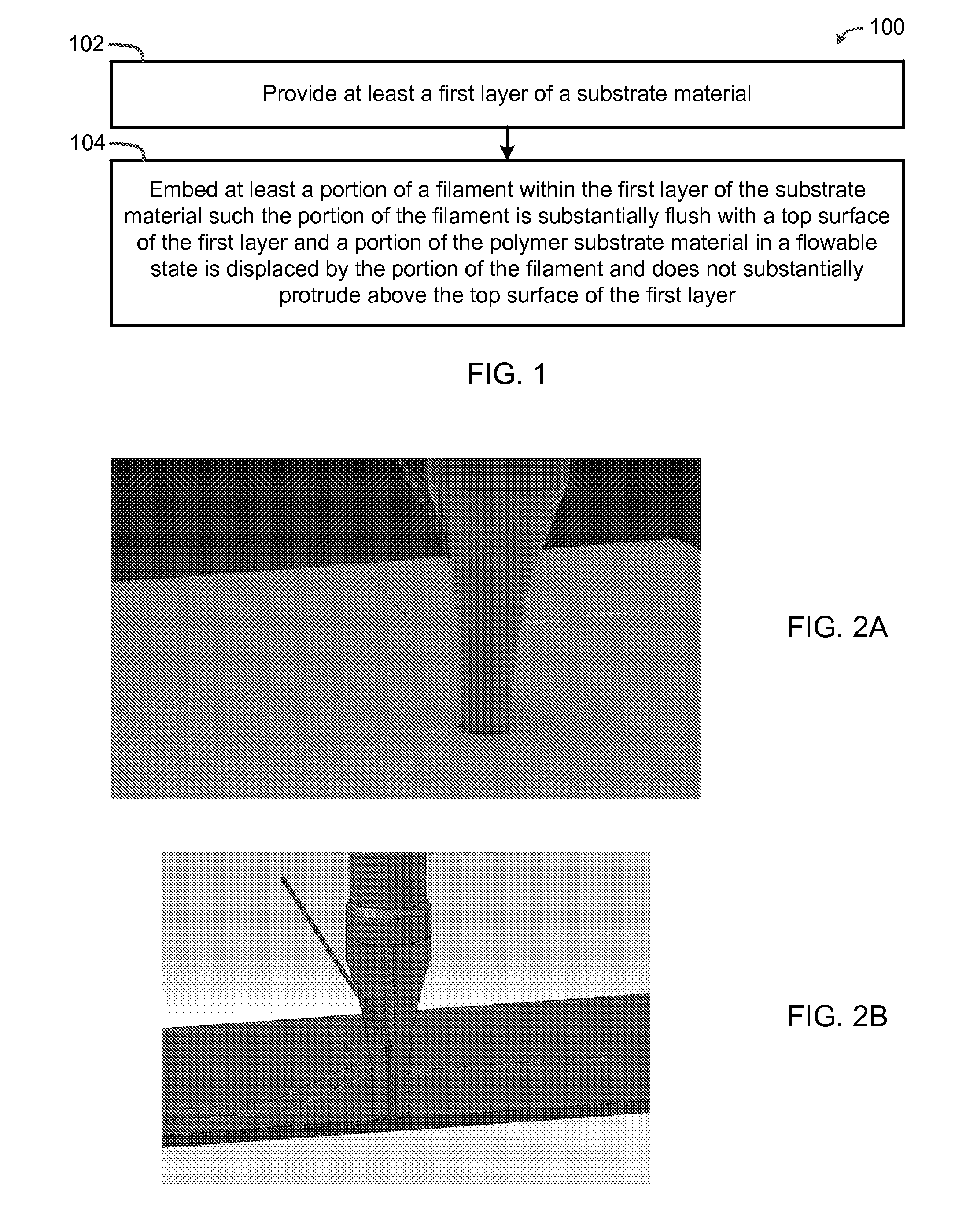

Methods and Systems For Embedding Filaments in 3D Structures, Structural Components, and Structural Electronic, Electromagnetic and Electromechanical Components/Devices

ActiveUS20140268604A1High mechanical strengthElectric discharge heatingCeramic shaping apparatusElectricityEngineering

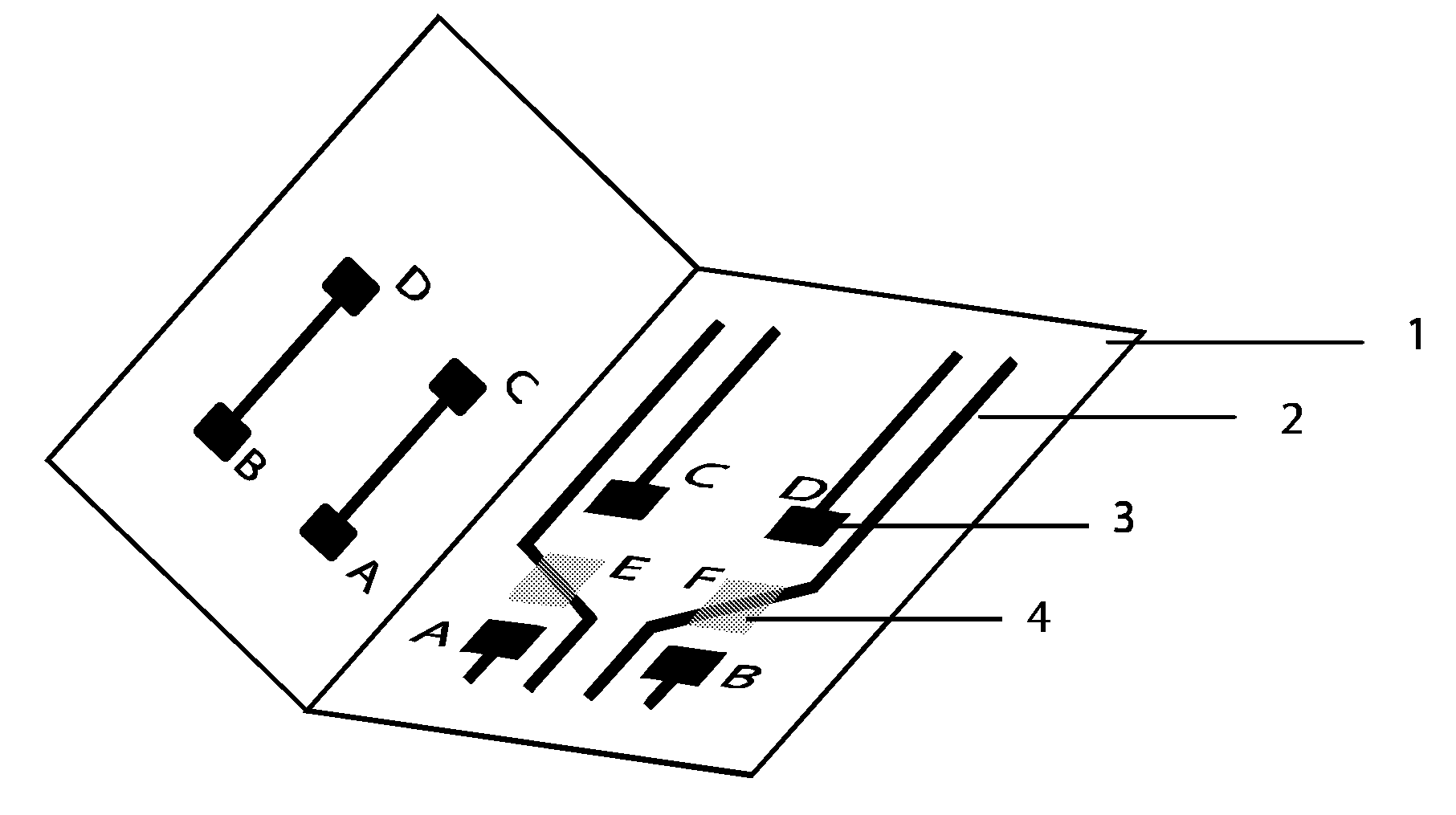

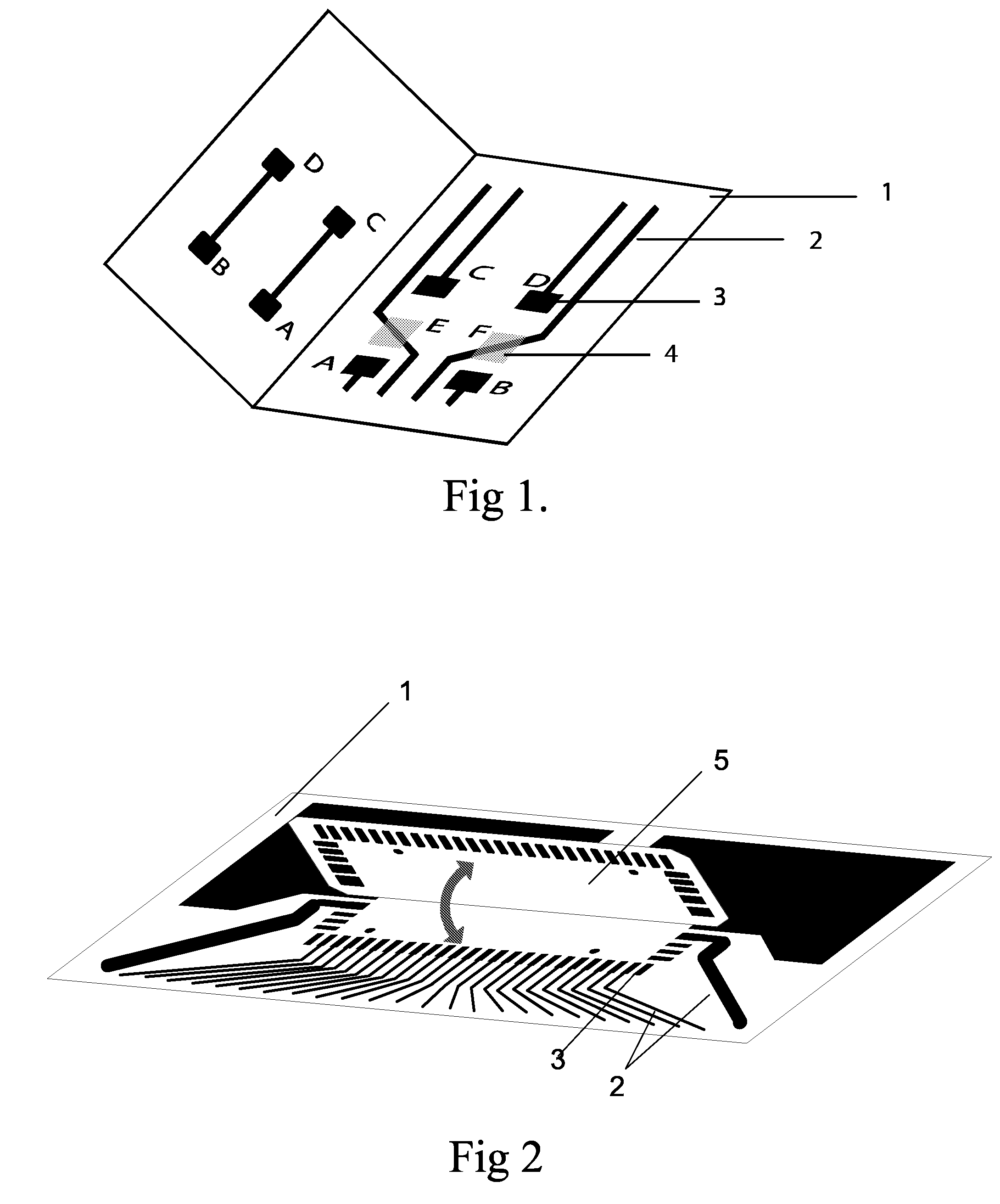

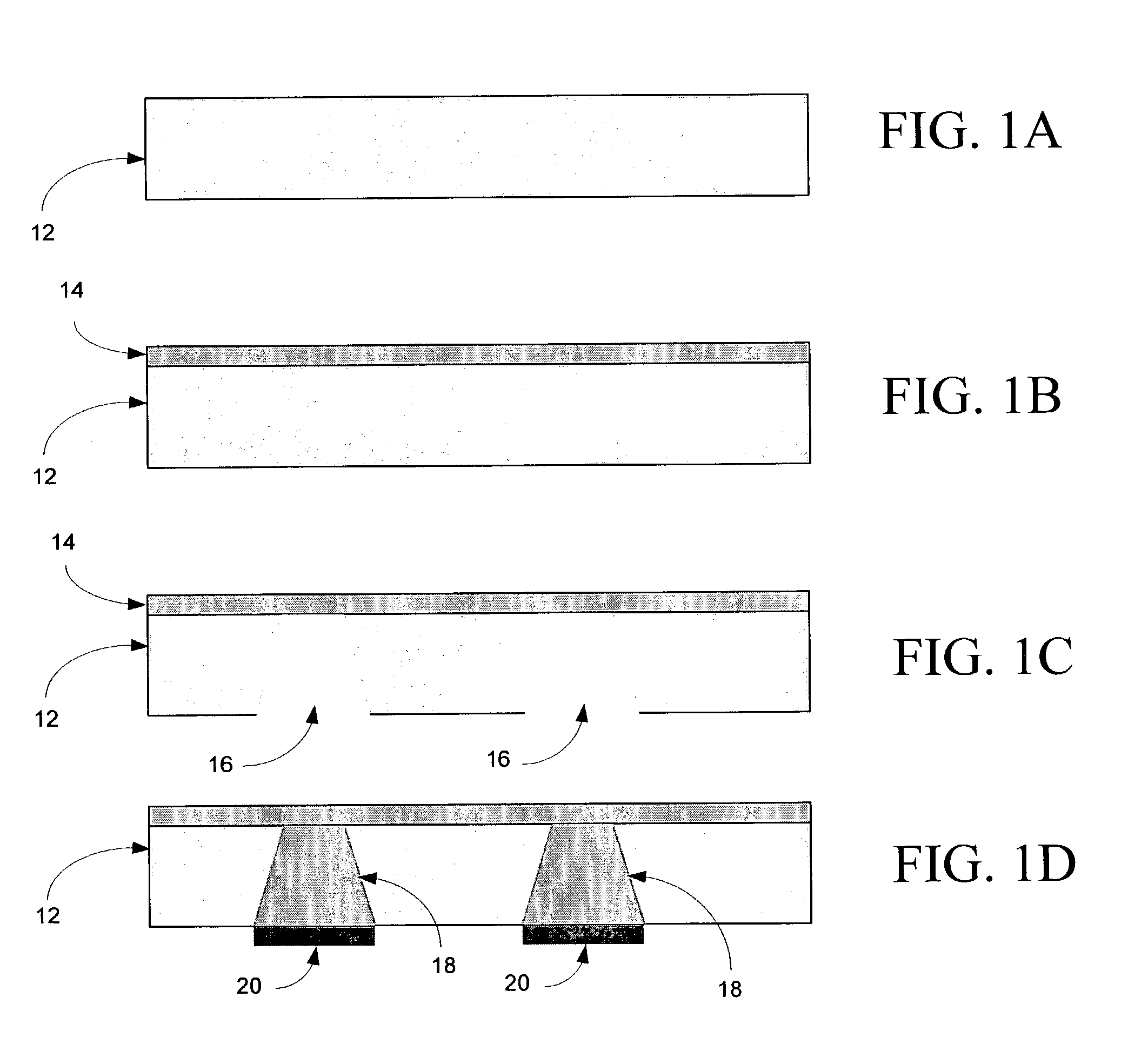

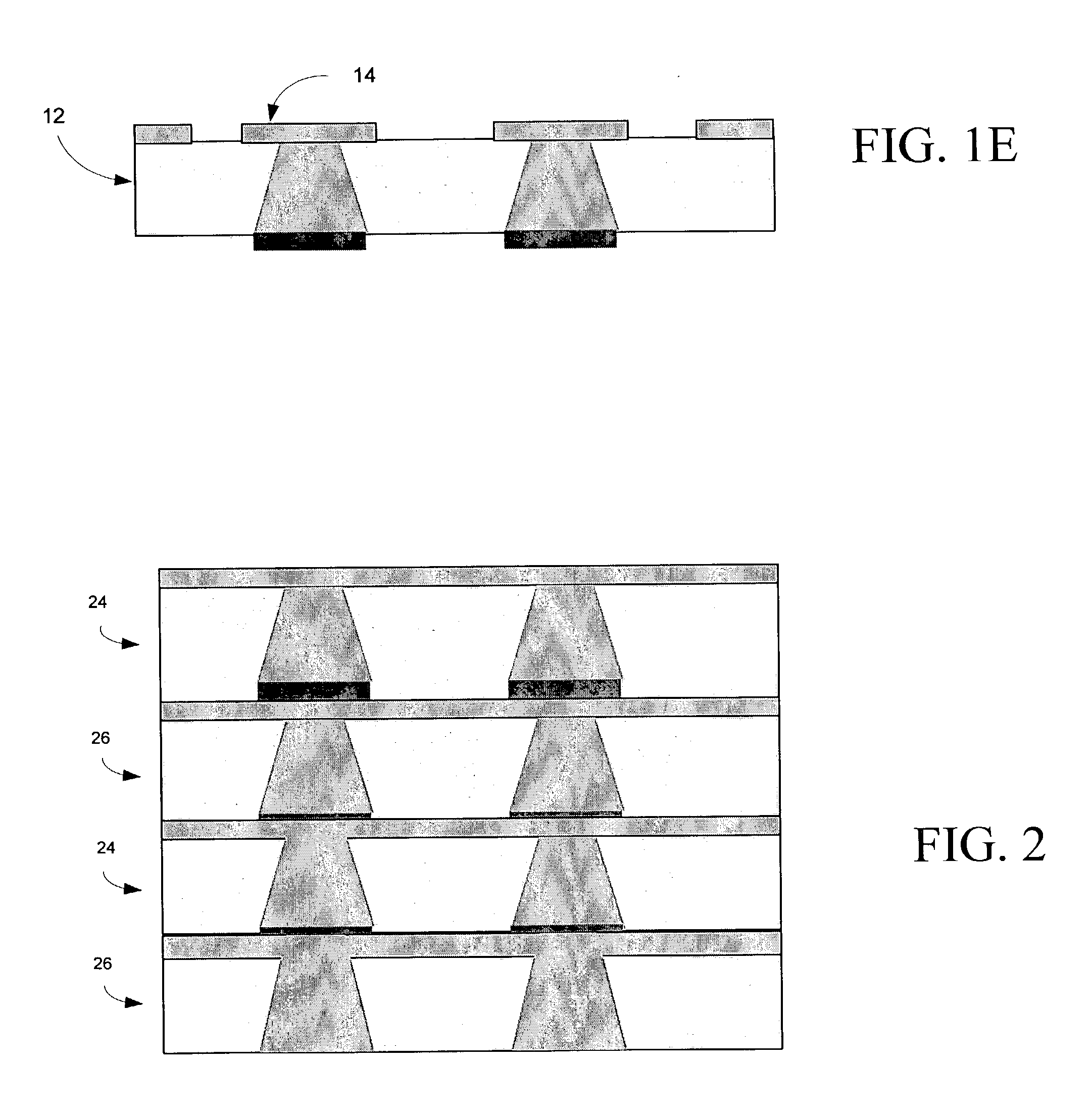

The present invention provides systems and methods for embedding a filament or filament mesh in a three-dimensional structure, structural component, or structural electronic, electromagnetic or electromechanical component / device by providing at least a first layer of a substrate material, and embedding at least a portion of a filament or filament mesh within the first layer of the substrate material such the portion of the filament or filament mesh is substantially flush with a top surface of the first layer and a substrate material in a flowable state is displaced by the portion of the filament and does not substantially protrude above the top surface of the first layer, allowing the continuation of an additive manufacturing process above the embedded filament or filament mesh. A method is provided for creating interlayer mechanical or electrical attachments or connections using filaments within a three-dimensional structure, structural component, or structural electronic, electromagnetic or electromechanical component / device.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

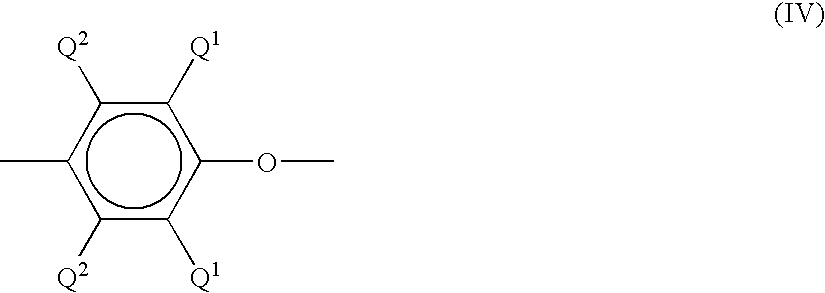

High dielectric constant laser direct structuring materials

ActiveUS20090292051A1High dielectric constantReduce lossDuplicating/marking methodsLiquid/solution decomposition chemical coatingOptoelectronicsPersonal computer

High dielectric constant thermoplastic compositions that are capable of being used in a laser direct structuring process. The compositions include a thermoplastic base resin, a laser direct structuring additive, and at least one ceramic filler. The compositions provide a high dielectric constant, low loss tangent thermoplastic composition. The compositions can be used in a variety of applications such as personal computers, notebook and portable computers, cell phone antennas and other such communications equipment, medical applications, RFID applications, and automotive applications.

