Method for detecting shape and depth error of tooth surface of mouse tooth disc

A technology of error detection and mouse tooth disc, which is applied in the direction of mechanical depth measurement, etc., can solve the problems of complex operation and long detection cycle, and achieve the effect of simple operation steps, convenient error detection and shortened detection cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

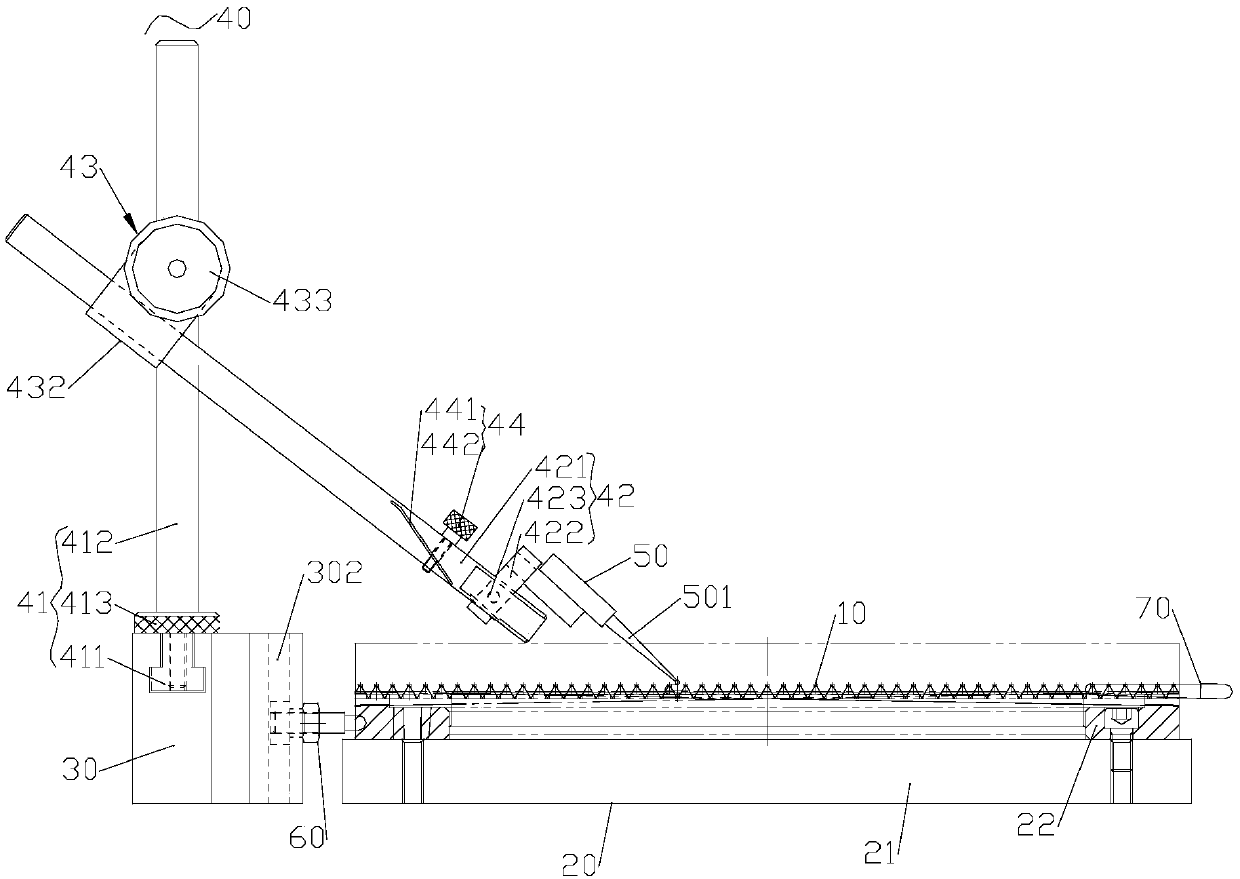

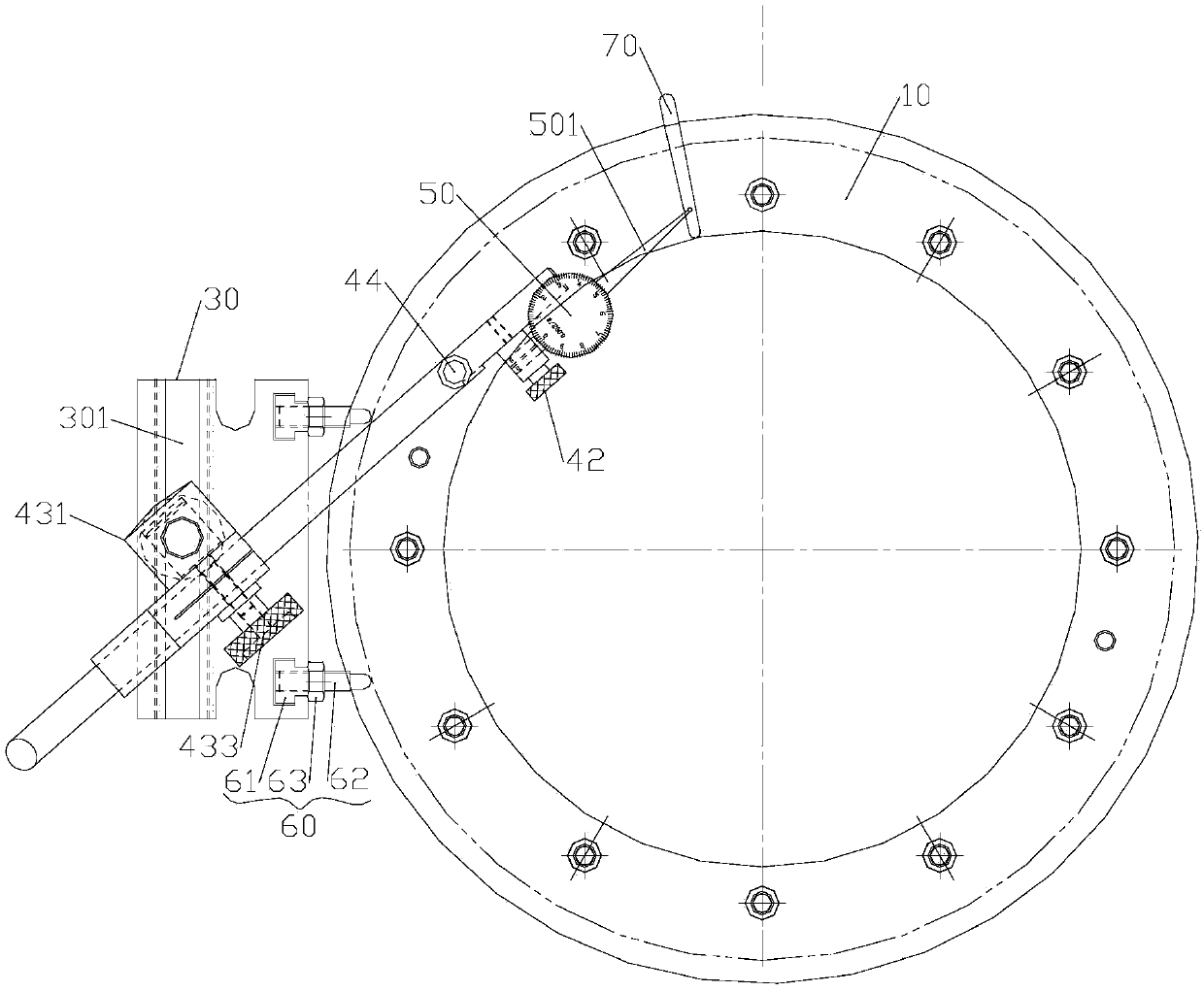

[0027] refer to figure 2 and image 3 , a preferred embodiment of the present invention provides a method for detecting a tooth surface shape depth error of a Hirth plate, comprising the following steps:

