High-thermal conductivity diamond/copper composite material applicable to wide temperature range and method

A composite material and diamond technology, applied in the field of thermal management material preparation, can solve the problems of affecting the performance stability of the system, unable to achieve satisfactory results, limited heat dissipation capacity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

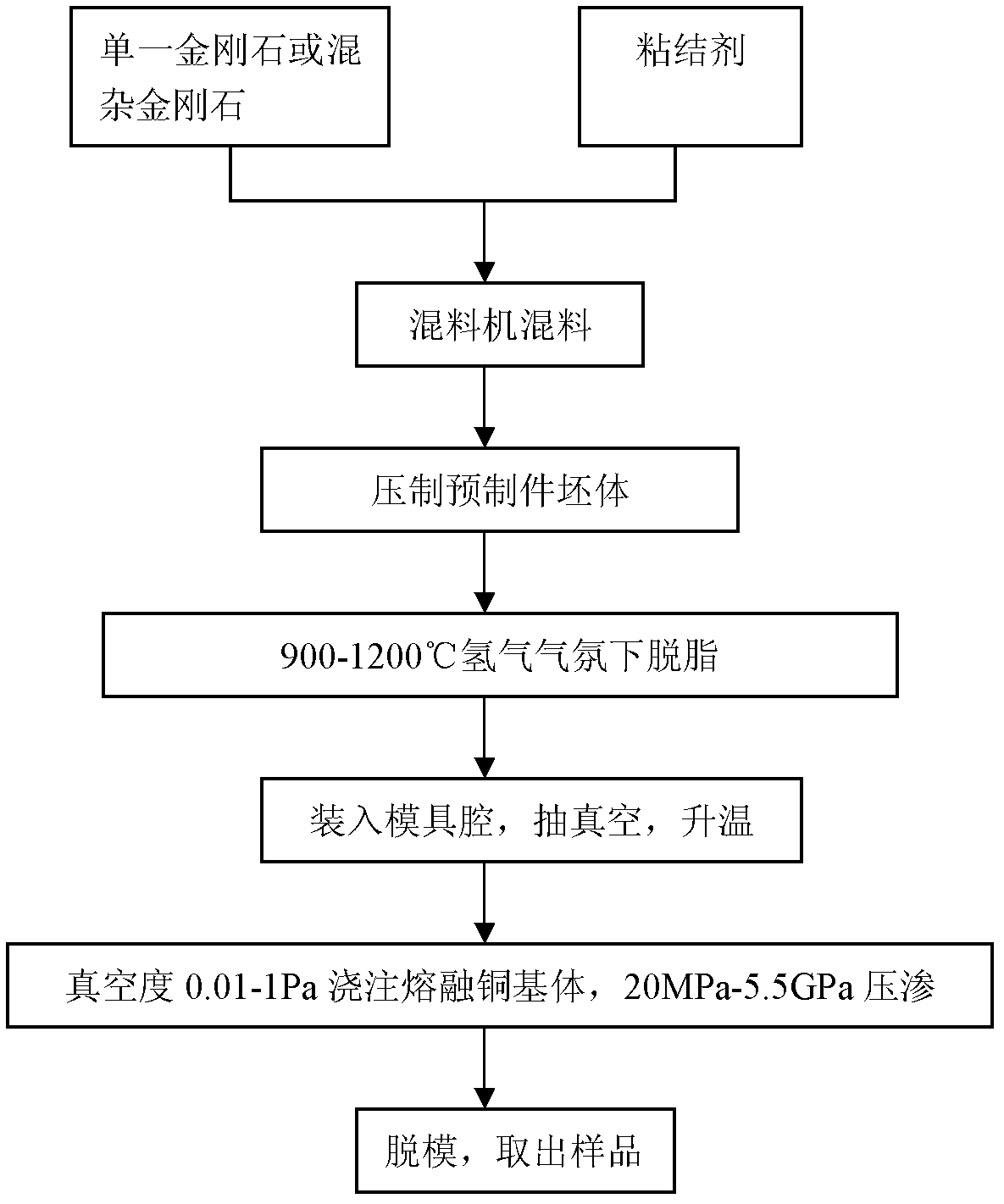

Method used

Image

Examples

Embodiment 1

[0036] Raw material: diamond grain size 200 μm, crystal form: hexahedron, copper matrix: CuCr (Cr1wt%).

[0037] The diamond particles and the paraffin-based binder are prepared according to the volume ratio of 75:25; the mixer is mixed evenly, and the uniformly mixed powder is prepared on the press to prepare the preform body; after the preform body is air-dried, the Degreasing and sintering are carried out under a hydrogen atmosphere; put the sintered preform into a graphite mold, put it into a pressure infiltration furnace to evacuate, and raise the temperature at the same time; the vacuum degree in the vacuum pressure infiltration furnace reaches 0.05Pa, and the temperature rises to At 1150°C, melt the copper matrix, pour it into a graphite mold, infiltrate the metal at 5GPa, keep the pressure for 5 minutes, and the volume ratio of the reinforcement to the copper matrix is 75:25; cool with the furnace and demould.

[0038] The density of the obtained composite material i...

Embodiment 2

[0040] Raw materials: diamond 1 particle size: 50 μm, crystal form: hexocahedron, diamond 2: 100 μm crystal form: hexocahedron; mass ratio: diamond 1: diamond 2 volume ratio: 16: 2; copper matrix: CuCr (Cr1wt% ).

[0041]The diamond particles and the paraffin-based binder are prepared according to the volume ratio of 65:35; the mixer is mixed evenly, and the mixed powder is prepared on the press to prepare the preform body; after the preform body is air-dried, it is heated at 900°C Degreasing and sintering are carried out under a hydrogen atmosphere; put the sintered preform into a graphite mold, put it into a pressure infiltration furnace to evacuate, and raise the temperature at the same time; the vacuum degree in the vacuum pressure infiltration furnace reaches 0.01Pa, and the temperature rises to At 1200°C, melt the copper matrix, pour it into a graphite mold, infiltrate the metal at 60MPa, keep the pressure for 8 minutes, and the volume ratio of the reinforcement to the c...

Embodiment 3

[0044] Raw materials: diamond particle size: 100 μm, crystal form: square, copper matrix: CuCr (Cr1wt%).

[0045] The diamond particles and the paraffin-based binder are prepared according to the volume ratio of 60:40; the mixer is evenly mixed, and the uniformly mixed powder is prepared on the press to prepare the preform body; after the preform body is air-dried, the Degreasing and sintering are carried out under a hydrogen atmosphere; put the sintered preform into a graphite mold, put it into a pressure infiltration furnace to evacuate, and raise the temperature at the same time; the vacuum degree in the vacuum pressure infiltration furnace reaches 0.1Pa, and the temperature rises to At 1200°C, melt the copper matrix, pour it into a graphite mold, infiltrate the metal at 50MPa, keep the pressure for 10 minutes, and the volume ratio of the reinforcement to the copper matrix is 55:45; cool with the furnace and demould.

[0046] The density of the obtained composite material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com