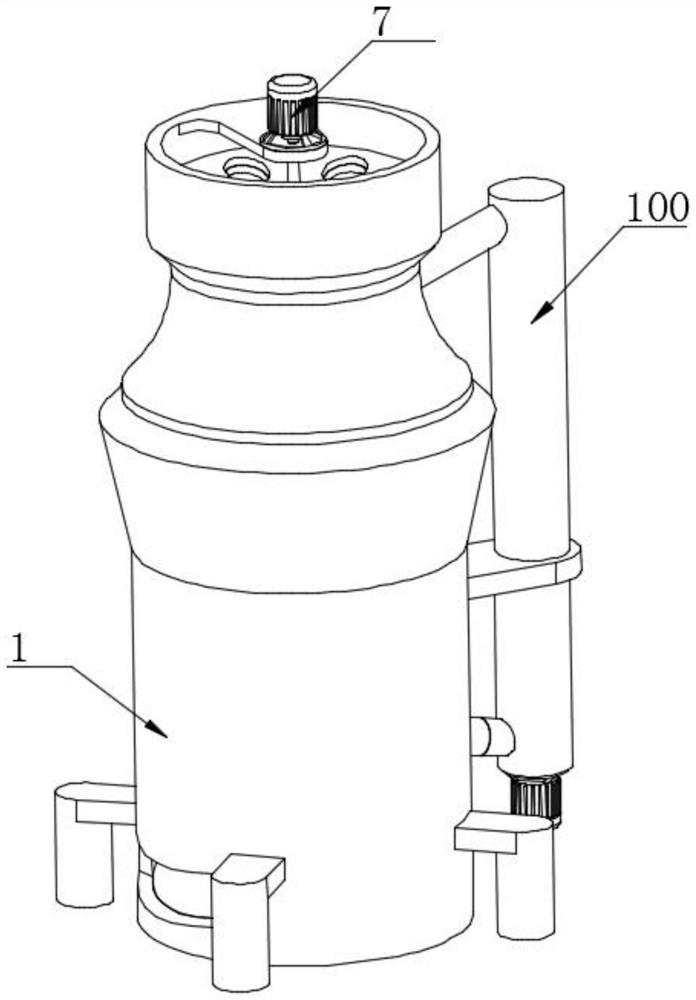

Ore crushing and screening machine

A kind of ore crushing and screening machine technology, which is applied in cocoa, grain processing, food science, etc., can solve the problems of insufficient crushing, difficult crushing, equipment damage, etc., and achieve the effect of improving crushing effect, speeding up screening, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

