El display device and method for manufacturing same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments

[0028]In one aspect of the present invention, an EL display device comprises: a substrate; a plurality of pixel electrodes located on the substrate with intervals therebetween; wiring located on the substrate in at least one of the intervals between the pixel electrodes; a plurality of light-emitting layer portions, each located on or above a corresponding one of the pixel electrodes in electrical connection therewith; a common electrode located on or above the light-emitting layer portions, and in electrical connection with the light emitting layer portions and the wiring; and a protective layer located on or above the common electrode, and preventing oxidization of the common electrode, wherein the common electrode is made of alkali metal or alkaline earth metal.

[0029]Alternatively, in another aspect of the present invention the EL display device may further comprise an intermediate layer including alkali metal or alkaline earth metal, located between the light-emitting layer port...

first embodiment

Overall Configuration of EL Display Device 1

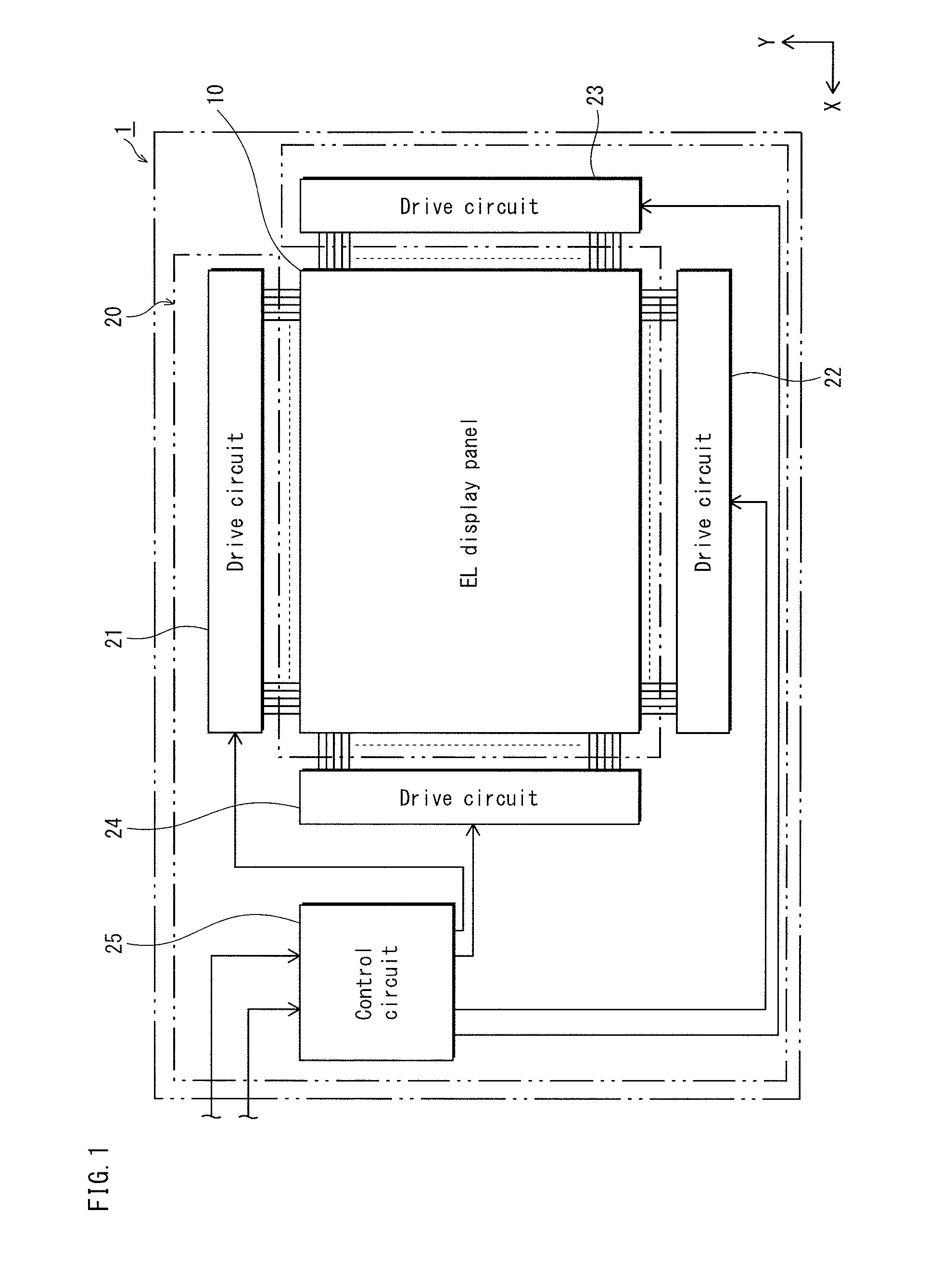

[0049]FIG. 1 is a block diagram that schematically illustrates overall configuration of an EL display device 1. The EL display device 1 includes an EL display panel 10 and a drive controller 20 which is connected to the EL display panel 10.