Owner:SHPP GLOBAL TECH BV

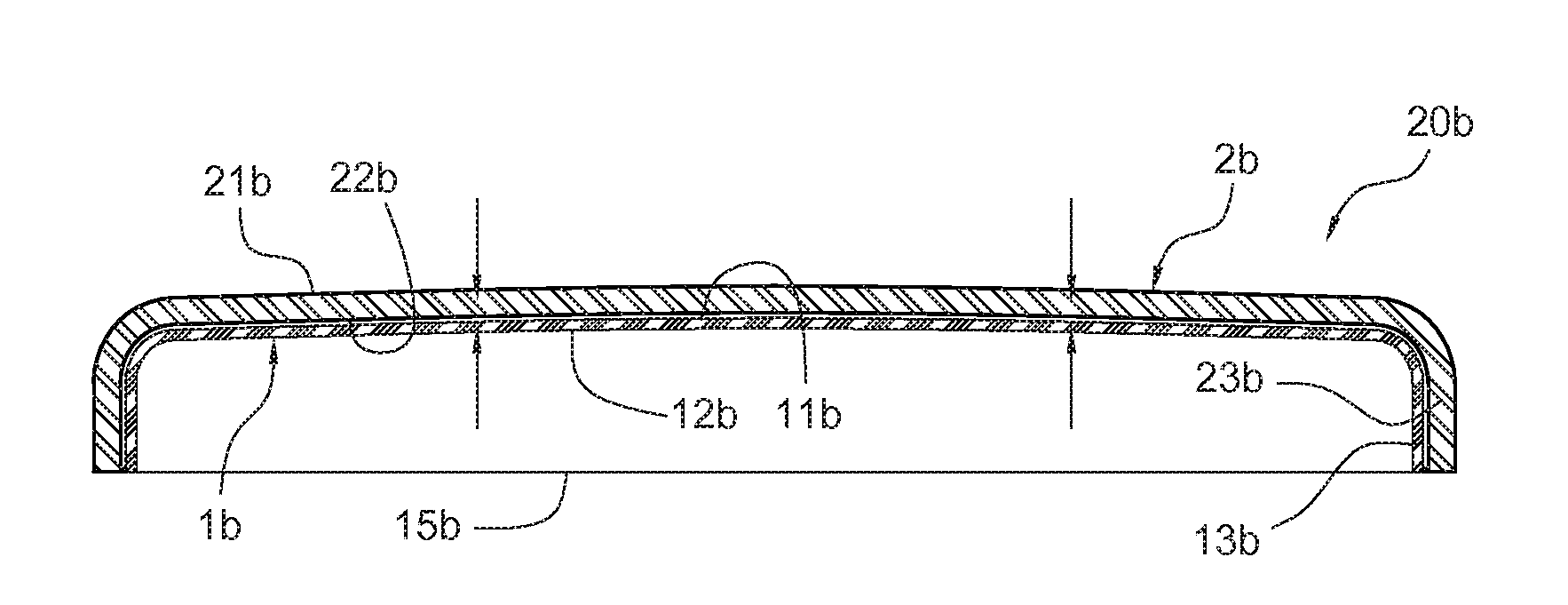

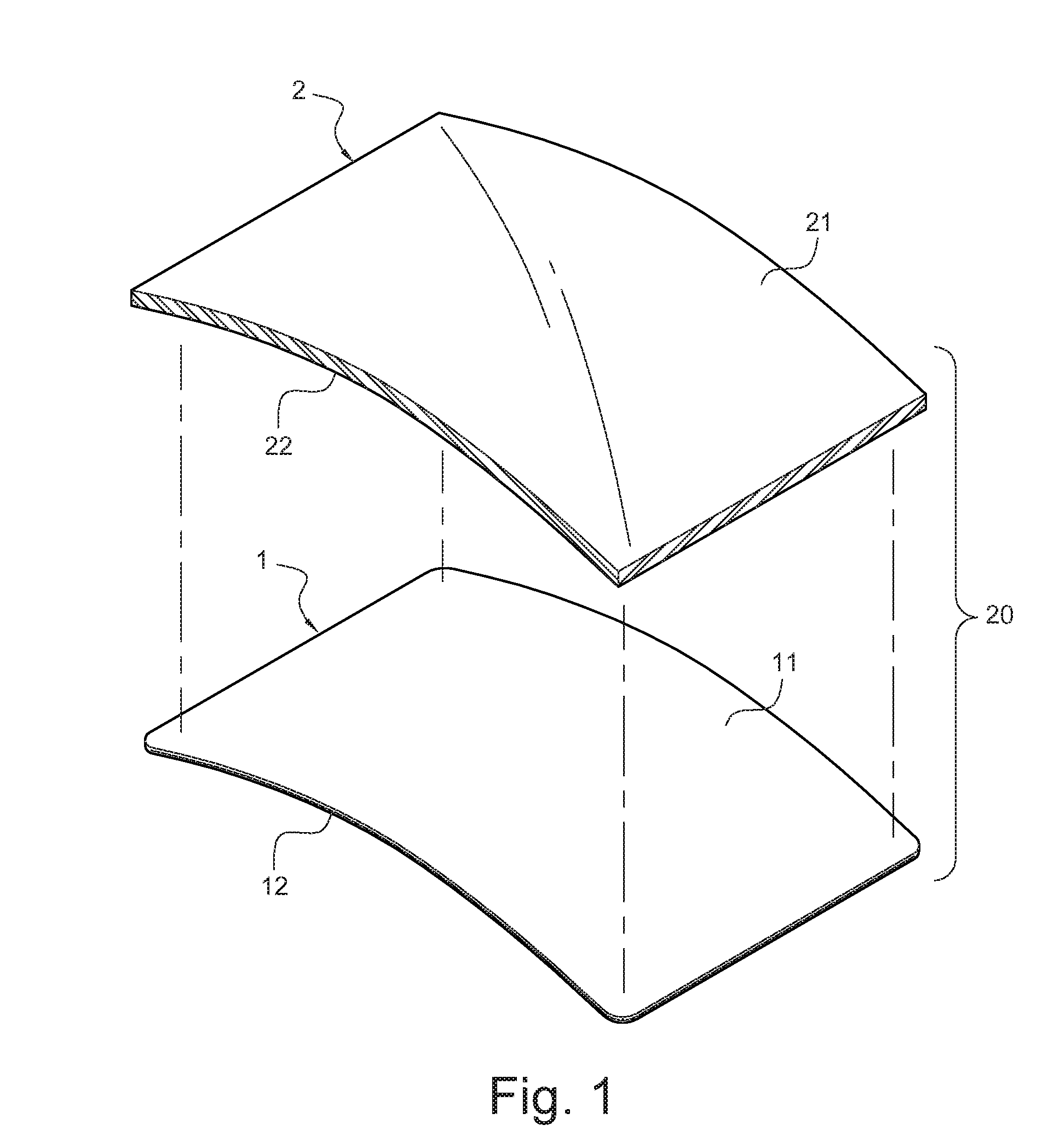

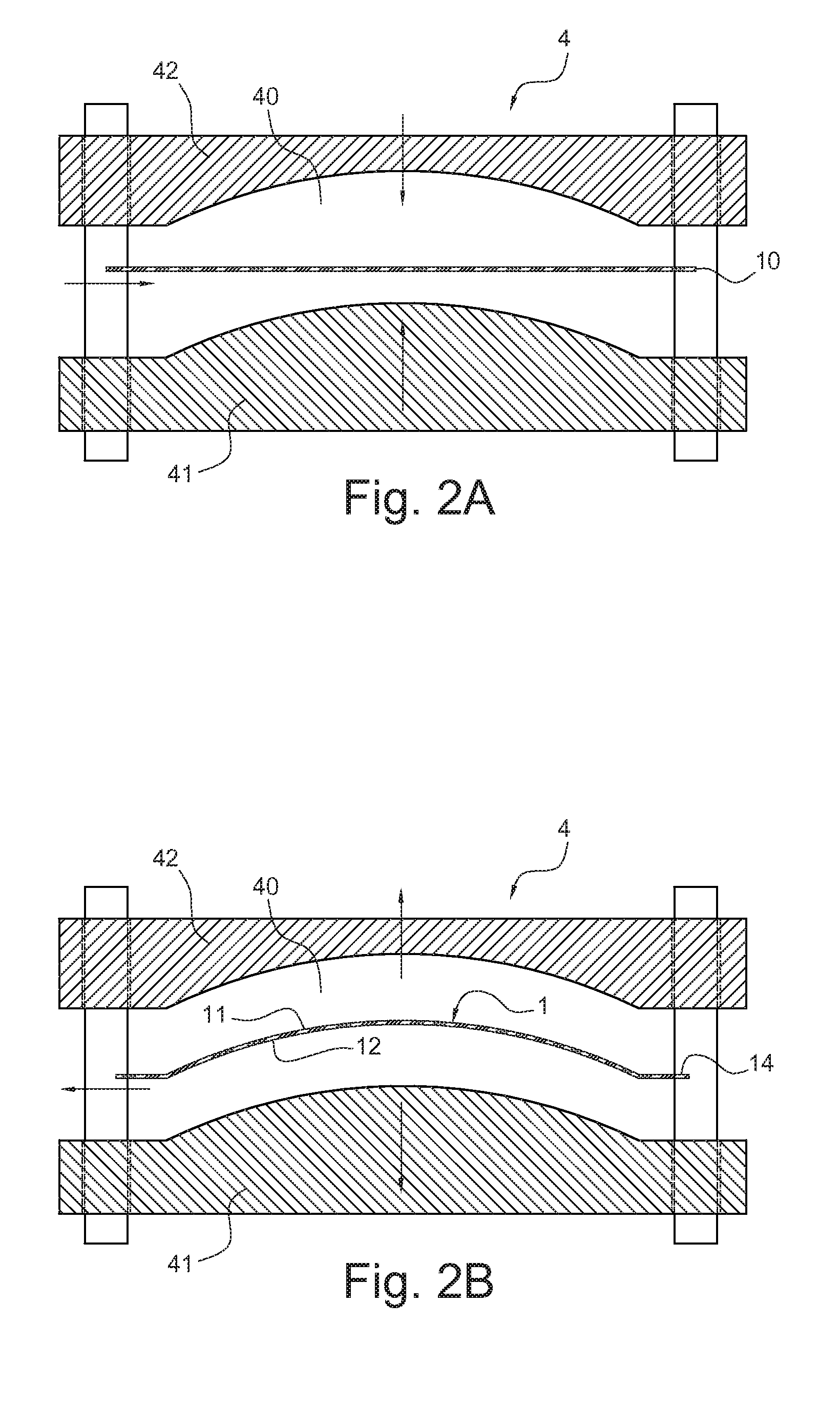

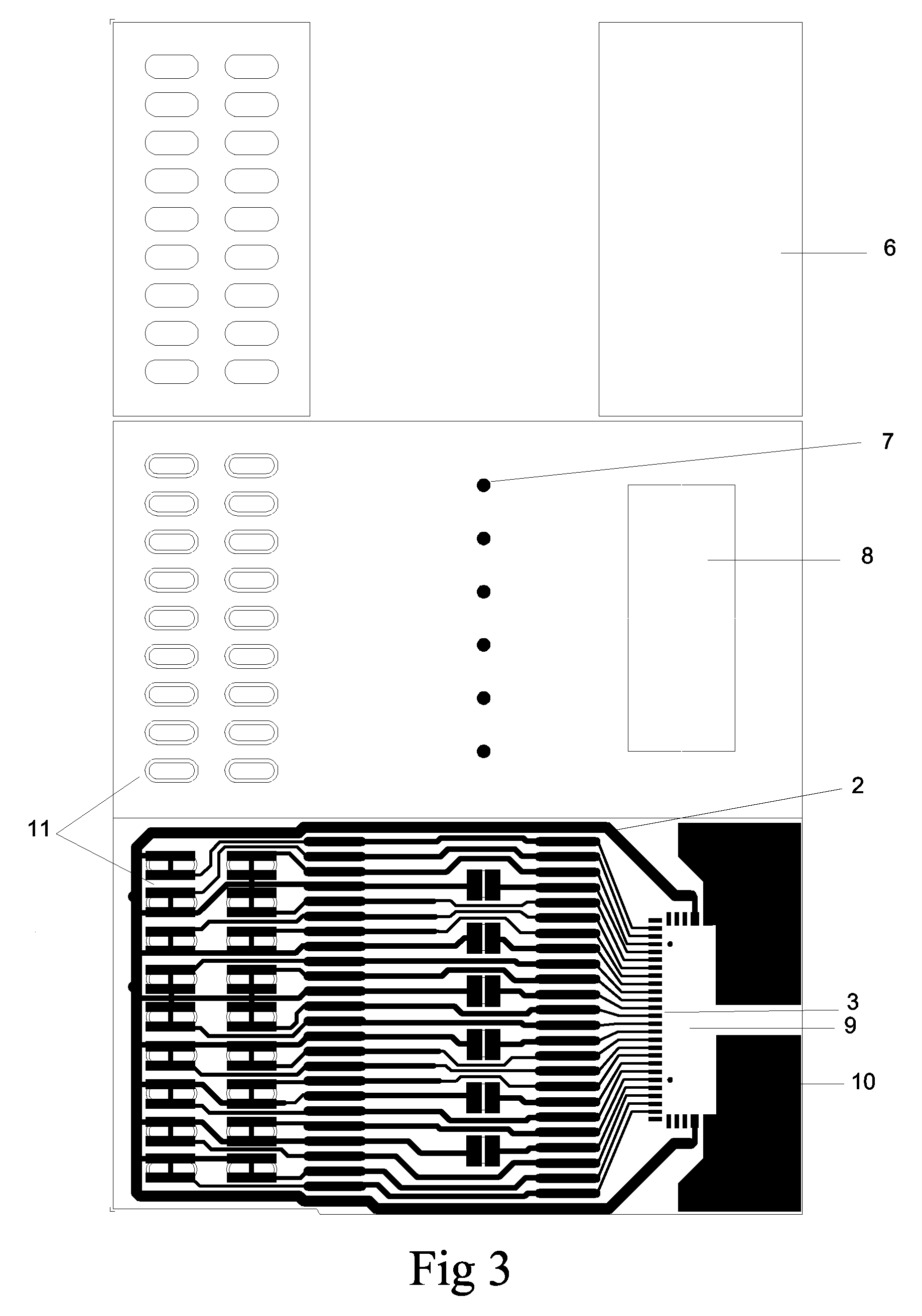

Curved capacitive touch panel and manufacture method thereof

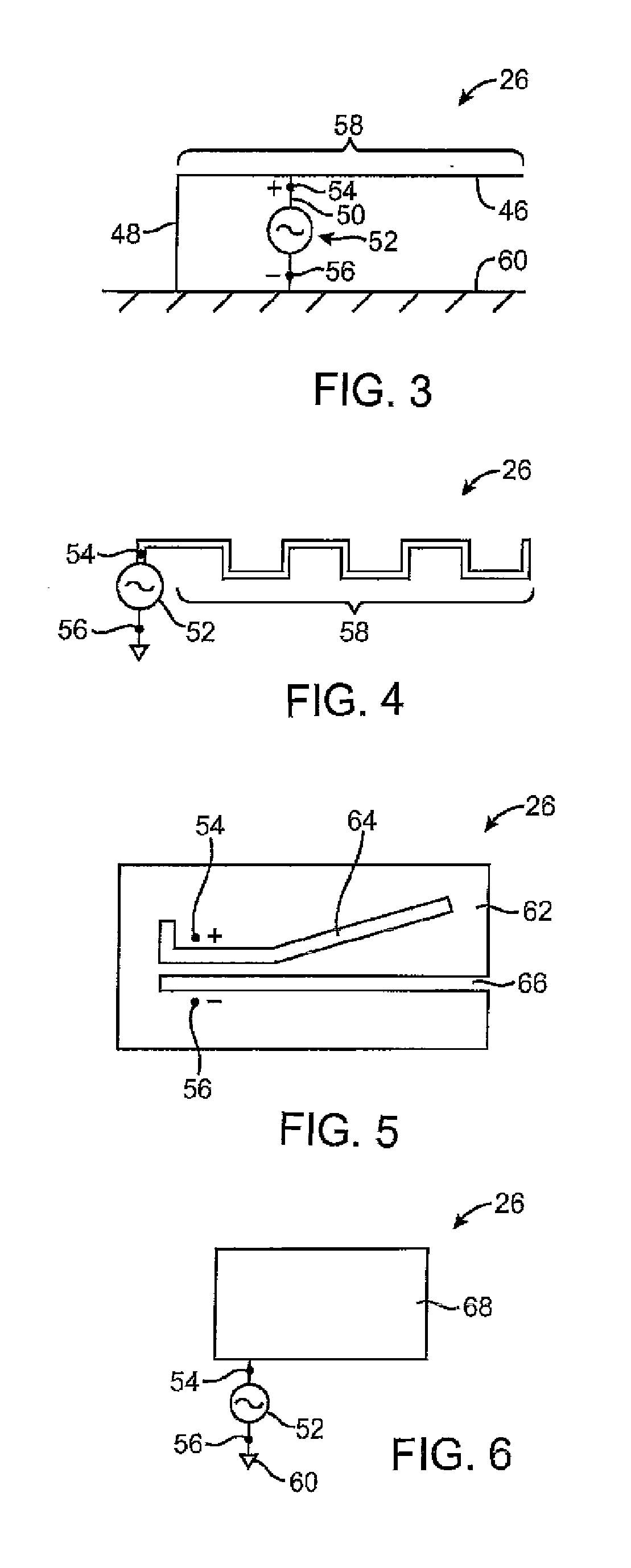

ActiveUS20100103138A1Laminating printed circuit boardsThermoplastic polymer dielectricsFlexible electronicsTouch panel

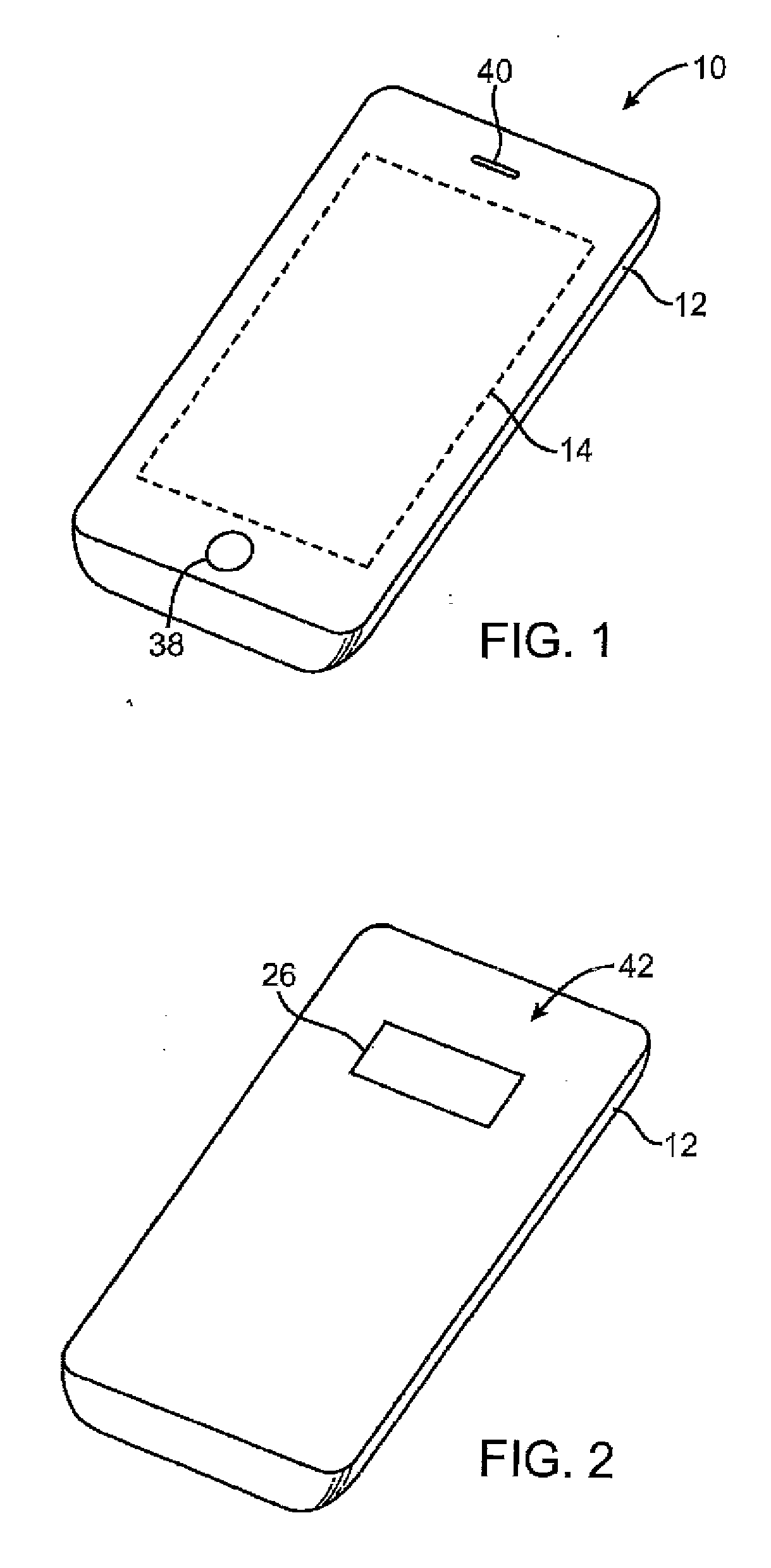

A manufacture method and structure of a curved capacitive touch panel is disclosed. A flat flexible printed circuit board (FPCB) with capacitive touch sensing / detecting capability is provided, followed by subjecting the flat FPCB to compressing molding to form a curved FPCB. Subsequently, a curved substrate is provided, wherein an outer curved surface of the curved FPCB is bonded to an inner curved surface of the substrate, thereby forming the curved capacitive touch panel.

Owner:TRENDON TOUCH TECHNOLOGY CORPORATION

Anisotropic conductive adhesive and method for preparation thereof and an electronic apparatus using said adhesive

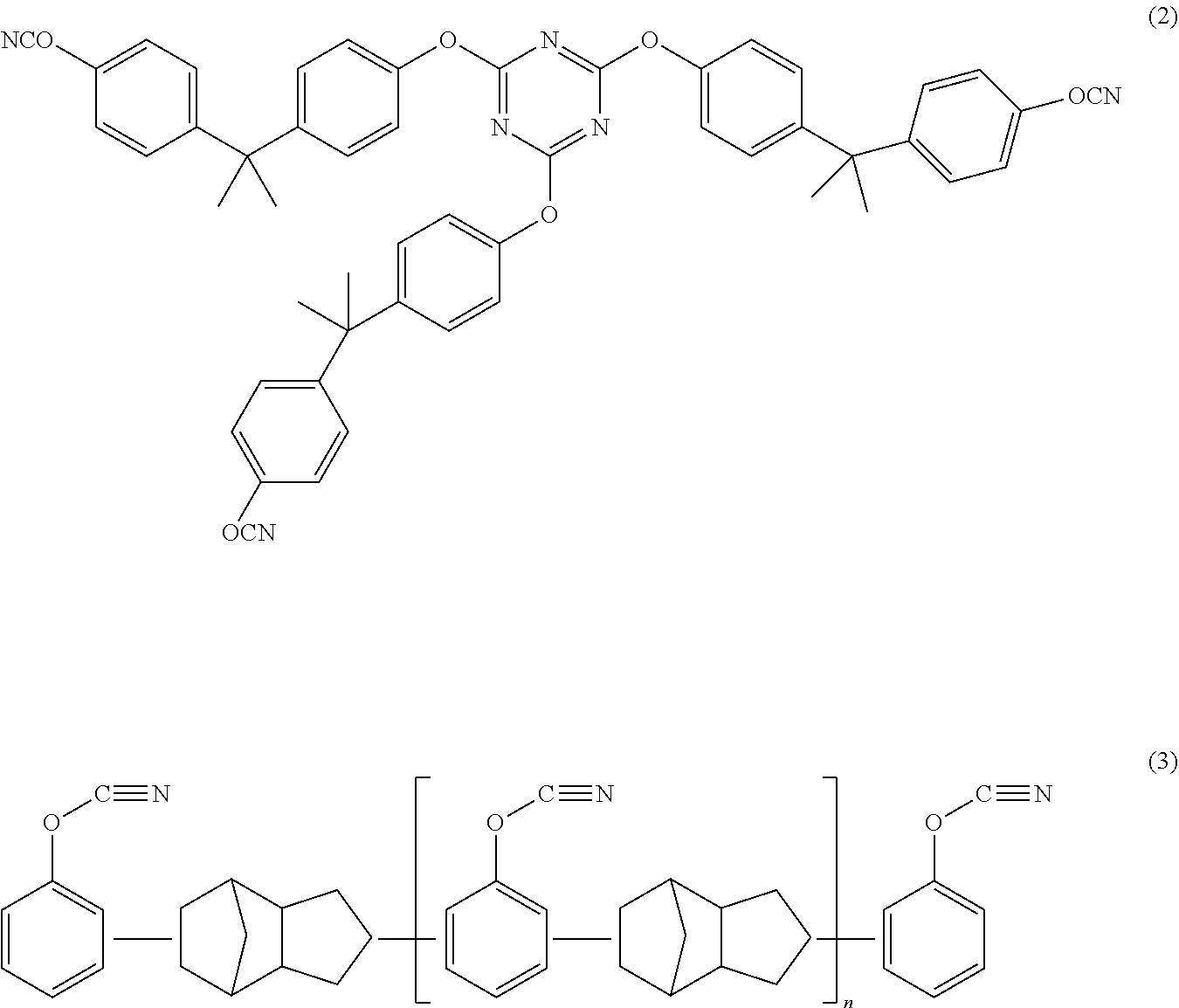

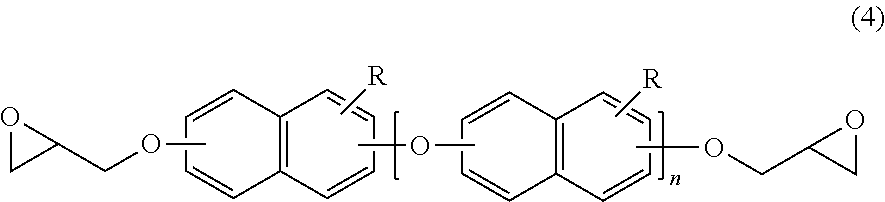

InactiveUS6039896AReduce weightEasy to manufactureNon-macromolecular adhesive additivesDigital data processing detailsEpoxyPhosphoric Acid Esters

An anisotropic conductive adhesive contains conductive particles dispersed in a resin composition, wherein the resin composition includes a radical polymerization resin (A), an organic peroxide (B), a thermoplastic elastomer (C) and a phosphoric ester (D). The resin composition can further contain an epoxy silane coupling agent (E) represented by formula (2) or (3). The resin composition is mixed with other components after the radical polymerization resin (A), the thermoplastic elastomer (C), the phosphoric ester (D) and the epoxy silane coupling agent (E) are reacted. It is also possible to preliminarily react only the phosphoric ester (D) and the epoxy silane coupling agent (E) and to react the product of the preliminary reaction with the radical polymerization resin (A) and the thermoplastic elastomer (C), and then to add other components. The anisotropic conductive adhesive of the present invention can be used for electrical joining of electronic or electric parts of electrical apparatus.

Owner:SUMITOMO BAKELITE CO LTD

Methods for Fabricating Three-Dimensional All Organic Interconnect Structures

InactiveUS20070267138A1High frequency and high bandwidth applicationsSemiconductor/solid-state device detailsSolid-state devicesLiquid crystallineMaterials science

The present invention includes methods for making liquid crystalline polymer (LCP) interconnect structures using a high temperature and low temperature single sided LCP, where both the high and low temperature LCP are provided with a z-axis connection. The single sided conductive layer is a bus layer to form z-axis conductive stud within the high and low temperature LCP. High and low temperature LCP layers are etched or built up to form circuit patterns and subsequently bonded together to form final multilayer circuit pattern where the low temperature LCP melts to form both dielectric to dielectric bond to high temperature LCP circuit layer, and dielectric to conductive bond.

Owner:GEORGIA TECH RES CORP

Use Of Heat-Activated Adhesive For Manufacture And A Device So Manufactured

InactiveUS20080191174A1Promote degradationIncrease resistanceCircuit security detailsConductive materialElectrical connectionMechanical stability

The invention is based on use of a heat-activated adhesive for manufacturing of intelligent devices comprising printed conductive electronics on a flexible substrate, where the adhesive is an anisotropic electrically conductive adhesive and is applied to the substrate as a thin film which can be used for electrical connections and for providing mechanical stability to the printed conductive electronics.

Owner:CYPAK

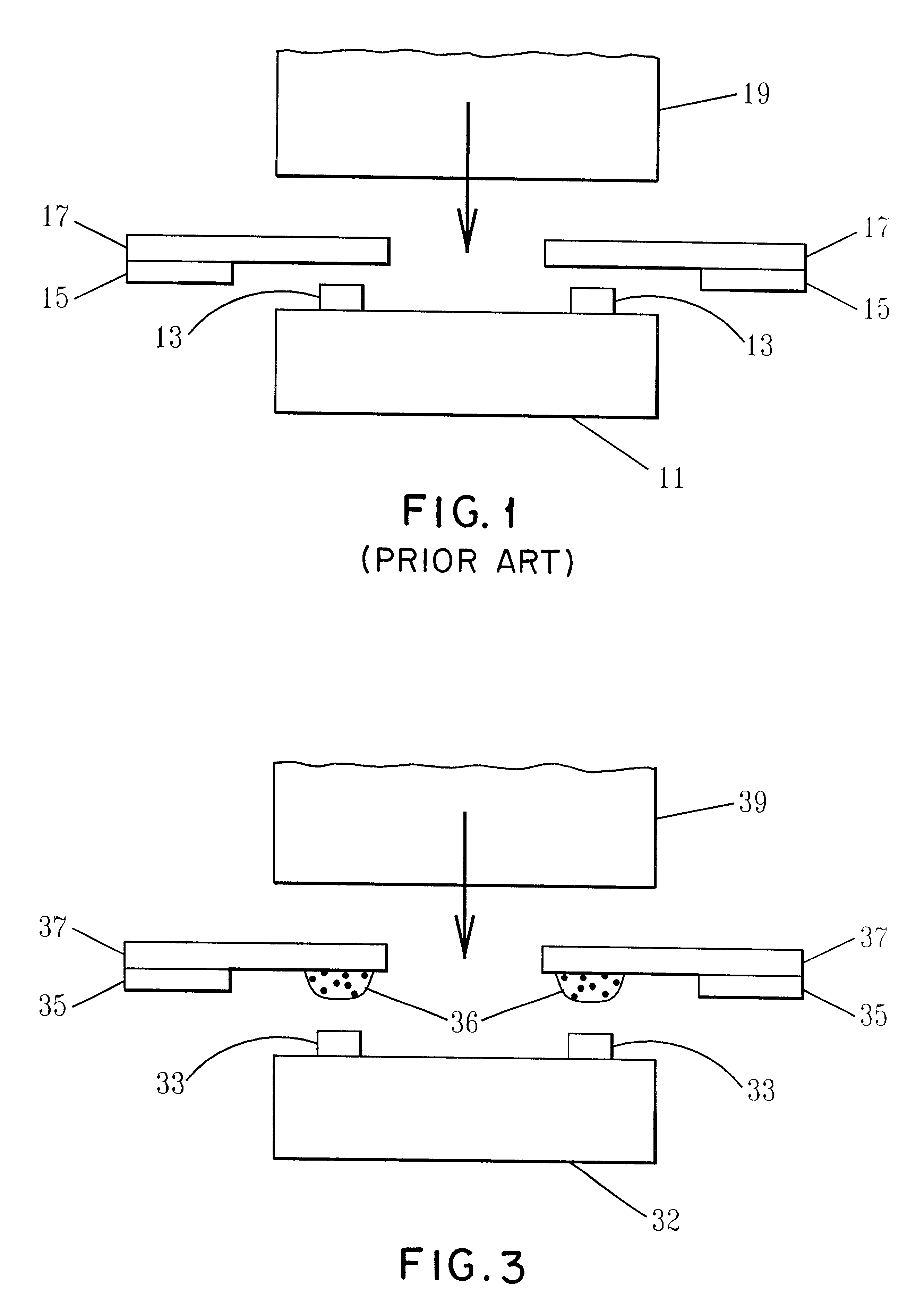

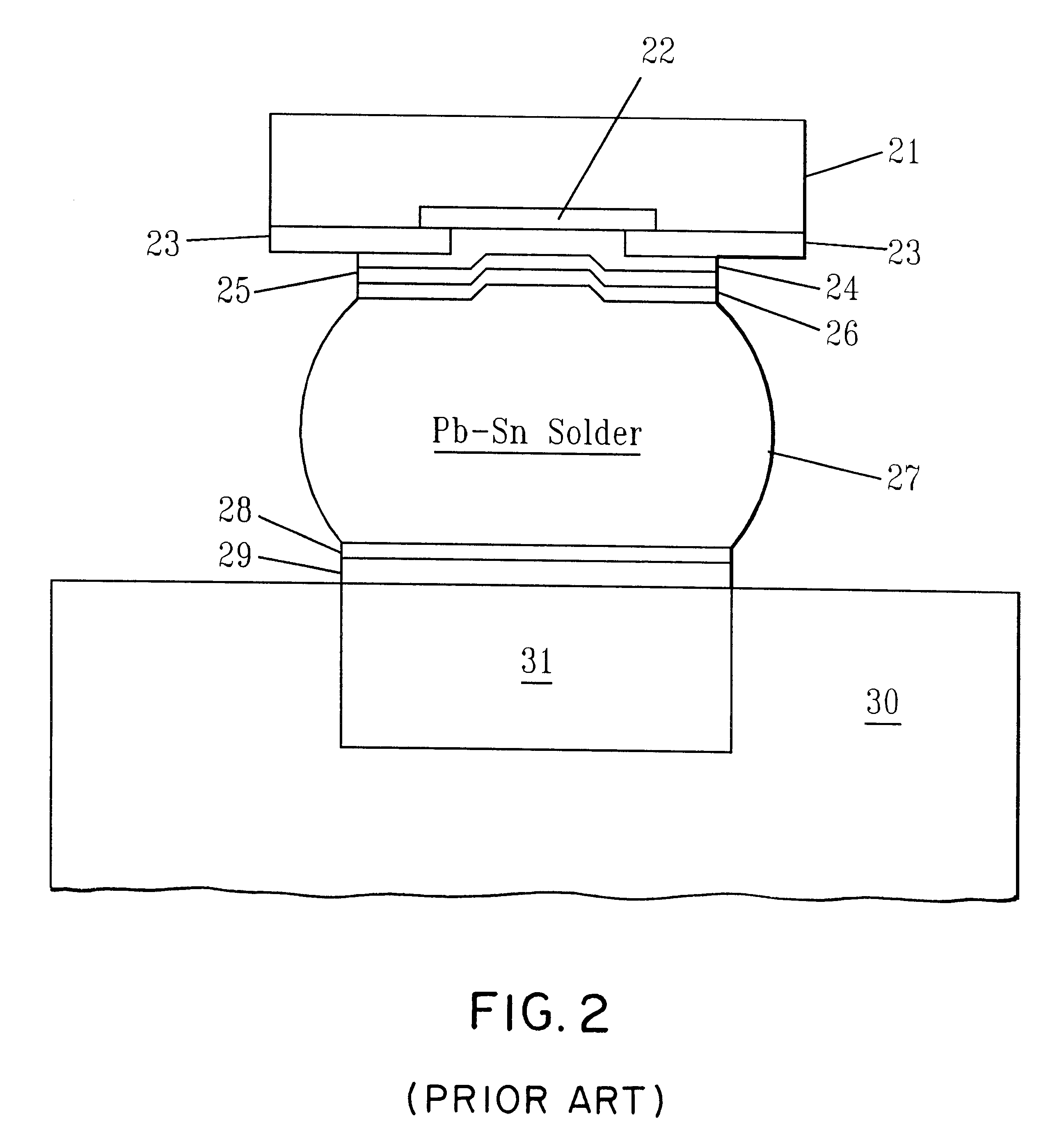

Structure employing electrically conductive adhesives

InactiveUS6337522B1Stable TAB joint structureImprove fatigue lifePrinted circuit assemblingLayered productsInterfacial reactionActive-matrix liquid-crystal display

A new interconnection scheme is disclosed for a tape automated bonding (TAB) package, a flip chip package and an active matrix liquid crystal display (AMLCD) panel, where an electrically conducting adhesive is used to form an electrical interconnection between an active electronic device and its components. The electrically conducting adhesive can be a mixture comprising a polymer resin, a no-clean solder flux, a plurality of electrically conducting particles with an electrically conducting fusible coating which provides a metallurgical bond between the conducting particles as well as to the substrates. The advantages of using the electrically conducting adhesives include reduction in bonding pressure and / or bonding temperature, control of interfacial reactions, promotion of stable metallurgical bonds, enhanced reliability of the joints, and others.

