Mechanism and method for tooth difference rigidity dividing adjustment for thread spinners

A technology for adjusting the mechanism and tooth difference, which is used in mechanical equipment, textiles and papermaking, mechanical drive clutches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

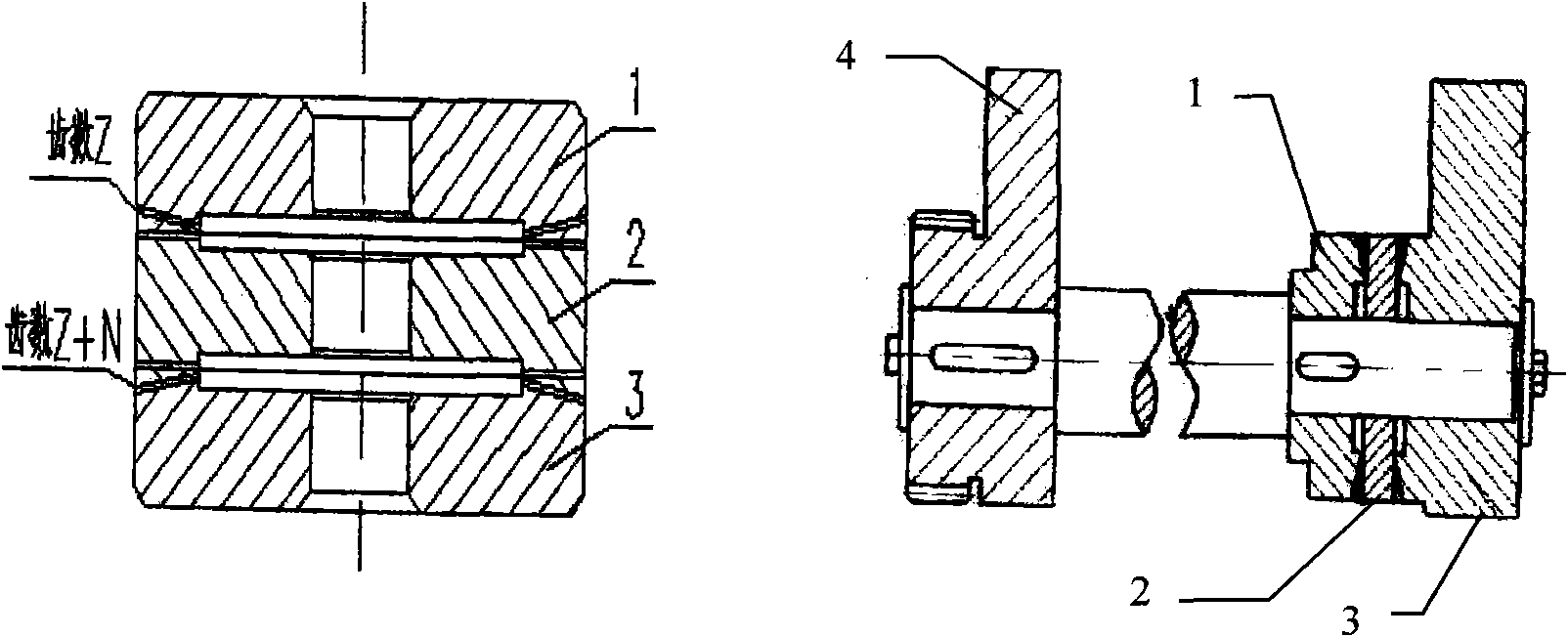

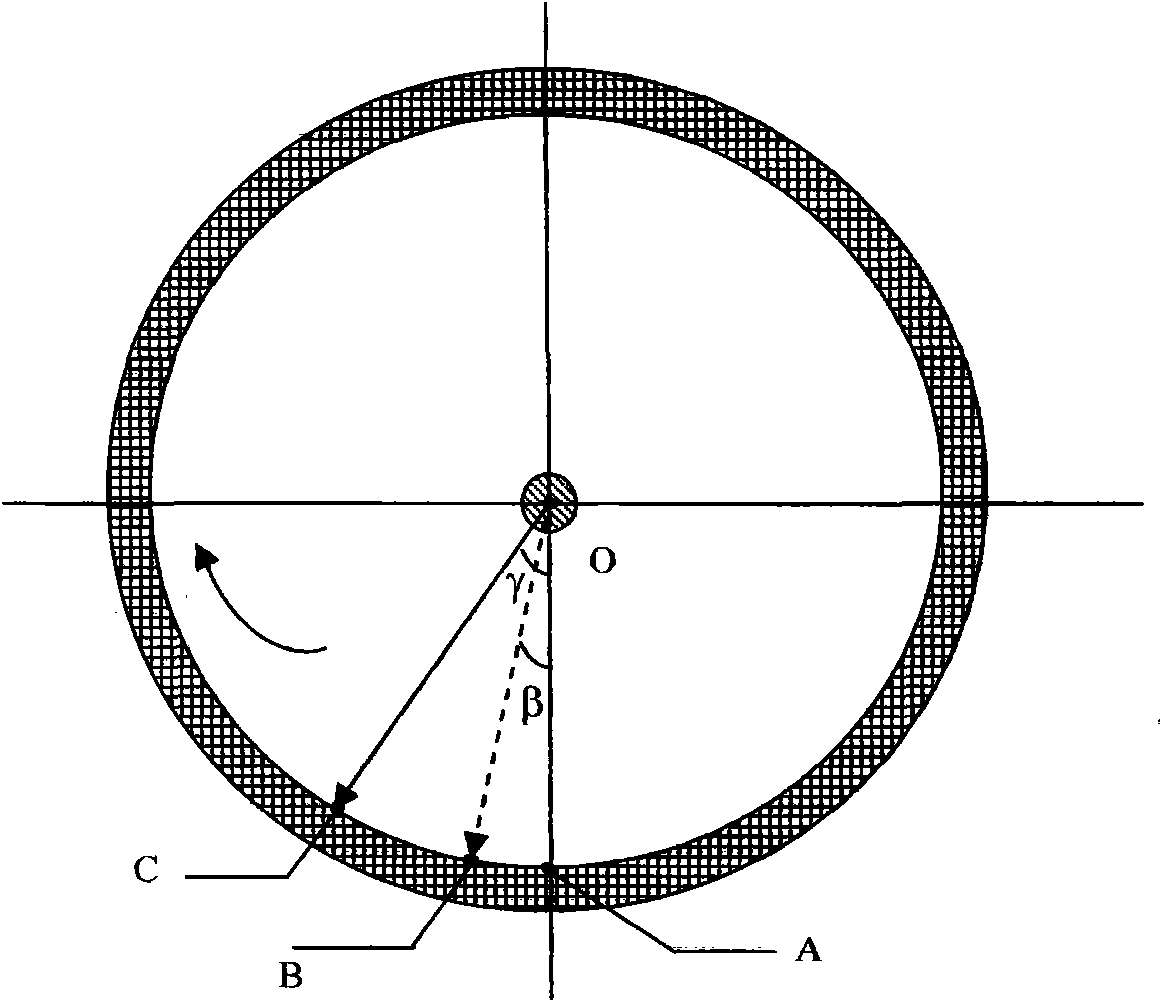

[0029] Refer to figure 1 As shown, the tooth difference rigidity indexing adjustment mechanism is divided into three layers: the upper part (1), the middle part (2) and the lower part (3). The layers are connected in the form of a rat tooth clutch and are on the same axis. on. In the figure, in order to ensure that the calculation cam (4) and the lower part (3) are kept synchronized, the following method proposed in this structure is adopted: set the number of teeth between the upper part (1) and the middle part (1) as Z, and the lower part (3) The number of teeth between (3) and the middle part (2) is Z+N; in the design of the mechanism, the upper part of the middle part (2) maintains the same number of teeth as the upper part (1), and the middle part ( The lower part of 2) maintains the same number of teeth as the lower part (3). The difference in the number of teeth between the upper and lower parts can be 1, or 2, 3, or N. N is an integer greater than or equal to 1. When adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com