[0050]The EL display panel 10 is for example a top-emission organic EL display panel which uses electroluminescence of an organic material.

[0051]The drive controller 20 includes four drive circuits 21-24 and a control circuit 25.

[0052]In the EL display device 1, in terms of positioning of the drive controller 20 relative to the EL display panel 10, the drive controller 20 is not limited to being located surrounding four sides of the EL display panel 10 as illustrated in FIG. 1.

(Configuration of EL Display Panel 10)

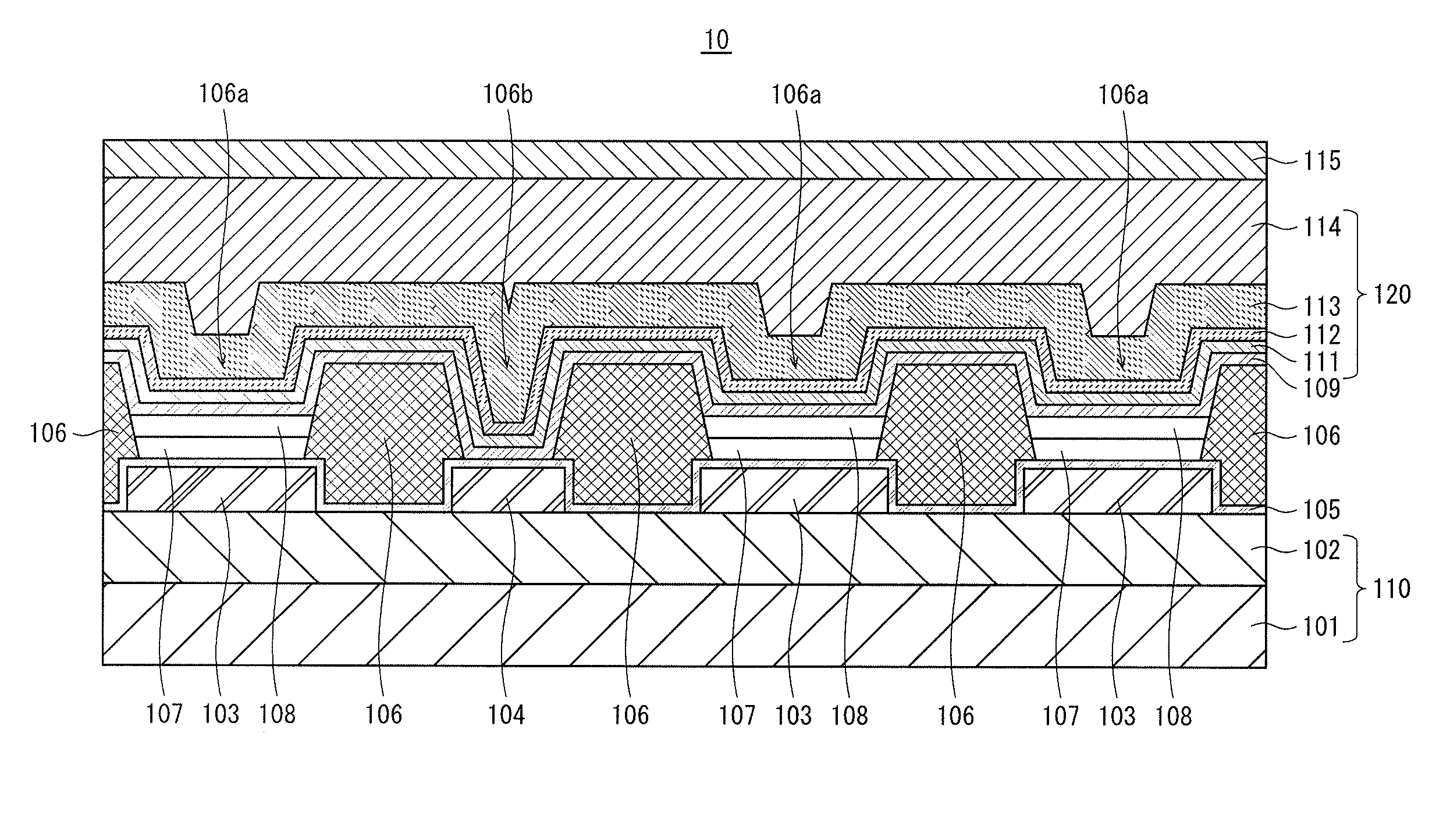

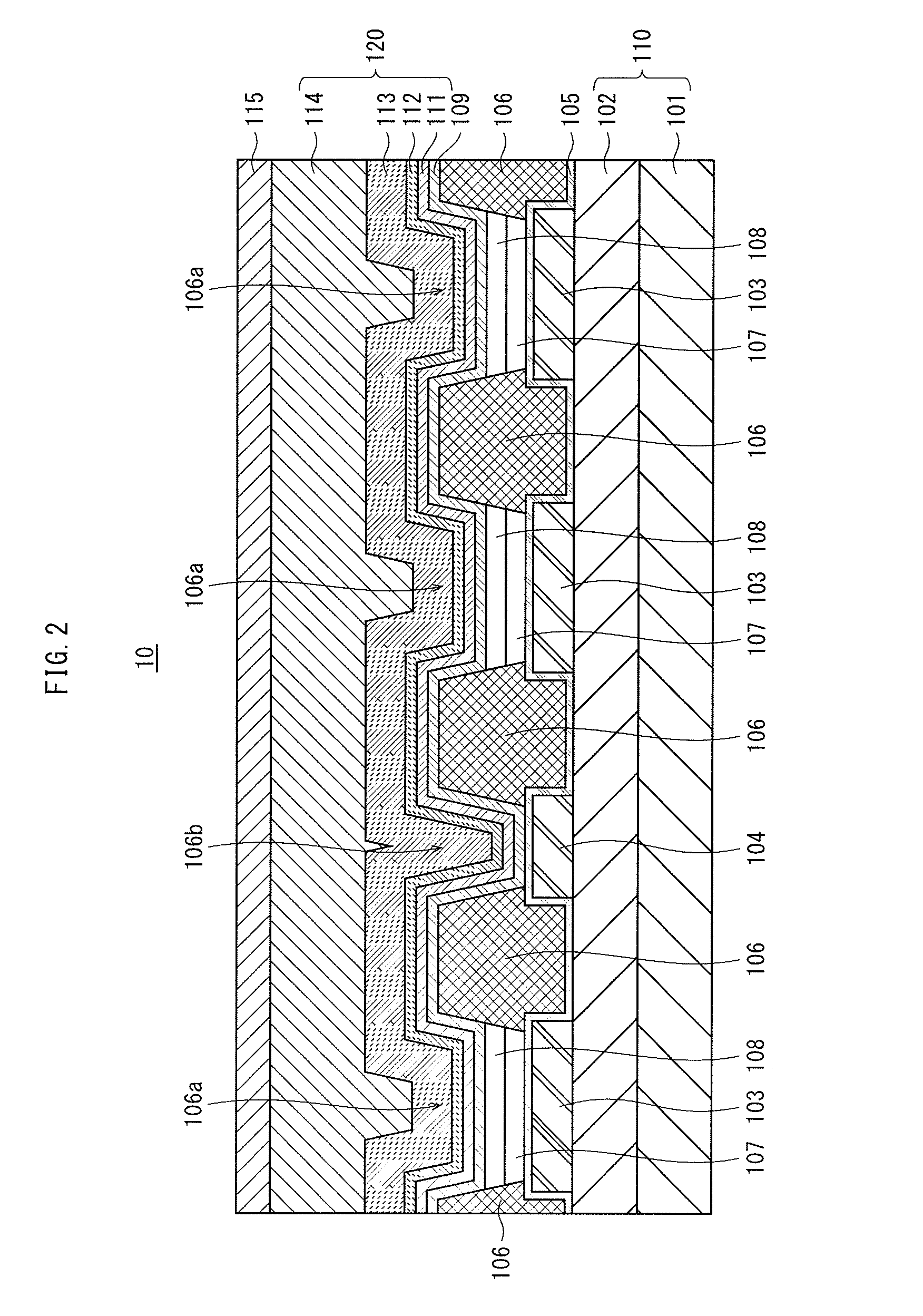

[0053]FIG. 2 is a partial cross-sectional diagram that schematically illustrates configuration of the EL display panel 10. FIG. 2 schematically illustrates one part of the EL display panel 10. ...

first modified example

[0112]The following explains a modified example in which an intermediate layer is located between a common electrode and a hole injection layer, above electrical supply wiring.

[0113]In the EL display panel 10 illustrated in FIG. 2, the electrical supply wiring 104 and the common electrode 109 are in electrical connection via the hole injection layer 105. Also, the common electrode 109 is made of alkali metal or alkaline earth metal. When the hole injection layer 105 is made of metal oxide including a transition metal oxide such as WOx, MoOx, or MoxWyOz, oxidization of the common electrode 109 may occur through the common electrode 109 stripping oxygen from the hole injection layer 105 due to a difference in electronegativity of the common electrode 109 and the hole injection layer 105. Through the above, the common electrode 109 is converted to an oxide insulator, and thus the problem of voltage drop may occur in the common electrode 109. One strategy for responding to the above pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com