Patents

Literature

30results about How to "Reduce drying difficulty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

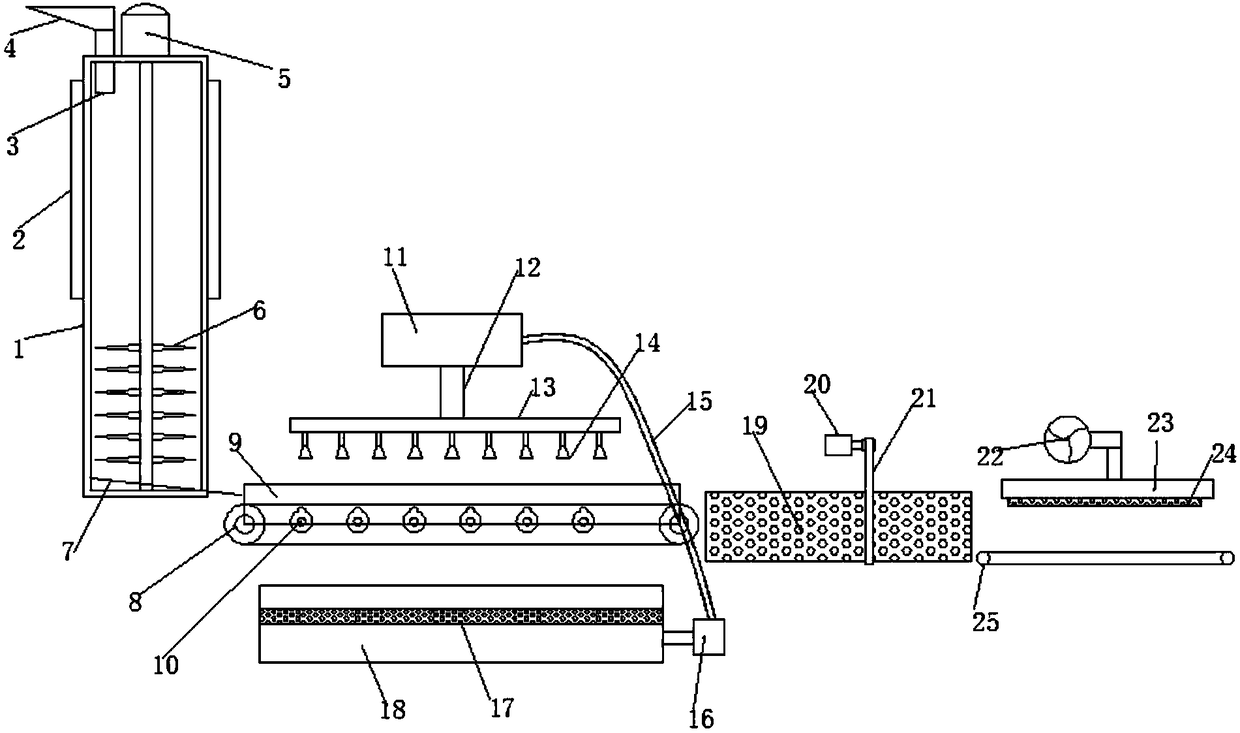

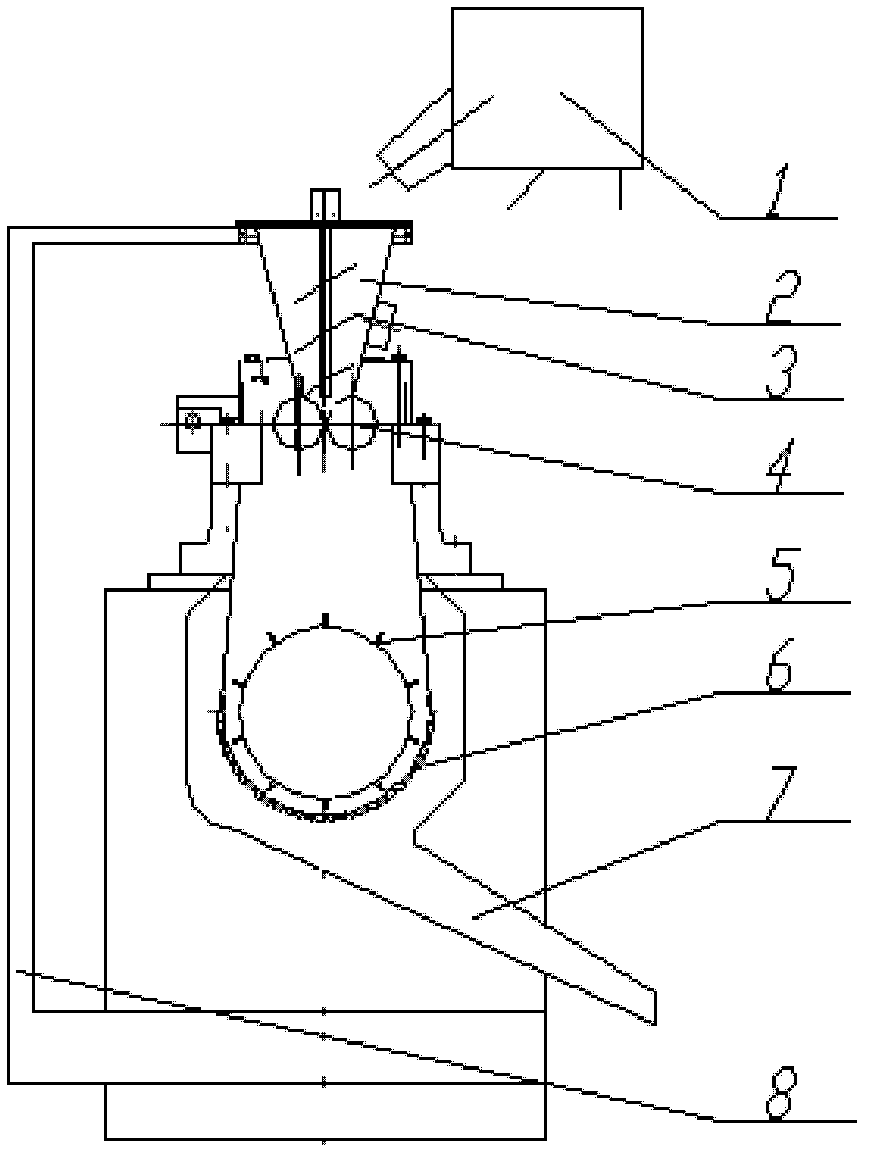

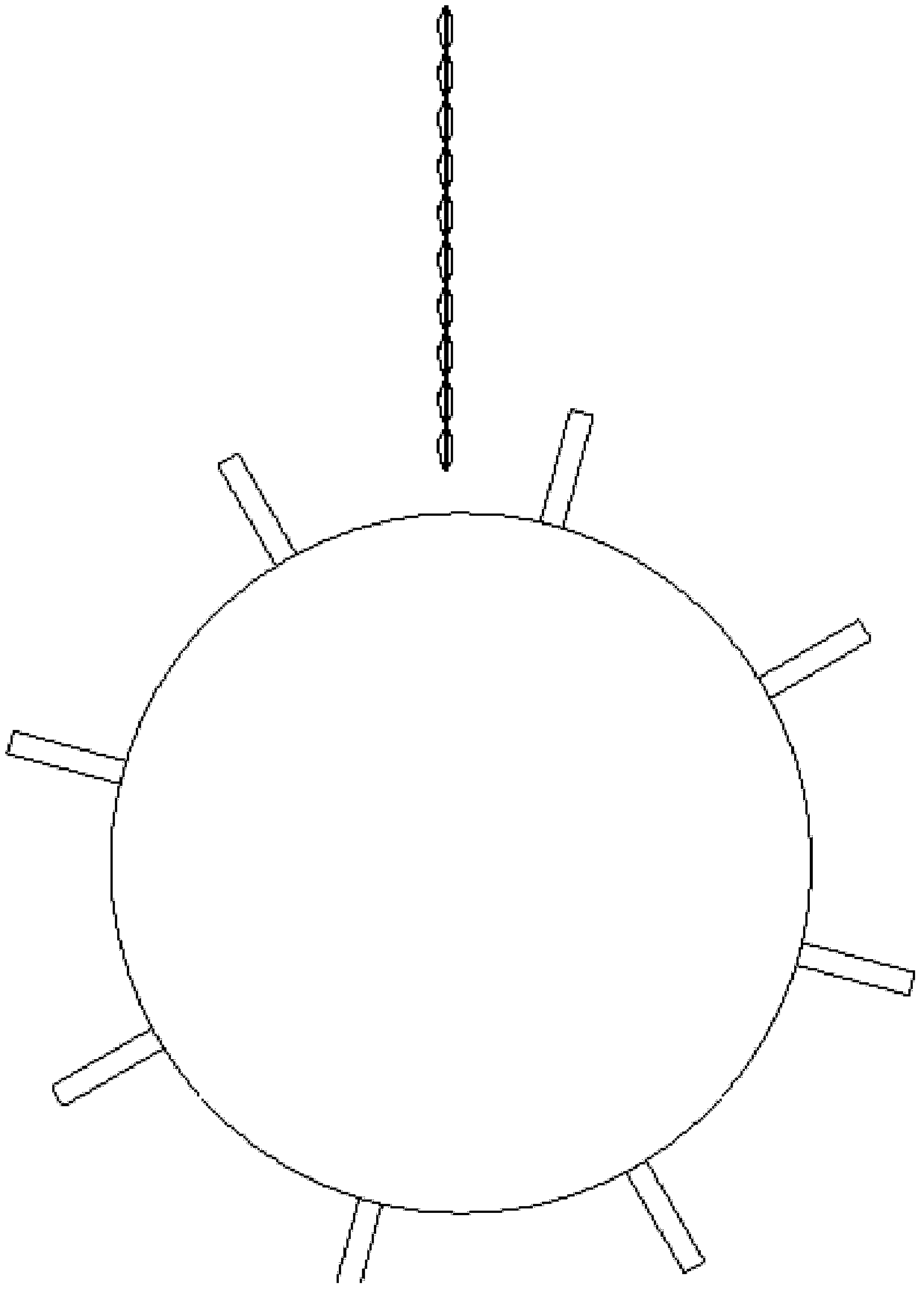

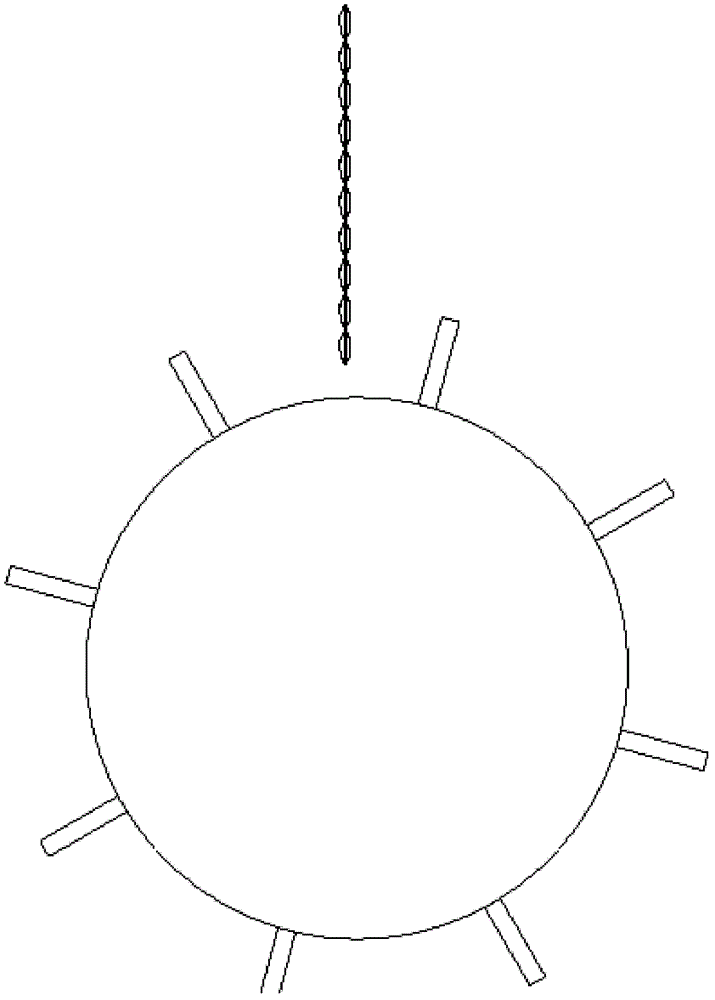

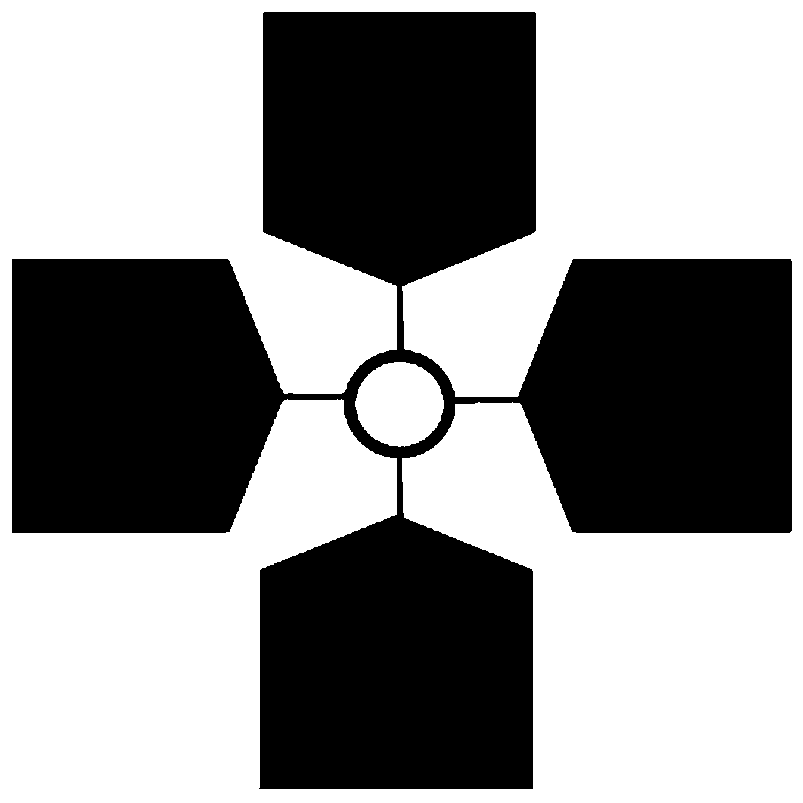

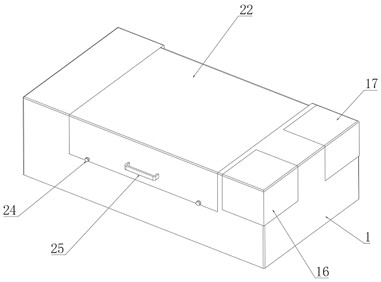

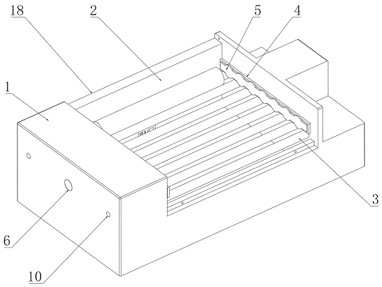

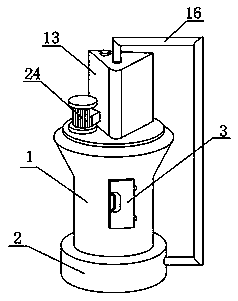

Plastic recycling and cleaning device

InactiveCN108127814ASimple structureEasy to cleanPlastic recyclingDrying gas arrangementsEngineeringWater tanks

The invention discloses a plastic recycling and cleaning device. The plastic recycling and cleaning device comprises a smashing barrel, and a smashing motor is fixe to the middle position of the upperend of the smashing barrel; a smashing shaft is arranged at the output end of the smashing motor; smashing cutters are symmetrically arranged on the portion, close to the bottom of the smashing barrel, of the smashing shaft; an electromagnetic heating coil is wound on the surface of the portion, on the upper sides of the smashing cutters, of the smashing barrel; a material guiding inclined plateis arranged at the bottom of the smashing barrel, and a conveying belt is arranged on the right lower side of the material guiding inclined plate; baffles are symmetrically arranged on the two conveying sides of the conveying belt; a water tank is arranged above the conveying belt; a lower end port of the water tank is provided and connected with a cross pipe through a connection pipe; and a plurality of sprinkling heads are arranged on the lower side face of the cross pipe at equal intervals. The plastic recycling and cleaning device is simple and reasonable in structure; and by performing smashing treatment on materials in advance, later cleaning of plastics is facilitated, the materials are subjected to preliminary spin-drying treatment after cleaning by the device through centrifugal force, and therefore the subsequent drying difficulty is reduced, the device integrates cleaning and drying, and therefore the work efficiency of the device is greatly improved.

Owner:GUANGDONG DEXIN TECH INCUBATOR CO LTD

Preparation method of anti-corrosion plate

