Camera module set one time programmable (OTP) burning photosource coefficient remedying and controlling method

A camera module and light source technology, applied in image communication, television, electrical components, etc., can solve problems such as poor product consistency and lack of color temperature difference, and achieve the effect of improving consistency and enhancing consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

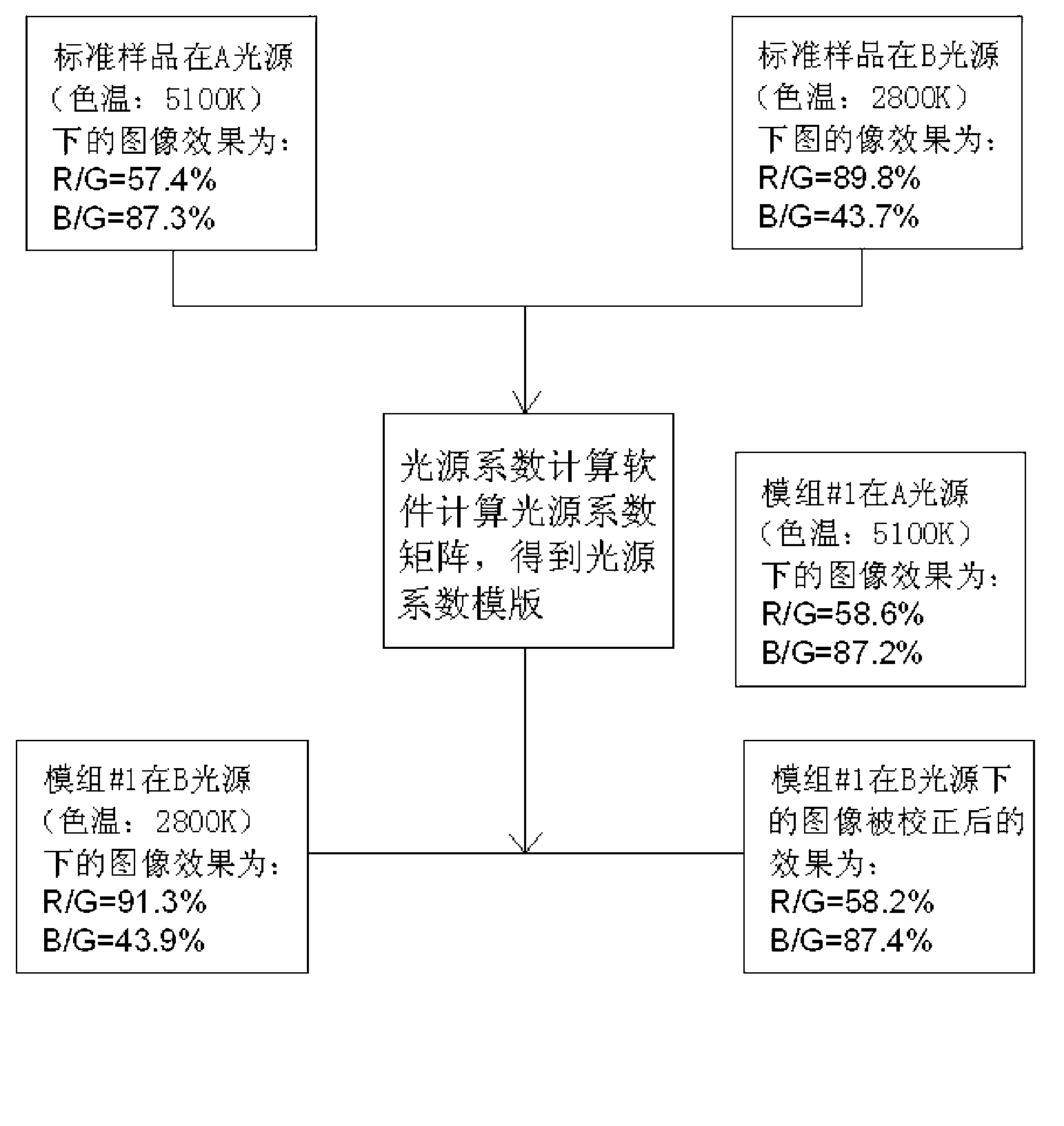

[0015] A method for compensation and management and control of the OTP burning light source coefficient of the camera module includes the following steps:

[0016] a. Collect the light source image A of the standard sample in the OTP burning standard environment;

[0017] b. Collect the light source image B of the standard sample in the corrected environment of OTP burning;

[0018] c. Calculate the light source coefficient matrix of image A in step a and image B in step b through the light source coefficient calculation software to obtain a light source coefficient template;

[0019] d. When the camera module is burned in an environment where the OTP burn is corrected, the light source coefficient template in step c is called for coefficient correction, and the light source image C after the coefficient correction is obtained;

[0020] e. When the camera module OTP is burned, data is burned according to the corrected light source image C in step d. In this way, through the above method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com