Spiral array cold cathode X-ray tube with large emission area field emission composite material

A composite material and emission area technology, applied in the directions of X-ray tube electrodes, X-ray tube components, etc., can solve the problem of poor consistency of the sharp cone array, poor consistency of large-area cathodes, and small-area cathodes that cannot meet the needs of high-dose X-rays and other problems, to achieve the effect of resistance to ion bombardment, good chemical stability, and improved stability and life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

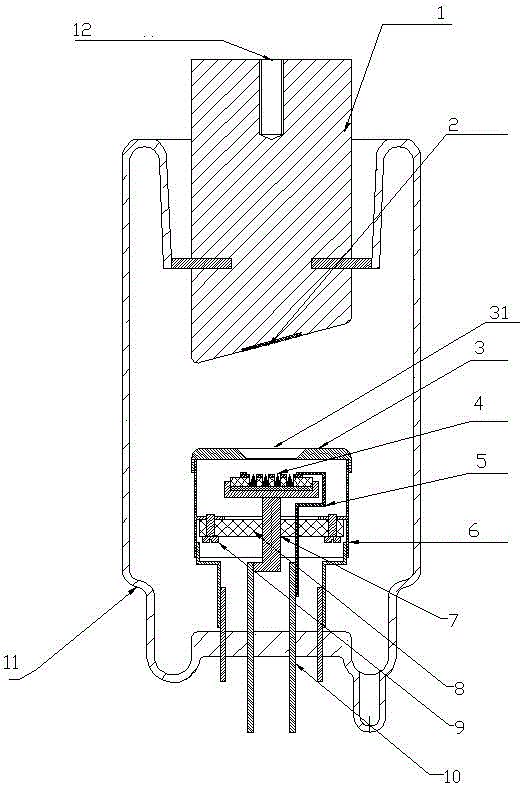

[0032] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

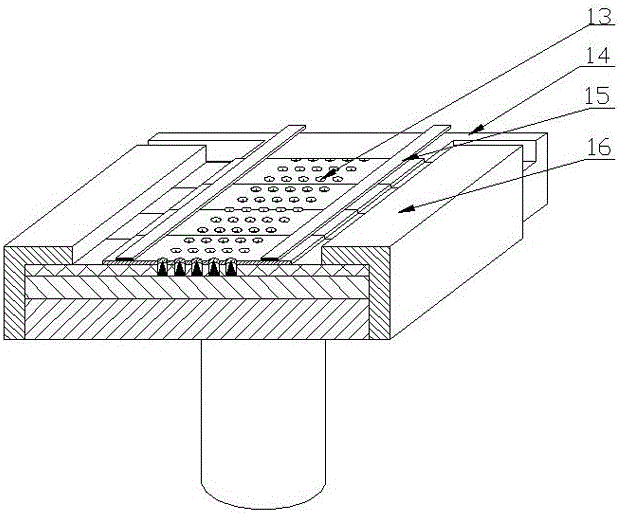

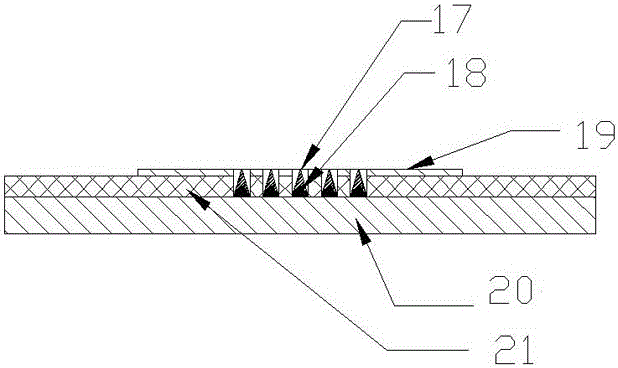

[0033] The pointed cone array cold cathode X-ray tube with a large emission area field emission composite material according to the present invention includes a cathode part; The sheet includes a base, an inner grid sheet, and a plurality of sub-cathodes arranged in an array on the base. grid hole; there is an insulating layer between the base and the inner grid sheet; the cathode component also includes an electrical connection compression structure for fixing a plurality of pointed cone array cold cathode sheets and having lead-out electrodes.

[0034] Such as Figures 2 to 3 A specific embodiment of the cathode part is shown. The cathode part is continuously spliced by 4 rectangular-shaped pointed cone array cold cathode sheets. The inner grid sheet above the cathode is composed of a plurality of inner grid holes, and each su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com