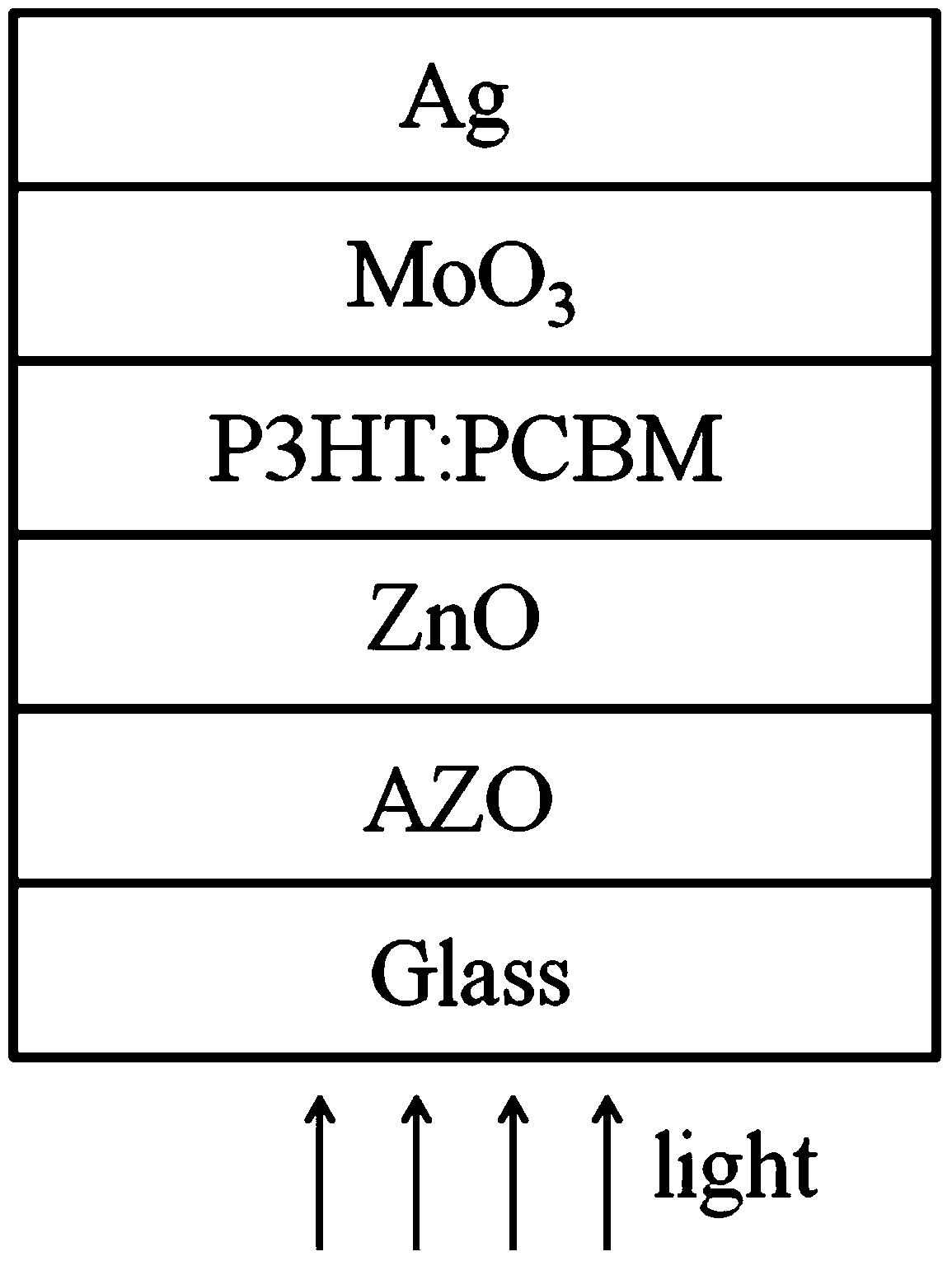

Polymer solar cell based on AZO/ZnO cathode and manufacturing method of polymer solar cell

A technology of solar cells and polymers, applied in the field of solar cells, can solve problems such as incompatibility and high cost, and achieve the effects of reducing energy loss, improving light transmittance, and improving energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1: Clean the substrate substrate

[0034] The AZO glass substrate was ultrasonically cleaned in deionized water, acetone, absolute ethanol and deionized water for 15 min in turn, and dried with a nitrogen gun after cleaning. The thickness of glass is about 1.9mm, the thickness of AZO is about 980nm, and the sheet resistance is about 10Ω / □.

[0035] Step 2: Deposit ZnO electron transport layer

[0036] a) Prepare ZnO precursor solution: dissolve 150mg of ZnO powder (particle size less than 5 microns) in 15ml of ammonia water (concentration 25%wt), put it in the refrigerator after ultrasonic vibration for 3-5min, the temperature is 0-10℃, time Be 24h, obtain the ZnO precursor solution that concentration is 0.125M;

[0037] b) Spin-coat the ZnO precursor solution on the AZO, the spin-coating speed is 3000r / min, and the time is 40s; then anneal in an oven for 30min, the temperature is 150°C, and the thickness of the obtained ZnO electron transport layer is about 10nm...

Embodiment 2

[0050] Step 1: Clean the substrate substrate

[0051] The AZO glass substrate was ultrasonically cleaned in deionized water, acetone, absolute ethanol and deionized water for 15 min in turn, and dried with a nitrogen gun after cleaning. The thickness of glass is about 2mm, the thickness of AZO is about 980nm, and the sheet resistance is about 10Ω / □.

[0052] Step 2: Deposit ZnO electron transport layer

[0053] a) Prepare ZnO precursor solution: dissolve 150mg of ZnO powder (particle size less than 5 microns) in 15ml of ammonia water (concentration 25%wt), put it in the refrigerator after ultrasonic vibration for 3-5min, the temperature is 0-10℃, time Be 24h, obtain the ZnO precursor solution that concentration is 0.125M;

[0054] b) Spin-coat the ZnO precursor solution on the AZO, the spin-coating speed is 3000r / min, and the time is 40s; then anneal in an oven for 60min, the temperature is 100°C, and the thickness of the obtained ZnO electron transport layer is about 10nm; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com