Stamping, bending and welding equipment

A stamping bending and welding equipment technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as damage to the health of operators, generation of harmful gases, low production efficiency, etc., and achieve the goal of improving processing Efficiency, efficiency improvement, and effect of reducing processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

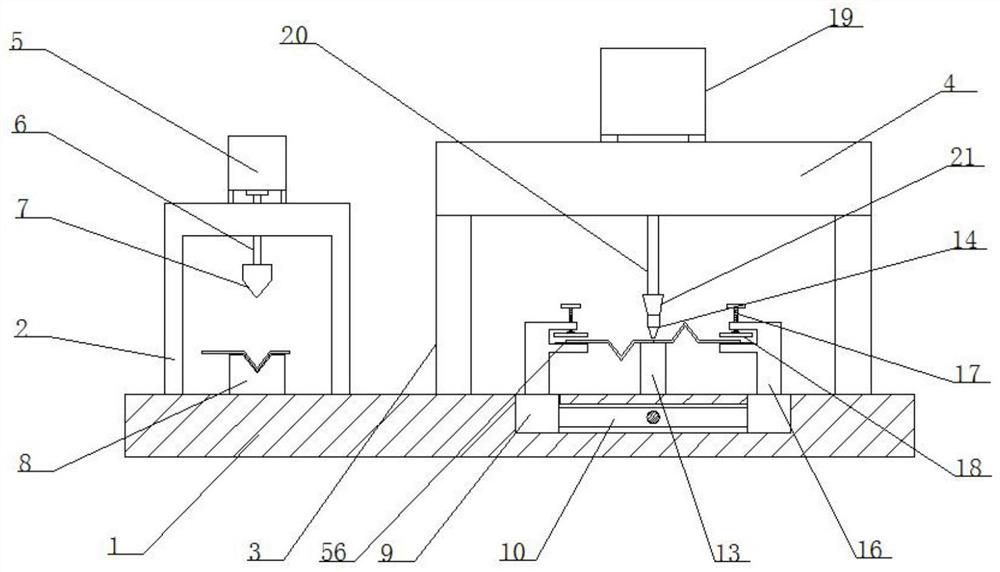

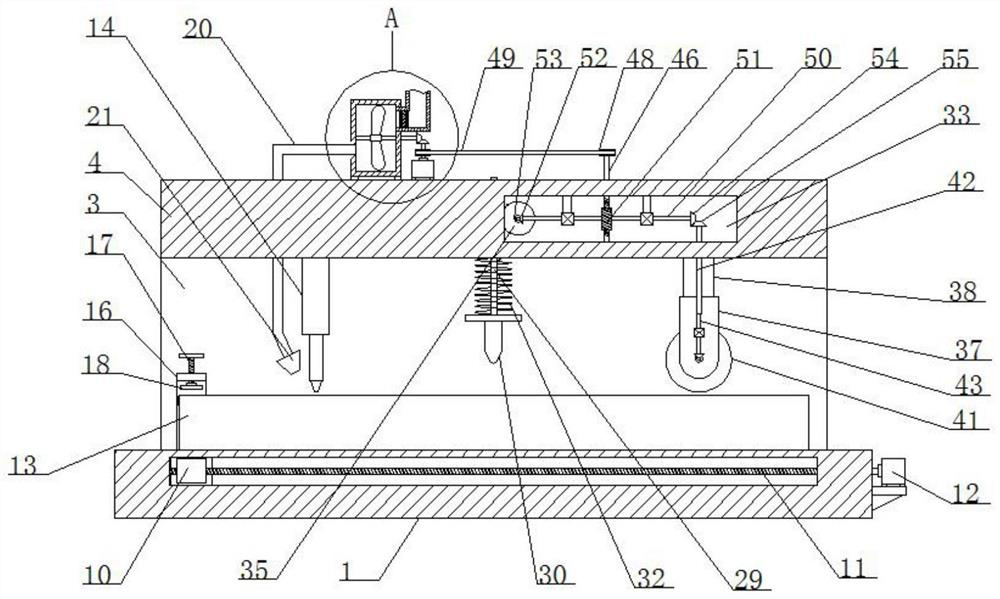

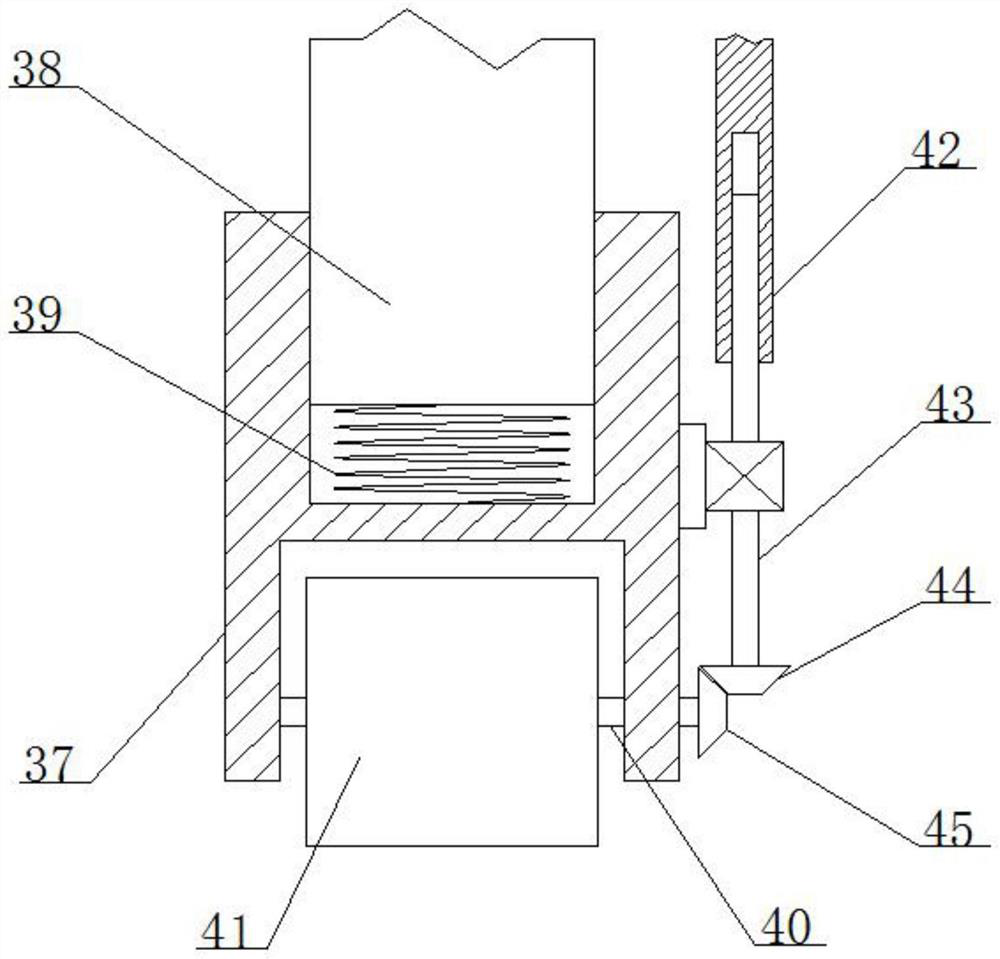

[0031] refer to Figure 1-7, a stamping bending welding equipment, including a base plate 1, the top of the base plate 1 is fixedly connected with a U-shaped frame 2 and two side plates 3 by welding, and the top of the two side plates 3 is fixedly connected with the same top plate 4 by welding, The top of the U-shaped frame 2 is fixed with a hydraulic press 5 by bolts, the output shaft of the hydraulic press 5 is provided with a telescopic rod 6, the bottom end of the telescopic rod 6 is fixedly connected with a stamping and bending block 7 by welding, and the top of the bottom plate 1 is provided with a stamping The base 8, the stamping and bending block 7 cooperate with the stamping base 8, and the top of the bottom plate 1 is provided with two slider grooves, and a slider 9 is slidably installed in the two slider grooves, and the two slider grooves are close to each other. One side is provided with the same sliding through groove, and a cross bar 10 is slidably installed in...

Embodiment 2

[0043] The difference from Embodiment 1 is that the clamping mechanism includes an F-shaped plate element 16 fixedly installed on the top of the slider 9, the top of the F-shaped plate element 16 is provided with a bolt 17, and the bottom end of the bolt 17 is fixedly connected with a clamping On the plate 18 , the F-shaped plate element 16 is provided with a rubber gasket 56 .

[0044] In the present invention, when in use, the hardware sheet is first placed on the stamping base 8, and then the hydraulic press 5 is started, so that the hydraulic press 5 stamps and bends the hardware sheet into a desired shape through the telescopic rod 6 and the stamping and bending block 7, and then Install the finished two metal plates on the two clamping mechanisms, turn the bolt 17 so that the bolt 17 passes through the clamping plate 18 to clamp and fix the hardware plate on the F-shaped plate element 16, and the F-shaped plate element 16 passes through The rubber spacer 56 can effective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com