Owner:AU OPTRONICS CORP

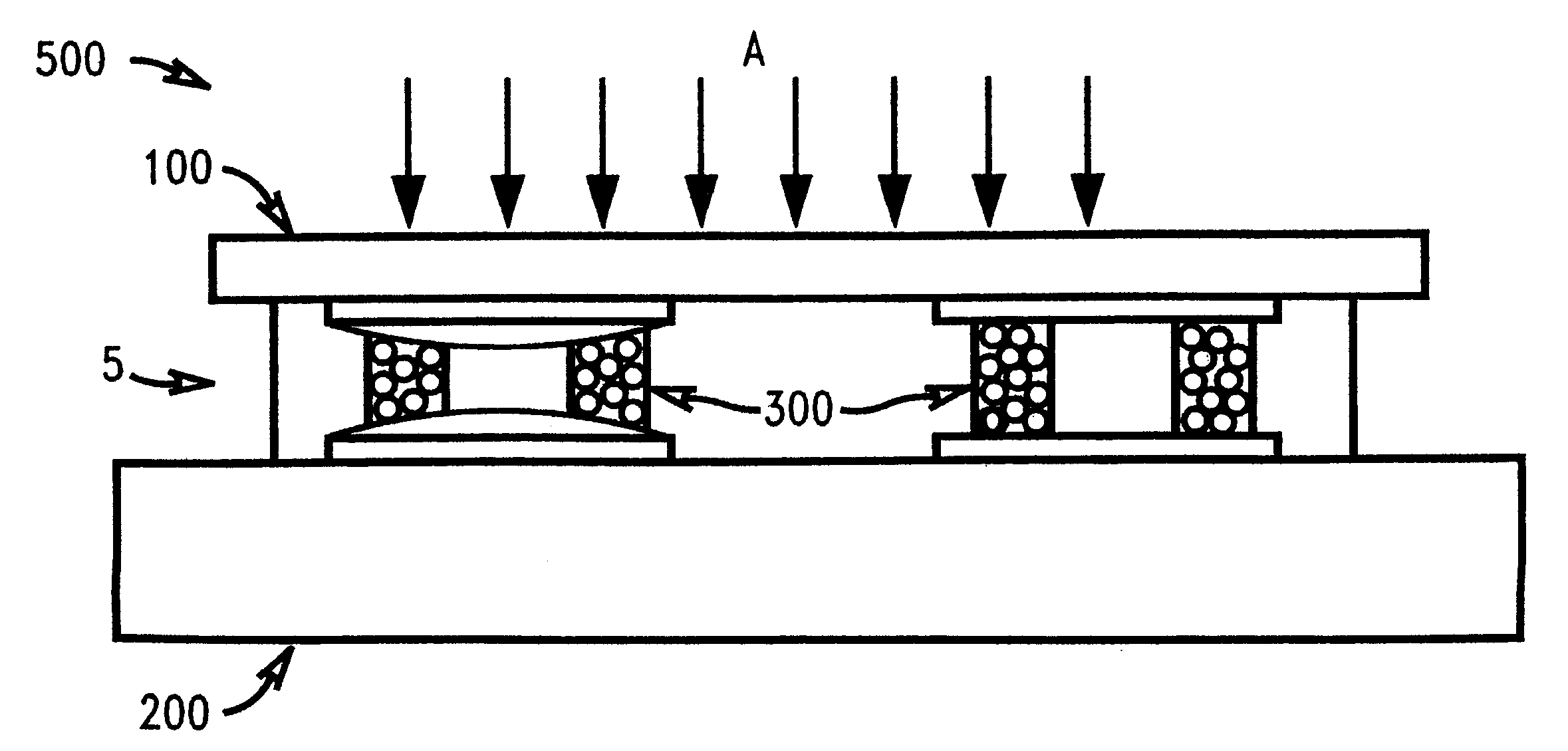

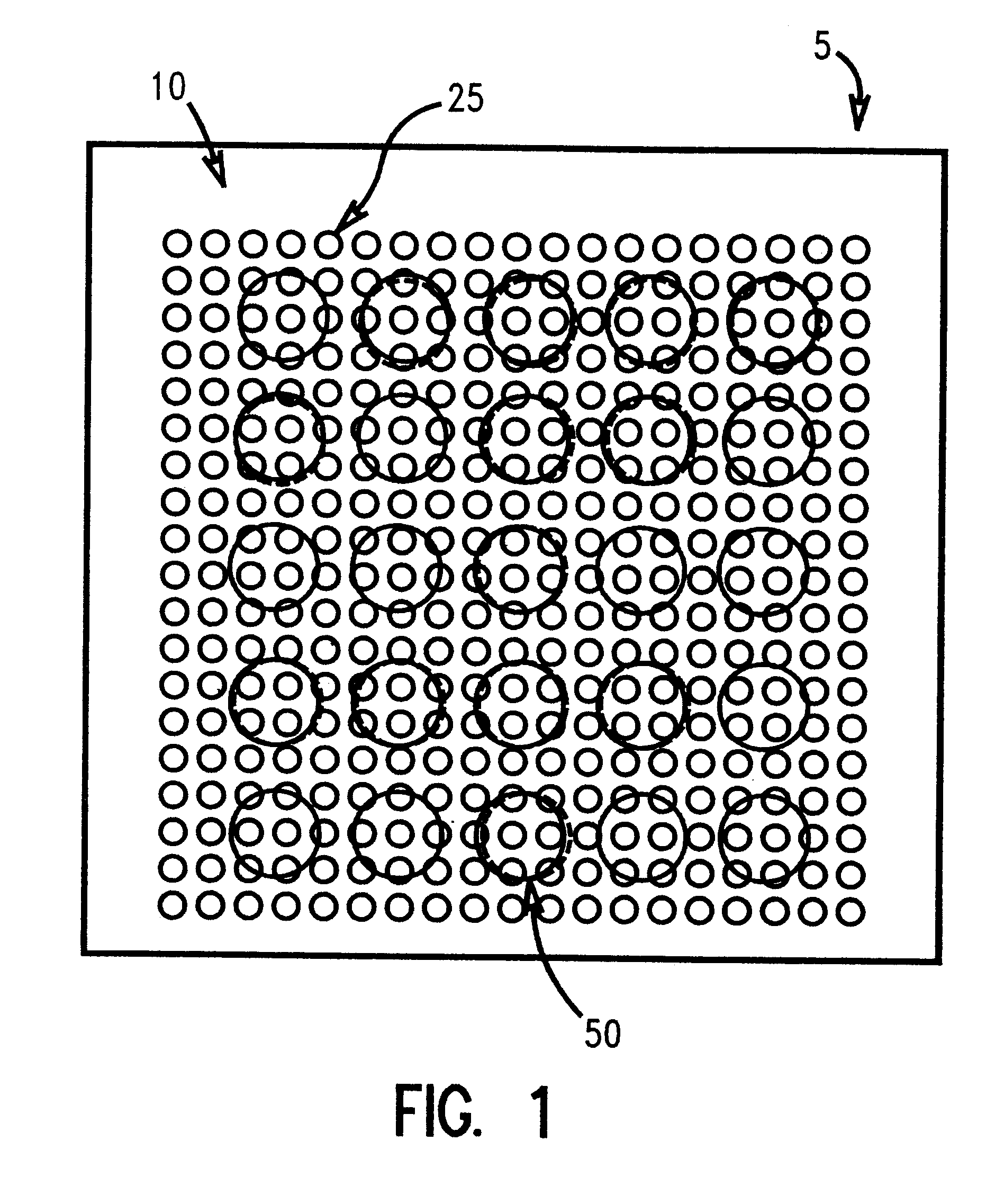

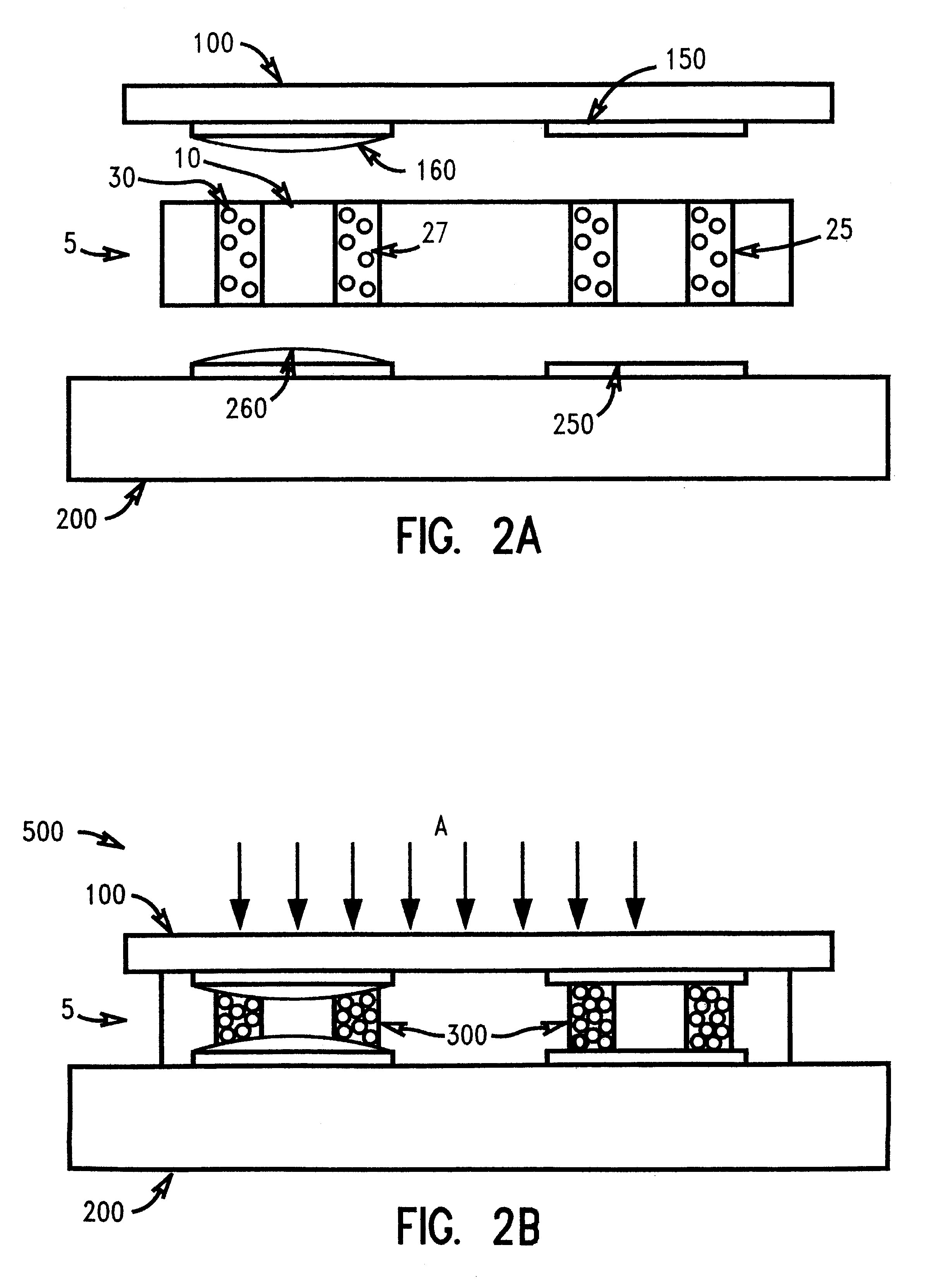

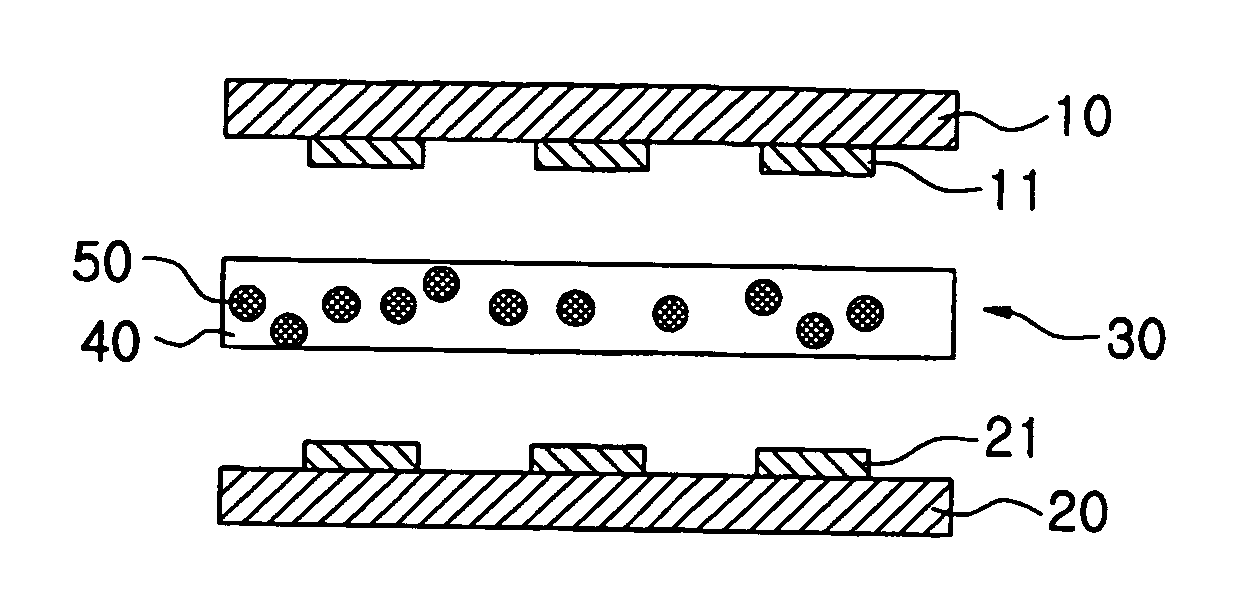

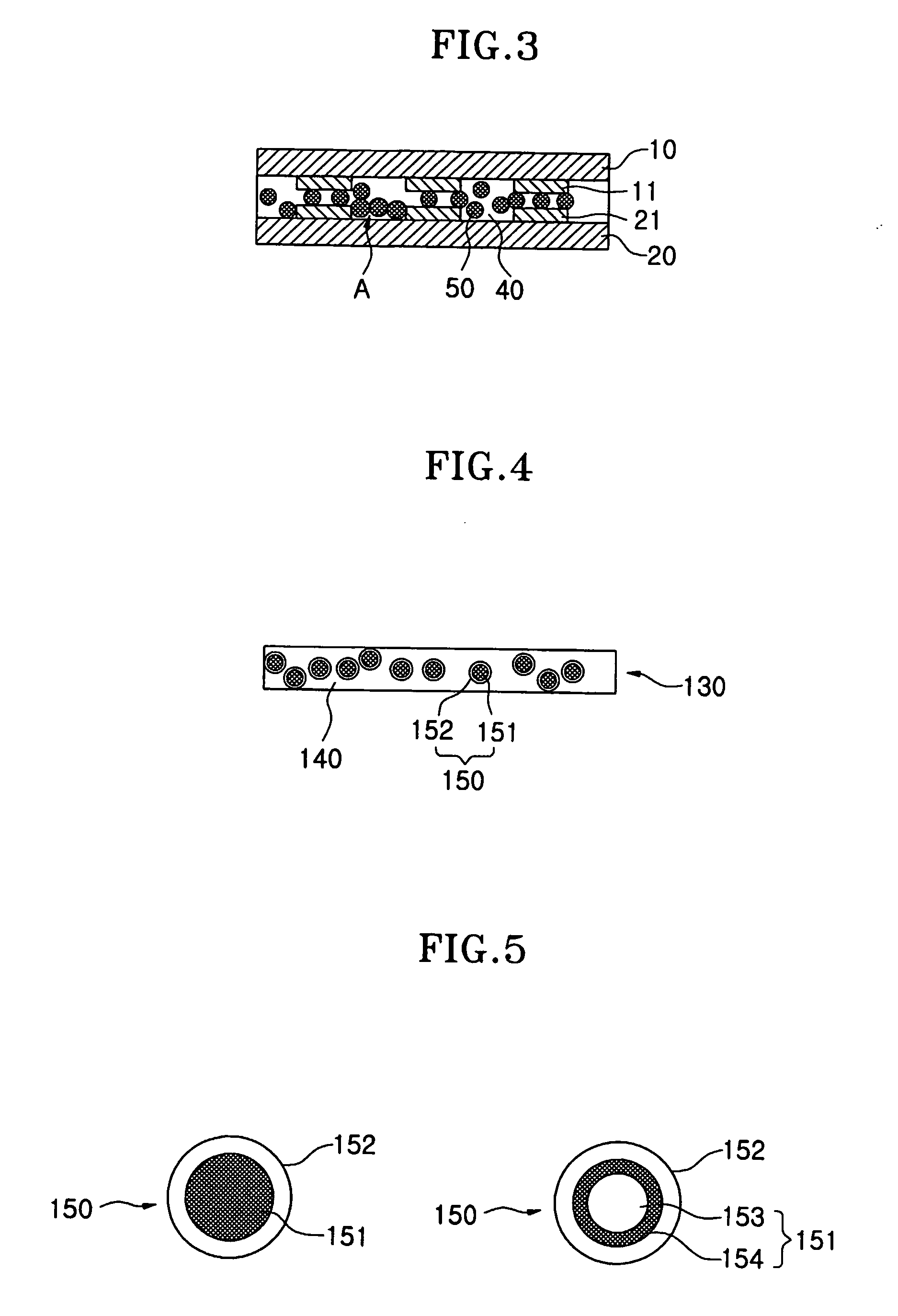

Z-axis compressible polymer with fine metal matrix suspension

InactiveUS6270363B1Reduce openingPrinted circuit assemblingLine/current collector detailsContact padAlloy

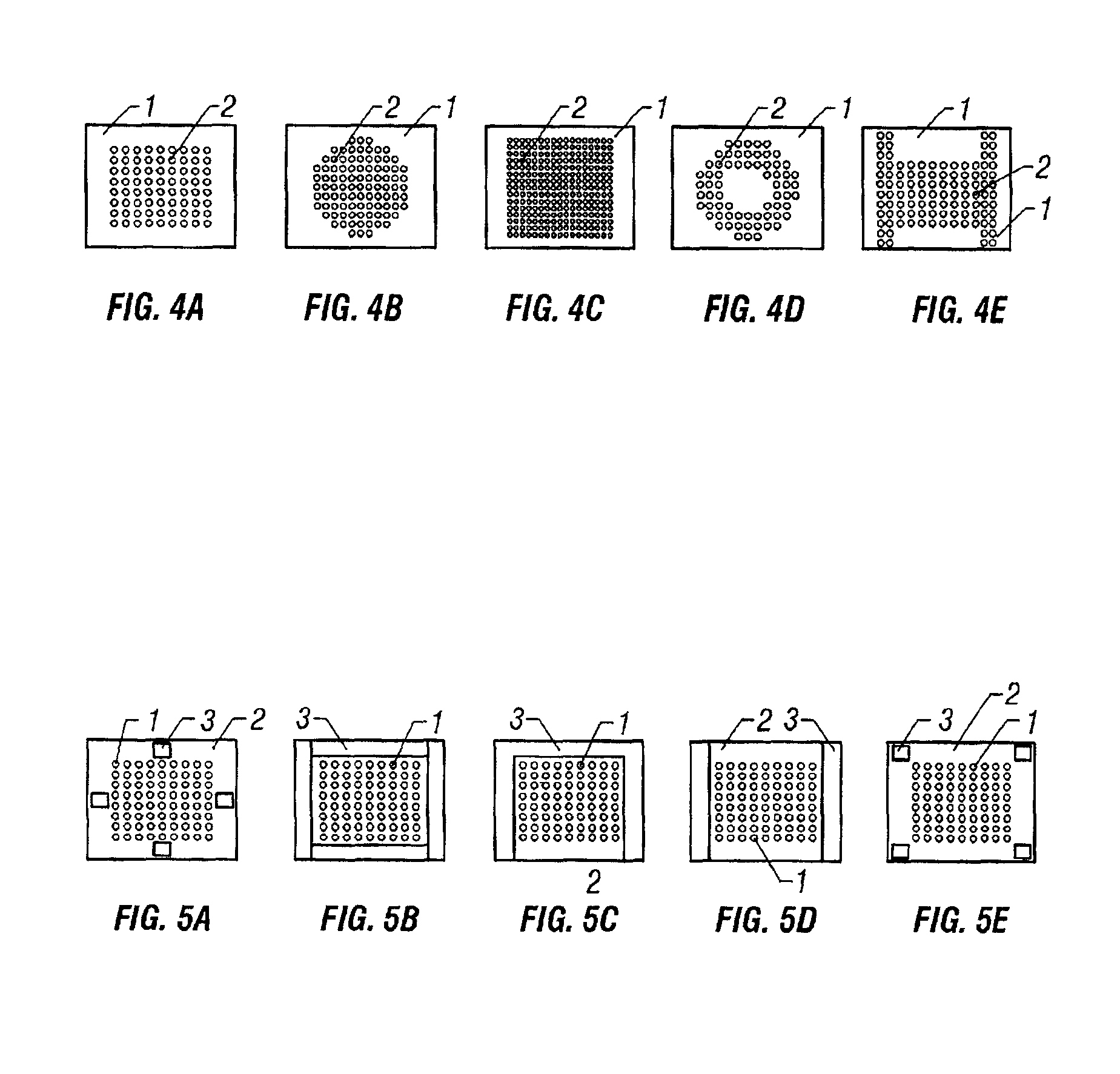

A compressible interposer comprising an interposer sheet having a plurality of apertures filled with a dielectric material having a substantially uniform suspension of conductive particles therein forming a plurality of conductive sites. Preferably, the number of conductive sites on the interposer are greater in number than the number of contact pads on the electronic components such that precise alignment of the interposer between the electronic components is not required. The apertures of the interposer sheet confine the conductive particles within the dielectric material such that during compression of the interposer between the electronic components, z-axis conductive pathways are formed without shorting in the x and y directions. Preferably, the interposer sheet comprises polyimide. Preferably, the dielectric material comprises polyimide-siloxane. Preferably, the conductive particles have a diameter of about 2 to about 20 mum and comprise of a material selected from the group consisting of copper, gold, silver, nickel, palladium, platinum, and alloys thereof. The particles may also be coated with an additional conductive material such as solder having a lower melting temperature. Most preferably, the conductive particles comprise solder coated copper particles. The conductive particles are present in an amount of about 30 to about 90 wt. % of the total weight of the conductive particles and the dielectric material.

Owner:IBM CORP

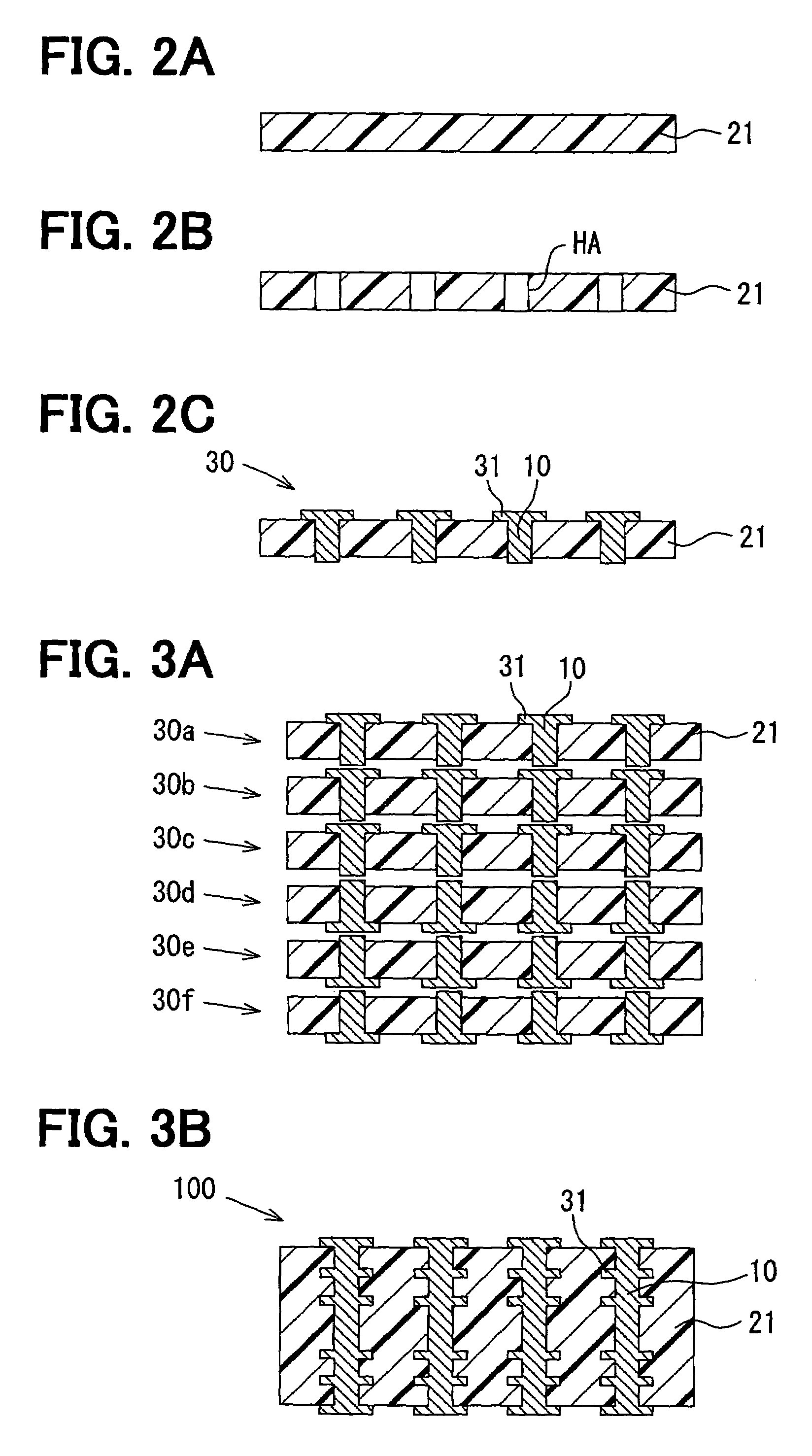

Methods for fabricating three-dimensional all organic interconnect structures

InactiveUS20040000425A1Semiconductor/solid-state device detailsSolid-state devicesLiquid crystallineAdhesive

The present invention comprises methods for making three-dimensional (3-D) liquid crystalline polymer (LCP) interconnect structures using a high temperature singe sided liquid crystalline polymer, and low temperature single sided liquid crystalline polymer, whereas both the high temperature LCP and the low temperature LCP are drilled using a laser or mechanical drill or mechanically punch to form a z-axis connection. The single sided Conductive layer is used as a bus layer to form z axis conductive stud conductive stud within the high temperature and low temperature LCP, followed by deposition of a metallic capping layer of the stud that serves as the bonding metal between the conductive interconnects to form the z-axis electrical connection. High temperature and low temperature LCP circuit layers are etched or built up to form circuit patterns and subsequently bonded together to form final 3-D multilayer circuit pattern whereas the low temperature LCP melts to form both dielectric to dielectric bond to high temperature LCP circuit layer, and dielectric to conductive bond, whereas, metal to metal bonding occurs with high temperature metal capping layer bonding to conductive metal layer. The resultant structure is then packaged using two metallized organic cores that are laminated onto either side of the device using a low temperature adhesive with similar electrical properties and subsequently metallized to form the input output terminals and EM shielding.

Owner:GEORGIA TECH RES CORP

Devices, compositions, and methods incorporating adhesives whose performance is enhanced by organophilic clay constituents

InactiveUS6884833B2Faster build-upImprove adhesionPrinted circuit assemblingNon-insulated conductorsOrganoclayHot melt

Incorporating organophilic clay into hot melt adhesive compositions, particularly those comprising semi-crystalline, thermoplastic polymers, greatly improves the adhesive properties in many respects. Some of these improvements are particularly beneficial to the specific use of hot melt adhesives filled with electrically conductive particles for use as electrically conductive adhesives.

