DPF carrier carbon loading amount test apparatus

A test device, DPF technology, which is used in measurement devices, suspension and porous material analysis, scientific instruments, etc., can solve the problems of long loading time and high resource costs, and achieve convenient maintenance and inspection operations, less resource consumption, and economical effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

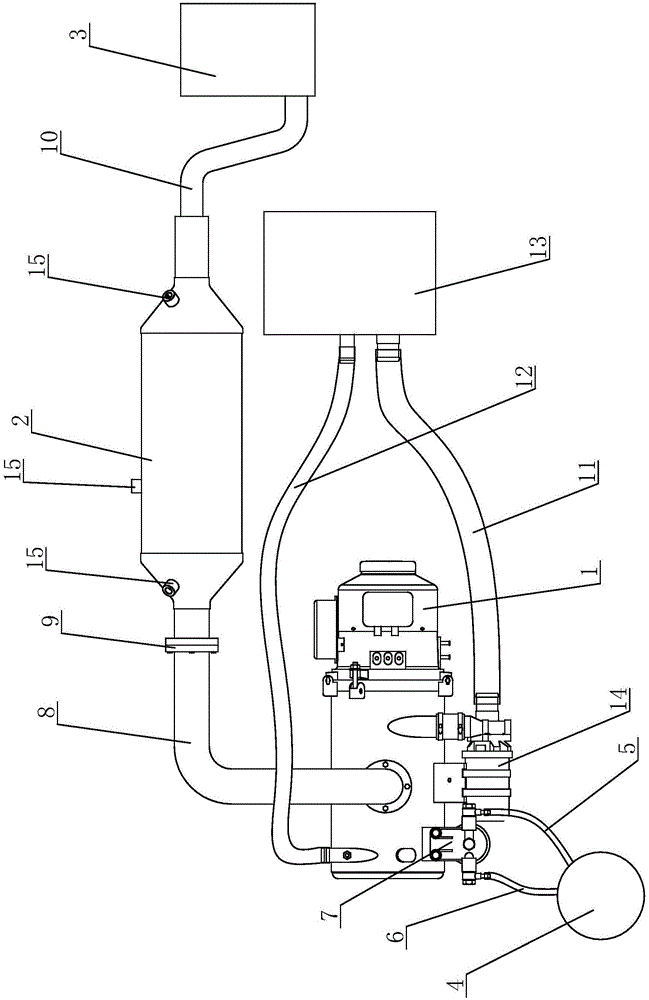

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0020] see figure 1 as shown, figure 1 It is a schematic structural diagram of the DPF carrier carbon loading test device provided in Embodiment 1 of the present invention.

[0021] In this embodiment, a DPF carrier carbon load test device includes an oil supply device, a burner 1, a DOC+DPF packaging carrier 2, a vacuum cleaner 3 and a controller, and the oil supply device includes a fuel tank 4 and an oil inlet pipe 5 , an oil return pipe 6 and a filter 7, the oil inlet pipe 5 and the oil return pipe 6 are connected to the filter 7, and the filter 7 is connected to the burner 1 to supply oil thereto. A transition pipe 8 is connected between the inlet end of the DOC+DPF packaging carrier 2 and the exhaust end of the burner 1, and the two ends of the transition pipe 8 are respectively connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com