Heat treatment method of thin-wall damage tolerance type TC4-DT titanium alloy part

A technology of TC4-DT and heat treatment method, which is applied in the field of titanium alloy parts processing, can solve problems such as stress deformation, achieve the effects of solving stress deformation, stabilizing processing size, and improving pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

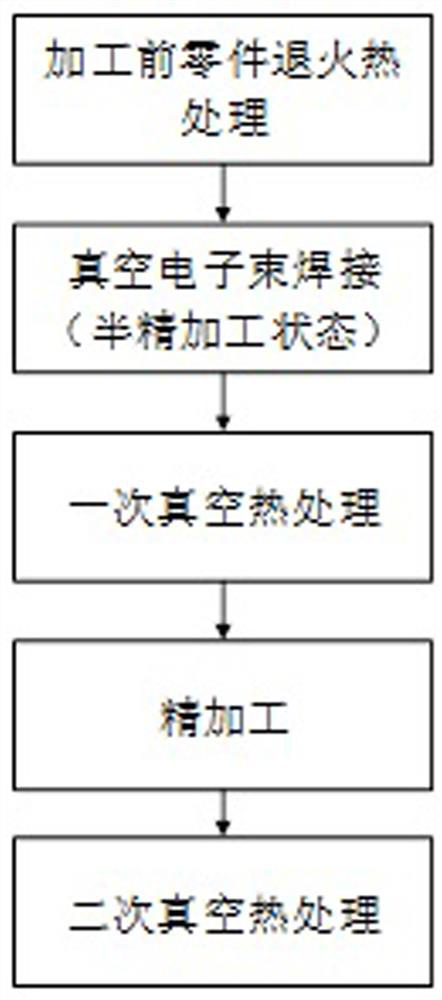

[0028] This embodiment provides a heat treatment method for a thin-walled damage-tolerant titanium alloy part. The heat treatment method for a thin-walled damage-tolerant titanium alloy part includes the following steps:

[0029] (1) Before processing, an annealing treatment is performed on the damage-tolerant titanium alloy parts. The heat treatment temperature is 730 ° C, kept for 2 hours, and air-cooled. Mechanical processing after heat treatment;

[0030] (2) Thin-wall damage-tolerant titanium alloy parts in the semi-finishing state are placed in a vacuum welding furnace for 1-2 hours for a vacuum electron beam welding;

[0031] (3) Put the thin-walled damage-tolerant titanium alloy parts after vacuum electron beam welding into the heat treatment tooling (1), and the positioning reference adopts the CNC machining process hole of the part, and the upper part of the tooling adds a 150kg counterweight;

[0032] (4) Put thin-walled damage-tolerant titanium alloy parts and hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com