Owner:3M INNOVATIVE PROPERTIES CO

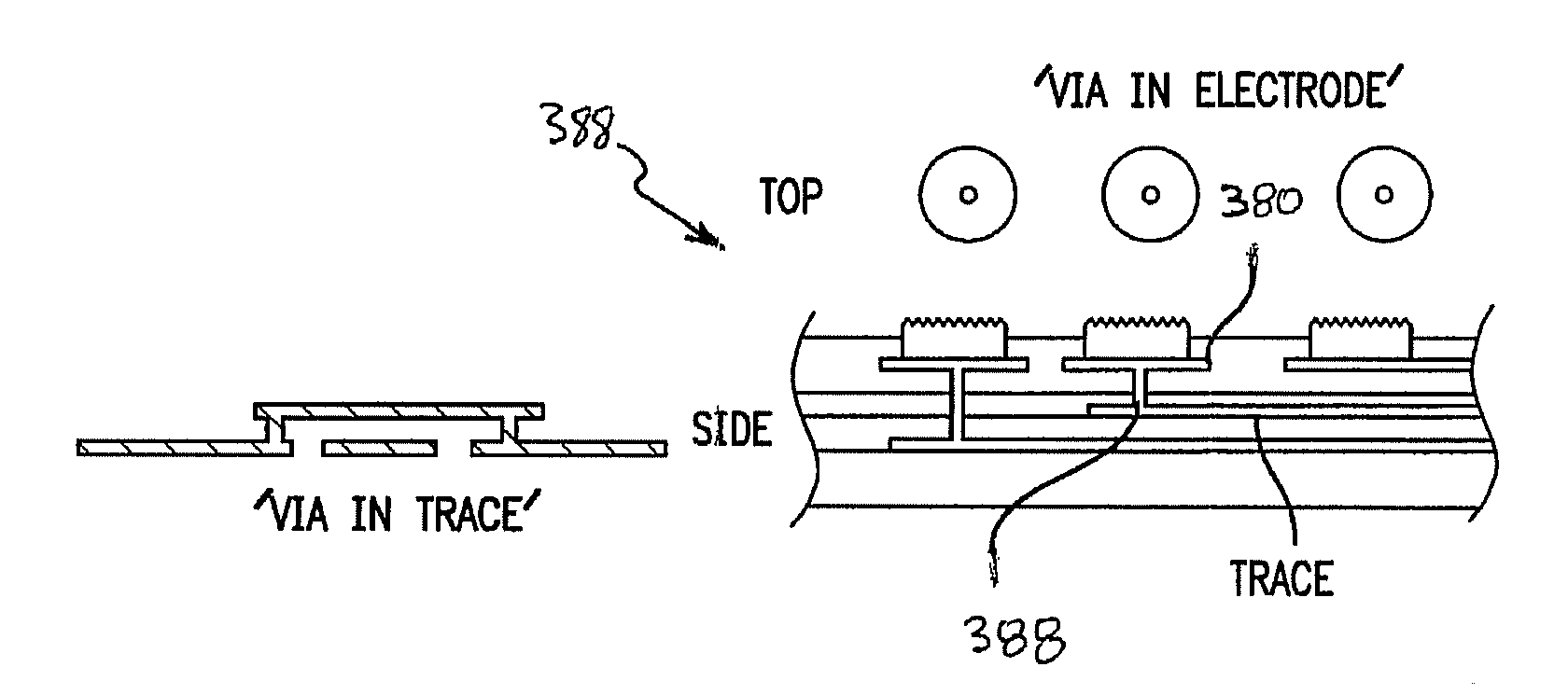

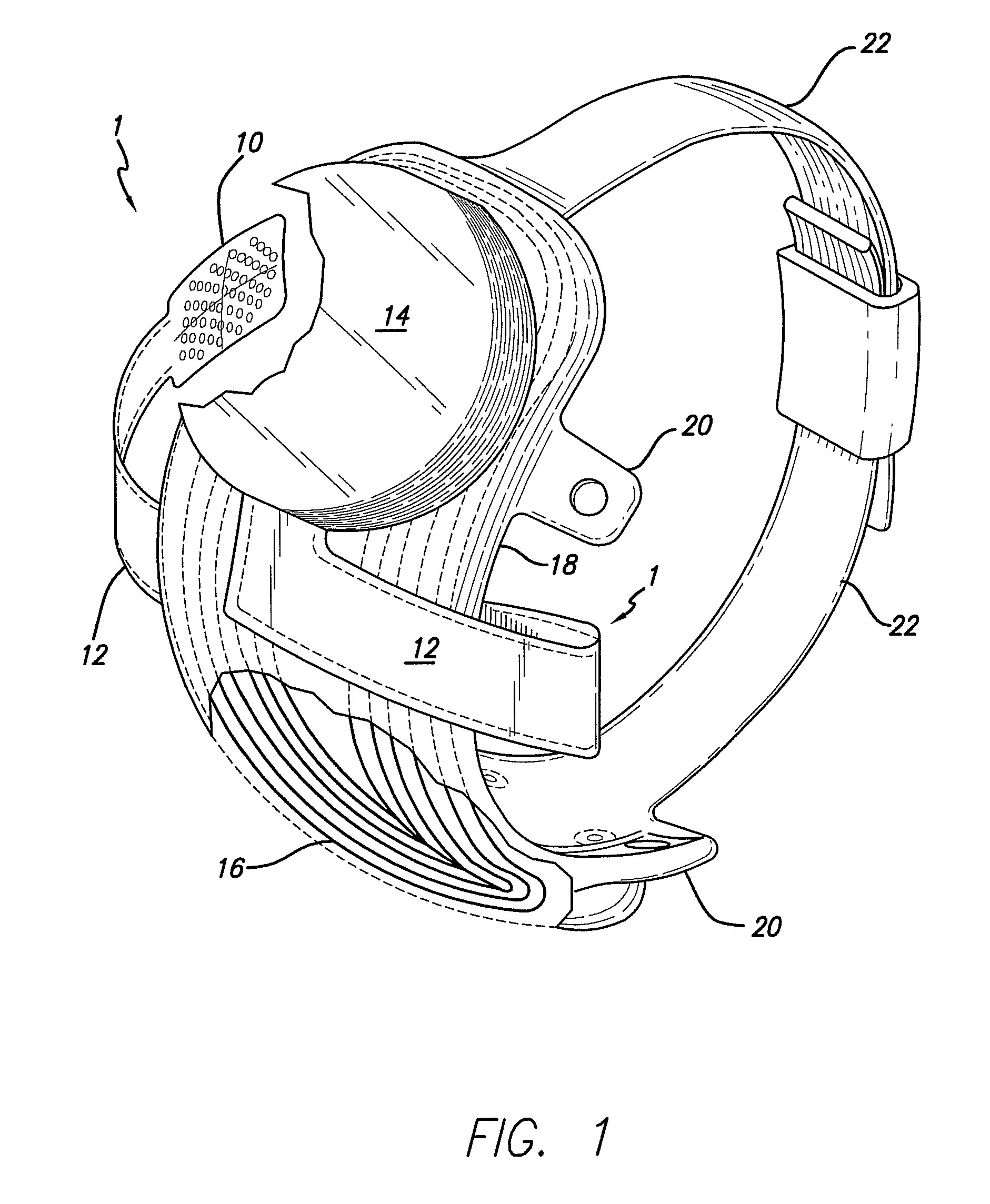

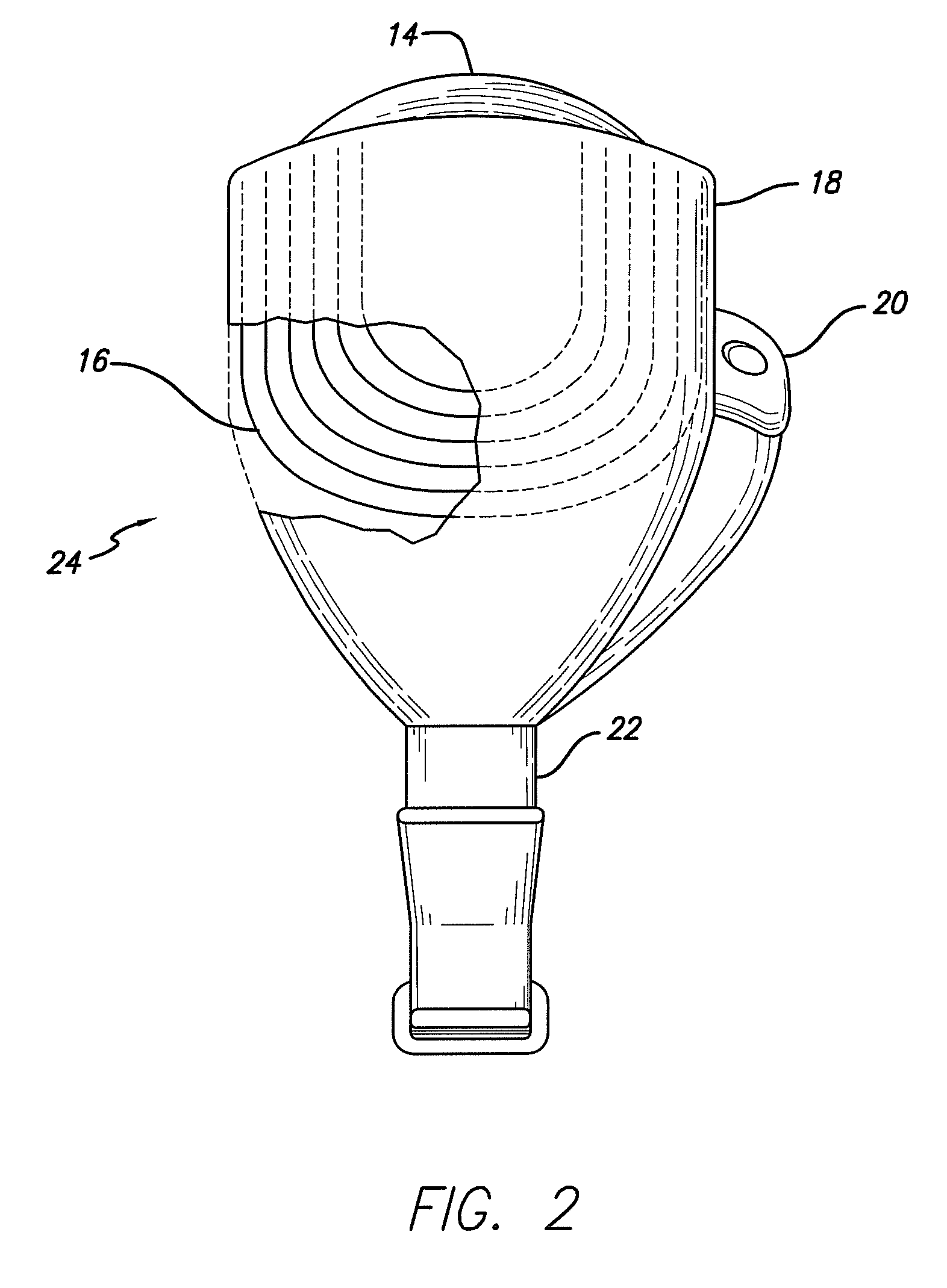

Flexible Circuit Electrode Array

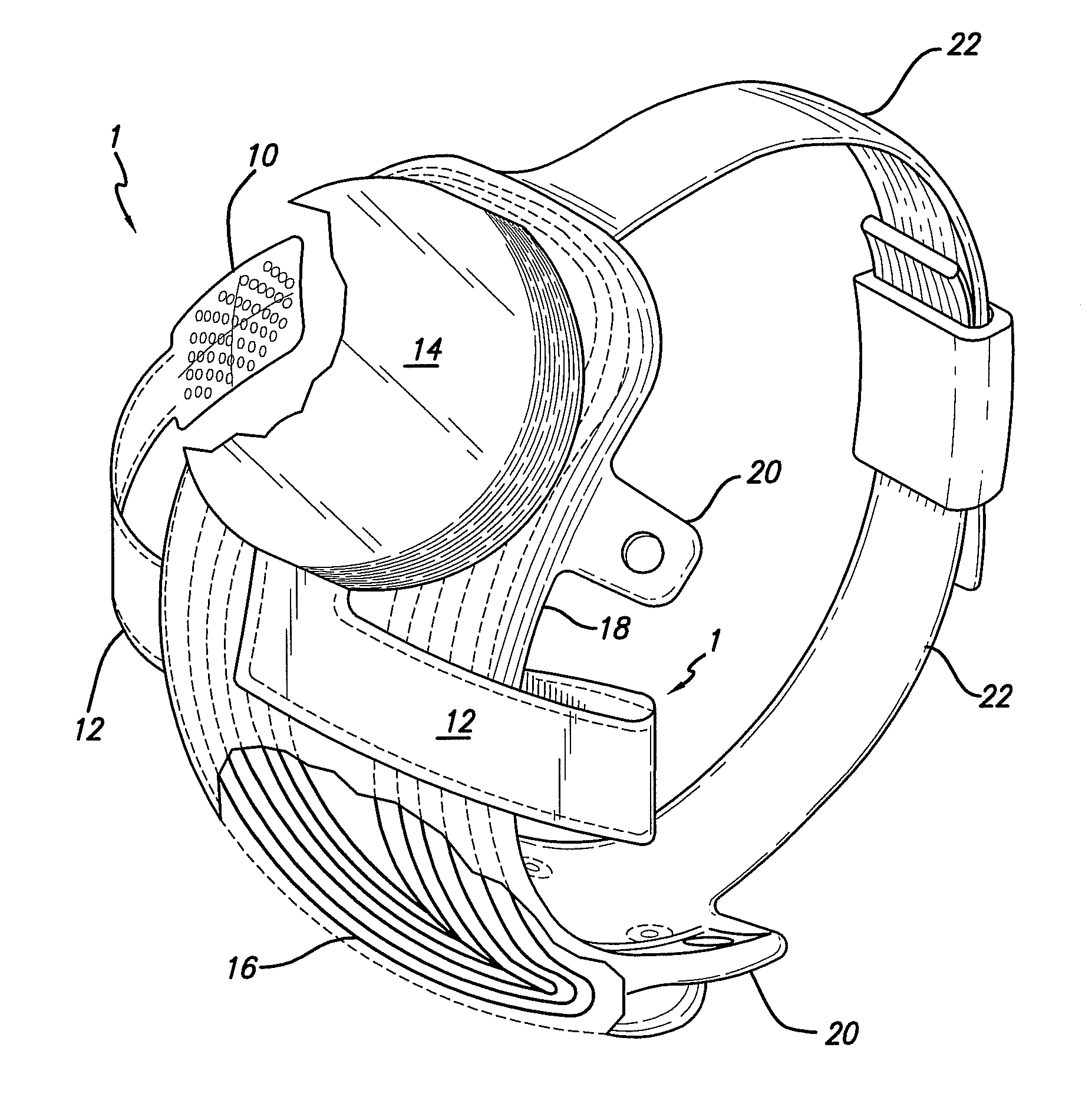

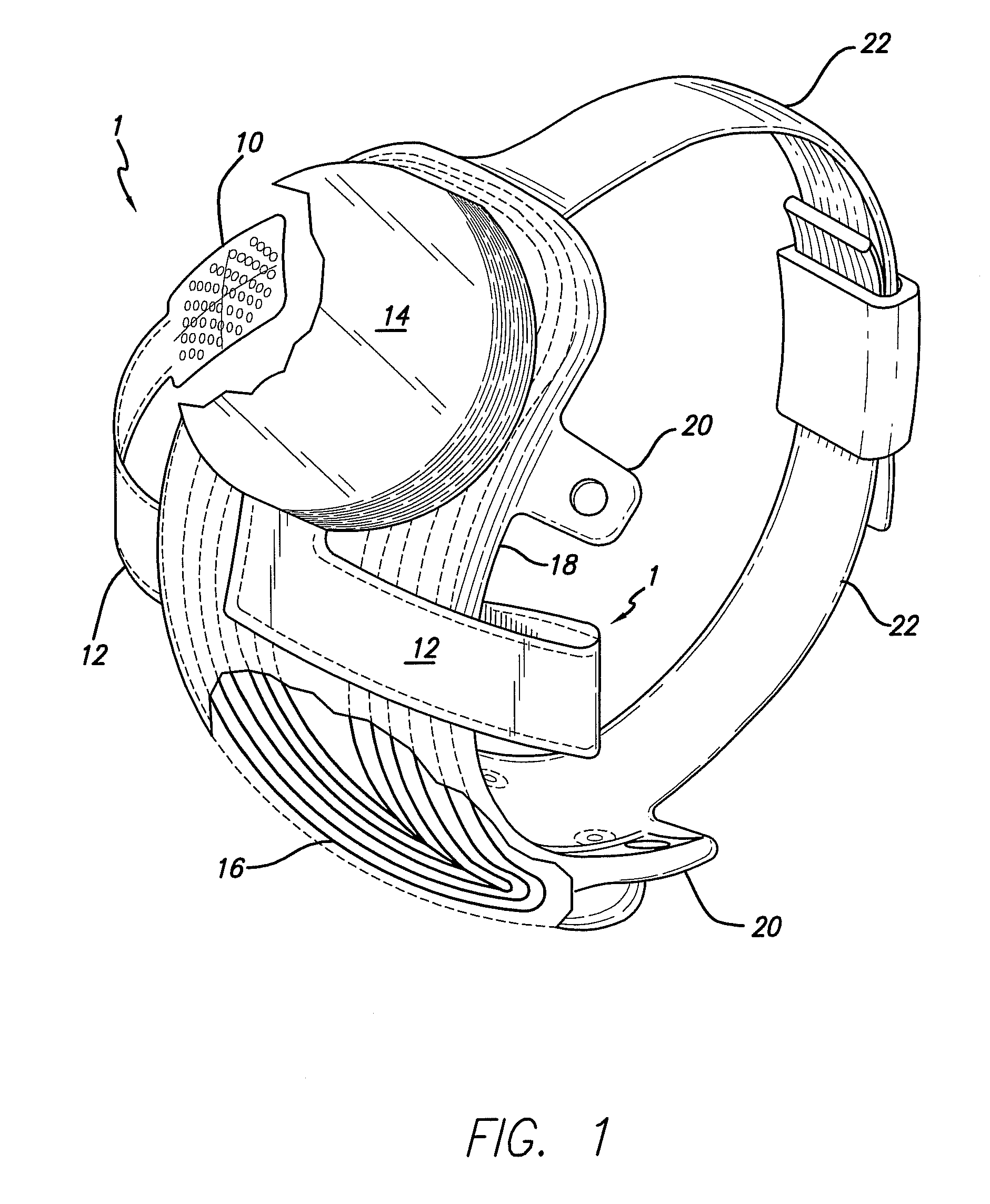

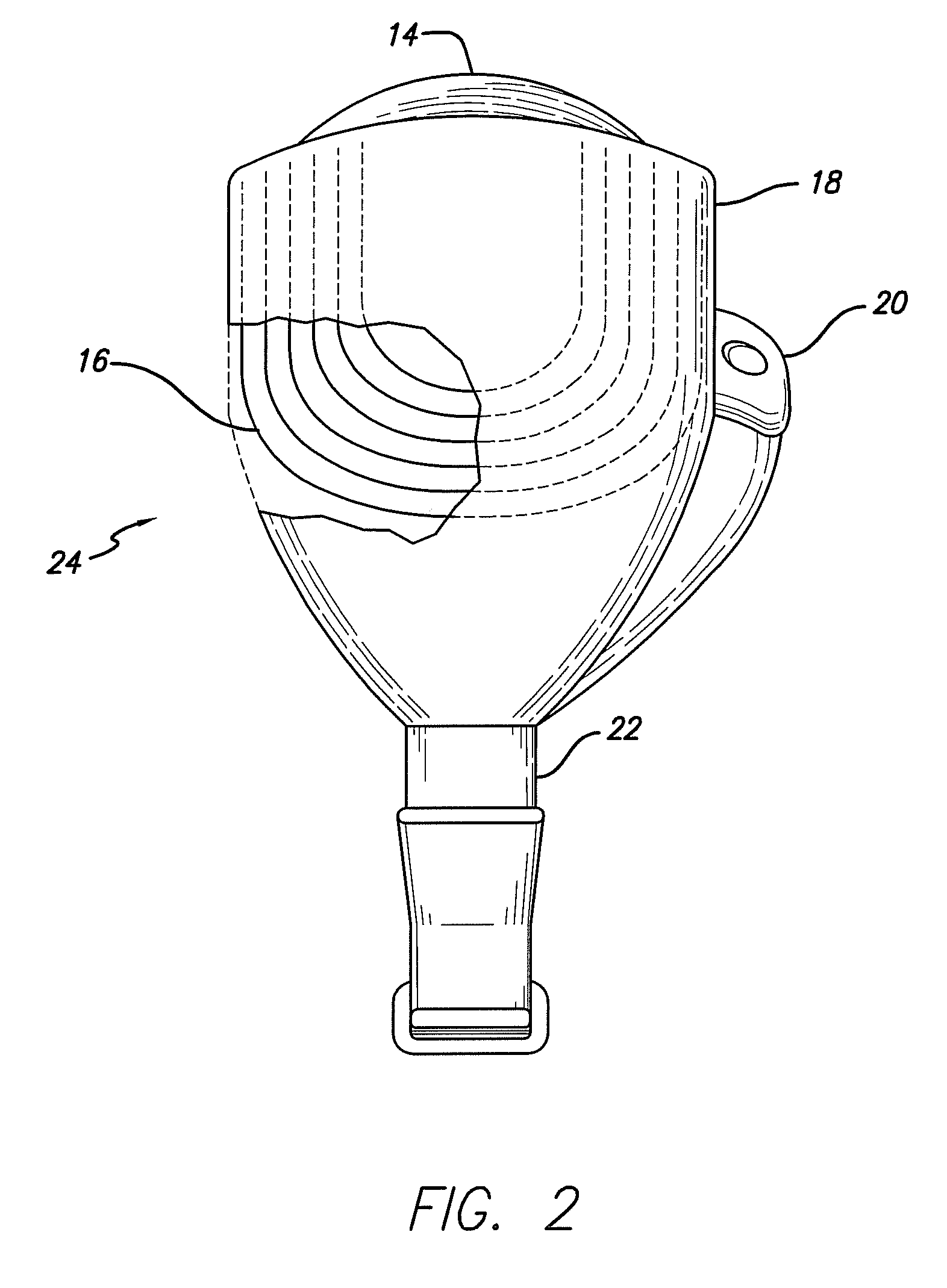

ActiveUS20080288037A1Head electrodesPrinted circuit secondary treatmentFlexible circuitsElectrode array

A flexible circuit electrode array with more than one layer of metal traces comprising: a polymer base layer; more than one layer of metal traces, separated by polymer layers, deposited on said polymer base layer, including electrodes suitable to stimulate neural tissue; and a polymer top layer deposited on said polymer base layer and said metal traces. Polymer materials are useful as electrode array bodies for neural stimulation. They are particularly useful for retinal stimulation to create artificial vision, cochlear stimulation to create artificial hearing, or cortical stimulation many purposes. The pressure applied against the retina, or other neural tissue, by an electrode array is critical. Too little pressure causes increased electrical resistance, along with electric field dispersion. Too much pressure may block blood flow.

Owner:CORTIGENT INC

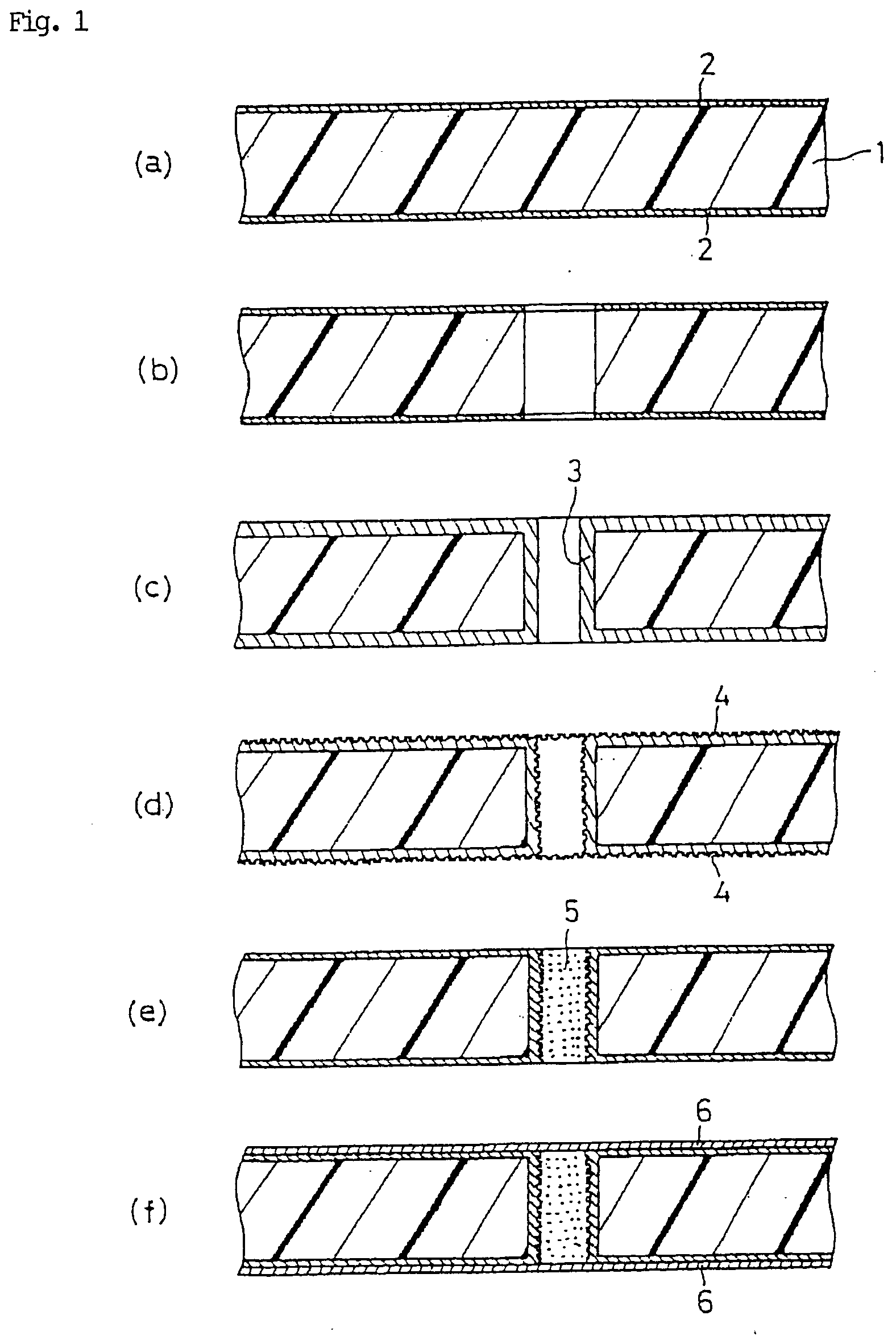

Printed wiring board and method for producing the same

InactiveUS20050258522A1Satisfactory in adhesionSatisfactory in dielectric constantInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsElectrical conductorPolyolefin

The present invention has for its object to provide a multilayer printed circuit board which is very satisfactory in facture toughness, dielectric constant, adhesion and processability, among other characteristics. The present invention is directed to a multilayer printed circuit board comprising a substrate board, a resin insulating layer formed on said board and a conductor circuit constructed on said resin insulating layer, wherein said resin insulating layer comprises a polyolefin resin.

Owner:IBIDEN CO LTD

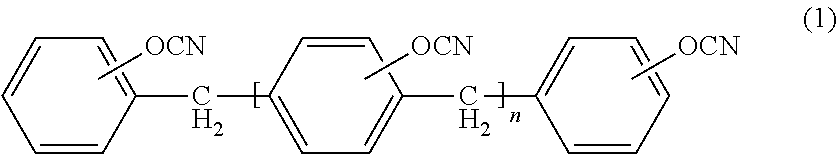

Resin composition

A resin composition which is low in a roughness of an insulating layer surface and capable of forming thereon a plated conductor layer having a sufficient peel strength in a wet roughing step and which is excellent in dielectric characteristics and a coefficient of thermal expansion, is disclosed. The resin composition contains a cyanate ester resin and a specified epoxy resin.

Owner:AJINOMOTO CO INC

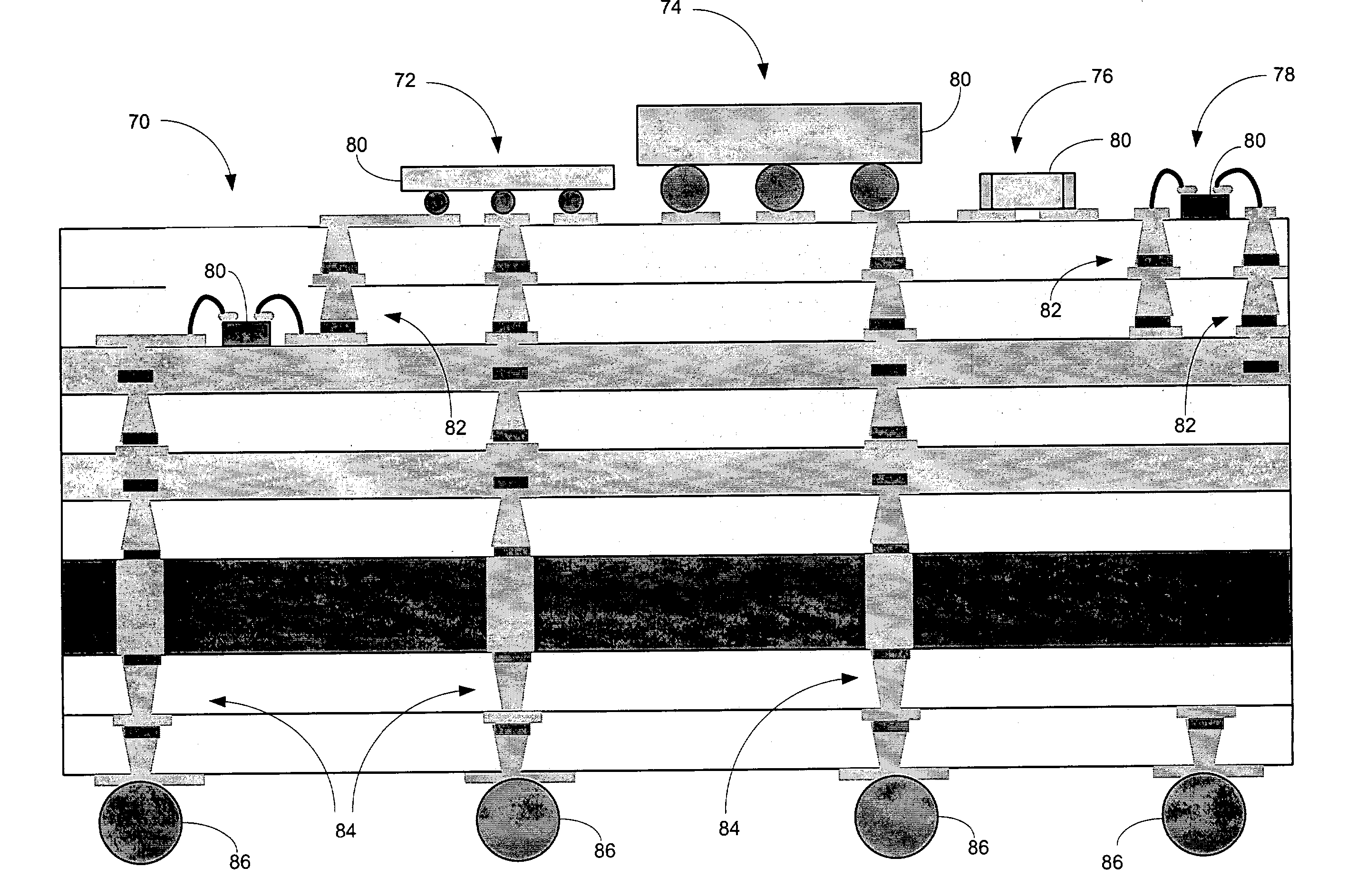

Methods and Systems For Connecting Inter-Layer Conductors and Components in 3D Structures, Structural Components, and Structural Electronic, Electromagnetic and Electromechanical Components/Devices

ActiveUS20140268607A1High mechanical strengthPrinted circuit assemblingLine/current collector detailsElectrical conductorElectrical connection

The present invention provides systems and methods for creating interlayer mechanical or electrical attachments or connections using filaments within a three-dimensional structure, structural component, or structural electronic, electromagnetic or electromechanical component / device.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Electric contact and an electric connector both using resin solder and a method of connecting them to a printed circuit board

InactiveUS6717065B2Increase the cross-sectional areaGreat freedomTwo pole connectionsContact member assembly/disassemblyElectrical conductorEngineering

An electric contact using resin solder is connected to a printed circuit board, which has a conductor provided on a surface thereof. This electric contact comprises a leg, which contacts the conductor of the printed circuit board, and a connecting part, which is connected to the conductor of the counterpart member. At least a part of the leg, which contacts the conductor of the printed circuit board, is made of a lead-free ultrahigh-conductive plastic being a conductive resin composite. An electric connector includes the electric contact and an insulating housing, which holds the electric contact so that the part of the leg, which contacts the conductor of the printed circuit board, is exposed.

Owner:JST MFG CO LTD

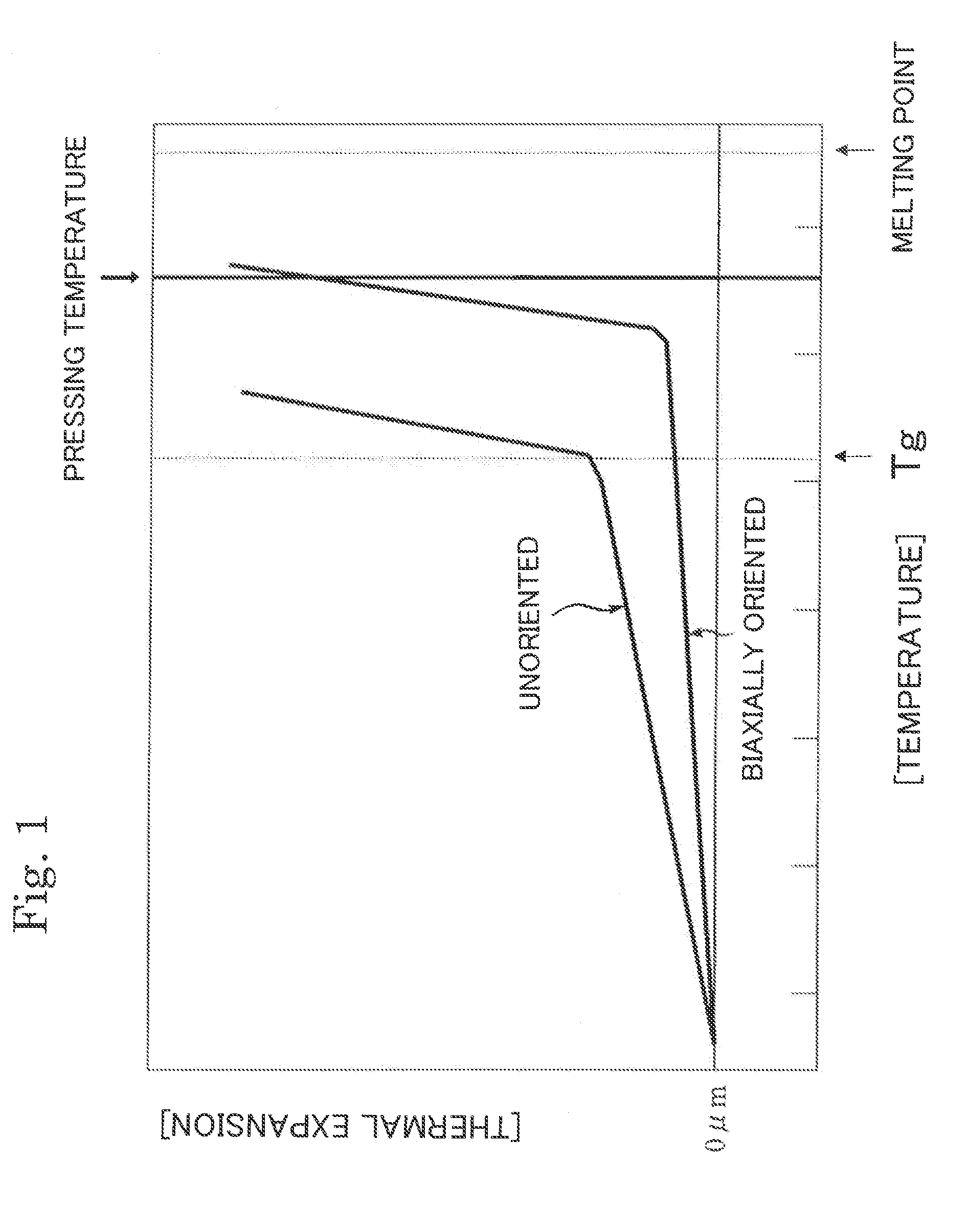

Biaxially oriented thermoplastic resin film

InactiveUS20050020803A1High modulusHigh melting pointFixed capacitor dielectricSynthetic resin layered productsPlane orientationPeak value

In order to provide a film having excellent heat resistance, thermal dimensional stability, and mechanical properties, in particular, a film capable of satisfying required properties, e.g., higher strength in accordance with the reduction in thickness of a base film, improved thermal dimensional stability and mechanical properties in a use environment, and higher heat resistance and improved thermal dimensional stability in accordance with the needs for miniaturization and more functionality in electrical and electronic areas, a thermoplastic resin is allowed to contain transition metal oxide particles, and is formed into a biaxially oriented thermoplastic resin film, wherein the melting point of the film is allowed to become higher than the melting point of the thermoplastic resin to be used. Preferably, the difference between a peak temperature (melting point T1) of the heat of fusion in the first run of the measurement of the biaxially oriented thermoplastic resin film with a differential scanning calorimeter (DSC) and a peak temperature (melting point T2) of the heat of fusion in the second run is allowed to satisfy the following Formula. 2° C.≦T1−T2≦30°C. Alternatively, the plane orientation factor of the biaxially oriented thermoplastic resin film containing the transition metal oxide particles is controlled at 0.120 or more and less than 0.280.