ActiveCN106182266AImprove performanceNice appearanceDrying oil coatingsWood treatment detailsSurface layerPulp and paper industry

The invention relates to the technical field of anti-corrosion plates, in particular to a preparation method of the anti-corrosion plate. By the selection and the proportion design of raw material components of anti-corrosion liquid, when a base plate is placed in the anti-corrosion liquid for soaking, harmful bacteria on the surface of the base plate can be effectively killed, and the anti-corrosion liquid can penetrate into the base plate to prevent the interior of a wood board from being eroded by worms; then tung oil is brushed onto the base plate, so that the surface layer of the base plate can be prevented from being soaked by water; furthermore, by the soaking in the anti-corrosion liquid and the control over the moisture content in a drying process, the shortcomings of rotting due to excessive moistening of the wood board and relatively low toughness and easiness in deformation due to over drying of the wood board are avoided; and therefore, the prepared anti-corrosion plate is higher in performance and attractive in appearance.

Owner:广西贺州恒达板业股份有限公司

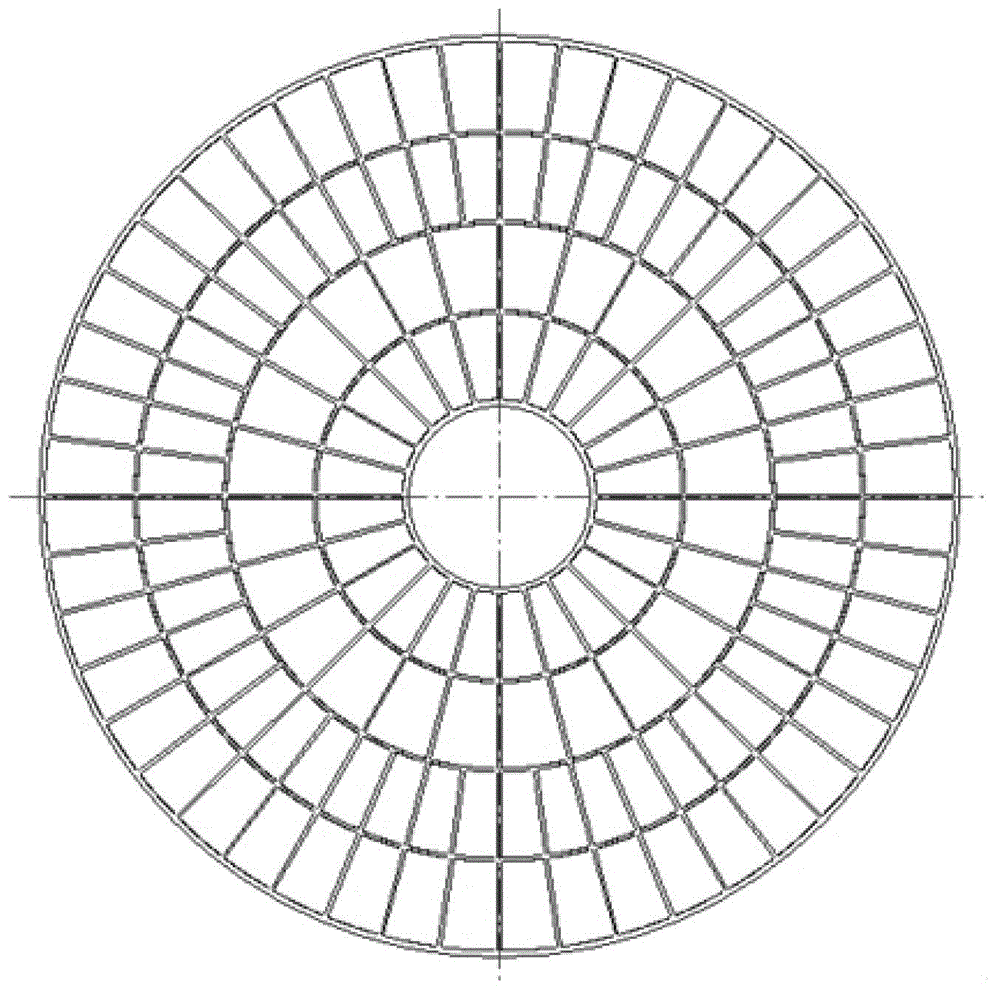

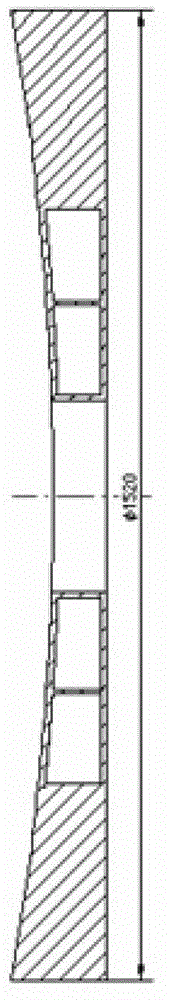

Drying process of gelcasting large-sized and complex-shaped silicon carbide ceramic biscuit

The invention provides a drying process of gelcasting large-sized and complex-shaped silicon carbide ceramic biscuit, which belongs to the field of ceramic drying technology and solves the shortcomings of easily cracking of and deformation of green bodies by adopting the existing ceramic wet green drying process. The process provided by the invention firstly prepares liquid ethanol and deionized water into drying solution with different concentration, then puts the SiC wet green into the bottom of a drying tank, respectively adds drying solution obtained by the step one into the drying tank for soaking to obtain the contracted SiC green body, and finally puts the contracted SiC green body in a drying oven for drying. The drying process provided by the invention greatly reduces the drying difficulty of large-sized and complex-shaped SiC biscuit, and achieves the non-defect drying of 1.5m-magnitude SiC ceramic biscuit prepared by a gelcasting process.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