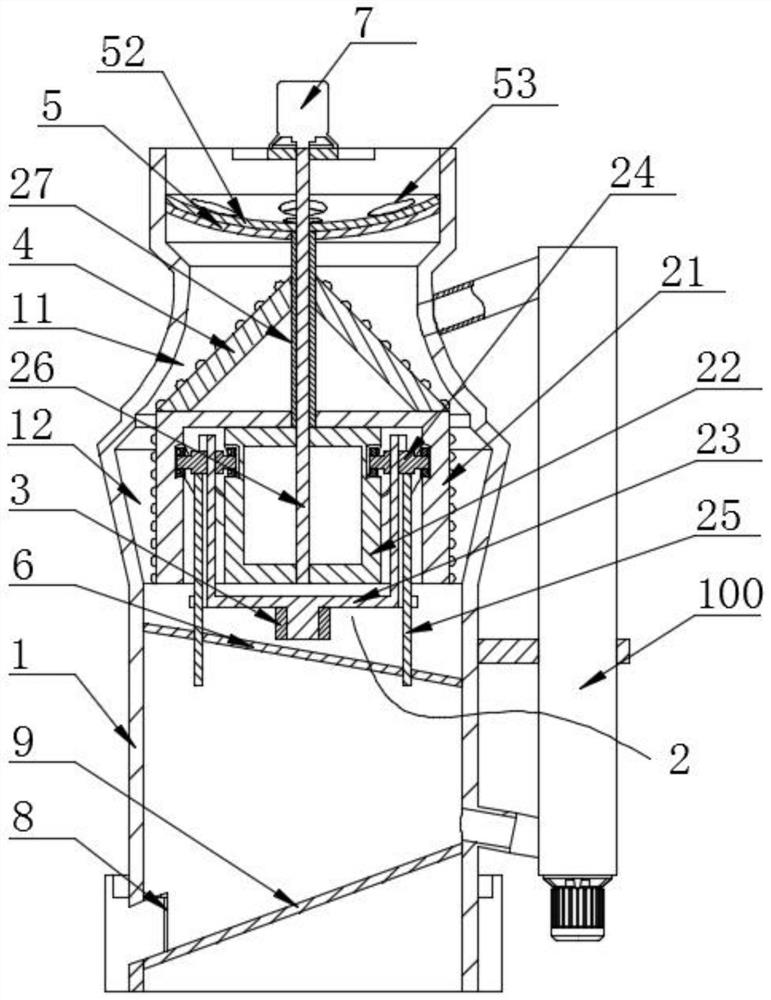

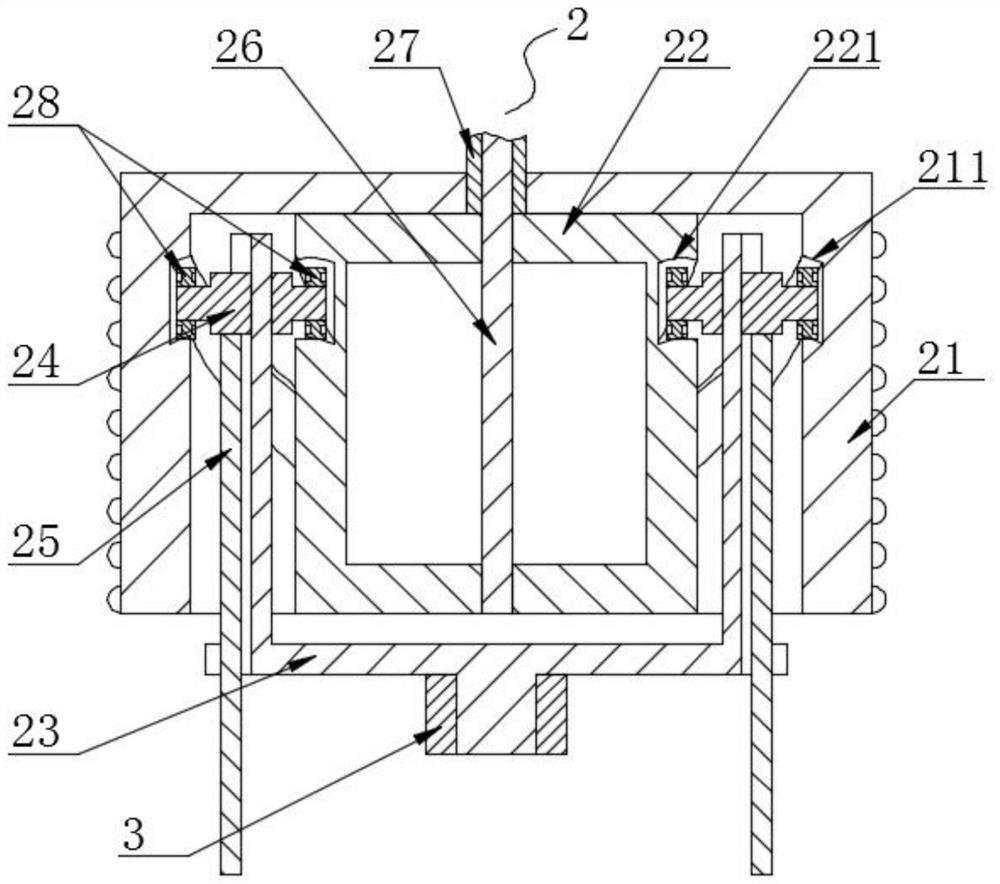

[0027]An example embodiment will now be described more fully with reference to the accompanying drawings. However, an example embodiment can be implemented in a variety of forms, and is not to be construed as being limited to the examples described herein; in contrast, providing these examples have enabled the description of the present disclosure to be more comprehensive and complete, and the concept of example implementation Comprehensively communicate to those skilled in the art. The drawings are only schematic illustrations of the present disclosure, and it is not necessarily drawn. The same reference numerals in the figure represent the same or similar portions, and thus repeats them will be omitted.

[0028]Further, the features, structures, or characteristics described may be incorporated in one or more examples in any suitable manner. In the following description, there is provided a number of specific details to give a sufficient understanding of the example embodiments of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com