Owner:TORAY IND INC

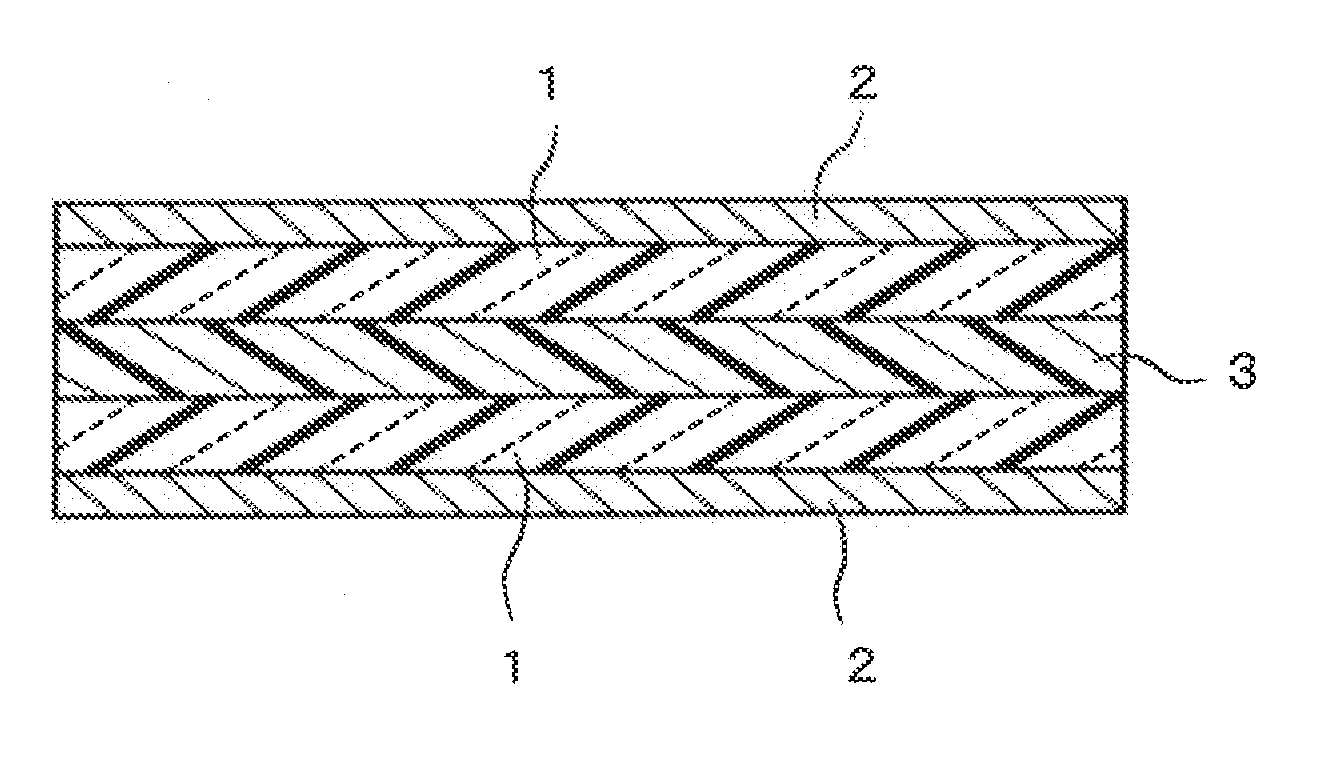

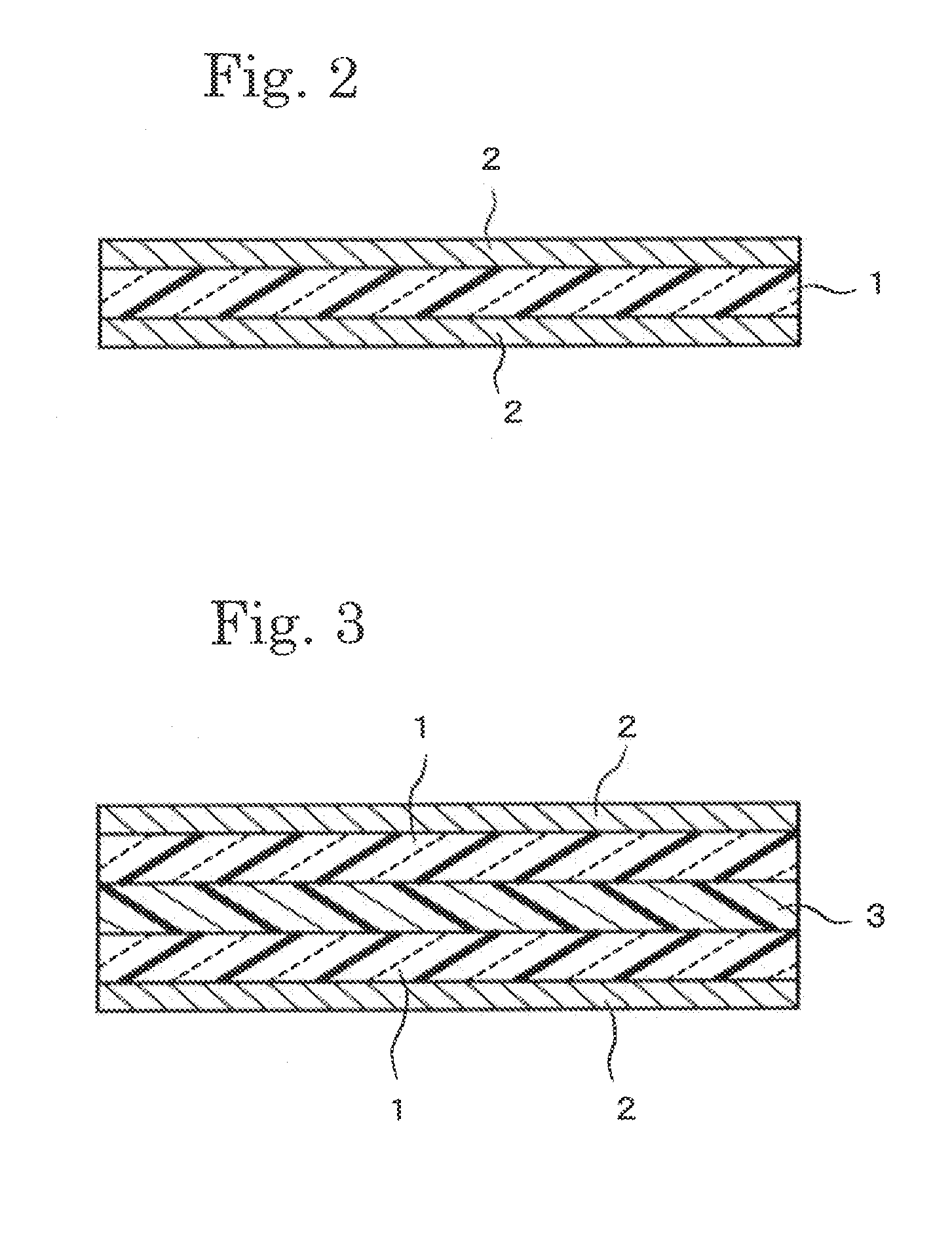

Flexible laminate having thermoplastic polyimide layer and method for manufacturing the same

InactiveUS20090035591A1Excellent heat resistance and electrical property and mechanical strengthEasy to manufactureSynthetic resin layered productsLaminationElectrical conductorHeat resistance

In a flexible laminate containing a metal foil layer / a thermoplastic polyimide layer or / and a conductor circuit layer / a thermoplastic polyimide layer, the metal foil layer or the conductor circuit layer is bonded to at least one side of the thermoplastic polyimide layer. The thermoplastic polyimide layer is formed from a thermoplastic polyimide resin film or sheet produced by melt extrusion of a thermoplastic polyimide resin. Alternatively, the thermoplastic polyimide layer is formed from a biaxially oriented thermoplastic polyimide resin film or sheet. Such a flexible laminate can be easily manufactured by a lamination method which comprises bonding a thermoplastic polyimide resin film (1) to a metal foil (2) or a conductive circuit layer (4) by heating under pressure, and has excellent heat resistance, electrical properties and mechanical strength inherent in a polyimide. When the biaxially oriented thermoplastic polyimide resin film or sheet is used, the flexible laminate can be improved in dimensional stability and resistance to soldering heat.

Owner:KURASHIKI BOSEKI KK +1

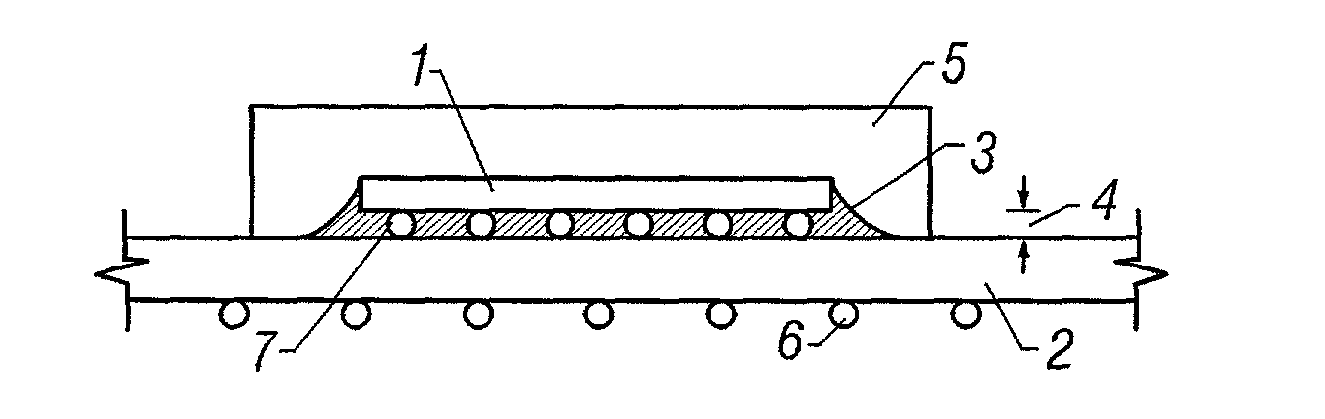

Attachment of surface mount devices to printed circuit boards using a thermoplastic adhesive

Owner:WESTLAKE EPOXY INC

Thermoplastic Composition for Use in Forming a Laser Direct Structured Substrate

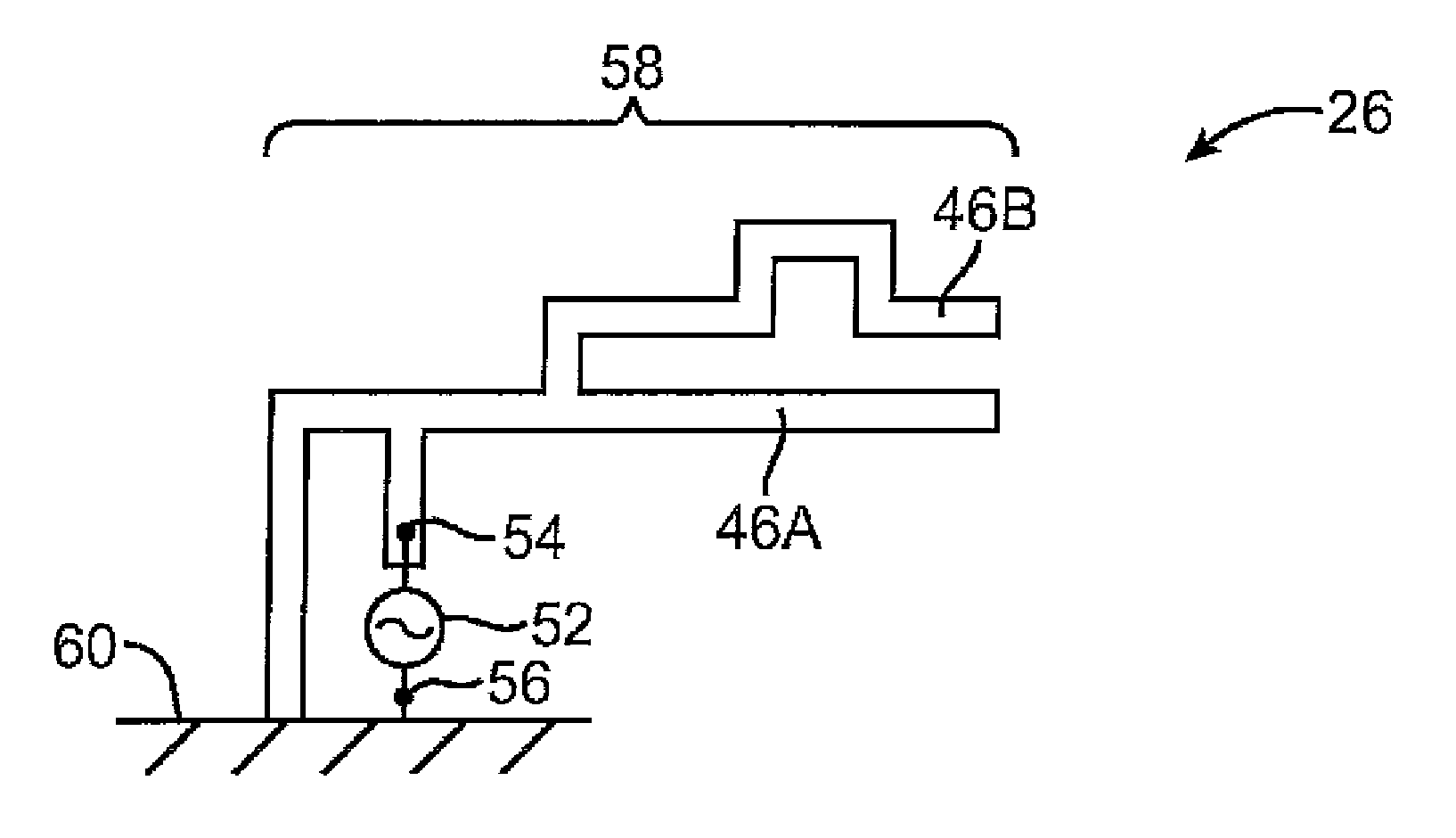

ActiveUS20130106659A1Liquid crystal compositionsSimultaneous aerial operationsLiquid crystallineFiber

A thermoplastic composition that contains a unique combination of a thermotropic liquid crystalline polymer, dielectric material, laser activatable additive, and a fibrous filler is provided. The nature of the components and / or their concentration are selectively controlled in the present invention to maintain a high dielectric constant, good mechanical properties (e.g., deflection under load), and good processibility (e.g., low viscosity), yet still be laser activatable. Thus, the thermoplastic composition can be readily shaped into a thin substrate and subsequently applied with one or more conductive elements using a laser direct structuring process (“LDS”).