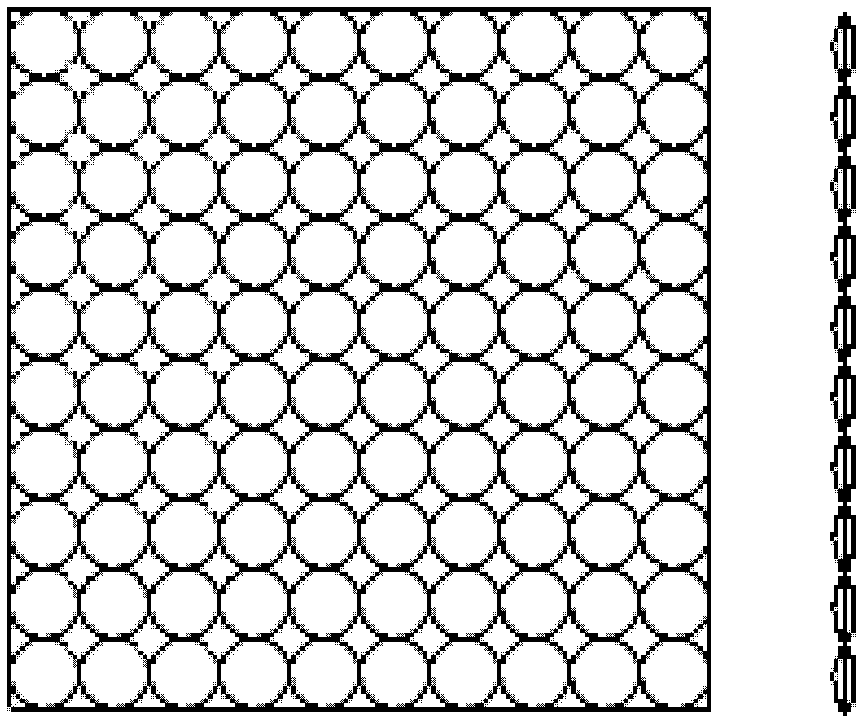

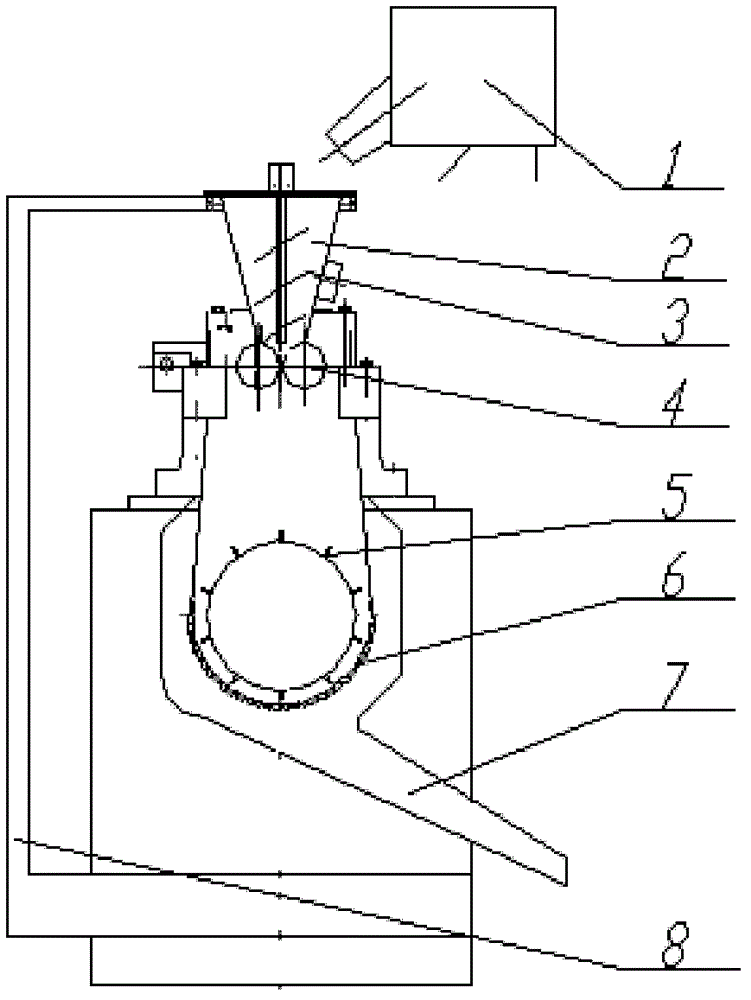

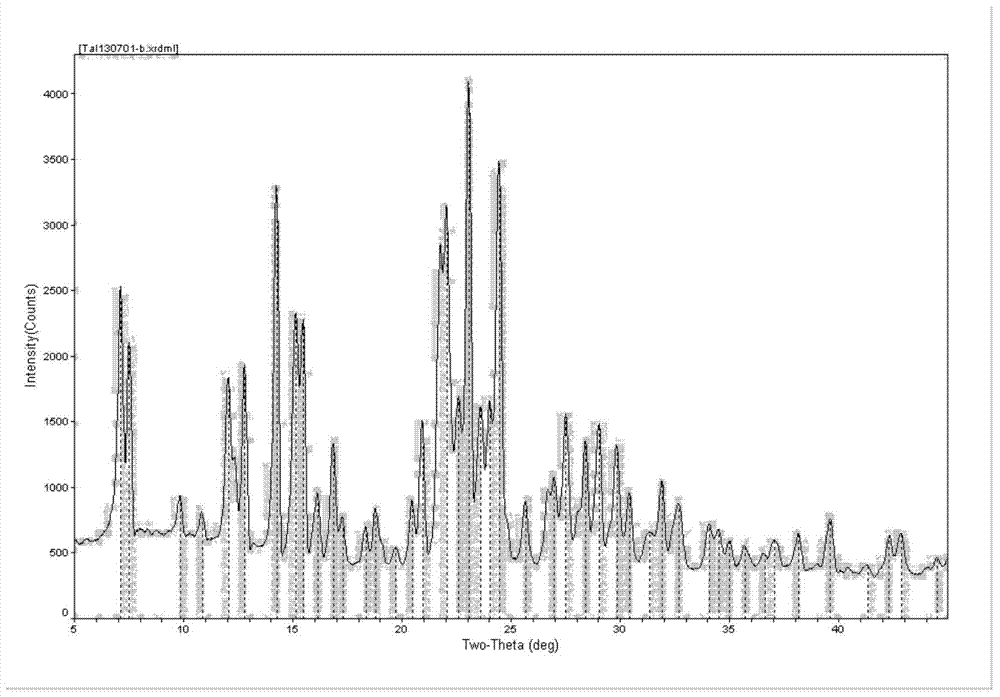

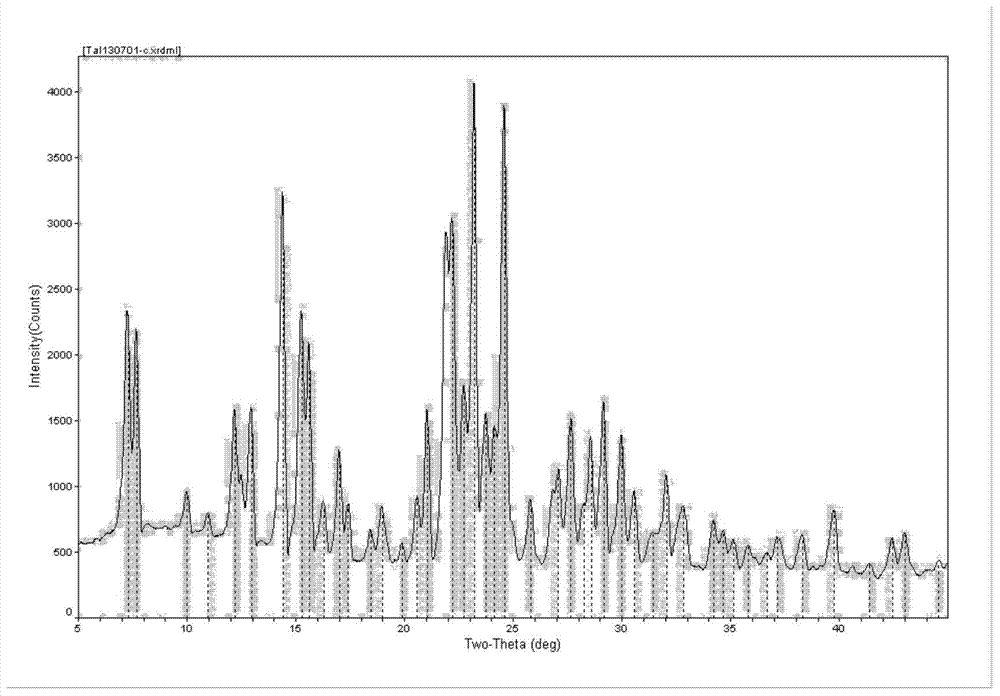

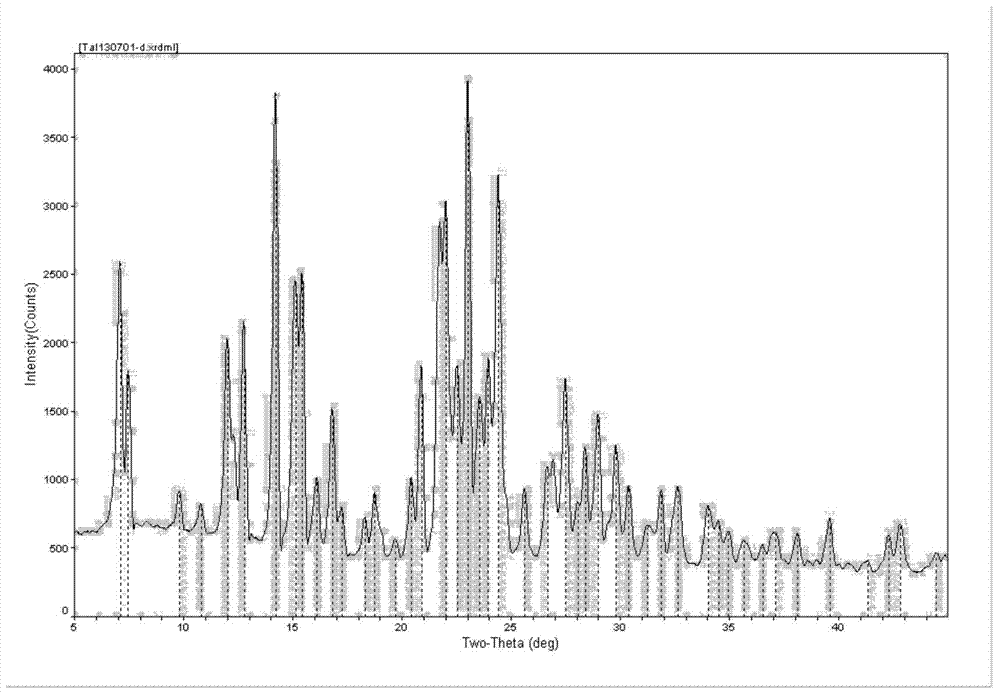

High-content high-universality talcum powder master filler and production equipment and method thereof

The invention discloses a high-content high-universality talcum powder master filler and production equipment and a method thereof. The talcum powder master filler is prepared by 90 to 98 parts of talcum powder, 1 to 2 parts of stearate, 1 to 3 parts of sodium silicate and 3 to 5 parts of water. The content of talcum powder of the master filler can reach 90% to 95%, a great quantity of energy forfusion and plasticization is saved, production cost of the master filler is reduced greatly, and the problem of high-temperature operation environments caused by high temperature equipment is solved.Talcum powder filling content is high, and adding content of the master filler is low in subsequent use, so that adding cost of the master filler is reduced, universality of the talcum powder master filler is realized thoroughly. Since the talcum powder master filler prepared by the method contains no plastic resin, the problem about consistency of matrix during subsequent use can be ignored, andthe high-content high-universality talcum powder master filler can be widely added and used in various talcum powder filling modified plastic products.

Owner:KINGFA SCI & TECH CO LTD +1

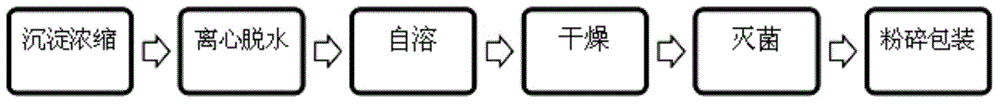

Method for producing aerobic type single-cell protein through autolysis process

PendingCN104893976AEnsure outflowImprove efficiencyMicroorganism lysisPeptide preparation methodsCell wall polysaccharideSingle-cell protein

The invention relates to the technical field of single-cell protein processing, in particular to a method for producing aerobic type single-cell protein through an autolysis process. The method comprises the steps of settling concentration, centrifugal dewatering, drying, sterilization and smashing and packaging, wherein autolysis and drying are carried out on materials with the moisture content of 78 percent to 85 percent obtained after the step of centrifugal dewatering in sequence. The autolysis process is adopted in the process and the manufactured product, autolytic enzymes fully decompose macromolecule nutrients and cell walls in the autolysis process, and high-content free amino acid and free nucleotide can be generated through autolysis. Meanwhile, polysaccharide of the cell walls is decomposed, so that cells are permeable, it is guaranteed that active substances can flow out of the cells, and therefore the active substances can be directly absorbed and utilized by animals. Autolysis is carried out after centrifugal dewatering, and the high efficiency of autolysis can be ensured; the content of moisture needing to be removed in a drying process after autolysis can be reduced, and therefore drying cost is lowered.

Owner:TAIZHOU ICELL BIO TECH CO LTD

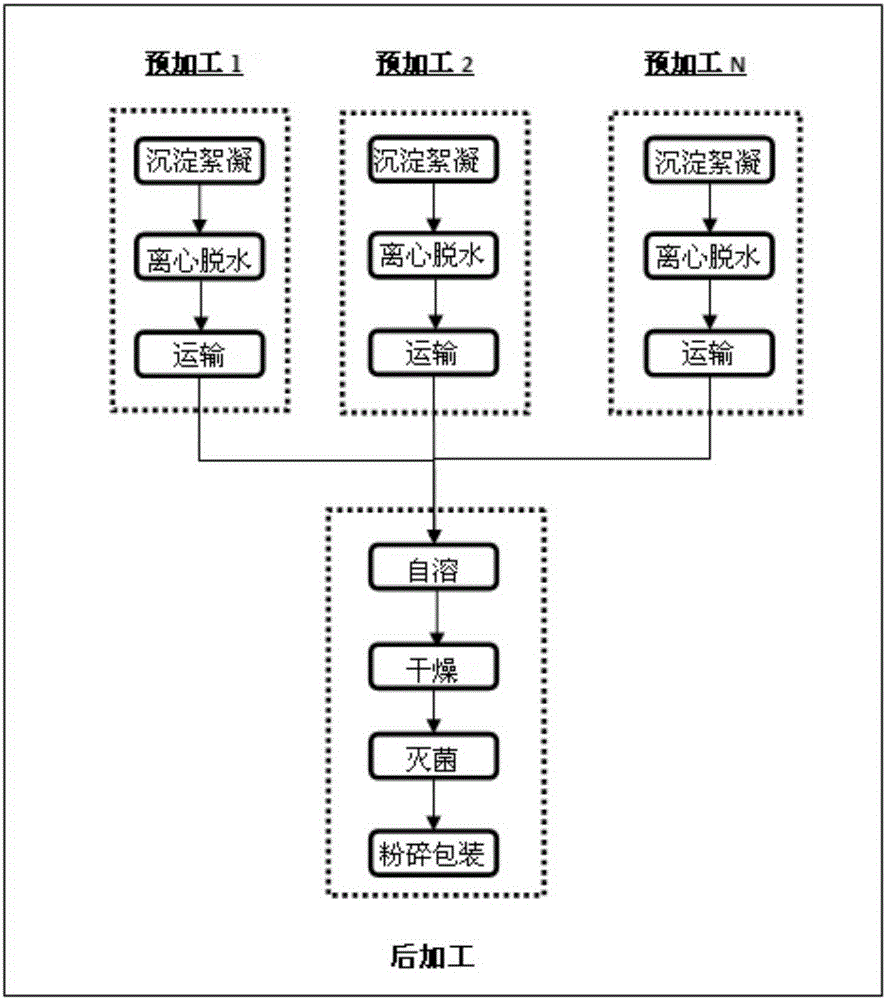

Method for high yield production of aerobic single-cell protein by autolysis process

InactiveCN105166322AEnsure outflowImprove efficiencyMicroorganism/unicellular-algae proteins working-upCell wall polysaccharideSingle-cell protein

The invention relates to the technical field of single-cell protein processing, in particular to a method for high yield production of aerobic single-cell protein by an autolysis process. The process is characterized in that in each pre-processing unit, the material obtained by a centrifugal dewatering step is transported to a post-processing unit to conduct centralized treatment, and the post-processing unit consists of an autolysis step, a drying step, a sterilization step and a crushing and packaging step. The technology and the prepared product involved in the invention employ the autolysis process, during autolysis, autolytic enzyme fully decomposes macromolecular nutrients and cell walls, autolysis can produce high content free amino acid and free nucleotide, and at the same time cell wall polysaccharides are decomposed, and cells can produce permeability so as to ensure that active substances can flow out of cells to as to be directly absorbed and utilized by animals. Autolysis is carried out after centrifugal dewatering, high efficiency of autolysis can be ensured, and the content of water needing to be removed in a drying process after autolysis can be reduced, thereby reducing the cost of drying.

