A kind of countercurrent extraction method of stevia leaf

A stevia leaf extraction technology, applied in chemical instruments and methods, organic chemistry, sugar derivatives, etc., can solve the problems of high water consumption, unsatisfactory stevioside content yield, and restrictions on the industrial production of steviosides. Achieve the effect of increasing energy consumption, reducing the difficulty of drying and crushing, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

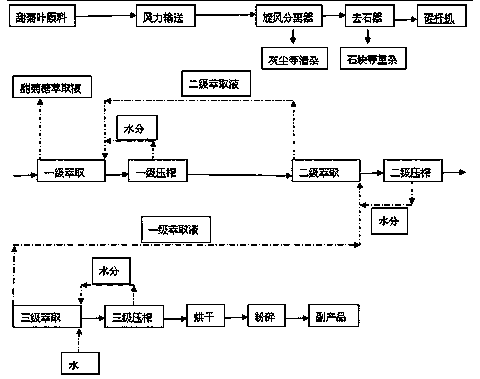

Image

Examples

Embodiment 1

[0020] Embodiment 1: The countercurrent extraction method of the stevia leaves adopts the following specific techniques.

[0021] The stevia leaves are subjected to secondary countercurrent extraction after pretreatment, wherein the primary extraction temperature is 90°C, the secondary extraction temperature is 100°C, and the overall extraction material-to-liquid ratio is 1:6. The yield of the stevioside content of the obtained extract was 99.17%.

Embodiment 2

[0022] Embodiment 2: The countercurrent extraction method of this stevia leaf adopts the following specific process.

[0023] The stevia leaves are pretreated and subjected to three-stage countercurrent extraction, wherein the primary extraction temperature is 70°C, the secondary extraction temperature is 75°C, and the third extraction temperature is 80°C, and the overall extraction material-to-liquid ratio is 1:10. The yield of the stevioside content of the obtained extract was 99.93%.

Embodiment 3

[0024] Embodiment 3: The countercurrent extraction method of this stevia leaf adopts the following specific process.

[0025] The stevia leaf is subjected to four-stage countercurrent extraction after pretreatment, wherein, the first-stage extraction temperature is 30°C, the second-stage extraction temperature is 33°C, the third-stage extraction temperature is 36°C, and the fourth-stage extraction temperature is 39°C. for 1:15. The yield of the stevioside content of the obtained extract was 99.72%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com