Owner:TICONA LLC

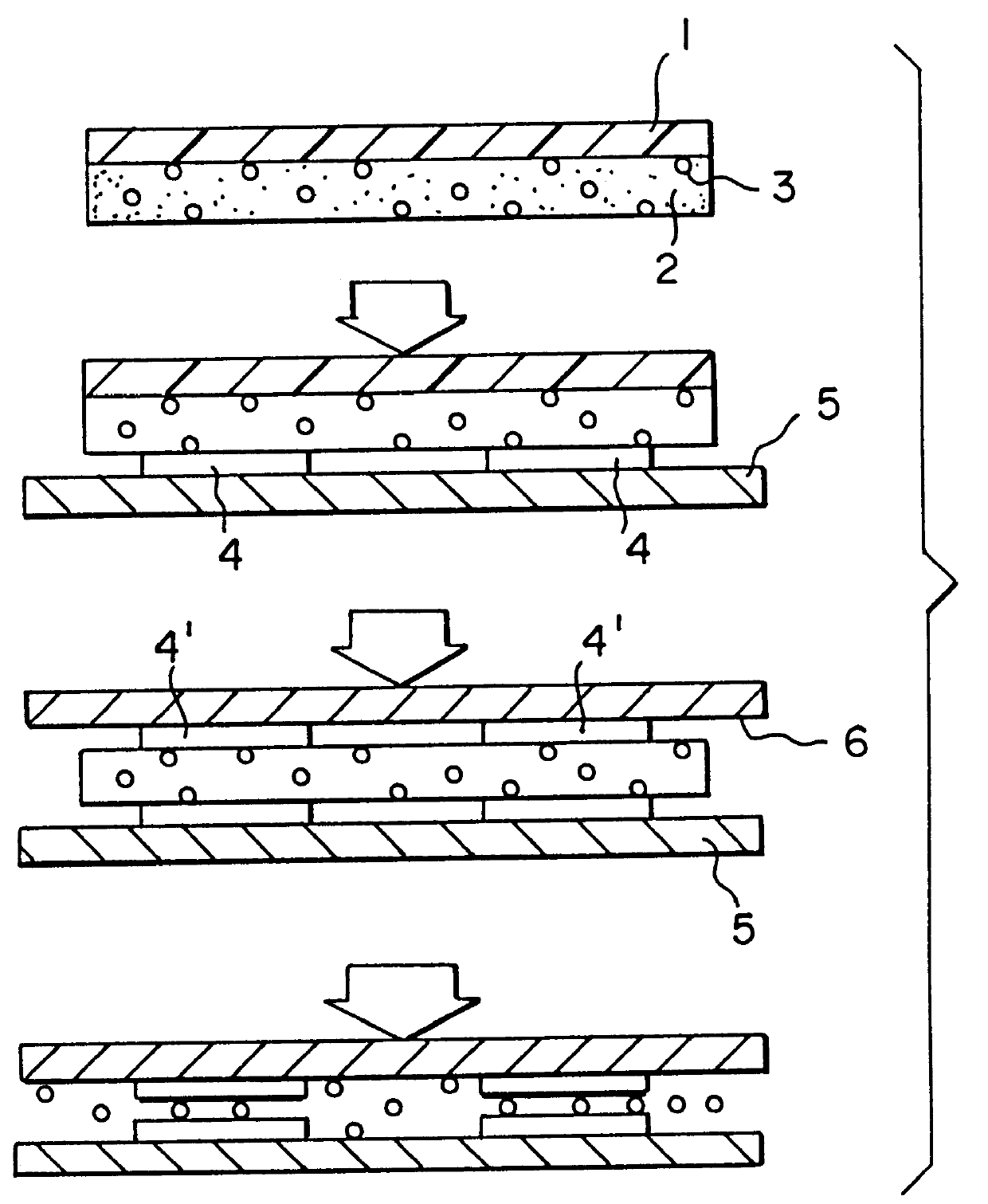

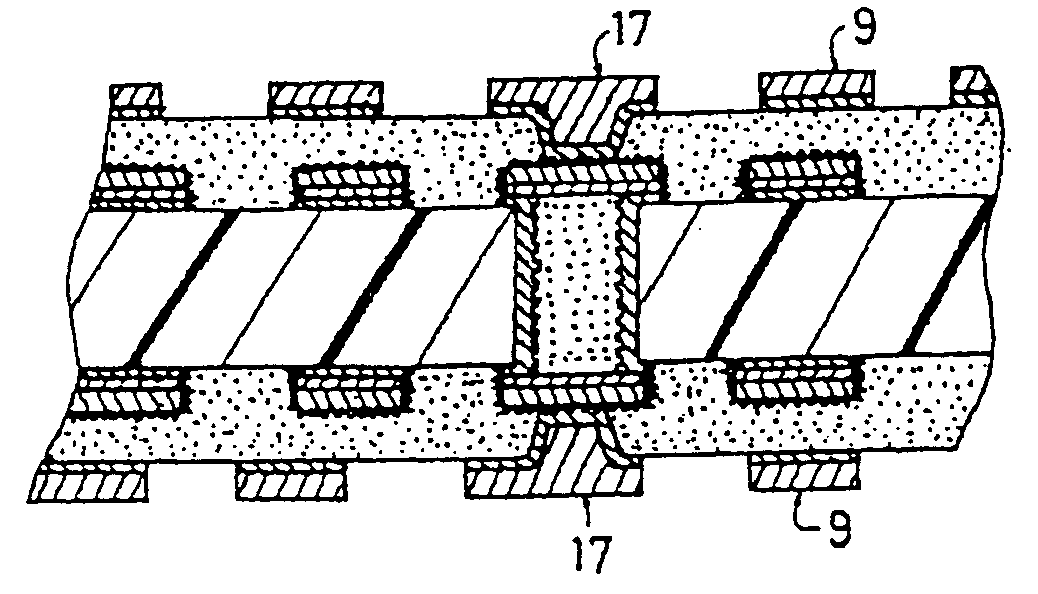

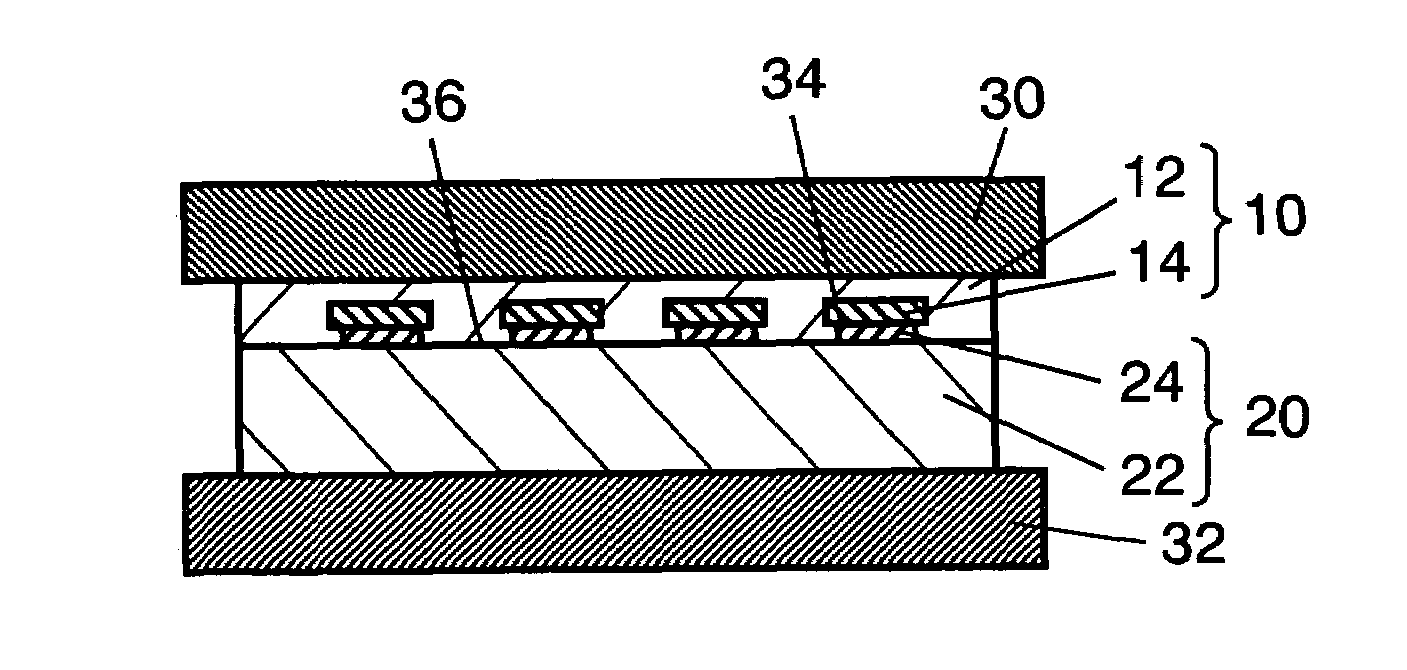

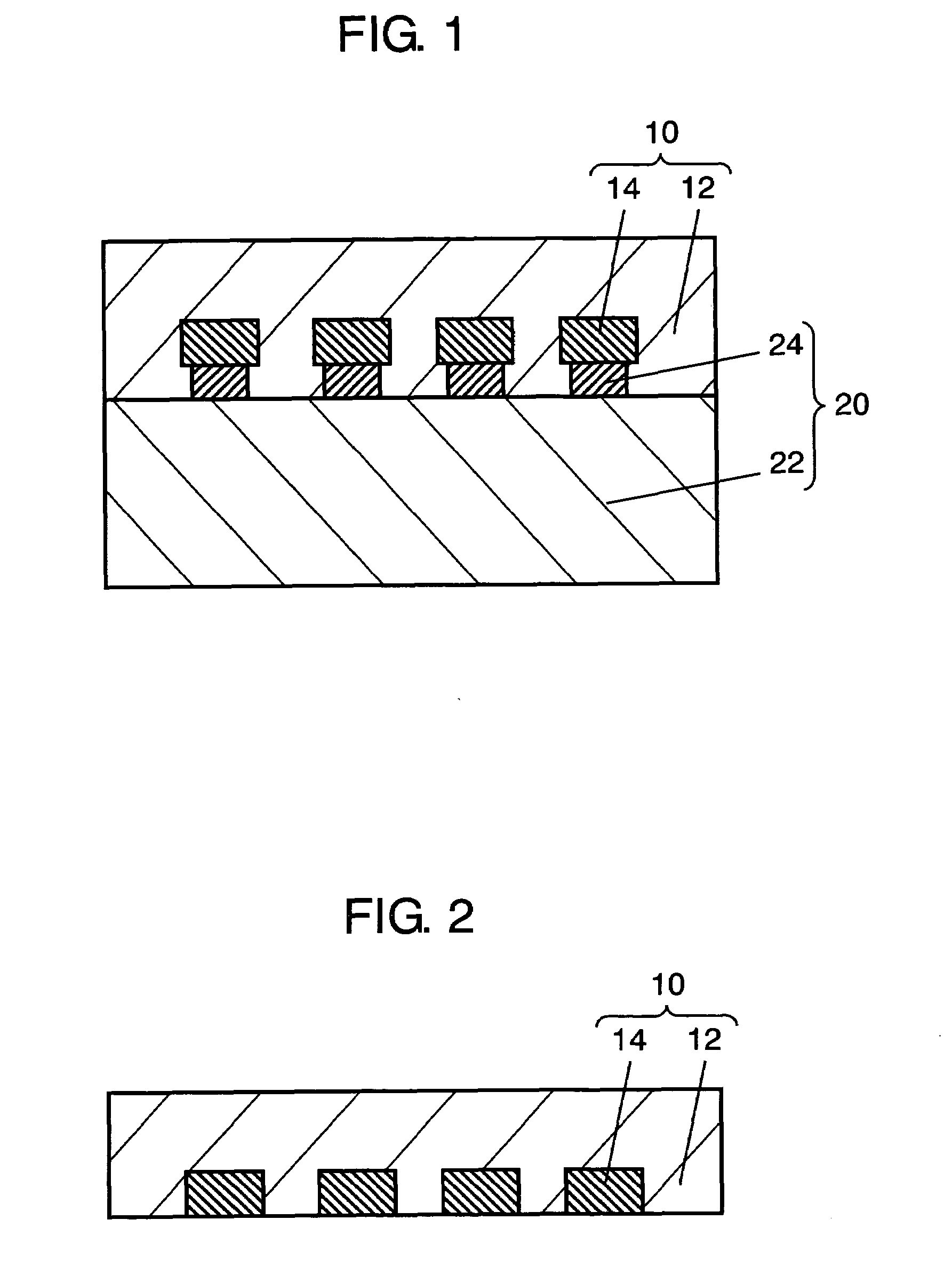

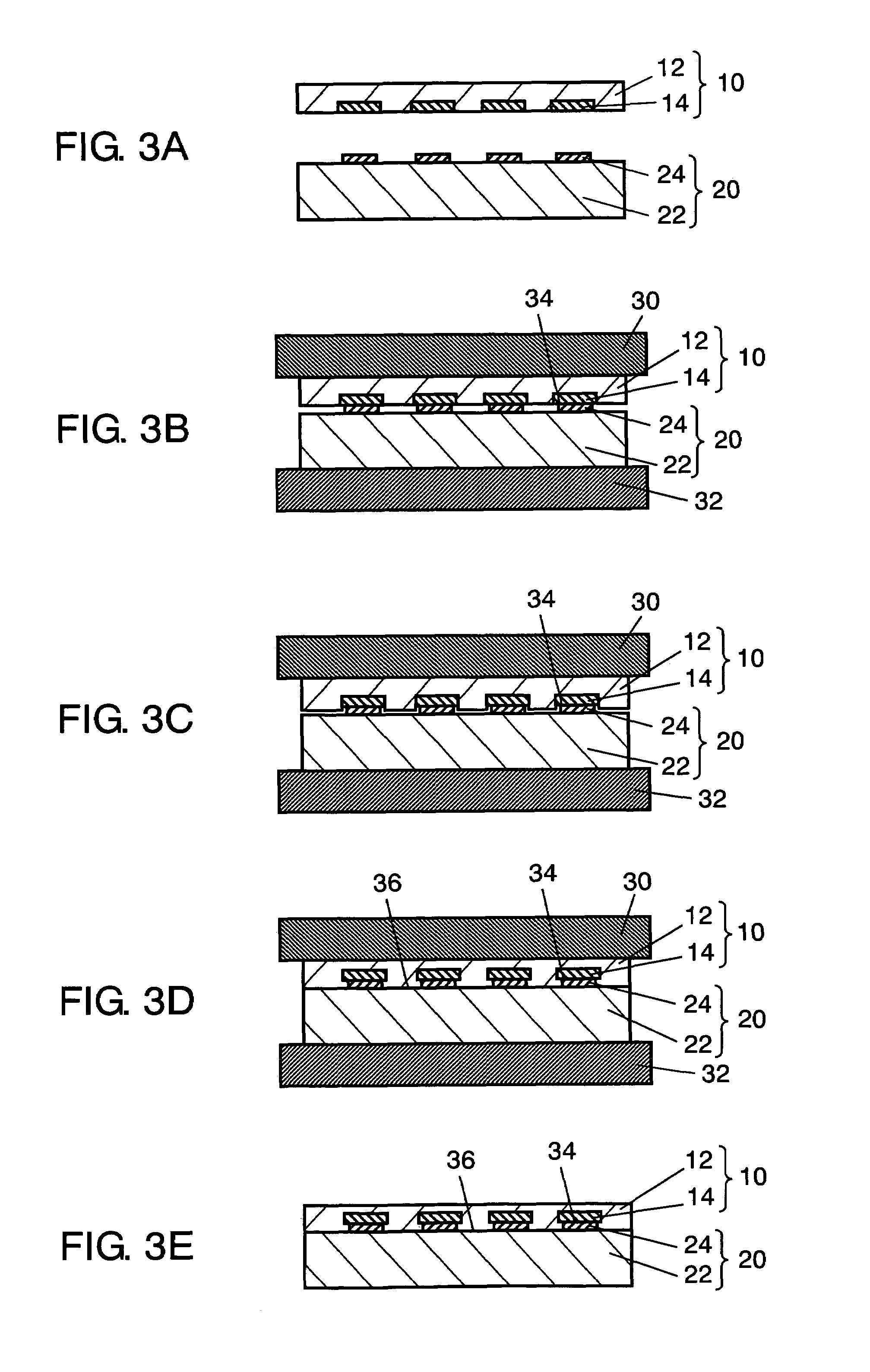

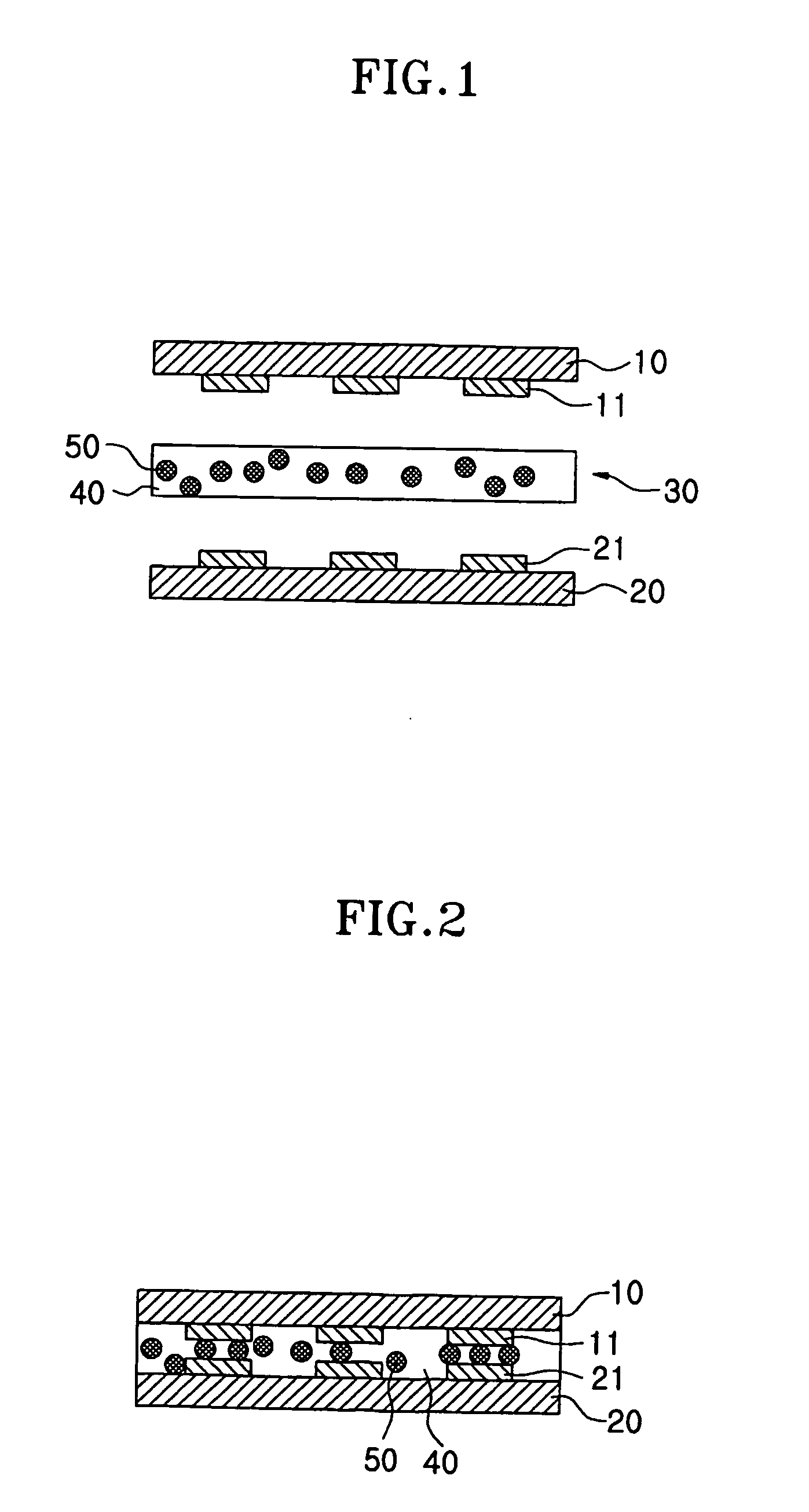

Connecting structure of circuit board and method for manufacturing the same

InactiveUS7229293B2Increase productionReduce connection resistanceSoldered/welded connectionsPrinted circuit manufactureElectrical conductorEngineering

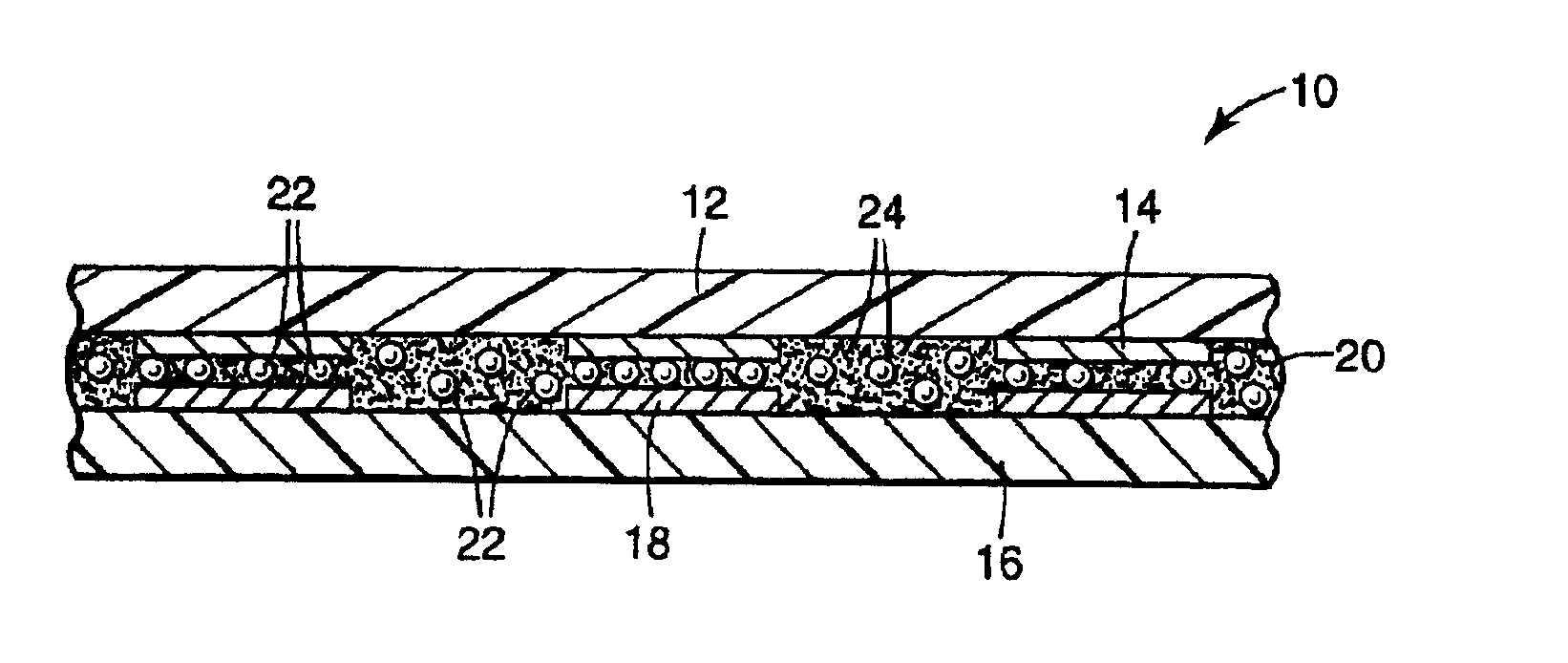

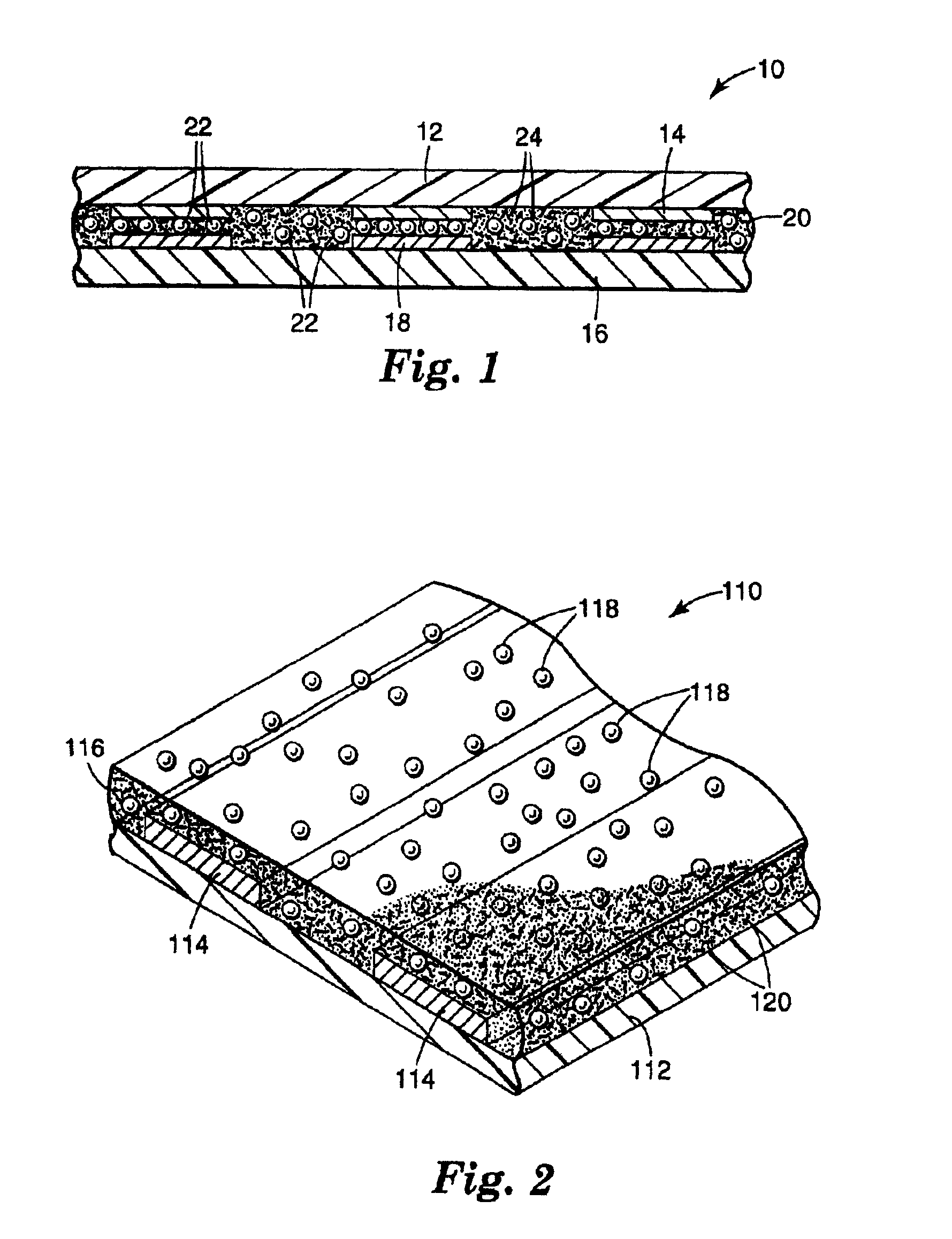

First circuit board 10 including first resin base material 12 which is softened by heating and has a fusing property, and a plurality of first conductor patterns 14 formed on a surface of first resin base material 12, and second circuit board 20 on which a plurality of second conductor patterns 24 are formed with the same pitch as that of first conductor patterns 14 are provided. In the configuration, first conductor patterns 14 and second conductor patterns 24 are brought into mechanical contact with each other to provide electrical conduction; first resin base material 12 covers first conductor patterns 14 and second conductor patterns 24 and is bonded to second resin base material 22 of second circuit board 20, thereby connecting first circuit board 10 and second circuit board 20 to each other.

Owner:PANASONIC CORP

Resin composition

InactiveUS20050107497A1Improve barrier propertiesImprove moisture resistanceSpecial tyresRecord information storagePolymer scienceAdhesive belt

A resin composition, substrate material, sheet, laminated board, resin-bearing copper foil, copper-clad laminate, TAB tape, printed board, prepreg and adhesive sheet are provided which exhibit improved mechanical properties, dimensional stability, heat resistance and flame retardance, particularly high-temperature physical properties. A resin composition containing 100 parts by weight of a thermosetting resin and 0.1-65 parts by weight of an inorganic compound, the resin composition having a mean linear expansion coefficient (α2) of up to 17×10−3 [° C.−1] over the temperature range from a temperature 10° C. higher than a glass transition temperature of the resin composition to a temperature 50° C. higher than the glass transition temperature of the resin composition.

Owner:SEKISUI CHEM CO LTD

Attachment of surface mount devices to printed circuit boards using a thermoplastic adhesive

An assembly having a surface mounted electronic device mounted onto a printed circuit board and a thermoplastic adhesive applied to the surface mounted electronic device facing the printed circuit board and providing for a gap between the thermoplastic adhesive and the printed circuit board. The assembly is heated at solder reflow temperatures to at least soften the thermoplastic adhesive sufficiently to flow across the gap and provide a thermoplastic adhesive joint between the surface mounted electronic device and the printed circuit board.

Owner:WESTLAKE EPOXY INC

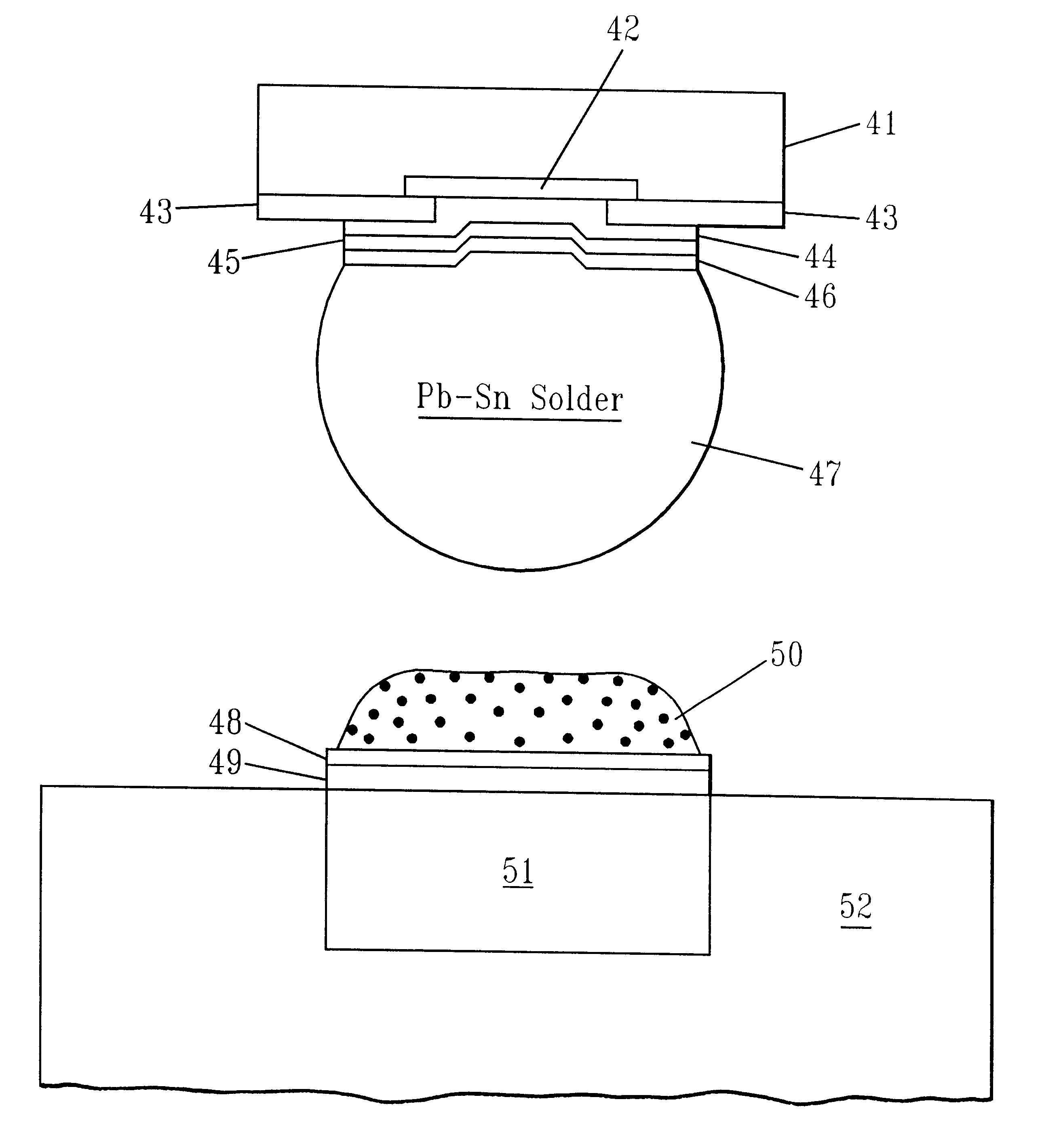

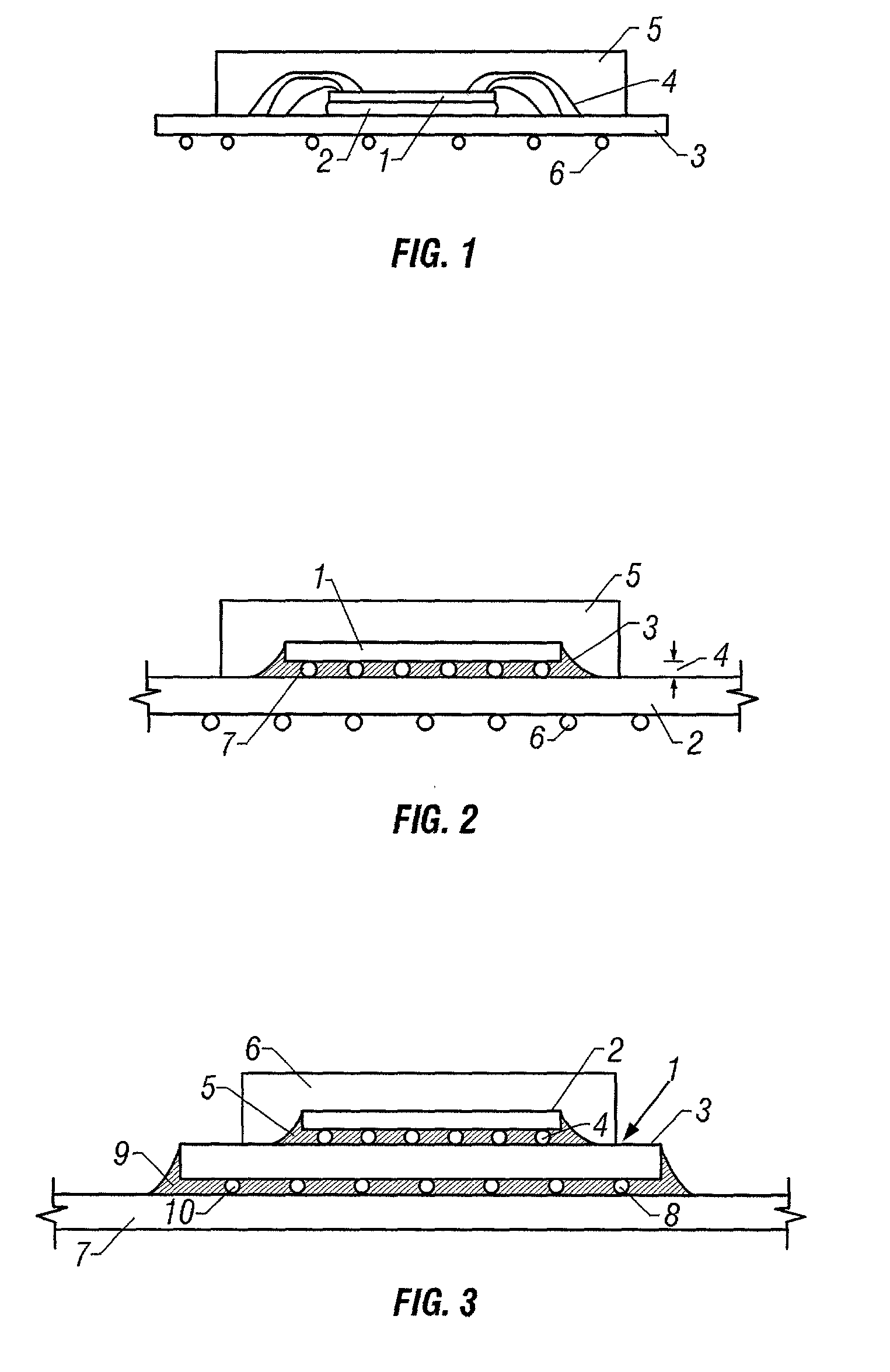

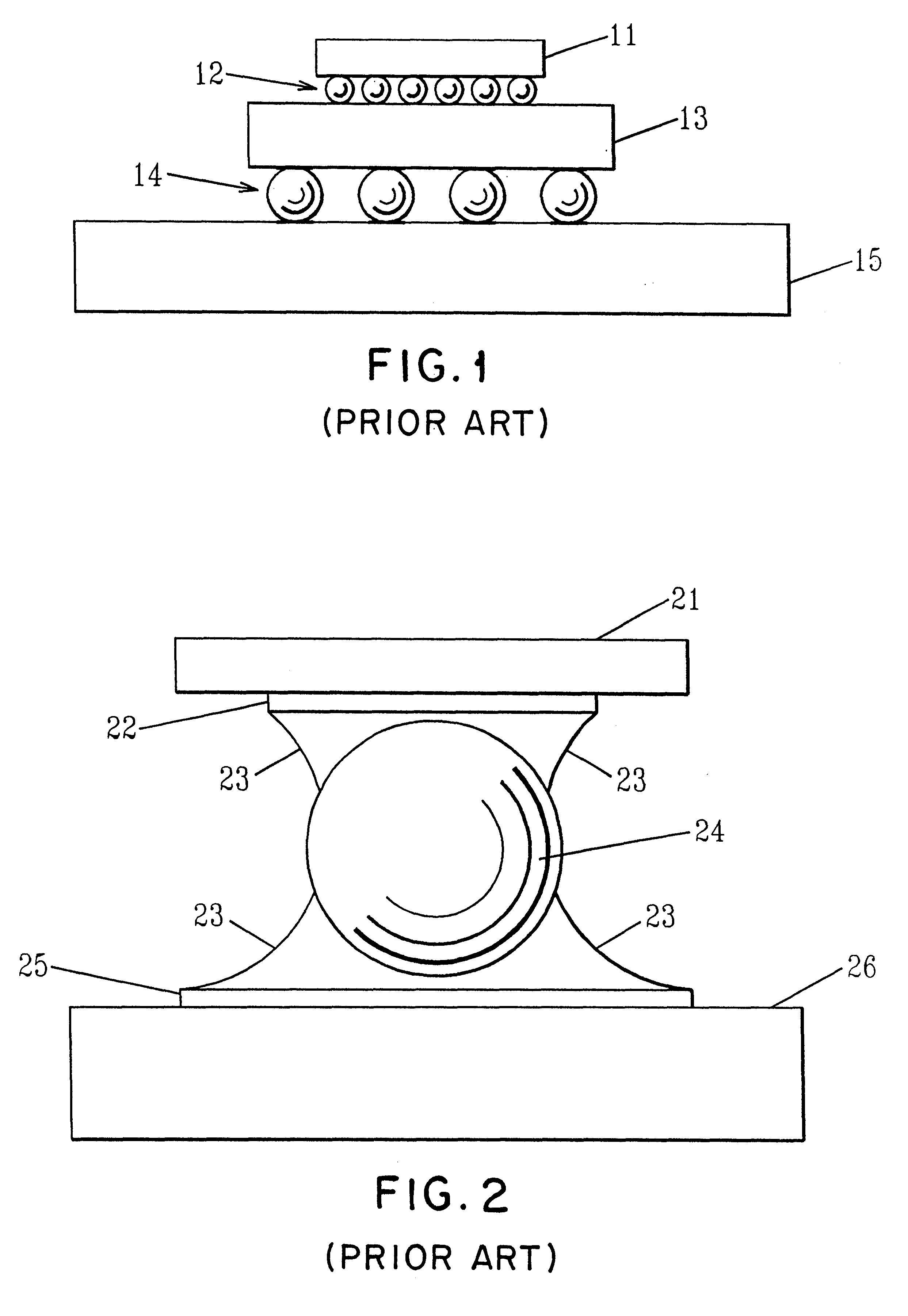

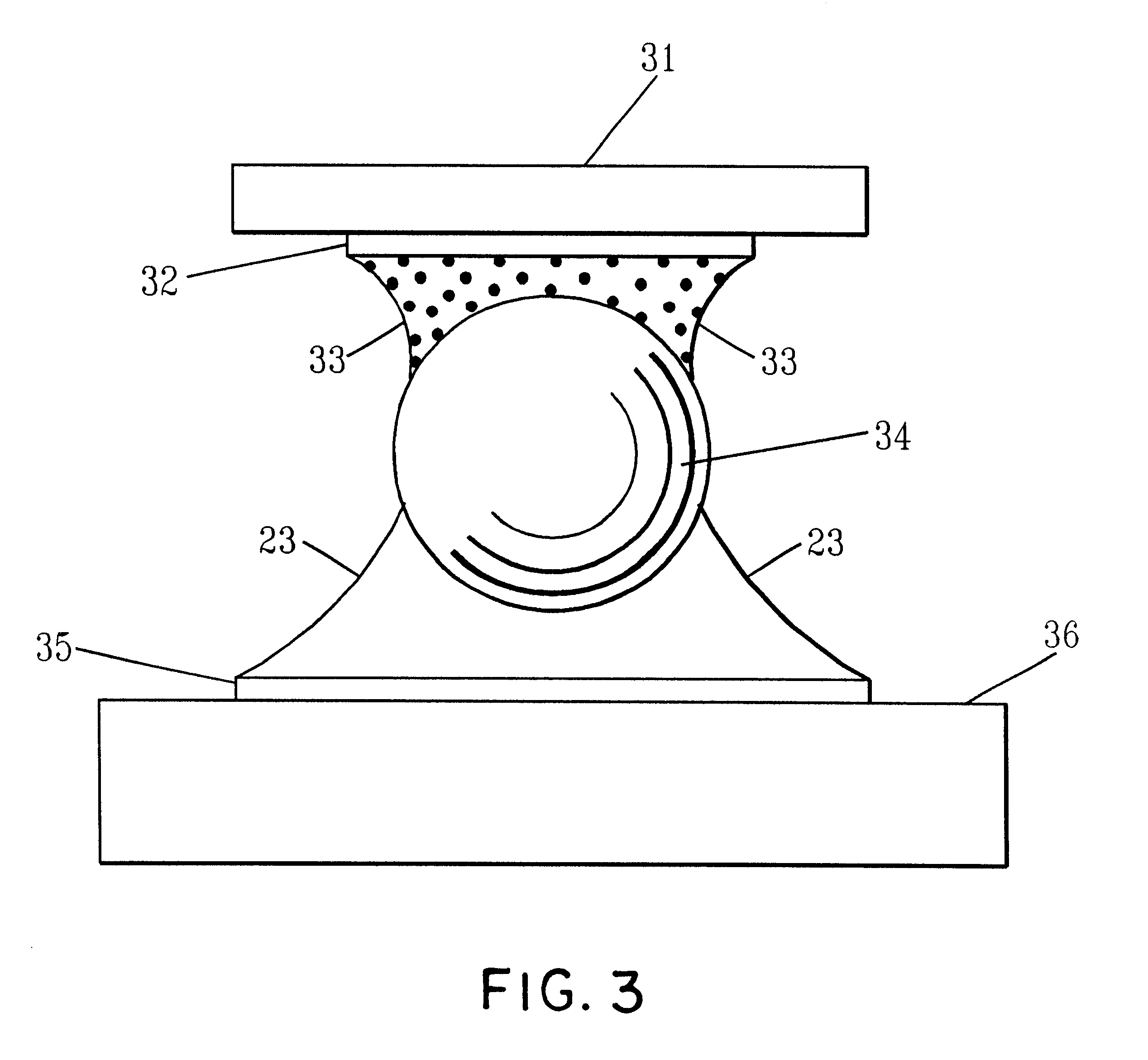

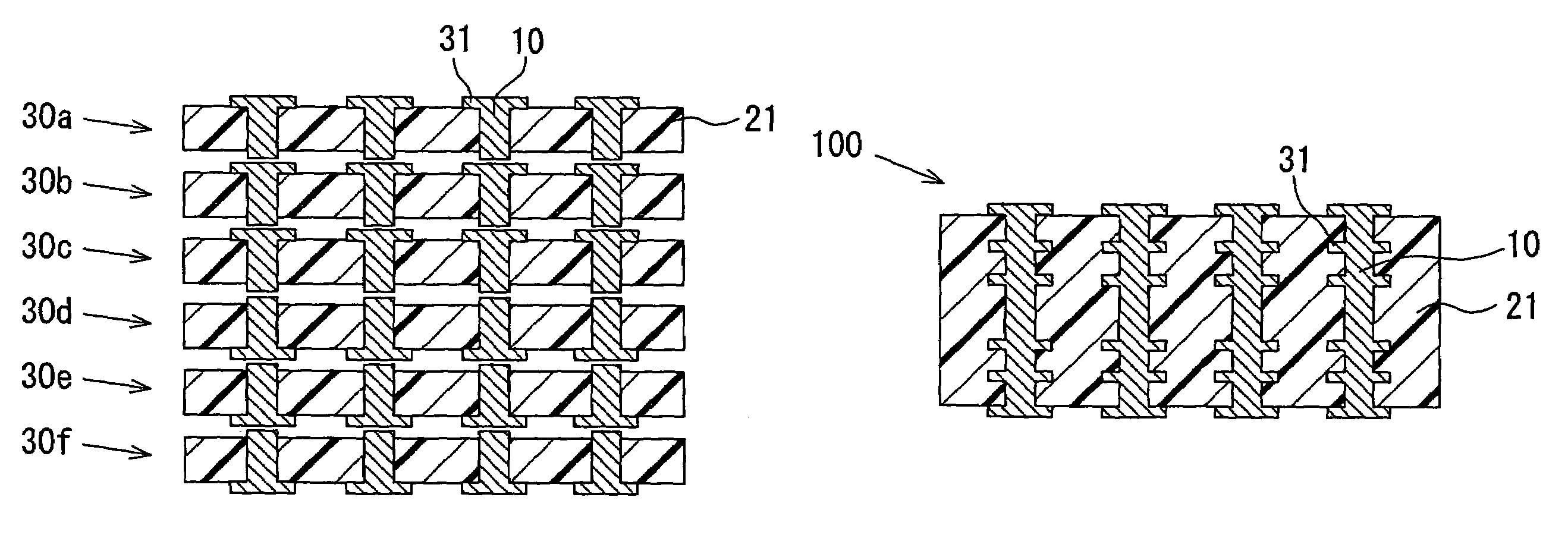

Structure, materials, and applications of ball grid array interconnections

InactiveUS6297559B1Increase in sizeStable structurePrinted circuit assemblingFinal product manufacturePolymer resinSolder ball

A new interconnection scheme of a ball grid array (BGA) module is disclosed where a solder ball is connected to the BGA module by use of an electrically conducting adhesive The electrically conducting adhesive can be a mixture comprising a polymer resin, no-clean solder flux, a plurality of electrically conducting particles with an electrically conducting fusible coating and others. The solder balls in a BGA module can also be connected to a printed circuit board by use of another electrically conductive adhesive which can be joined at a lower temperature than the first joining to the BGA module. Additionally, an electrically conducting adhesive can be formed into electrically conducting adhesive bumps which interconnect an integrated circuit device to the BGA module.