Owner:TAIZHOU ICELL BIO TECH CO LTD

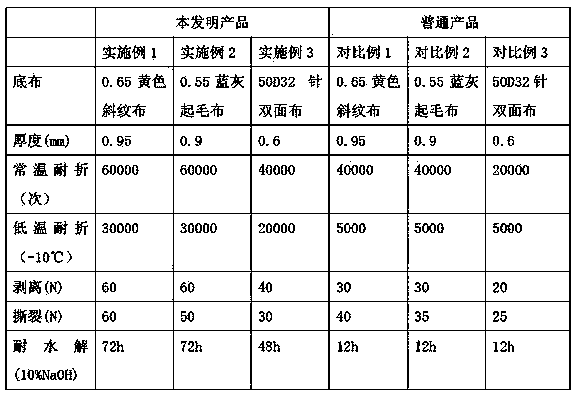

Preparation method of waterborne polyurethane synthetic leather Bayse and applications thereof

ActiveCN102787510BNo pollutionObvious cloth seamLamination ancillary operationsPolyureas/polyurethane adhesivesPolymer sciencePolymer chemistry

Owner:浙江昶丰新材料有限公司

High-content high-universality talcum powder master filler and production equipment and method thereof

Owner:KINGFA SCI & TECH CO LTD +1

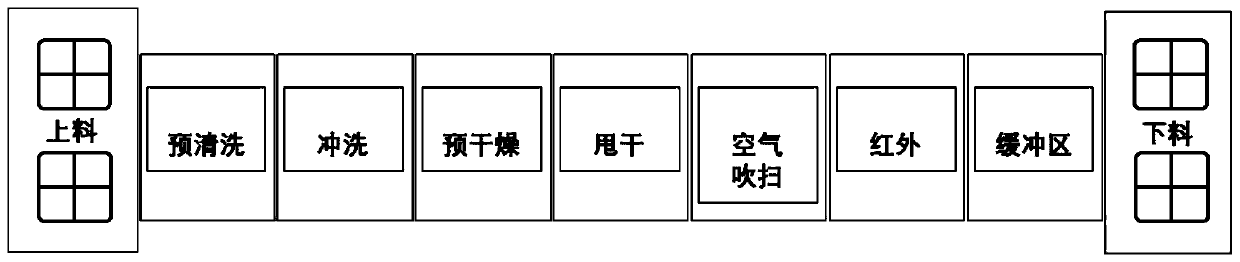

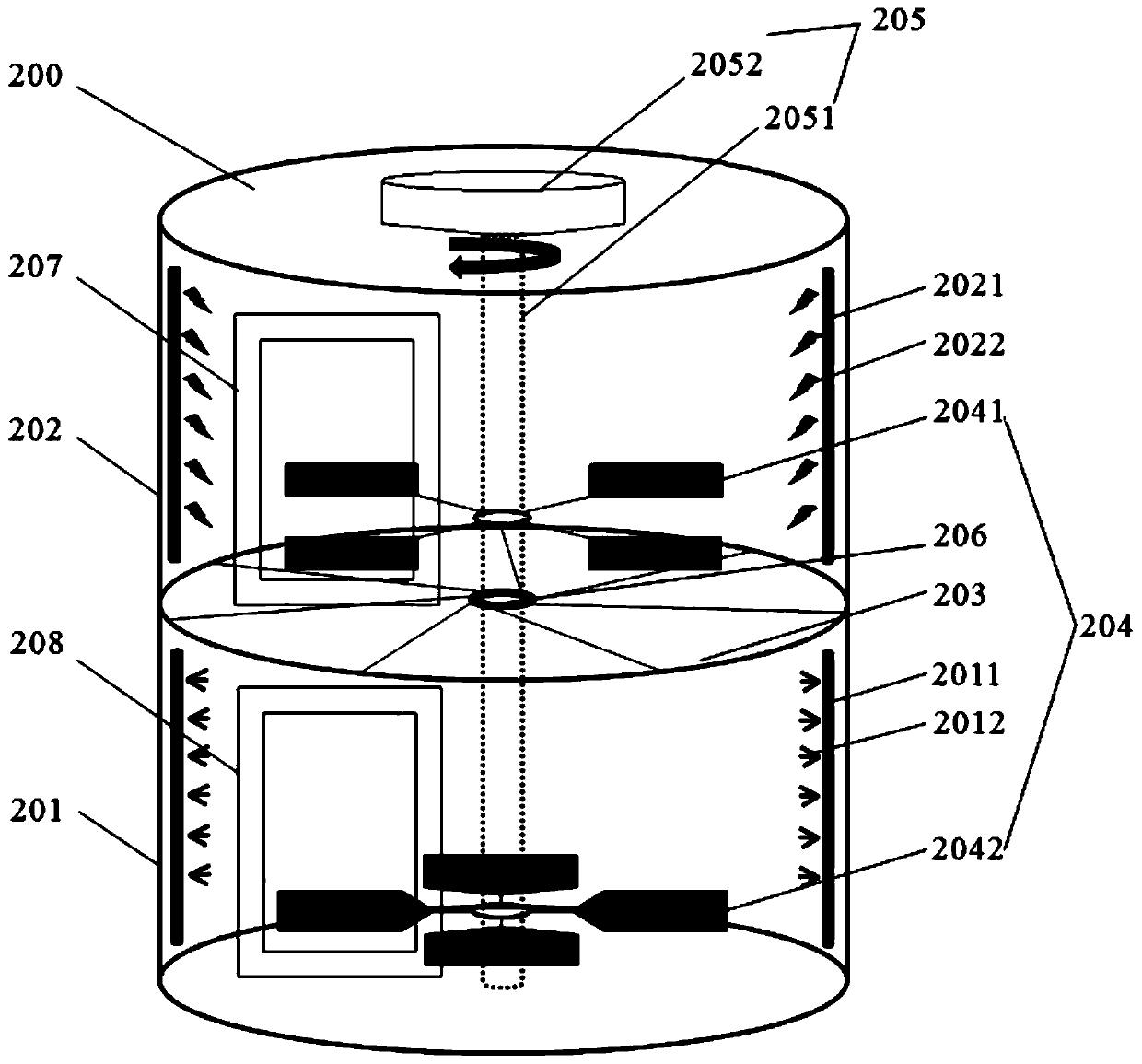

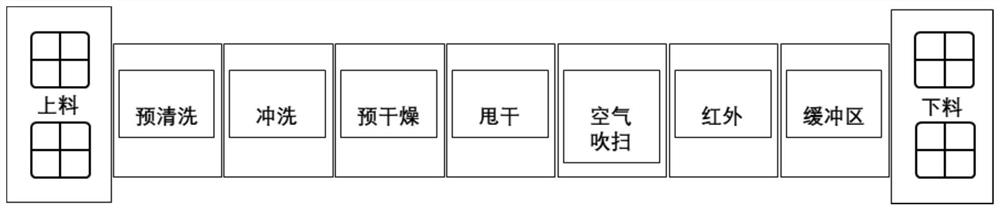

Wafer box cleaning device and method

ActiveCN110335839ASmall footprintLow costSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The invention provides a wafer box cleaning device and method, which relate to the field of semiconductor wafers. The wafer box cleaning device includes a cavity, a separation plate, a wafer box holder and a driving mechanism. The cavity includes a cleaning chamber and a drying chamber. The separation plate is located inside the cavity, and has a closed state and an open state. The separation plate is used to separate the cleaning chamber from the drying chamber when in the closed state. When the separation plate is in the open state, the cleaning chamber and the drying chamber are communicated. The wafer box holder is located inside the cavity and used for carrying a wafer box. The wafer box holder is arranged on the driving mechanism, and the driving mechanism can drive the wafer box holder to move between the cleaning chamber and the drying chamber and can drive the wafer box holder to rotate. The embodiment of the invention solves the problems of large floor area, high cost and lowdrying efficiency of the existing wafer box cleaning machine.

