Special pushing device for completely degradable occluder and method for connection of special pushing device with occluder

A technology of pushing device and occluder, which is applied in the field of medical devices or

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

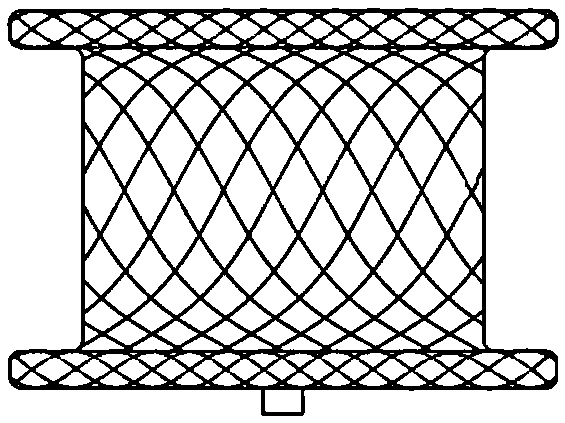

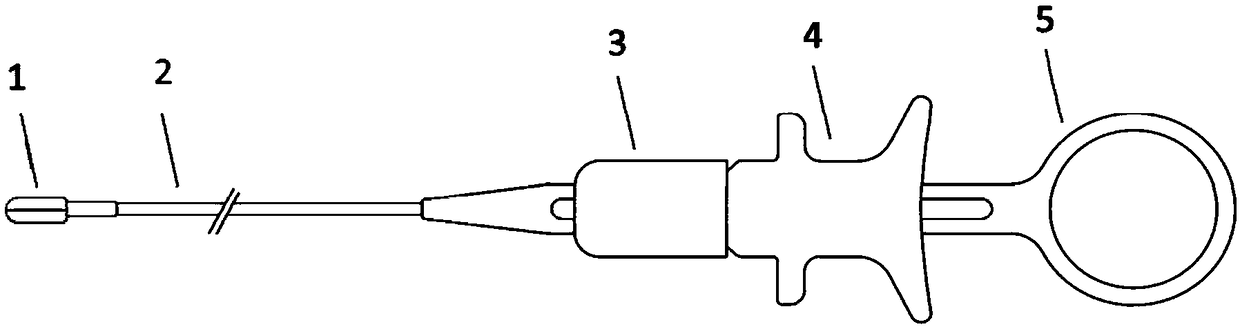

[0043] A special pushing device for a fully degradable occluder, such as Figure 2a As shown, it includes a push cable 2 and a handle, and the push cable 2 includes a clamp head 1, a spring cable 7 and an inner core wire 6; the handle includes a push ring 5, a slider 4 and a locking member 3.

[0044] The spring steel cable 7 is provided with an inner core wire 6 that can move back and forth, the front end of the spring steel cable 7 is fixedly connected with the middle position of the clamp head 1, the rear end of the clamp head 1 is connected with the front end of the inner core wire 6, and the inner core wire The rear end of 6 is connected with slide block 4, and slide block 4 is enclosed within on the push ring 5, and the push ring 5 is also covered with locking part 3, and the spring steel cable 7 is located in the push ring 5.

[0045] The pliers head is designed as two encircling clips, such as Figure 2b As shown, a circular arc-shaped top is formed after merging, and...

Embodiment 2

[0061] In this embodiment, the pliers head 1 has a rattooth (two-tooth) structure, and the pliers head 1 includes two clips that are staggered from each other, and each clip is a rattooth ("L" shape) structure, such as Figure 4a-Figure 4c As shown, the upper end of the "L"-shaped structural clip is connected to the front end of the spring steel cable 7, and the lower end of the "L"-shaped structural clip is connected to the front end of the inner core wire 6. The clamp head of this design has no special requirements on the structure of the welded part of the occluder, for example, the surface is rough (no roughness is required, or roughness does not affect the function of the clamp head), and even the occluder can have no tail. Grasp the bottom of the right disk of the occluder with two rat teeth to pull the occluder into the sheath.

[0062] Others are the same as in Example 1.

Embodiment 3

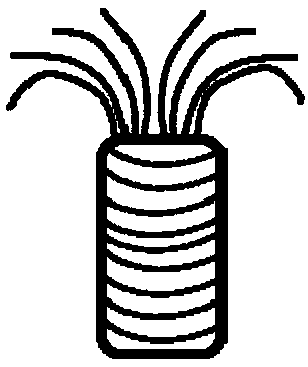

[0064] Such as Figure 5a , Figure 5b As shown, the clamp head 1 is a double-layer rope 8, and the two ends of the double-layer rope 8 are fixed on the front end of the spring steel cable 7, and the inner core wire 6 passes through the hole formed in the middle of the double-layer rope 8. In the middle of the spring steel cable 7 is a slidable inner core wire 6, and the slide block on the handle can adjust the expansion and contraction of the inner core wire 6. Specifically, push the slide block forward, the inner core wire 6 stretches out forward, slide the slide block backward, and the inner core wire 6 retracts backward. The two ends of double-layer rope 8 all are fixed on the same position (being in the groove 9) of the head end of spring steel cable 7. When the double-layer rope 8 is in use, it passes through the double-headed rivetless or single-rivet degradable occluder without the rivet end, and the inner core wire 6 must pass through the middle of the double-layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com