Terry knitting fabric, and its producing method and sewing method

A technology for knitted fabrics and terry needles, which is applied to the knitting machine, knitting, weft knitting and other directions of connecting knitted fabrics, can solve problems such as increase in increase and production cost, and achieve reduced contact resistance, easy sliding, and excellent size. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

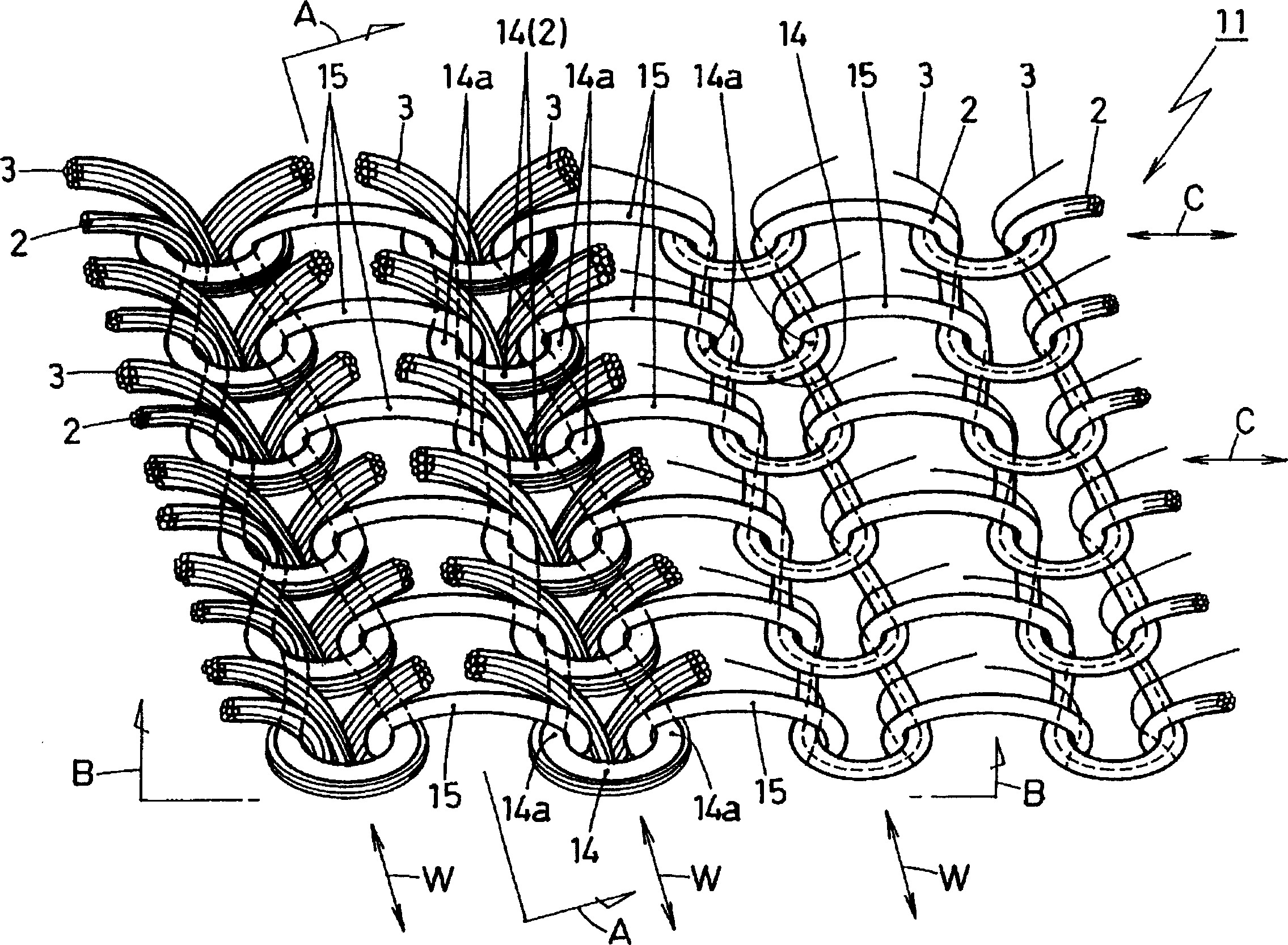

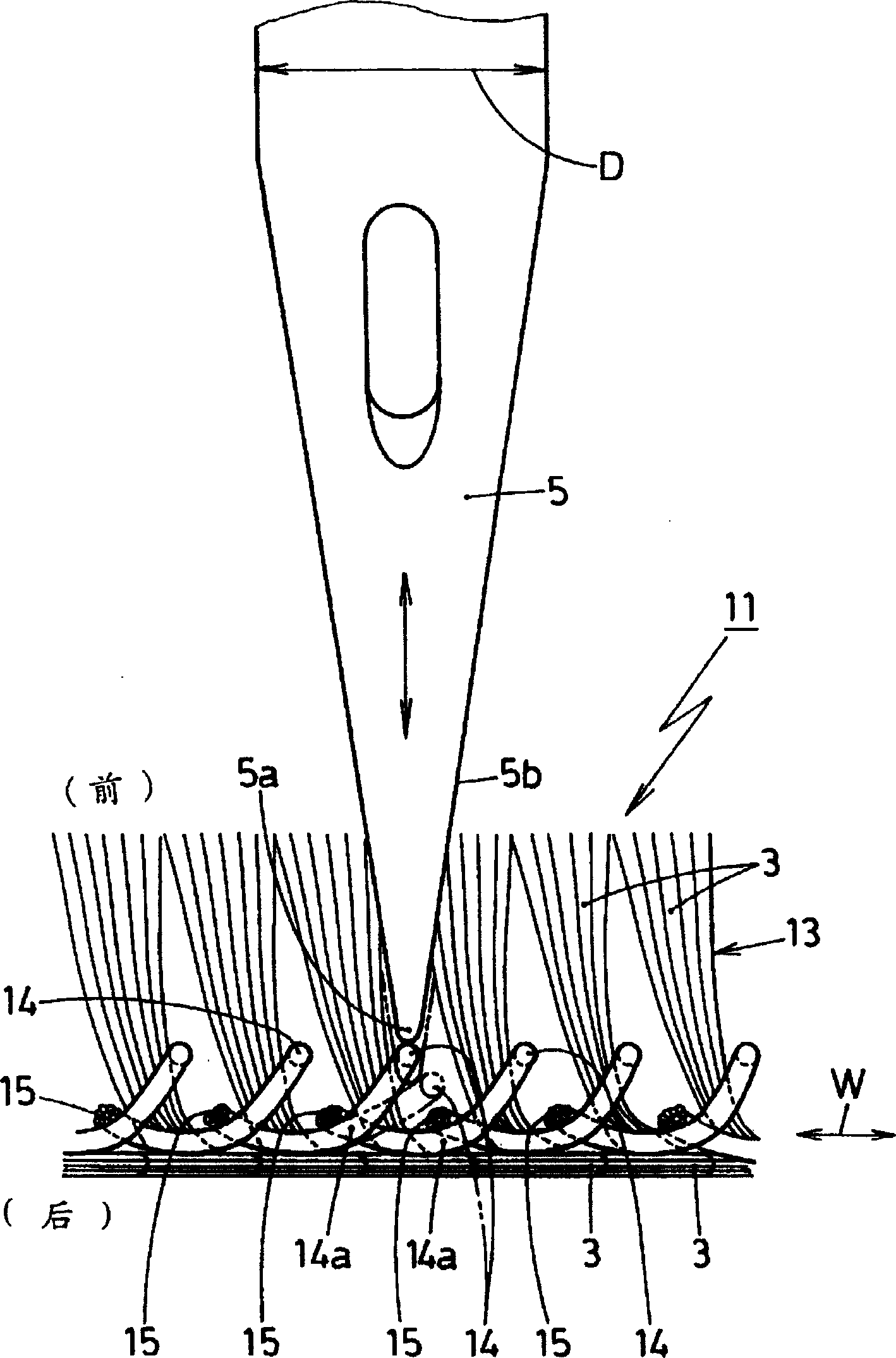