Owner:IBM CORP

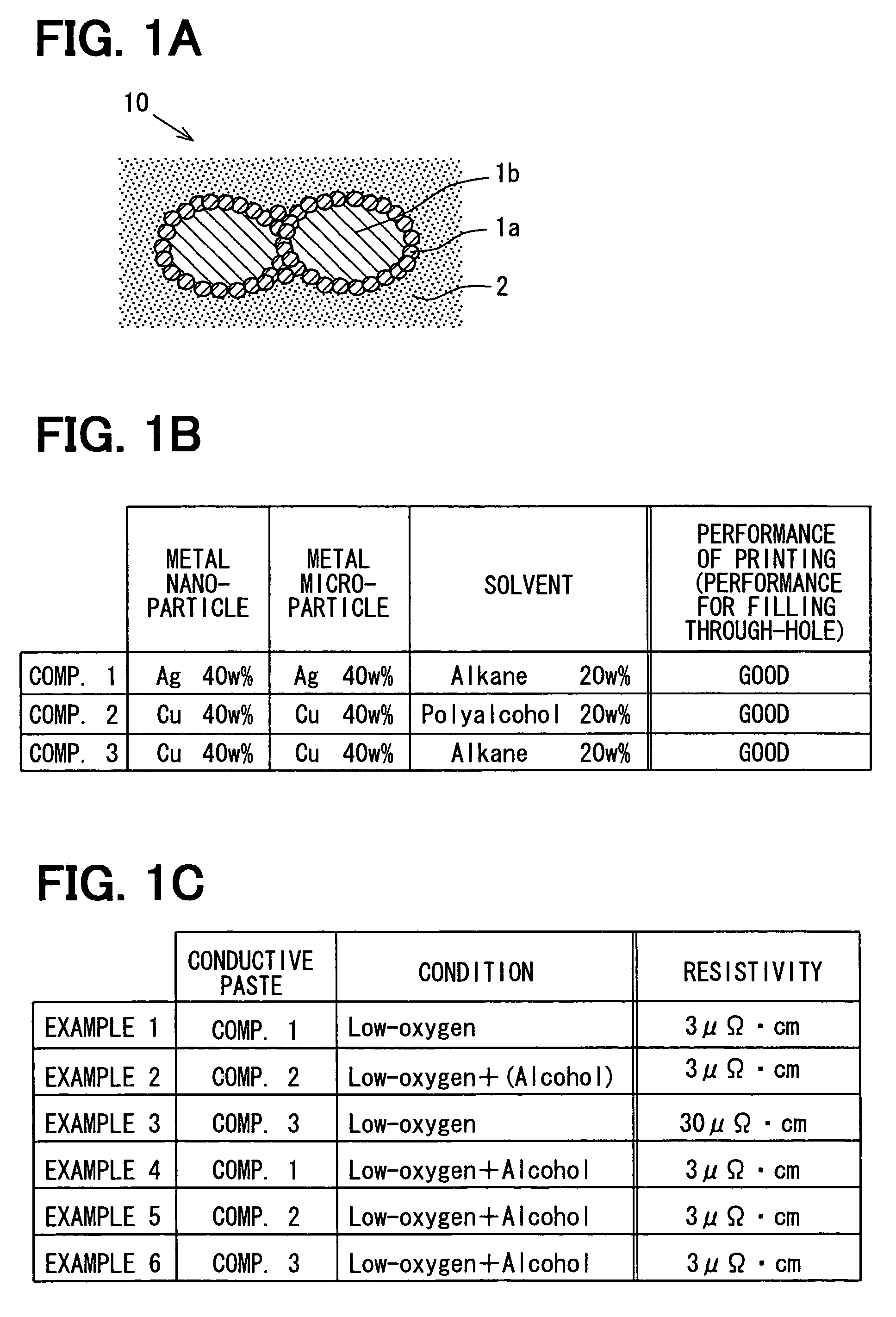

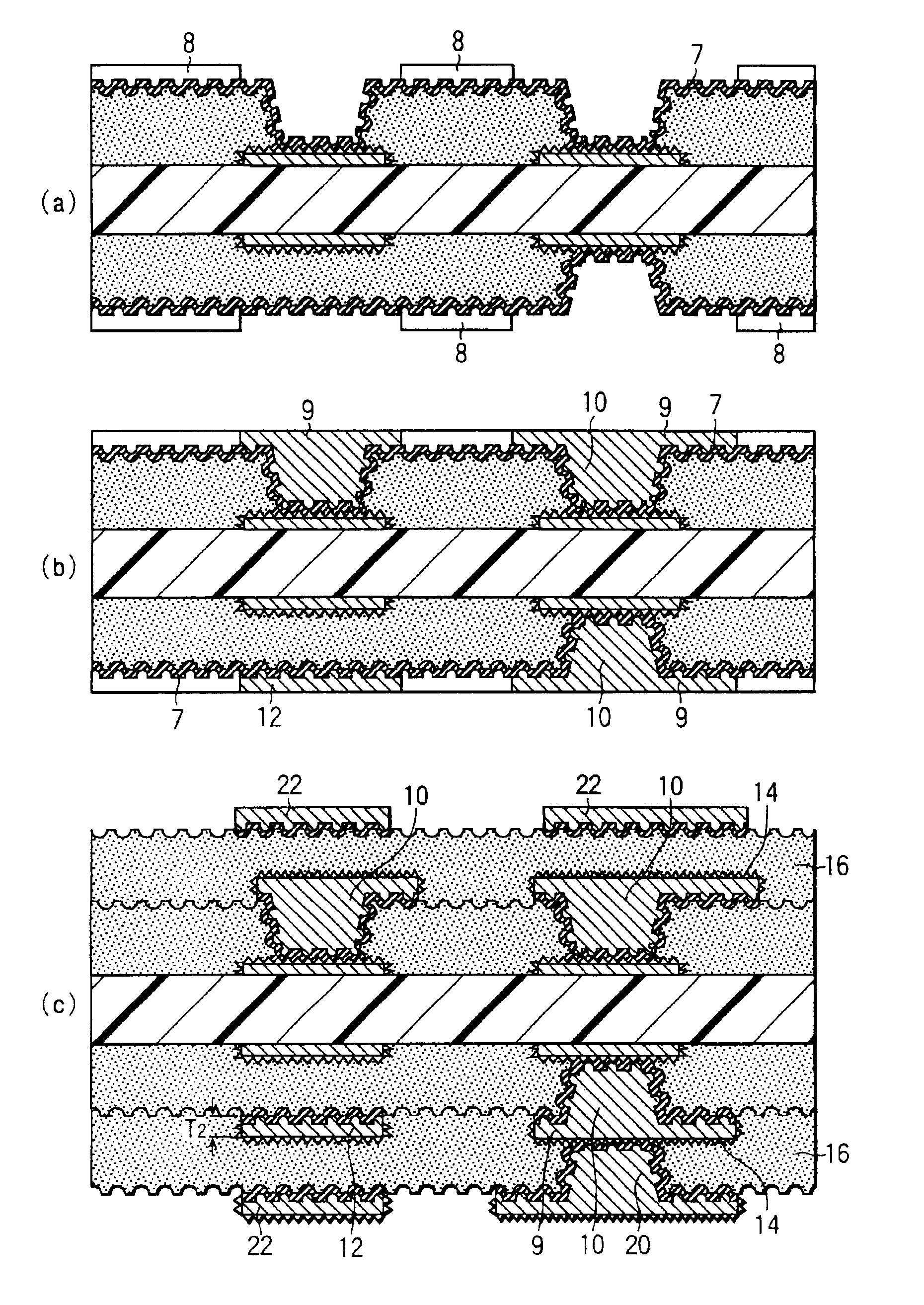

Method of producing circuit board

InactiveUS7458150B2Lower resistanceIncrease resistancePrinted circuit assemblingPhotomechanical apparatusConductive pasteOptoelectronics

A method of producing a circuit board includes a step of providing a conductive paste including metal nano-particles at an insulating substrate, and a step of sintering the conductive paste so as to form a circuit conductor. In the sintering step, the conductive paste is sintered in a low-oxygen condition including alcohol such that the metal nano-particles are sintered.

Owner:DENSO CORP

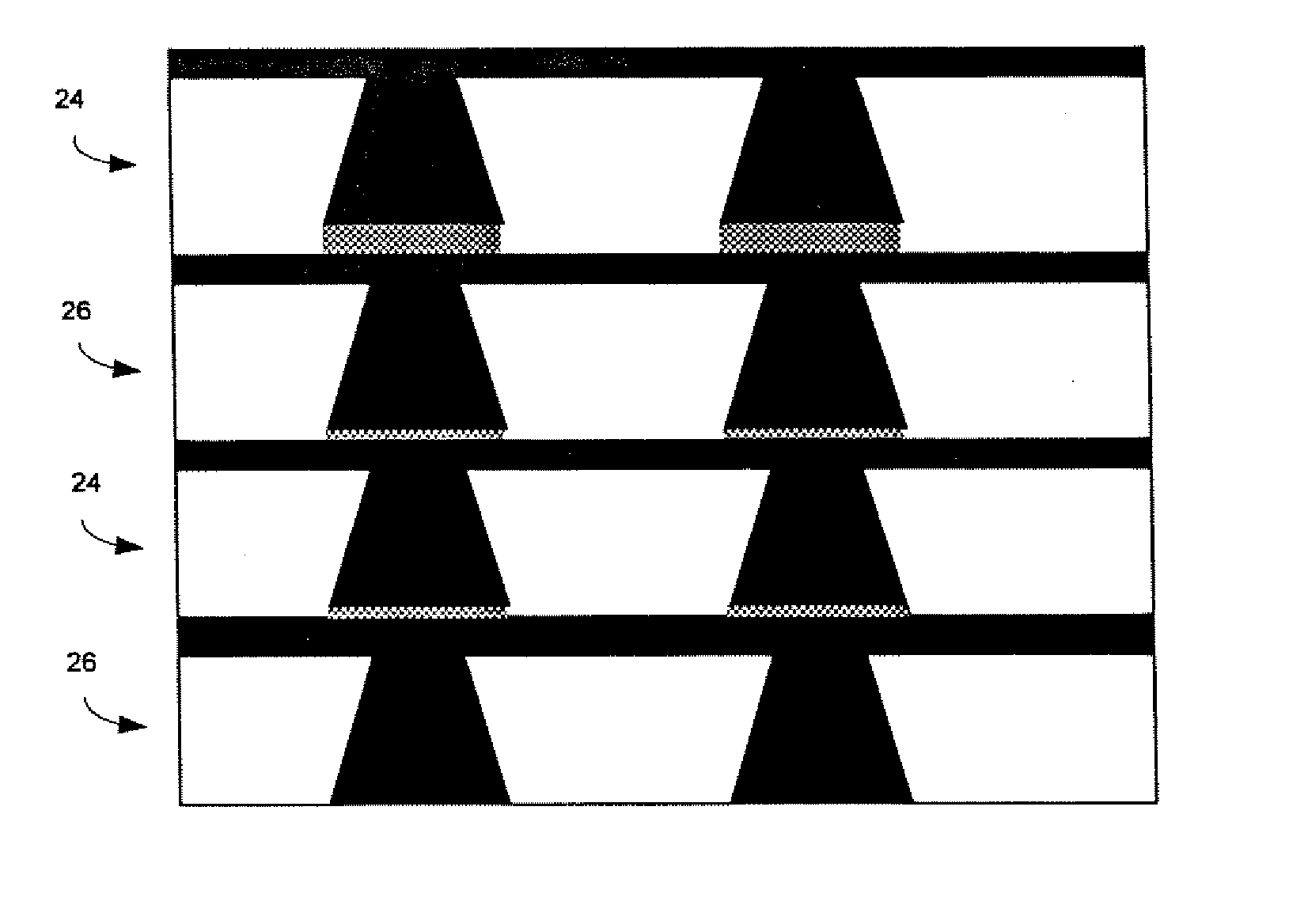

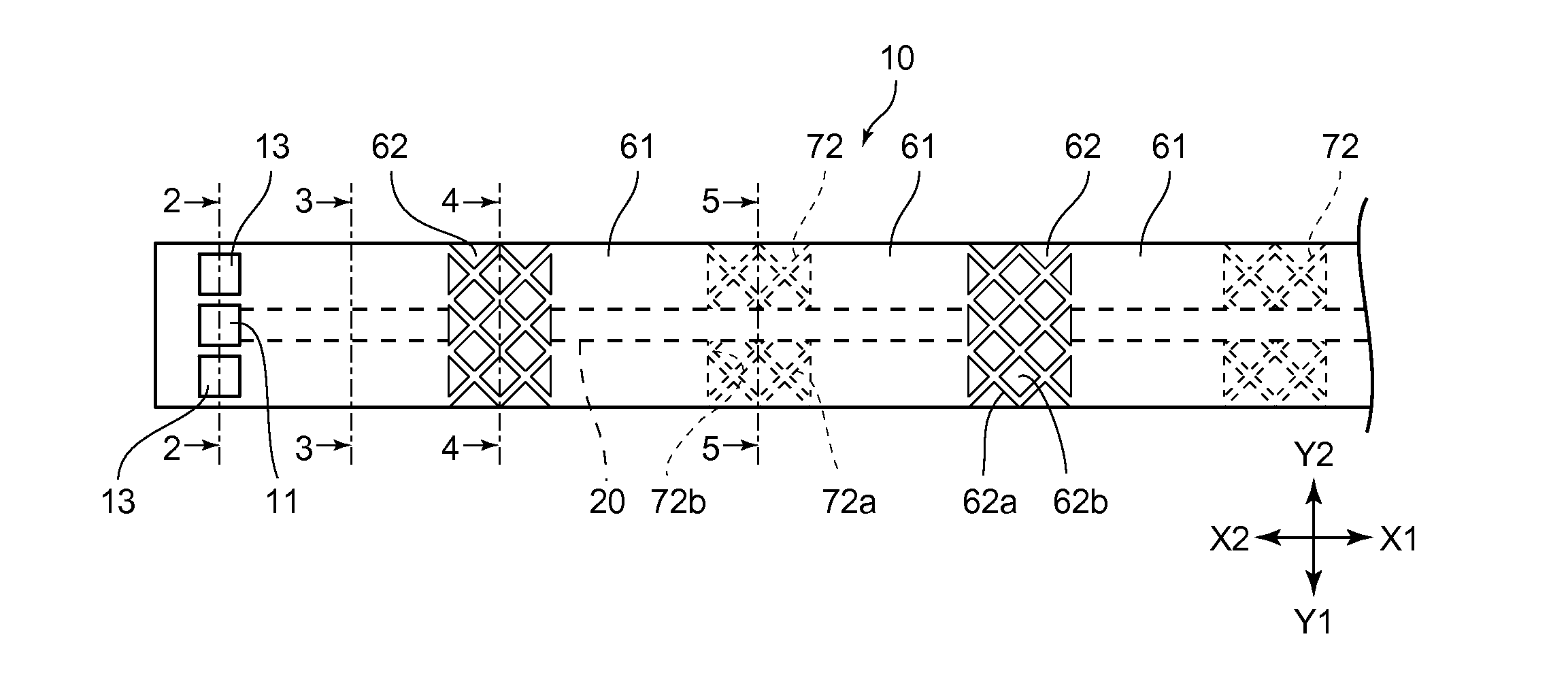

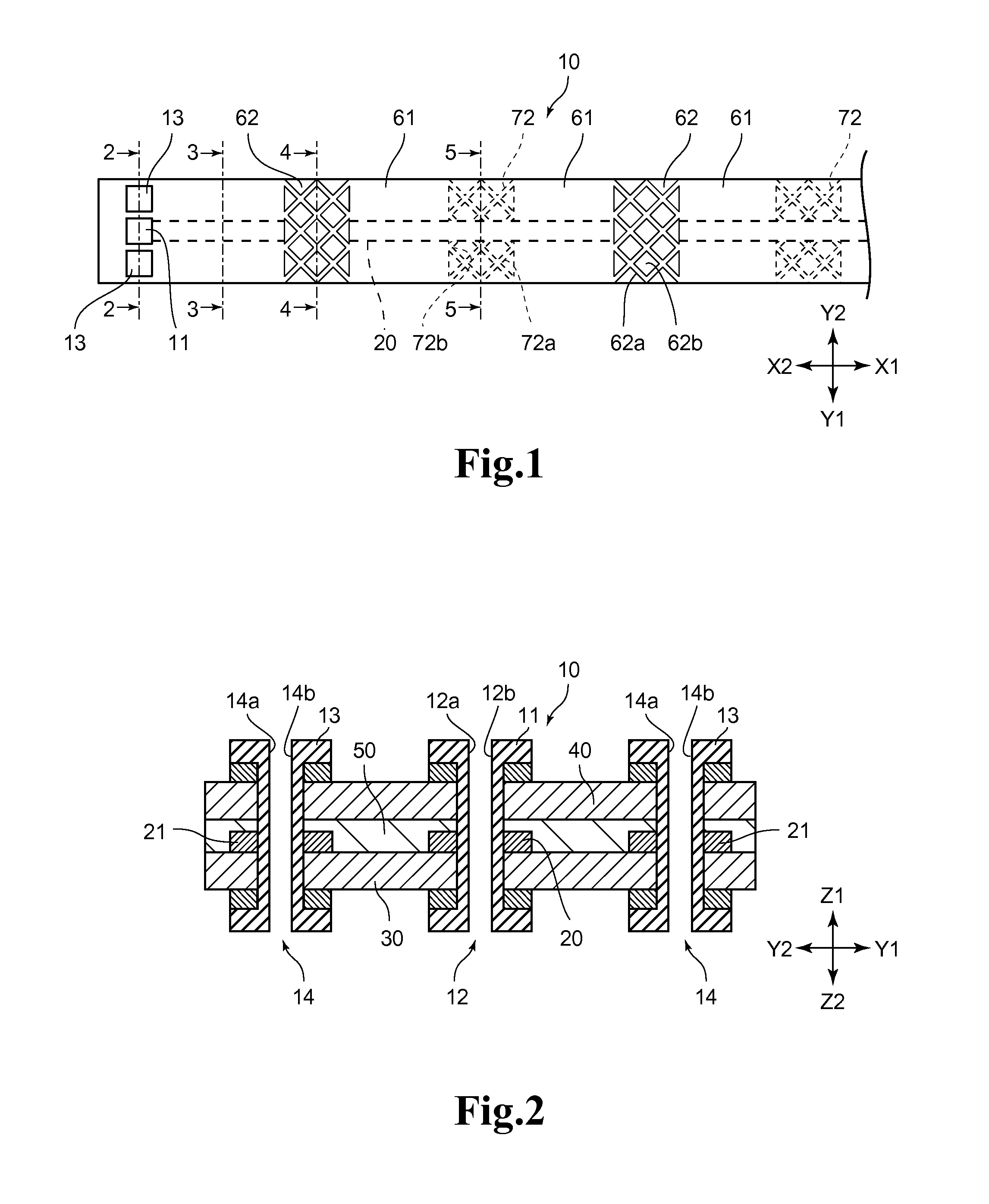

Flexible printed circuit board and manufacturing method of flexible printed circuit board

ActiveUS20160020500A1Electrical connection printed elementsWaveguidesEngineeringFlexible electronics

A flexible printed circuit board having at least a set of strip line transmission path by being provided with a signal line, and a pair of ground layers and, includes a pleated part PL having a plurality of curved portions which are curved so as to be opened or closed, in which in the ground layers, mesh ground layers in which conductive portions are provided in a mesh shape, and solid ground layers in which the conductive portions are provided in a planar state, are provided, in which the mesh ground layers are arranged on an outer peripheral side of the curved portions PL2, and the solid ground layers are arranged on an inner peripheral side of the curved portions.

Owner:NIPPON MEKTRON LTD

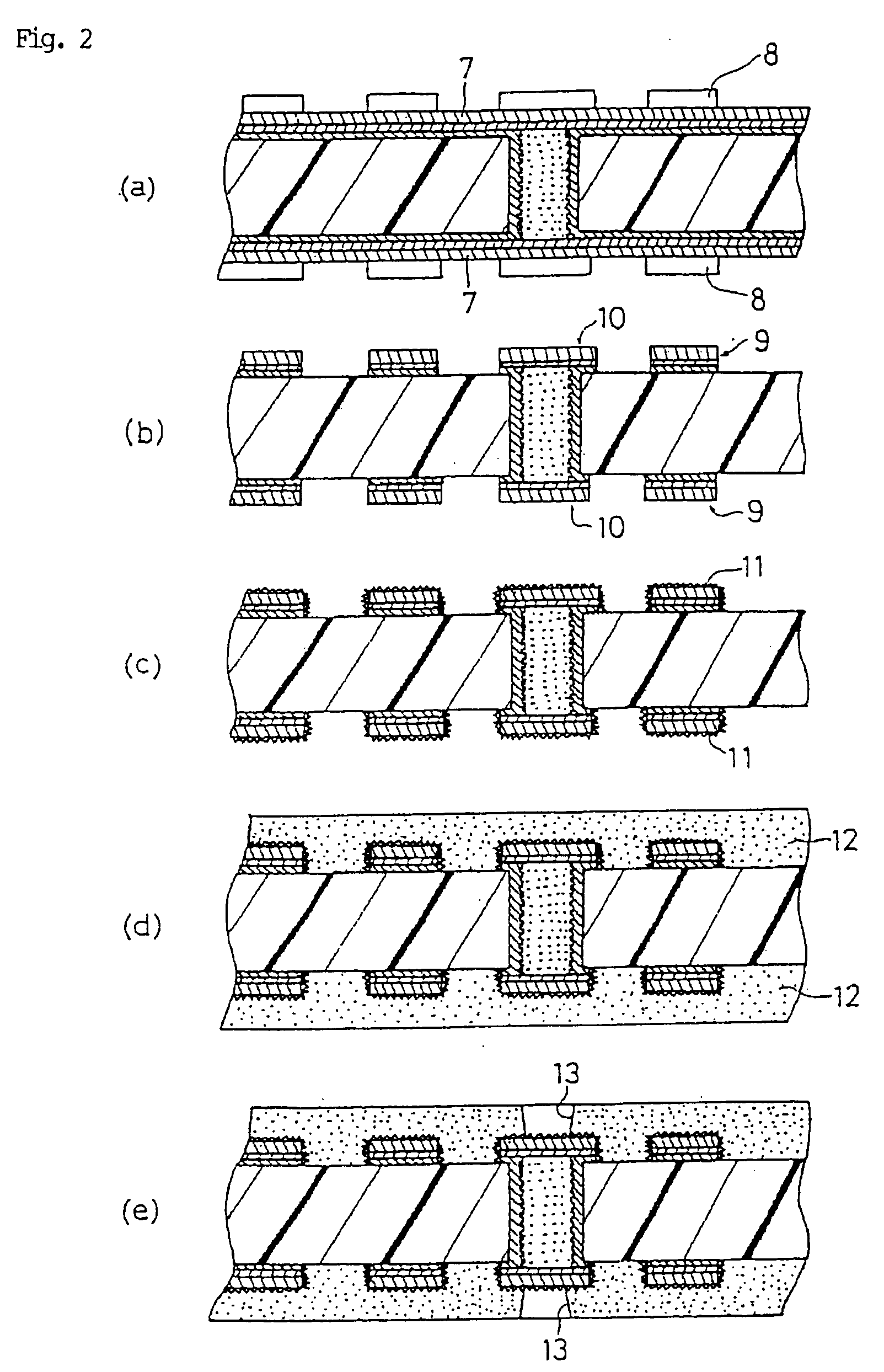

Multilayer printed wiring board having filled-via structure

InactiveUS7071424B1More highly reliableUniform thicknessInsulating substrate metal adhesion improvementDielectric materialsHigh fractureElectrical conductor

The present invention provides a multilayer printed wiring board having a filled viahole structure advantageously usable for forming a fine circuit pattern thereon, and having an excellent resistance against cracking under a thermal shock or due to heat cycle. The multilayer printed wiring board is comprised of conductor circuitry layers and interlaminar insulative resin layers deposited alternately one on another, the interlaminar insulative resin layers each having formed through them holes each filled with a plating layer to form a viahole. The surface of the plating layer exposed out of the hole for the viahole is formed substantially flat and lies at a substantially same level as the surface of the conductor circuit disposed in the interlaminar insulative resin layer. The thickness of the conductor circuitry layer is less than a half of the viahole diameter and less than 25 μm. The inner wall of the hole formed in the interlaminar insulative resin layer is roughened and an electroless plating layer is deposited on the roughened surface. An electroplating layer is filled in the hole including the electroless plating layer to form the viahole. The interlaminar insulative resin layer is formed from a composite of a fluororesin showing a high fracture toughness and a heat-resistant thermoplastic resin, a composite of fluororesin and thermosetting resin or a composite of thermosetting and thermoplastic resins.

