Ultrahigh-speed tensile testing machine driven by rocket engines

A rocket engine and tensile testing machine technology, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, measuring devices, etc., can solve the problems of high elongation, slow loading speed, limited loading stroke, etc., to achieve Large pulling force, short loading time and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

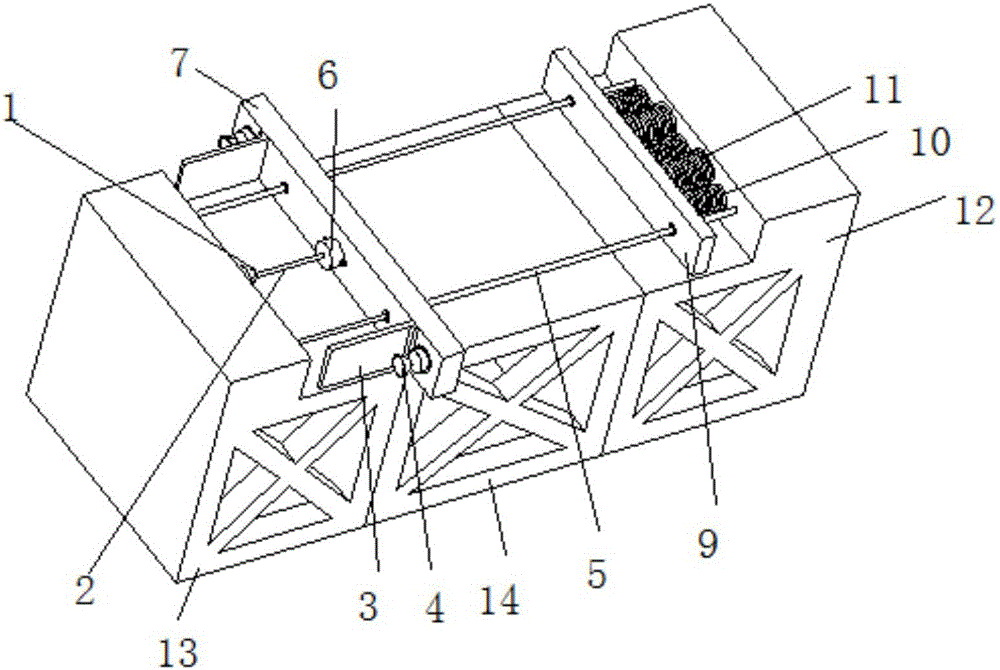

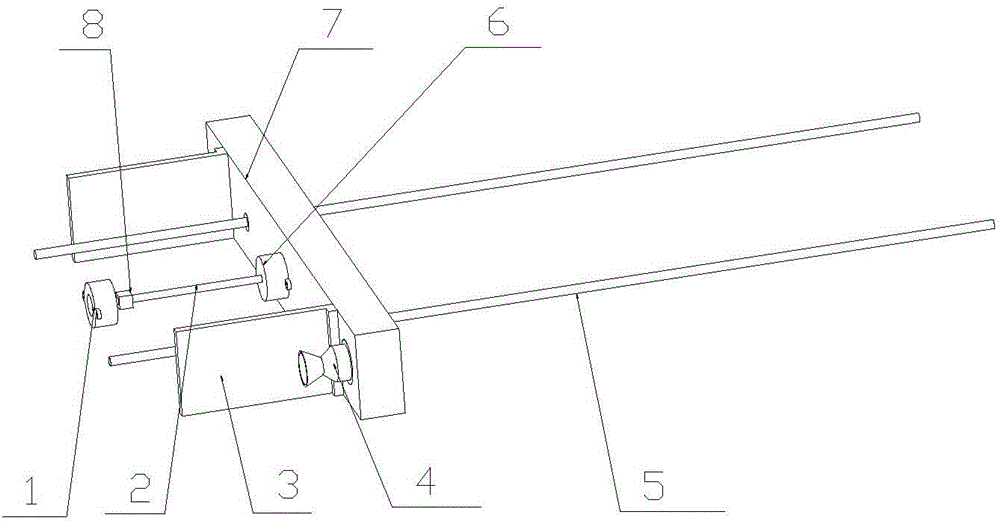

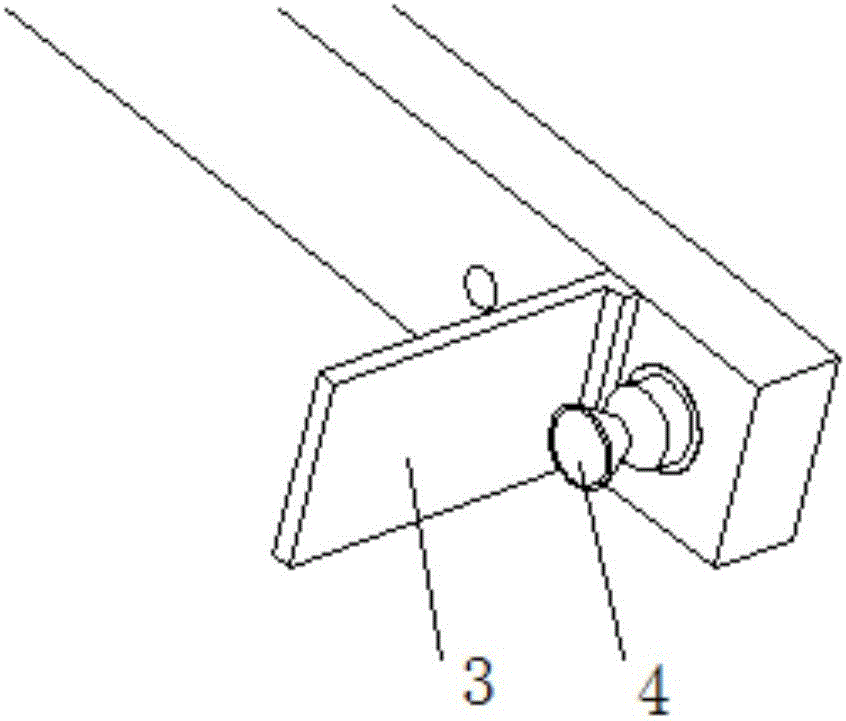

[0016] combine figure 1 , figure 2 , a rocket engine-driven ultra-high-speed tensile testing machine of the present invention includes a workbench, a stretching device, a driving device, a deceleration device, and a guide rail 5; the stretching device includes a first clamp 1, a second clamp 6 and a slide plate 7; the driving device includes a rocket motor 4; the guide rail 5 is fixed on the upper end of the workbench; the first clamp 1 is fixed on one end of the upper end of the workbench, and the first clamp 1 is used for clamping One end of the sample to be tested, the deceleration device is fixed on the other end of the upper end of the workbench, which is used for buffering and protecting the impact of the stretching device; the second clamp 6 is fixed on the slide plate 7, and the second clamp 6 is used for clamping Hold the other end of the sample to be tested, the connection line between the first clamp 1 and the second clamp 6 is parallel to the length direction of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com