Owner:XIAN ESWIN MATERIAL TECH CO LTD +1

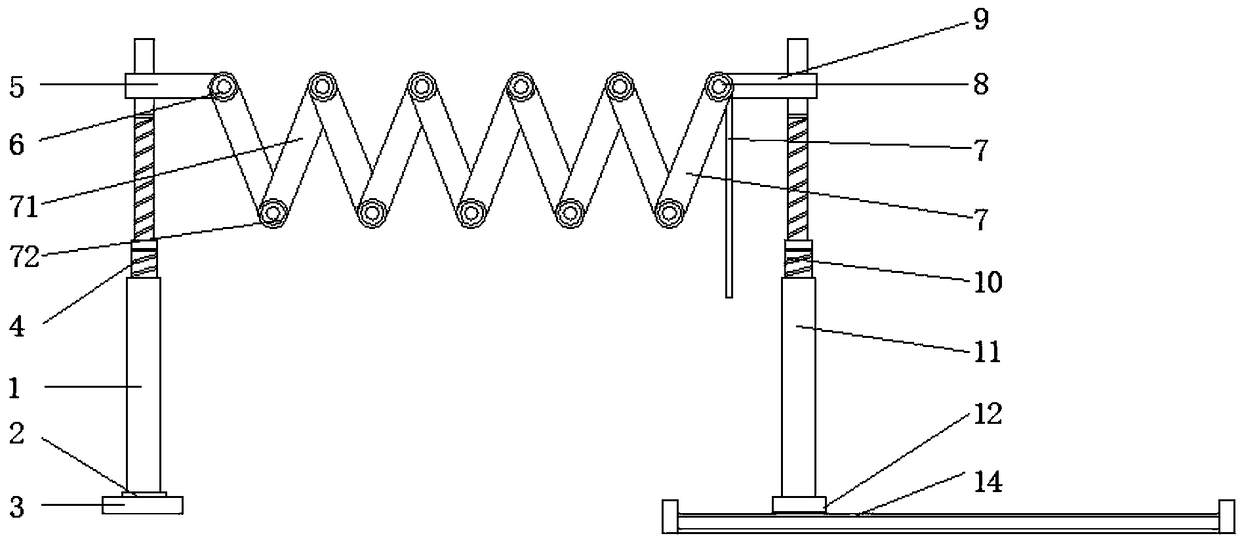

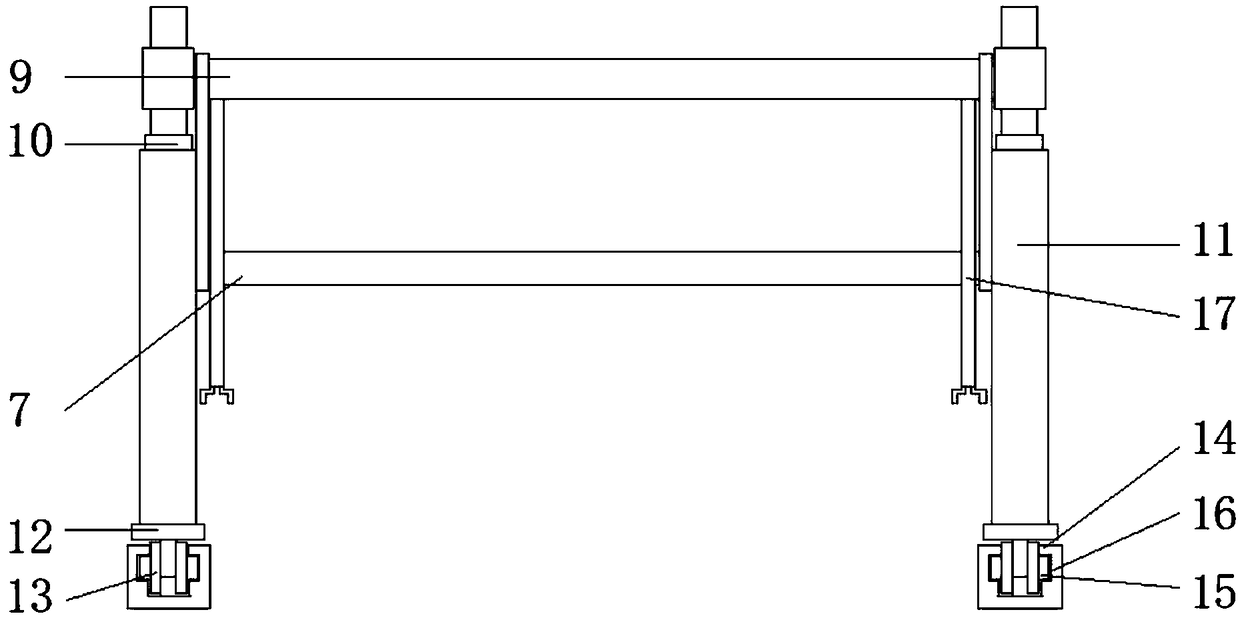

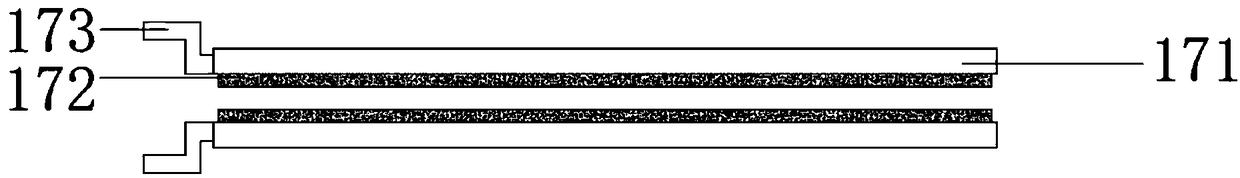

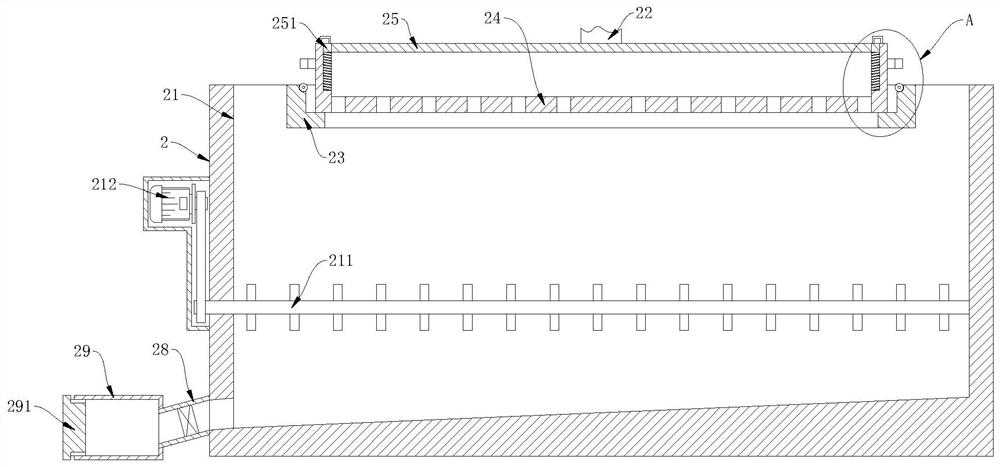

Textile fabric hanging and drying device

InactiveCN108842343AEnsure comprehensivenessTo achieve the purpose of stretching horizontallyLiquid/gas/vapor removalTextile treatment carriersEngineeringTextile

The invention discloses a textile fabric hanging and drying device which comprises fixing-end rotary fixed hollow supporting legs, wherein the bottom ends of the fixing-end rotary fixed hollow supporting legs are fixedly connected with rotary fixed bearings; the outer annular walls of the bottom ends of the rotary fixed bearings are rotationally connected with supporting and fixing legs; the innerannular walls of the top ends of the fixing-end rotary fixed hollow supporting legs are in threaded connection with first threaded telescopic supporting rods; the outer annular walls of the top endsof the first threaded telescopic supporting rods are fixedly connected with first fixing devices; one ends, which are far away from the first threaded telescopic supporting rods, of the first fixing devices are rotationally connected with telescopic supporting devices by virtue of first rotary connectors. The invention relates to the textile-related technical field. The textile fabric hanging anddrying device is low in cost and capable of realizing bidirectional telescopic folding, and the drying difficulty is reduced. Meanwhile, by enlarging the irradiation area of the fabrics, the drying and airing efficiency of the fabrics is improved, and the space utilization rate is improved.

Owner:安吉利宏纺织有限公司

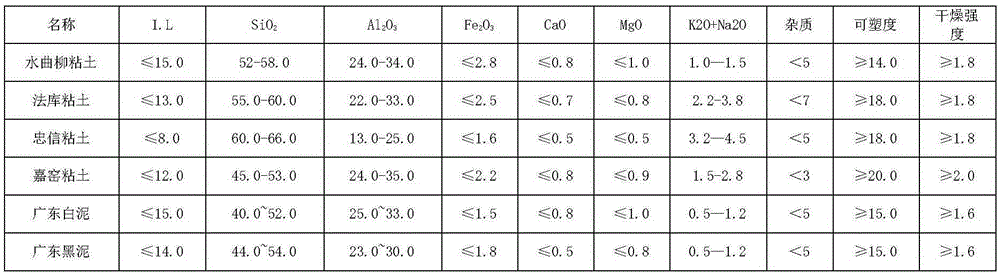

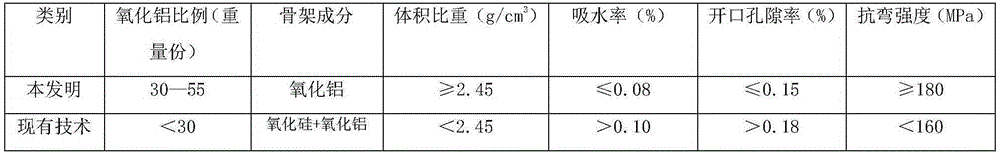

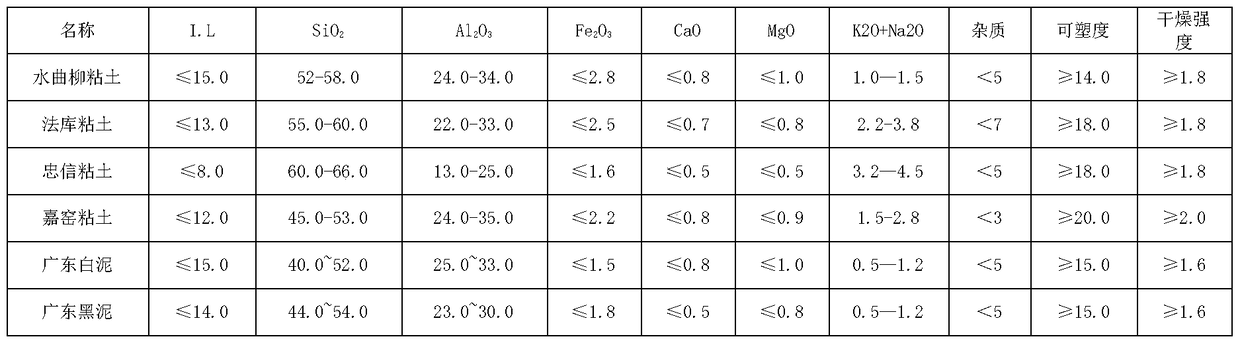

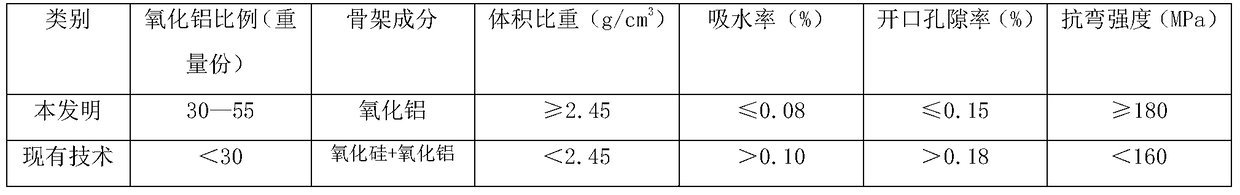

Formula of high-strength porcelain for manufacturing of suspension porcelain insulator

InactiveCN105294063AReduced electromechanical damage load dispersionImprove dry strengthClaywaresDispersityCoesite

The invention discloses a formula of high-strength porcelain for manufacturing of a suspension porcelain insulator. The high-strength porcelain consists of the following ingredients in parts by weight: 25-55 parts of clay, 10-45 parts of bauxite and 8-25 parts of feldspar, wherein clay consists of the following ingredients in parts by weight; 10-30 parts of ashtree clay produced in Shulan County, Jilin Province, 1-15 parts of Faku clay produced in Faku County, Shenyang Province, Zhongxin clay produced in Kuancheng County, Chengde City, 1-20 parts of Jiayao clay produced in Xinhui District, Jiangmen City, 1-10 parts of Guangdong white clay produced in Qingyuan City and 1-8 parts of Guangdong black clay produced in Huizhou City. Through adoption of the formula, the drying intensity can be improved, the drying difficulty of clay can be reduced, the bending strength and the performance of fired porcelain can be improved, the electromechanical failure load dispersity of the insulator can be reduced, and the running security of a grid can be improved.

Owner:萍乡华维电瓷科技股份有限公司

Preparation method of aerogel composite thermal insulation material

The invention provides a preparation method of an aerogel composite thermal insulation material. The method comprises the following steps: (a), mixing a silicon source, hexamethyl-disilazane, a pH regulator and a solvent; (b), soaking a silica sol precursor solution obtained through mixing into a magnesium silicate fiber felt, and leaving the solution to stand, so as to obtain a wet gel felt body;(c), soaking the wet gel felt body into 40 to 90 DEG C organo-siloxane, and then performing microwave drying, so as to obtain the aerogel composite thermal insulation material. The method has the advantages that purification, ageing, solvent exchange and alkylation treatment of the wet gel felt body can be synchronously realized by soaking the wet gel felt body formed in the step (b) into an organo-siloxane solution on the basis of the improvement of a precursor solution formula, so that the preparation period of a material is greatly reduced, the drying difficulty of the material can be further reduced through the treatment, and the materials can be rapidly dried under normal pressure through subsequent microwave drying, in addition, chlorine ion is not introduced during the material preparation, so that corrosion to adopted equipment is small.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

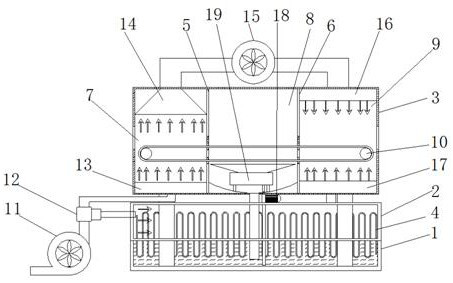

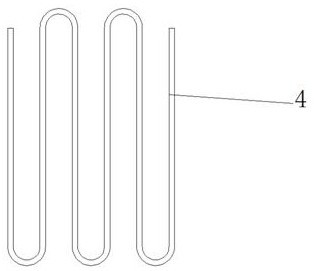

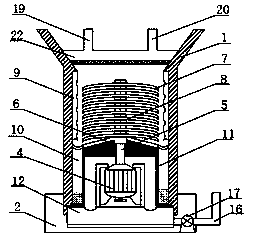

A cooling device for processing aluminum profiles

ActiveCN111112369BReduce the difficulty of dryingImprove drying efficiencyProcess engineeringEngineering

The invention discloses a cooling device for processing aluminum profiles, which comprises a water tank containing cooling water and a heat exchange box installed on the water tank. The four corners of the inner wall of the bottom of the water tank are fixed with support columns, and the four support columns A cooling box is installed on the top, and equidistantly distributed heat exchange tubes are inserted on the inner wall of the bottom of the heat exchange box, and the bottom of the heat exchange tubes is immersed in the cooling water. A baffle and a second baffle, and the first baffle and the second baffle divide the interior of the cooling box into an air-cooled room, a spray room and a drying room, and the inner walls of both sides of the cooling box are fixed with conveying device. The invention can cool the aluminum material through air cooling and water cooling, and can collect the heat dissipated during the cooling process of the aluminum material and the heat in the cooling water to dry the aluminum material, reuse the waste heat, and improve the cooling efficiency of the cooling water at the same time , improve the utilization of waste heat resources.