Owner:IBIDEN CO LTD

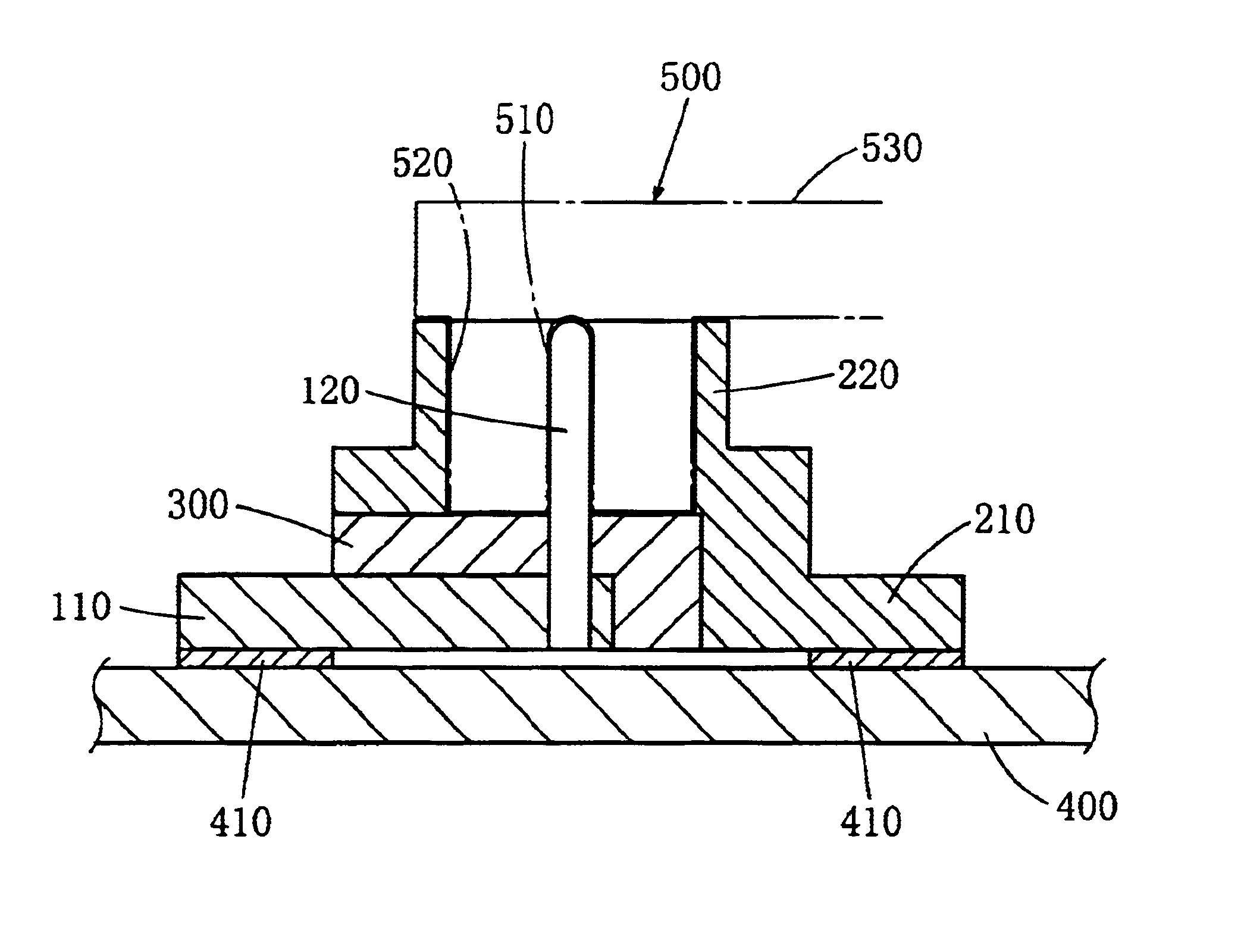

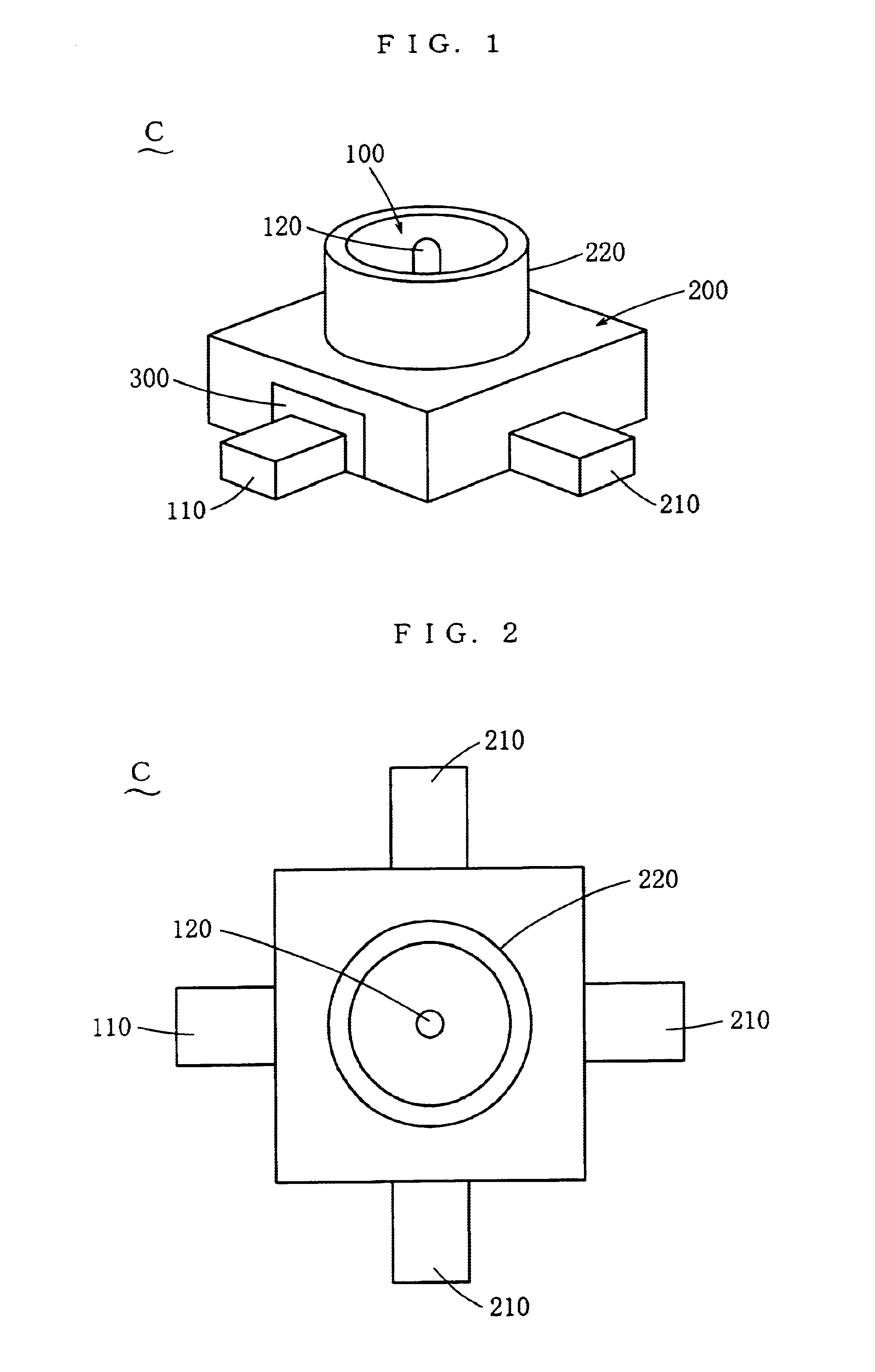

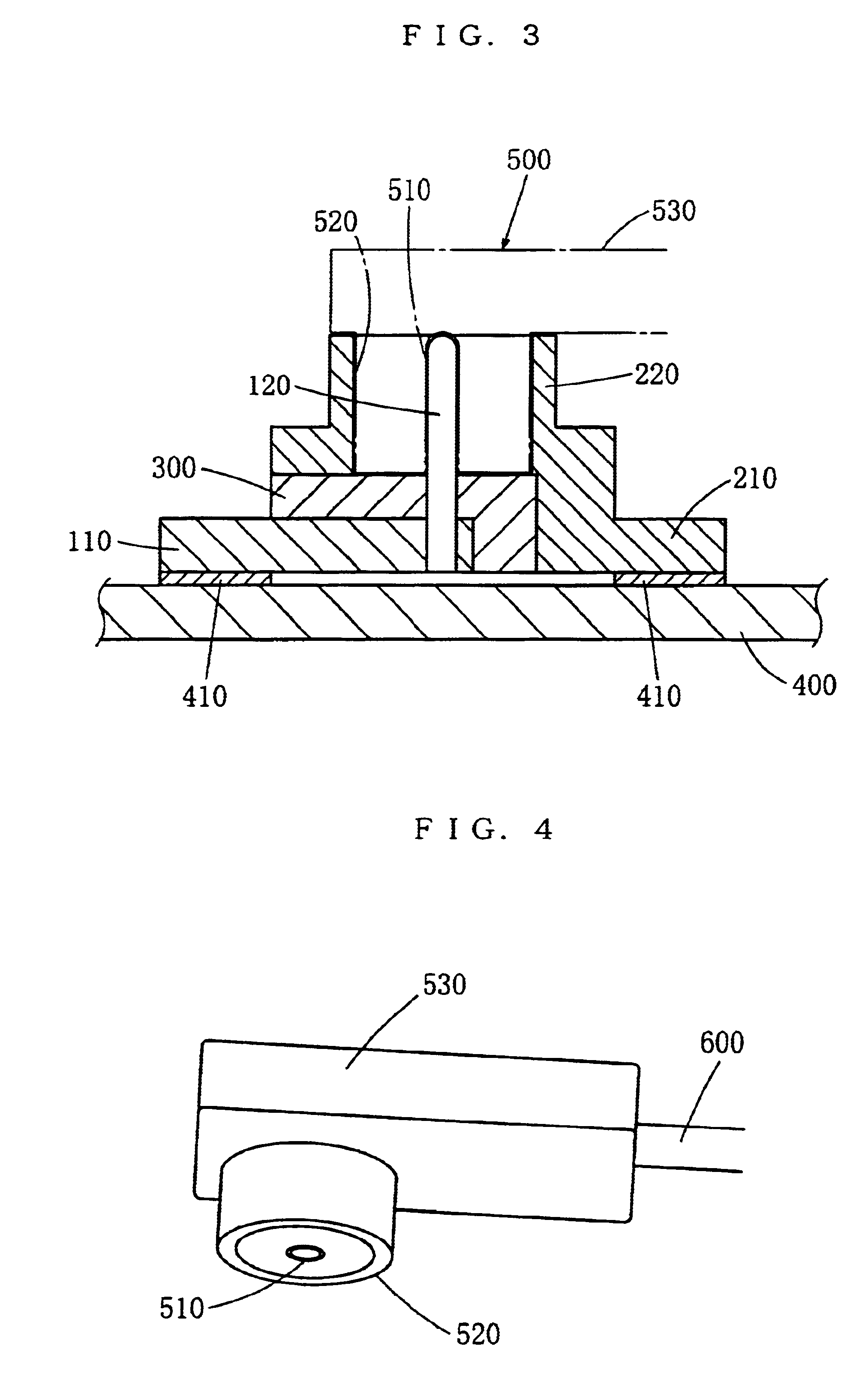

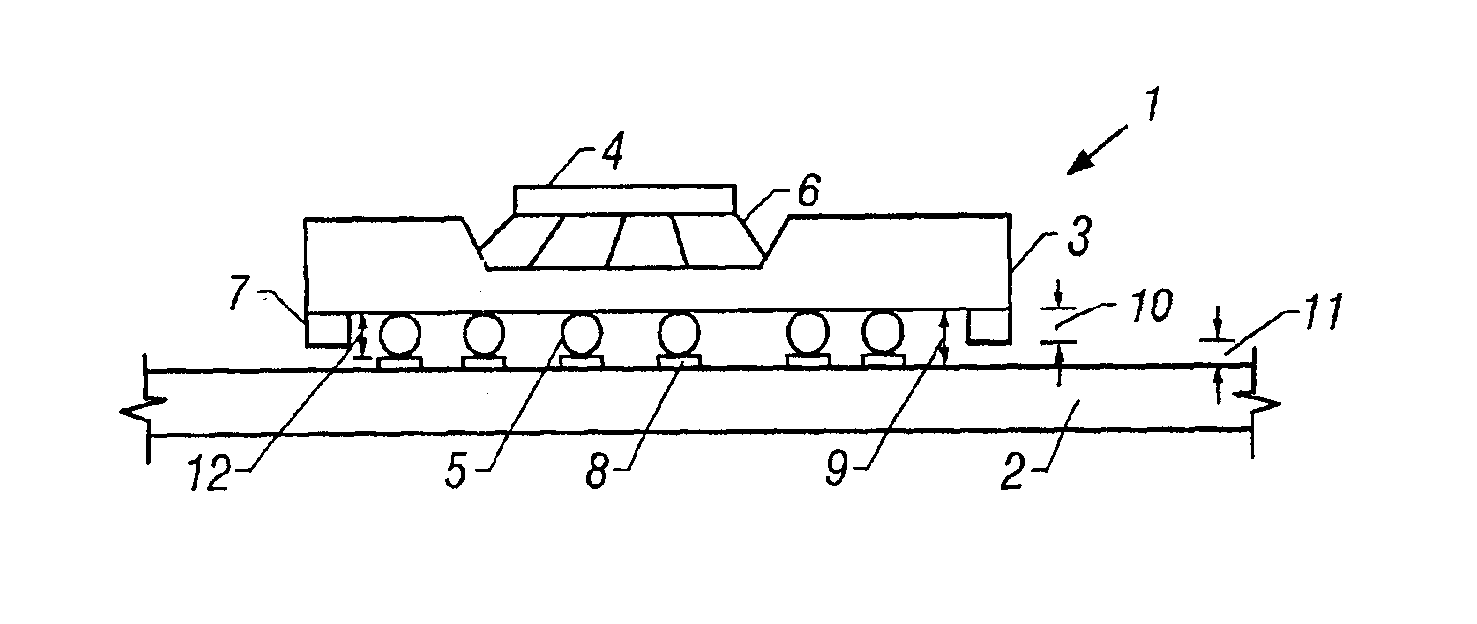

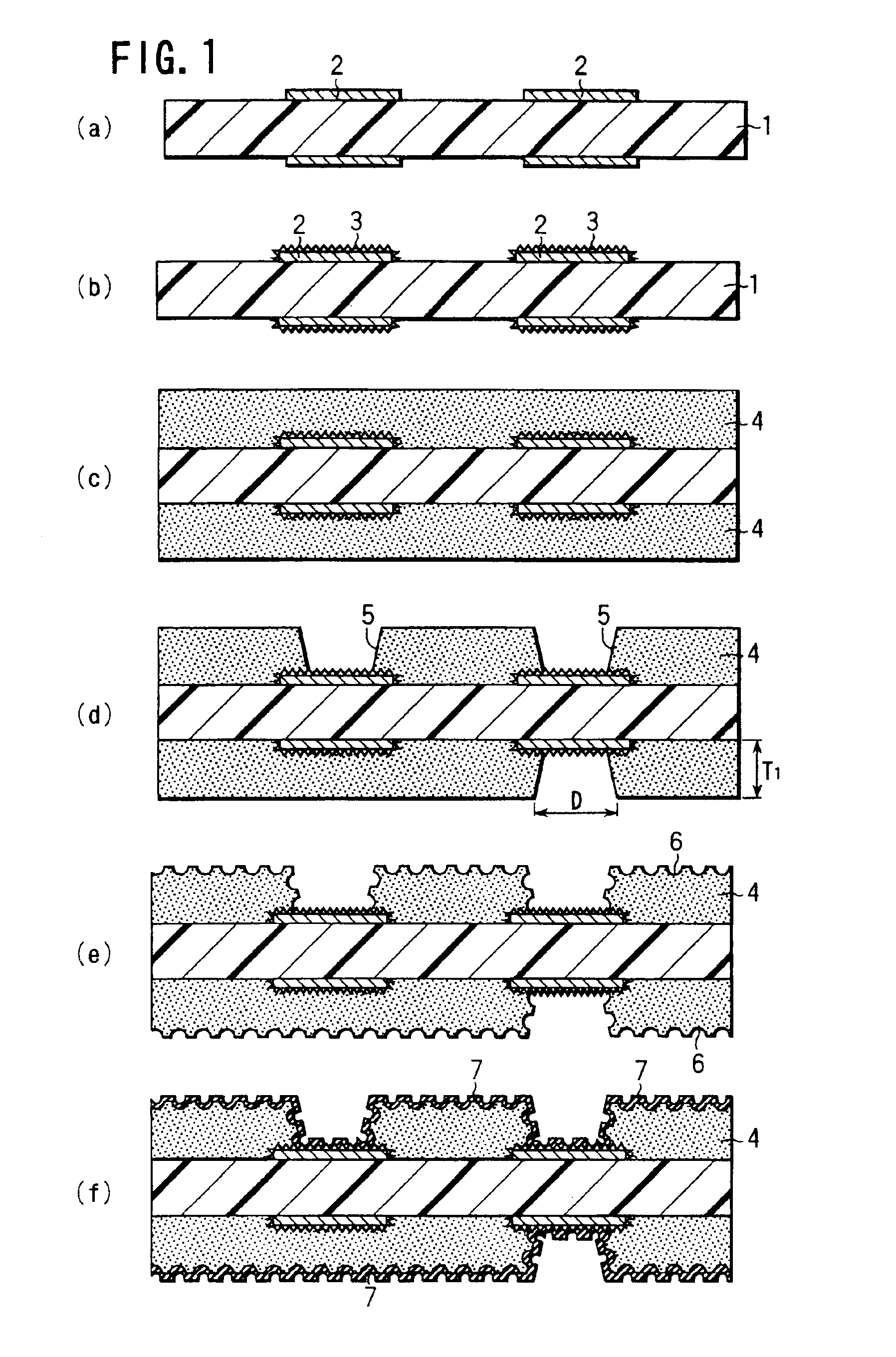

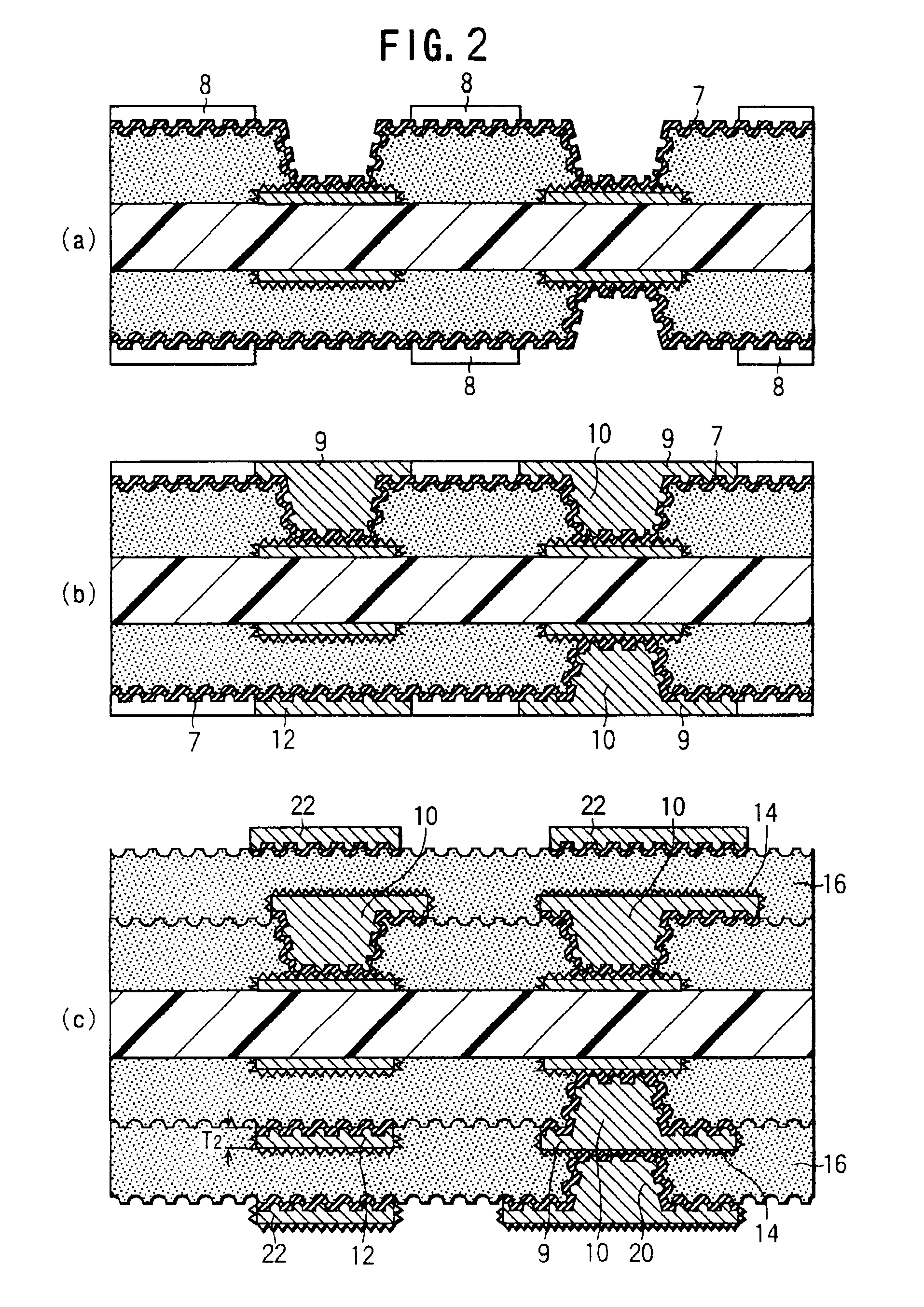

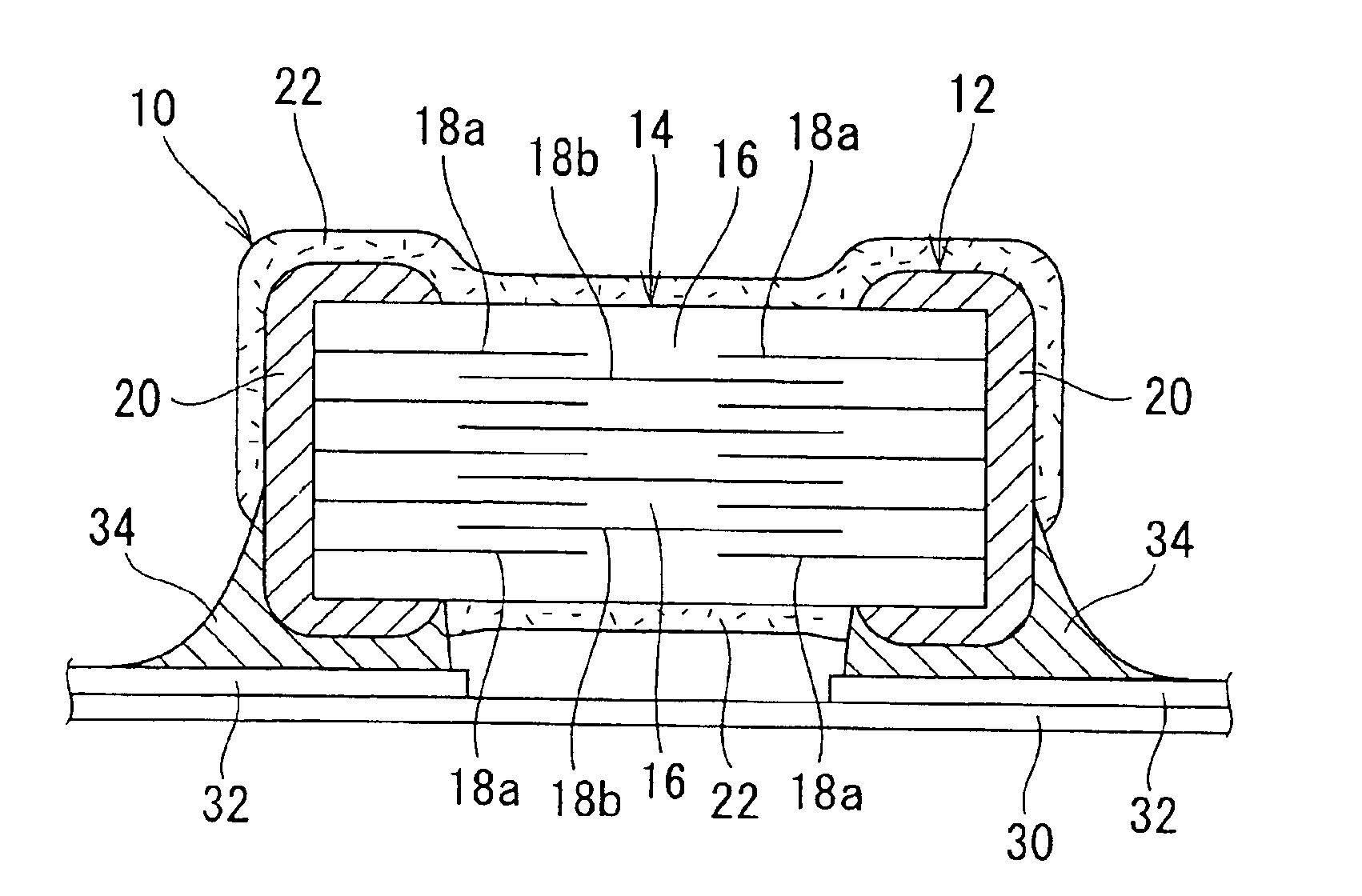

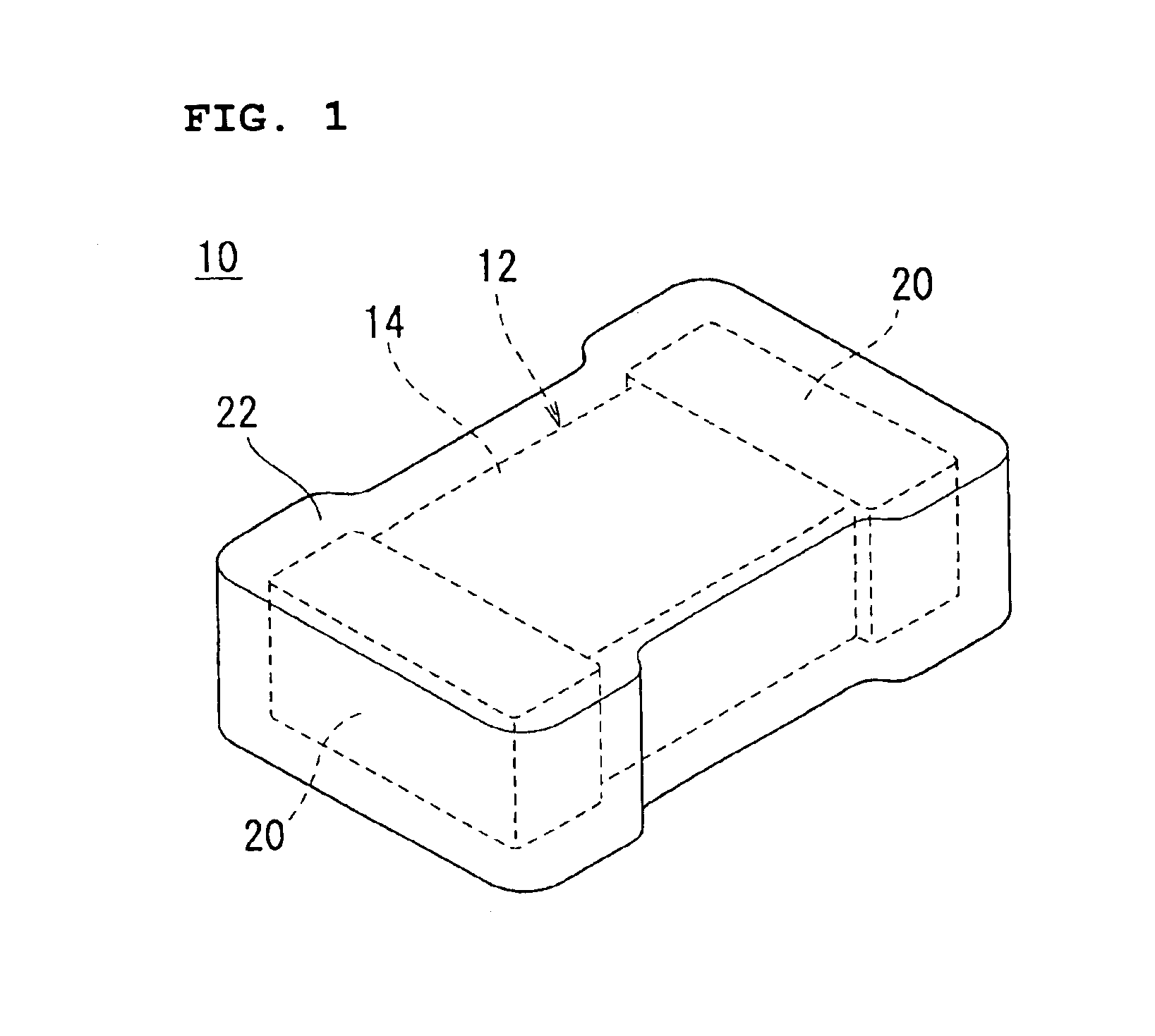

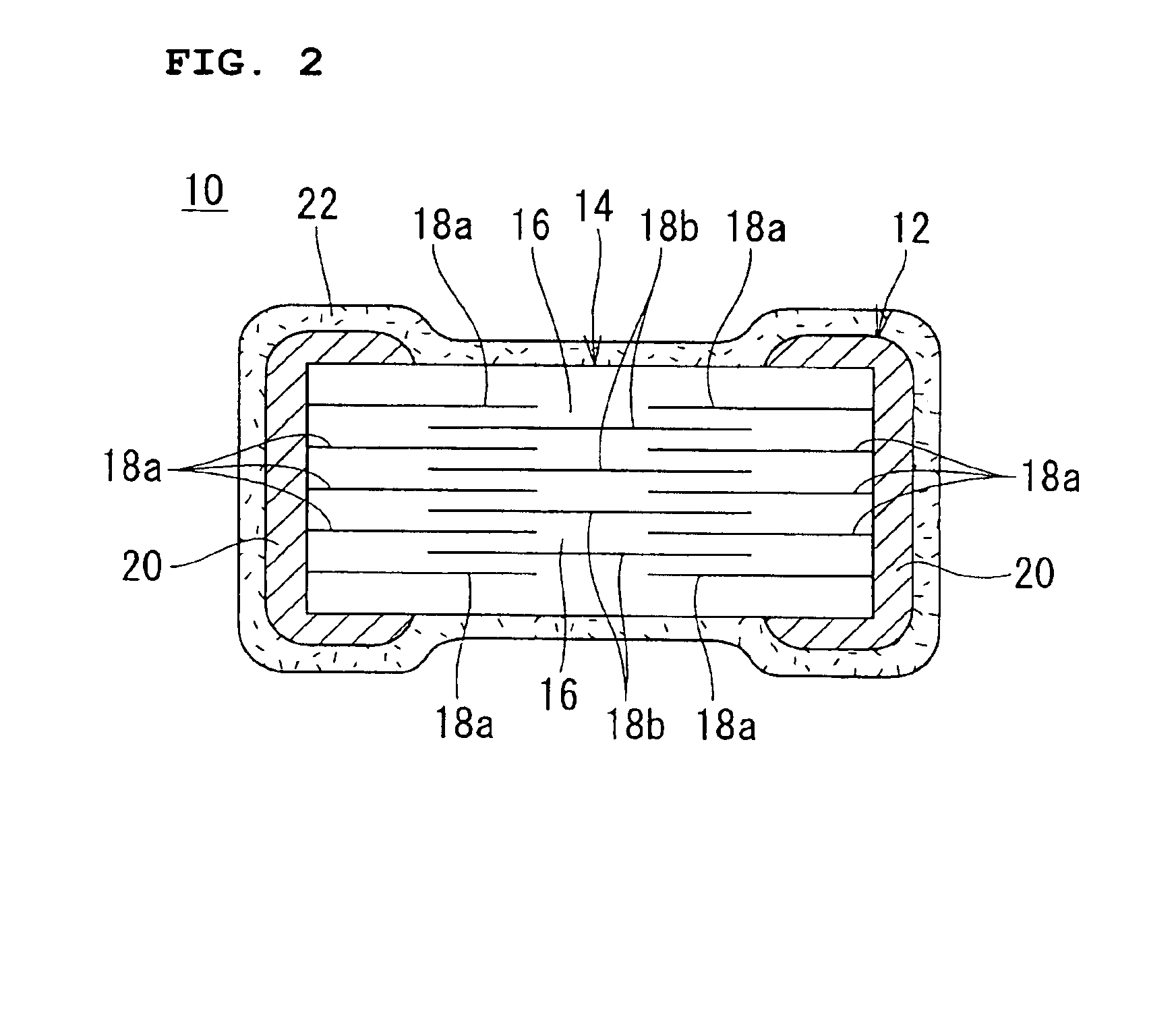

Multilayer ceramic electronic component and mounting structure and method for the same

ActiveUS6903919B2Increase resistancePrevent leakagePrinted circuit assemblingFinal product manufactureSolderingElectronic component

A multilayer ceramic electronic component is prepared by covering a capacitor element with a thermoplastic resin layer that is mounted on a substrate by soldering. The thermoplastic resin layer is molten due to the heat required for soldering. The molten resin layer flows to expose external electrodes of the electronic component. The exposed external electrodes are soldered to electrodes of the substrate. In the resultant mounting structure, the thermoplastic resin layer covers substantially the entire surface except for the soldered portion of the electronic component and a portion of the solder.

Owner:MURATA MFG CO LTD

Flexible circuit electrode array

ActiveUS8180460B2Head electrodesPrinted circuit secondary treatmentElectrical resistance and conductanceRetinal stimulation

A flexible circuit electrode array with more than one layer of metal traces comprising: a polymer base layer; more than one layer of metal traces, separated by polymer layers, deposited on said polymer base layer, including electrodes suitable to stimulate neural tissue; and a polymer top layer deposited on said polymer base layer and said metal traces. Polymer materials are useful as electrode array bodies for neural stimulation. They are particularly useful for retinal stimulation to create artificial vision, cochlear stimulation to create artificial hearing, or cortical stimulation many purposes. The pressure applied against the retina, or other neural tissue, by an electrode array is critical. Too little pressure causes increased electrical resistance, along with electric field dispersion. Too much pressure may block blood flow.

Owner:CORTIGENT INC

Anisotropic-electroconductive adhesive, circuit connection method and structure using the same

InactiveUS20060054277A1Avoid long connectionsPrevents a short circuitPrinted circuit assemblingLayered productsAdhesivePolymerization

Disclosed is an anisotropic-electroconductive adhesive, which includes an insulating adhesive component containing a radical polymerizable compound and a polymerization initiator; and a plurality of insulating coated electroconductive particles dispersed in the insulating adhesive component, the insulating coated electroconductive particle having a coating layer made of insulating thermoplastic resin on a surface of an electroconductive particle, wherein a softening point of the insulating thermoplastic resin is lower than an exothermic peak temperature of the insulating adhesive component. The anisotropic-electroconductive adhesive enables rapid curing of the insulating adhesive component at a low temperature and is very useful for making a circuit connection structure since it may prevent a short of circuit without connection failure even when the electroconductive particles are condensed.

Owner:LS MTRON LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com