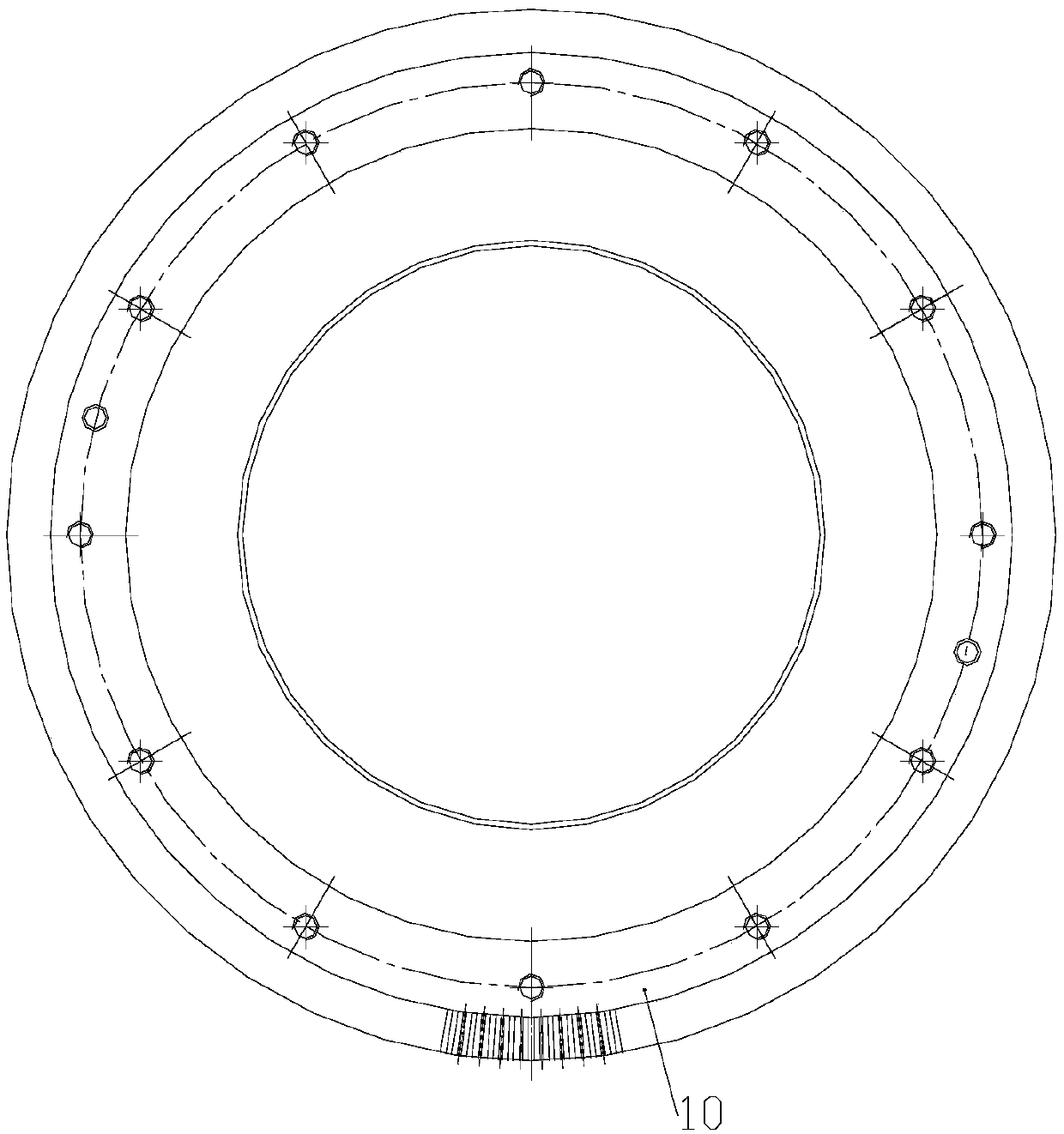

[0028] S10: Installing and positioning the Hirth 10 to be detected for tooth surface shape depth error.

[0029] S20: Install and position the measuring rod 70 in the testing device on the tooth profile surface of the Hirth plate 10 to be tested.

[0030] S30: Press the measuring gauge 50 in the detection device on the outer circle of the measuring rod 70, and move along the outer cone generatrix of the measuring rod 70 to display the maximum pressure gauge value of the outer cone generatrix.

[0031] S40: Repeat step S20 and step S30 in turn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com