Owner:ANHUI GAODE ALUMINUM

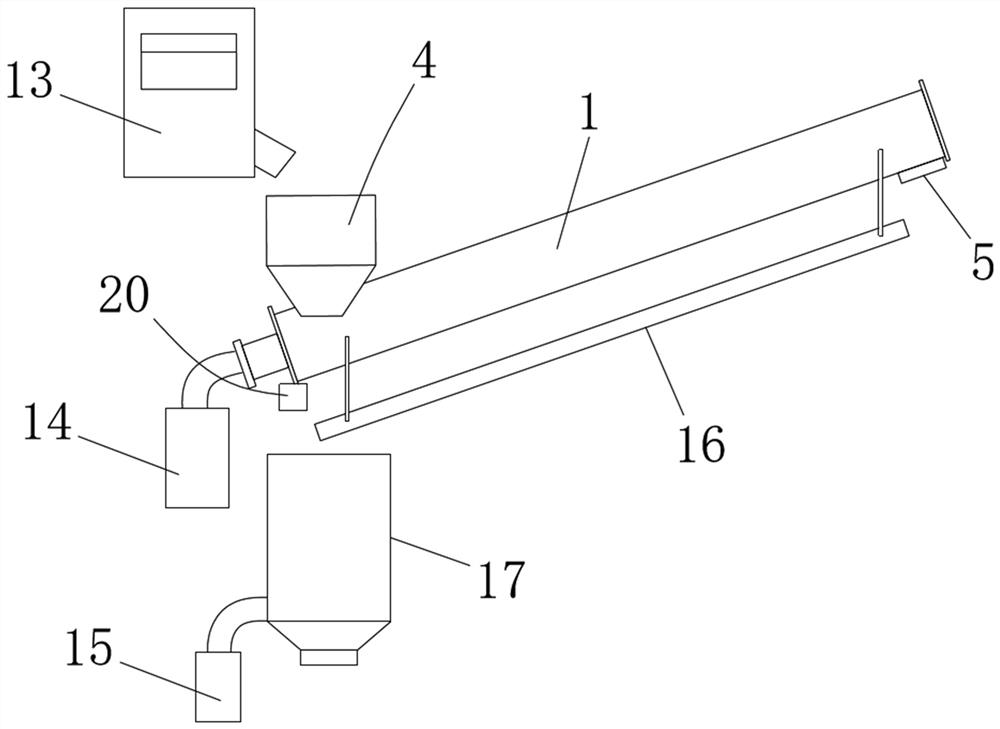

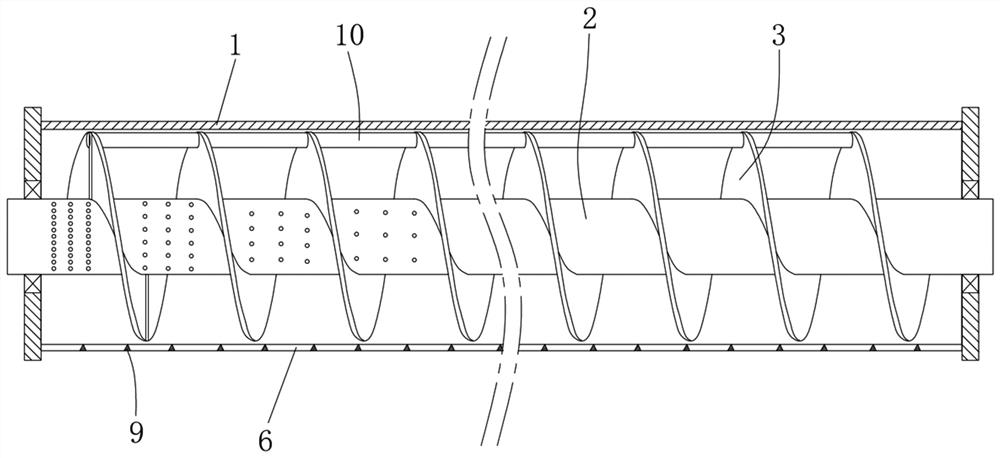

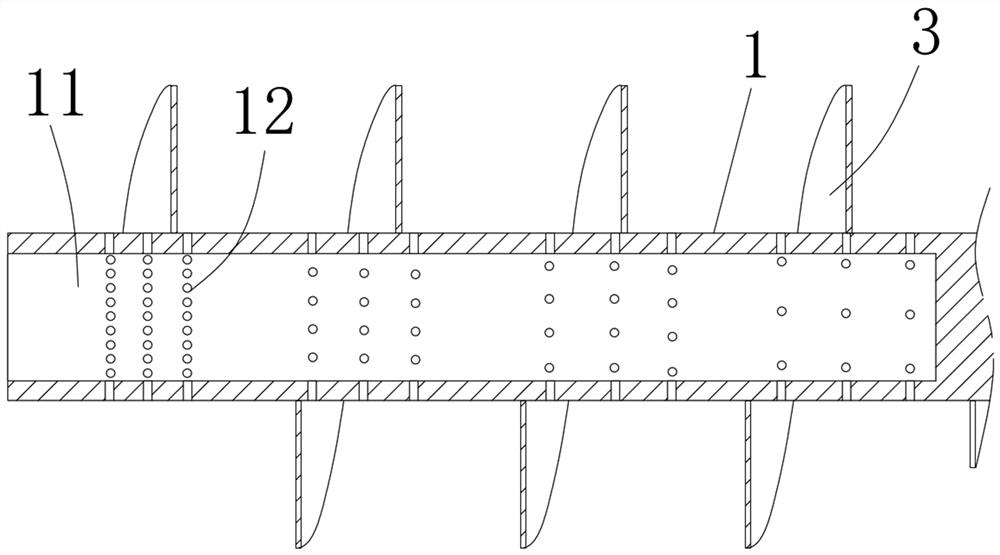

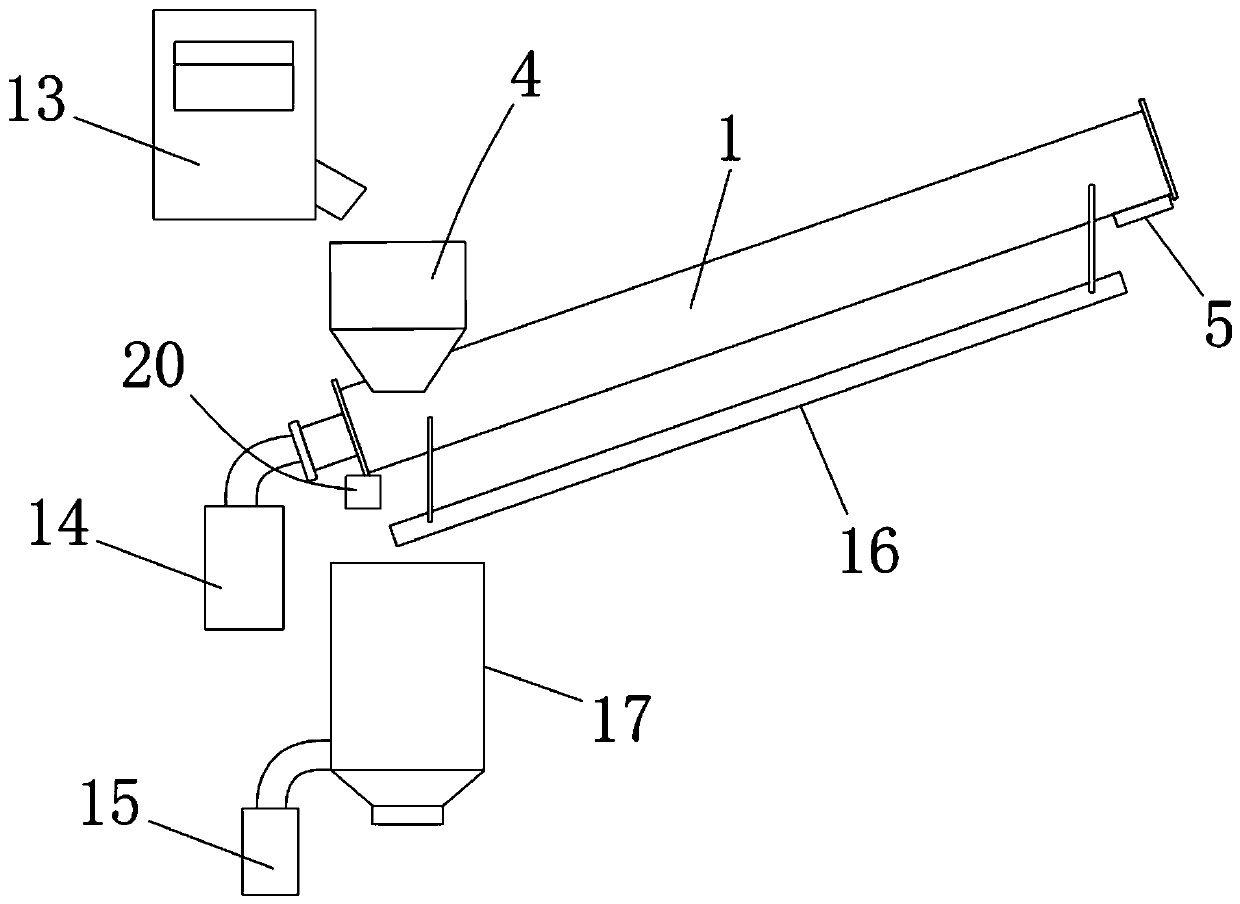

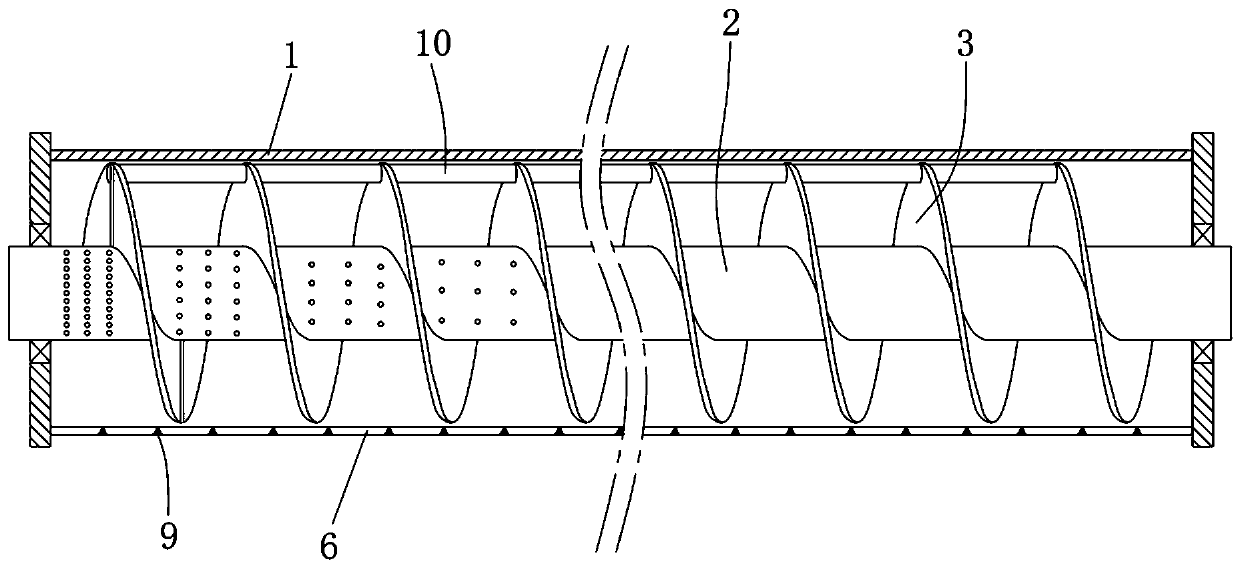

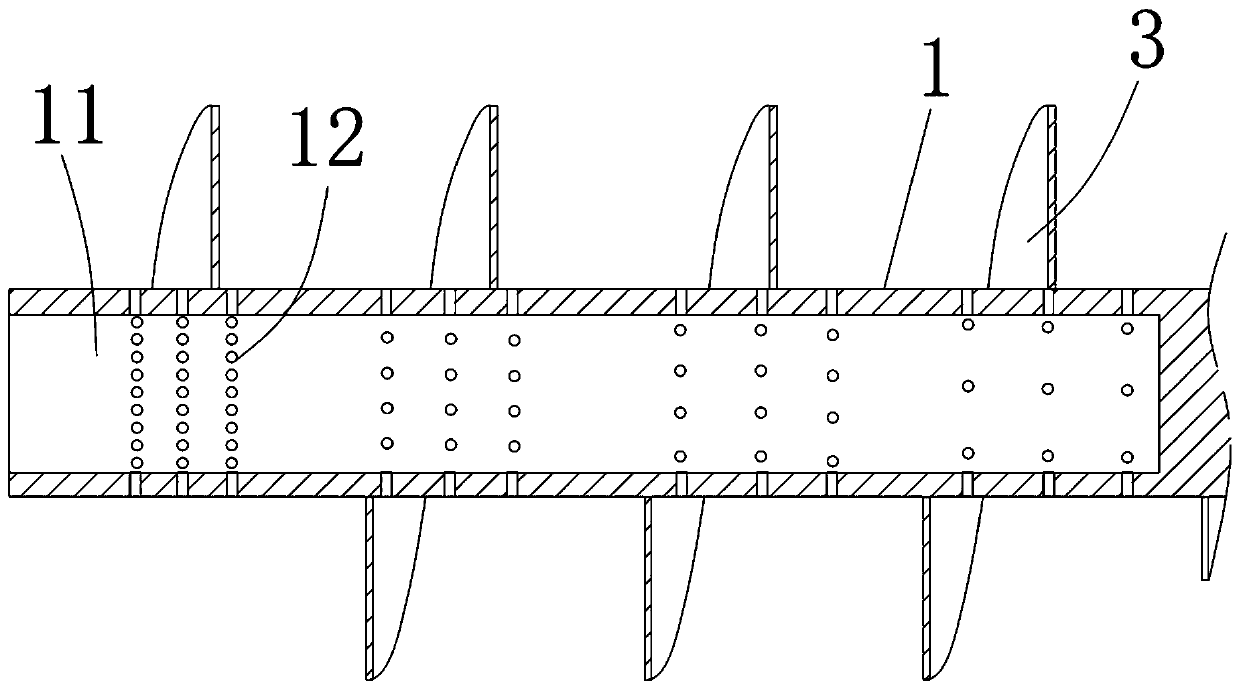

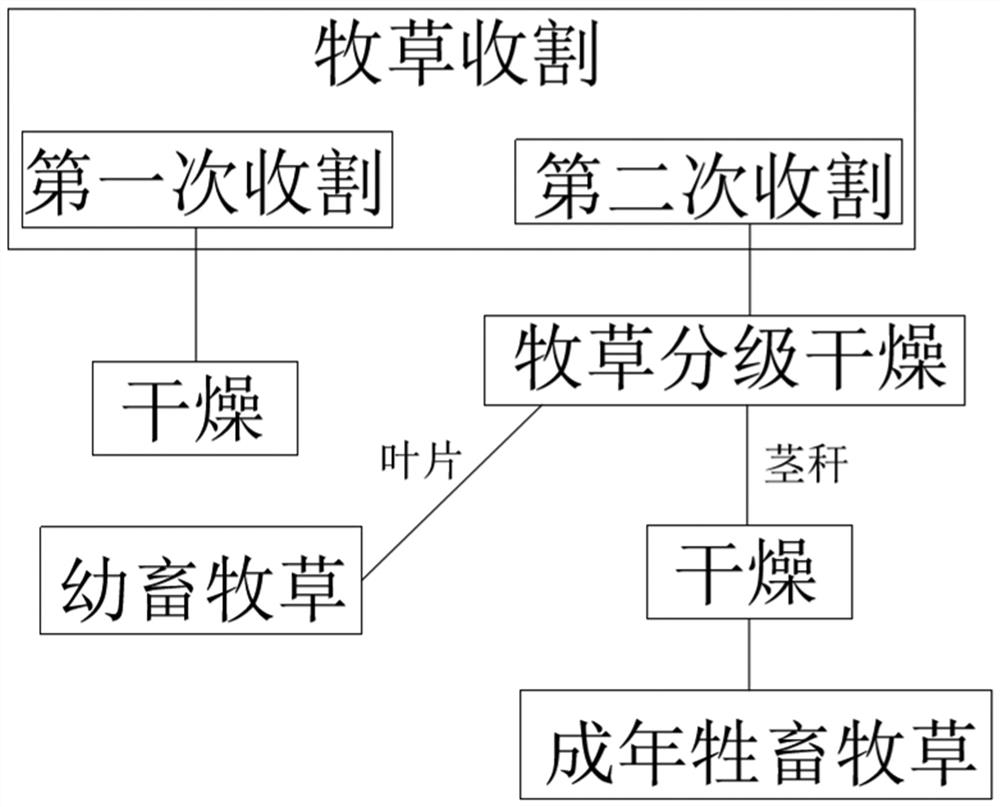

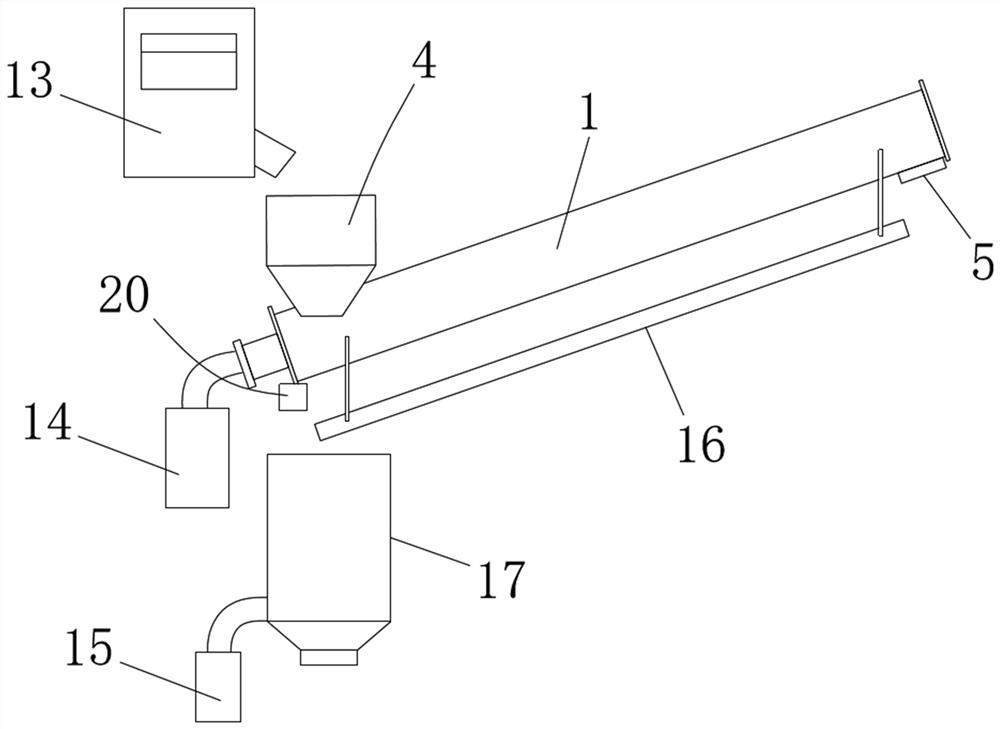

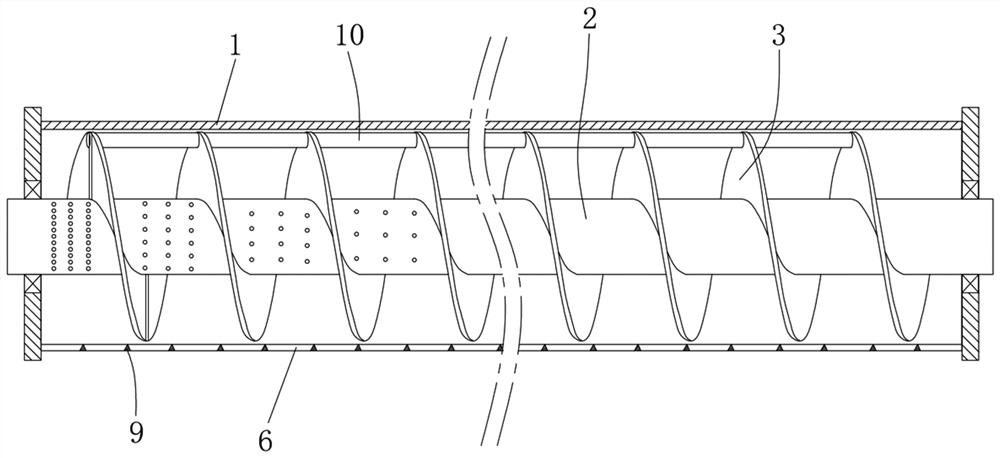

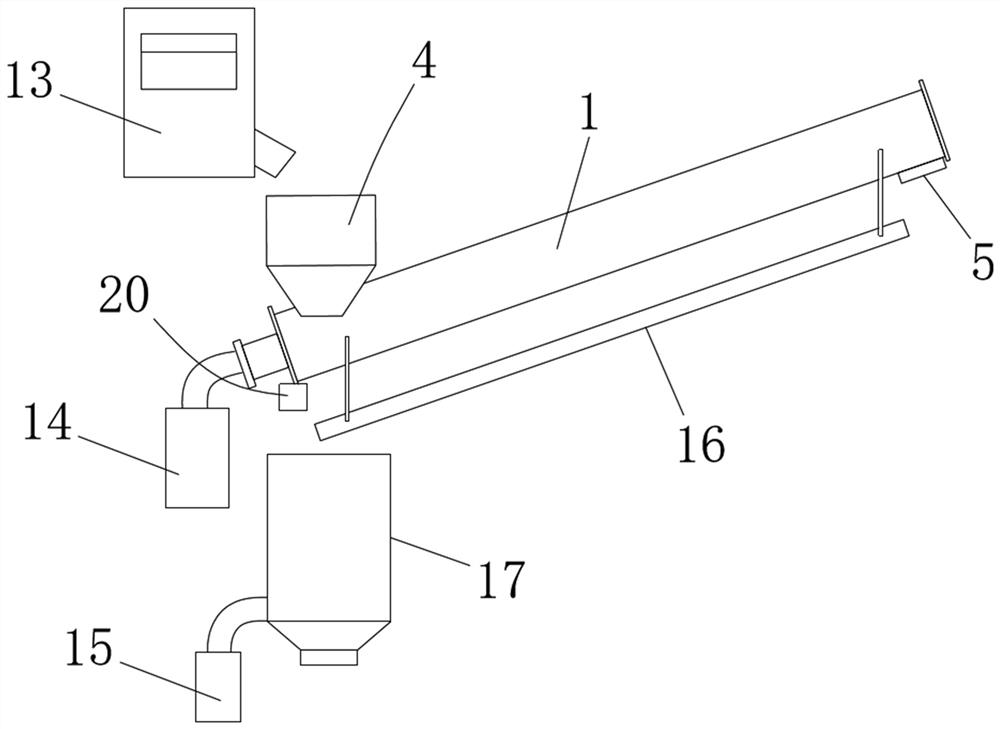

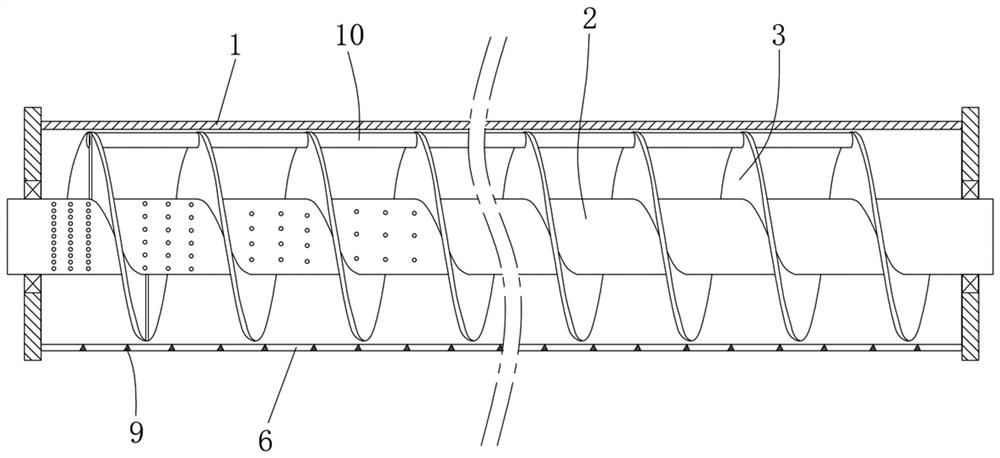

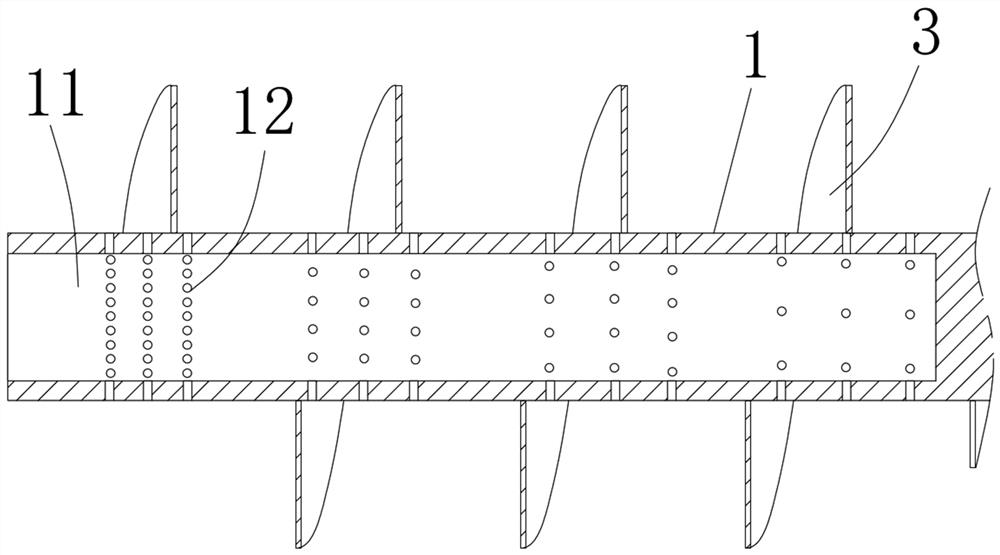

Grass Grading Drying System

ActiveCN111108925BProportionally largeConvenient drying workGrass dryingHarvestersAnimal scienceCrop livestock

The present invention relates to the technical field of animal husbandry, in particular to a pasture grading and drying system, which includes a grading conveying device, the grading conveying device includes an auger, and the auger includes a cylinder, a rotating shaft arranged in the cylinder, and a rotating shaft arranged on the rotating shaft. The helical blade on the upper side of the cylinder is provided with a strip-shaped gap along the direction of the generatrix of the cylinder. The pasture grading conveying device also includes a pasture cutting device and a first hot air device. The first hot air device is used to move toward the The blowing hole on the rotating shaft blows hot air, and a material receiving trough whose length matches the long strip-shaped notch is also arranged under the long strip-shaped notch of the cylinder. A drying device is also arranged under one end. The drying system of this application realizes the distinction between leaves and stalks of forage grass, avoids the risk of mildew in forage grass storage caused by uneven drying, and reduces the waste of forage grass and the occurrence of young animals eating stalks in the current feeding work. Adverse conditions such as indigestion.