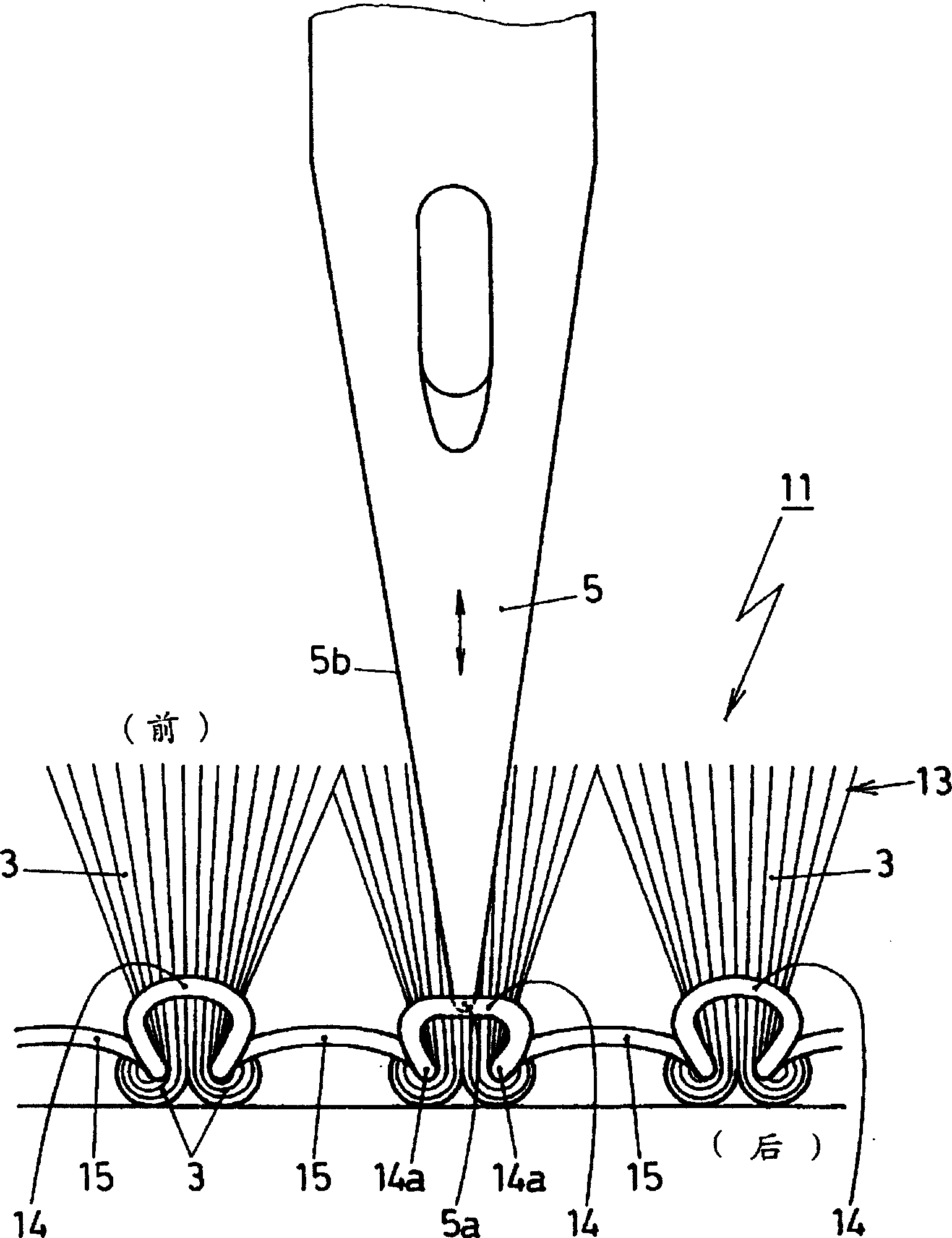

[0020] The invention is illustrated on the basis of the embodiments shown in the following figures. Figure 1 to Figure 3 An example of the terry knitted cloth of the present invention (hereinafter, referred to as "the cloth of the present invention") is described, wherein figure 1 is a surface view that magnifies the state where the cut pile has been cut and removed near the weave of the cloth, and linearly represents the right half of the cut pile, figure 2 for along figure 1 A cross-sectional view of the center line A-A, showing the cut pile uncut, image 3 for along figure 1 A cross-sectional view of the midline B-B, showing the cut pile uncut.

[0021] Such as Figure 1-3 As shown, the cloth 11 of the present invention is woven in a plain knitting state by the ground yarn 2 and the pile yarn 3, and is formed into a cut pile shape by cutting the pile portion 13 containing the pile yarn 3. The cloth 11 of the present invention is characterized by a corresponding wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com