Owner:黑龙江省农业科学院畜牧兽医分院

Method for preparing taltirelin tetrahydrate alpha crystal form crystal by using beater

InactiveCN104725468AImprove stabilityRetention of crystalline propertiesPeptide preparation methodsOperabilityTaltirelin

The present invention provides a taltirelin (formula I) tetrahydrate alpha crystal form crystal preparation method, particularly to a method for preparing a taltirelin tetrahydrate alpha crystal form crystal by using a beater. The method specifically comprises: adding taltirelin to a non-protonic solvent, stirring, and using crystallization of the temperature difference method, solid-liquid separation, and drying to obtain the taltirelin alpha crystal form crystal. The method is characterized in that the stirring is specifically the complete stirring at a temperature of 20-60 DEG C by using a beater, the stirring speed is controlled to 300-500 r / min, and the non-protonic solvent is tetrahydrofuran, ethyl acetate, acetone, and acetonitrile. According to the present invention, the method has characteristics of good process stability, strong operability, high yield, and the like; and the obtained product has characteristics of low free water content, melting point close to the upper limit of the standard value, easy formulation processing, storage, and transportation, and the like. The formula I is defined in the instruction.

Owner:重庆莱美隆宇药业有限公司

Process for drying thallus residues in lactic acid production

ActiveCN114145387AEasy to dryReduce drying difficultyAnimal feeding stuffAccessory food factorsChemistryEngineering

The invention discloses a process for drying thallus residues in lactic acid production, which comprises the following steps: step A, adding a urea solution into thallus residues filtered by a plate frame, uniformly stirring and mixing, and standing to obtain a mixed material A; step B, adding a treating agent into the mixed material A, uniformly stirring and mixing, and standing to obtain a mixed material B; step C, putting the mixed material B into a reaction kettle, spraying concentrated sulfuric acid into the reaction kettle while stirring, and obtaining a mixed material C after the reaction is finished; and step D, transferring the mixed material C into drying equipment for drying, and completing the drying process of the thallus residues in the lactic acid production after the drying is finished. The method solves the problem that the thallus residues are easy to rot and deteriorate during storage and stacking due to incomplete drying caused by high viscidity, complex components and the like of the thallus residues.

Owner:河南金丹乳酸科技股份有限公司

A film box cleaning device and method

ActiveCN110335839BSmall footprintLow costSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention provides a chip box cleaning device and method, which relate to the field of semiconductor wafers. The chip box cleaning device includes: a cavity, including a cleaning chamber and a drying chamber; an isolation plate, located inside the cavity, and the isolation plate has a closed state In the open state, in the closed state, it is used to isolate the cleaning chamber and the drying chamber, in the open state, the cleaning chamber and the drying chamber are connected; the film box bracket is located inside the cavity, and is used to carry the film box; mechanism, the film cassette support is arranged on the driving mechanism, and the driving mechanism can drive the film cassette support to move between the cleaning chamber and the drying chamber, and can drive the film cassette support to rotate. The embodiment of the present invention effectively solves the problems of large occupied area, high cost and low drying efficiency of the existing film cassette cleaning machine.

Owner:XIAN ESWIN MATERIAL TECH CO LTD +1

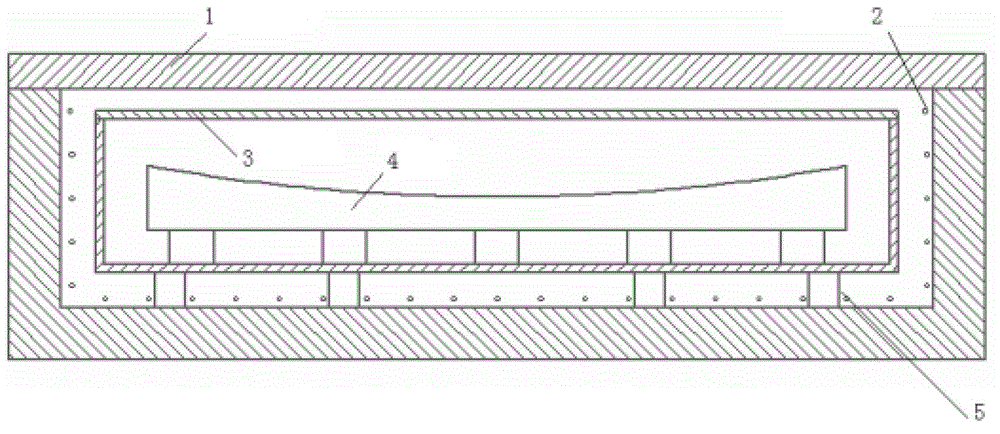

A kind of drying method of gel injection molding sic ceramic impeller wet blank

The invention provides a drying method for gel injection molding SiC ceramic impeller wet blanks. Aiming at the problems that the ceramic impeller wet blanks are easy to crack and deform in the initial drying stage in the gel injection molding process, it is proposed to use polyethylene glycol The method of drying the wet impeller with the drying liquid and supporting the wet impeller with an inert hard tray. In this method, a high-concentration polyethylene glycol drying liquid is firstly configured, and then the wet impeller and the inert support tray are immersed in the drying liquid to complete the second stage. Dry in the first stage, and then put it into a constant temperature and constant humidity drying box to complete the second stage of drying. Adopting this method makes the drying environment milder, the green body is dried evenly and thoroughly, and defects such as cracking and deformation of the green body caused by gravity and drying stress are avoided. The method is simple in operation, low in cost, short in production cycle and high in efficiency, greatly reduces the difficulty of drying large-sized impellers, and prepares large-sized impellers with a diameter of more than 350 mm.

Owner:UNIV OF SCI & TECH BEIJING

Forage grass grading and conveying device

ActiveCN111011011AProportionally largeConvenient drying workGrass dryingDrying gas arrangementsAnimal scienceCrop livestock

The present invention relates to the technical field of livestock breeding and particularly to a forage grass grading and conveying device. The forage grass grading and conveying device comprises an auger, the auger comprises a cylinder body, a rotating shaft arranged in the cylinder body and a helical blade arranged on the rotating shaft, sealing plates are arranged at both ends of the cylinder body, a bearing used for supporting the rotating shaft is arranged on each sealing plate, a feeding hopper is arranged on an upper side of a side wall at one end of the cylinder body, a discharge portis arranged on a lower side of the side wall at the other side, strip-shaped notches along a generatrix direction of the cylinder body are arranged in a lower side of the cylinder body, and the widthof the strip-shaped notches is 1 / 4-3 / 4 of diameter of stalks of forage grass to be conveyed. In the forage grass grading and conveying device, diameter of the forage grass stalks is the diameter of amiddle segment part of the forage grass stalks in the mature period. The grading and conveying device realizes separation of stalk segments and leaf blades, besides, when the stalk segments pass the notches, the stalks break, so that the grading and conveying device also greatly facilitates follow-up drying work of the stalk segments.

Owner:黑龙江省农业科学院畜牧兽医分院

A kind of grass classification drying method

ActiveCN111034473BProportionally largeConvenient drying workClimate change adaptationHarvestersBiotechnologyCrop livestock

Owner:黑龙江省农业科学院畜牧兽医分院

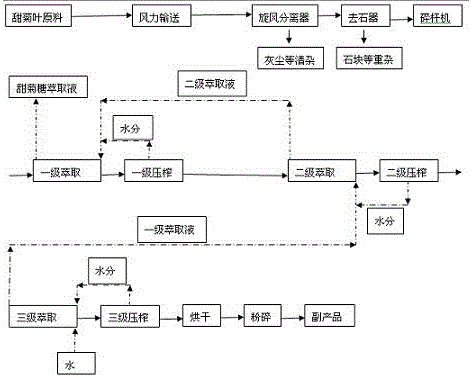

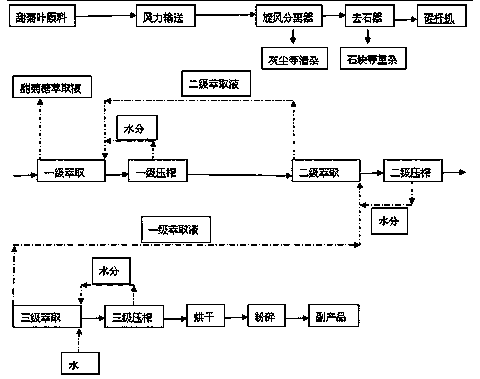

Counter-current extraction method for stevia rebaudian

ActiveCN106146575AReduce consumptionSubsequent production process is stableSugar derivativesSugar derivatives preparationSolventPre treatment

The invention discloses a counter-current extraction method for stevia rebaudian, which comprises the following steps: (1) using a cyclone separator for separating and removing light impurities from stevia rebaudian, using a wind power stone remover for removing heavy impurities, crushing stems and then performing multi-level counter-current extraction; (2) in a multi-level counter-current extraction process, extracting the materials at each level and then squeezing water; performing next level of extracting and squeezing on the squeezed material, returning the water squeezed at each level and extracting at the level; (3) in the multi-level counter-current extraction process, using new solvents as all the extraction agents for the latest level extraction; taking extract liquor generated from each level of extraction as the extract liquor for the superior extraction; obtaining the extraction liquor generated from level-1 extraction as final extraction liquor of stevia rebaudian. According to the invention, the pretreatment operation is performed for ensuring the basic constant characters of the materials for extraction and ensuring the stability of the subsequent production. Meanwhile, a multi-level squeezing system is added in the multi-level counter-current extraction system, so that the water consumption is reduced, energy consumption is reduced and the yield of the products is increased.

Owner:CHENGUANG BIOTECH GRP CO LTD

A kind of anticorrosion board preparation method

ActiveCN106182266BImprove performanceNice appearanceDrying oil coatingsWood treatment detailsSurface layerPulp and paper industry

Owner:广西贺州恒达板业股份有限公司

A high-strength porcelain formula for making suspension porcelain insulators

InactiveCN105294063BReduced electromechanical damage load dispersionImprove dry strengthClaywaresDispersityCoesite

The invention discloses a formula of high-strength porcelain for manufacturing of a suspension porcelain insulator. The high-strength porcelain consists of the following ingredients in parts by weight: 25-55 parts of clay, 10-45 parts of bauxite and 8-25 parts of feldspar, wherein clay consists of the following ingredients in parts by weight; 10-30 parts of ashtree clay produced in Shulan County, Jilin Province, 1-15 parts of Faku clay produced in Faku County, Shenyang Province, Zhongxin clay produced in Kuancheng County, Chengde City, 1-20 parts of Jiayao clay produced in Xinhui District, Jiangmen City, 1-10 parts of Guangdong white clay produced in Qingyuan City and 1-8 parts of Guangdong black clay produced in Huizhou City. Through adoption of the formula, the drying intensity can be improved, the drying difficulty of clay can be reduced, the bending strength and the performance of fired porcelain can be improved, the electromechanical failure load dispersity of the insulator can be reduced, and the running security of a grid can be improved.

Owner:萍乡华维电瓷科技股份有限公司

A kind of preparation method of airgel composite insulation material

The invention provides a preparation method of an aerogel composite thermal insulation material. The method comprises the following steps: (a), mixing a silicon source, hexamethyl-disilazane, a pH regulator and a solvent; (b), soaking a silica sol precursor solution obtained through mixing into a magnesium silicate fiber felt, and leaving the solution to stand, so as to obtain a wet gel felt body;(c), soaking the wet gel felt body into 40 to 90 DEG C organo-siloxane, and then performing microwave drying, so as to obtain the aerogel composite thermal insulation material. The method has the advantages that purification, ageing, solvent exchange and alkylation treatment of the wet gel felt body can be synchronously realized by soaking the wet gel felt body formed in the step (b) into an organo-siloxane solution on the basis of the improvement of a precursor solution formula, so that the preparation period of a material is greatly reduced, the drying difficulty of the material can be further reduced through the treatment, and the materials can be rapidly dried under normal pressure through subsequent microwave drying, in addition, chlorine ion is not introduced during the material preparation, so that corrosion to adopted equipment is small.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

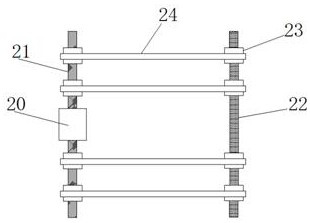

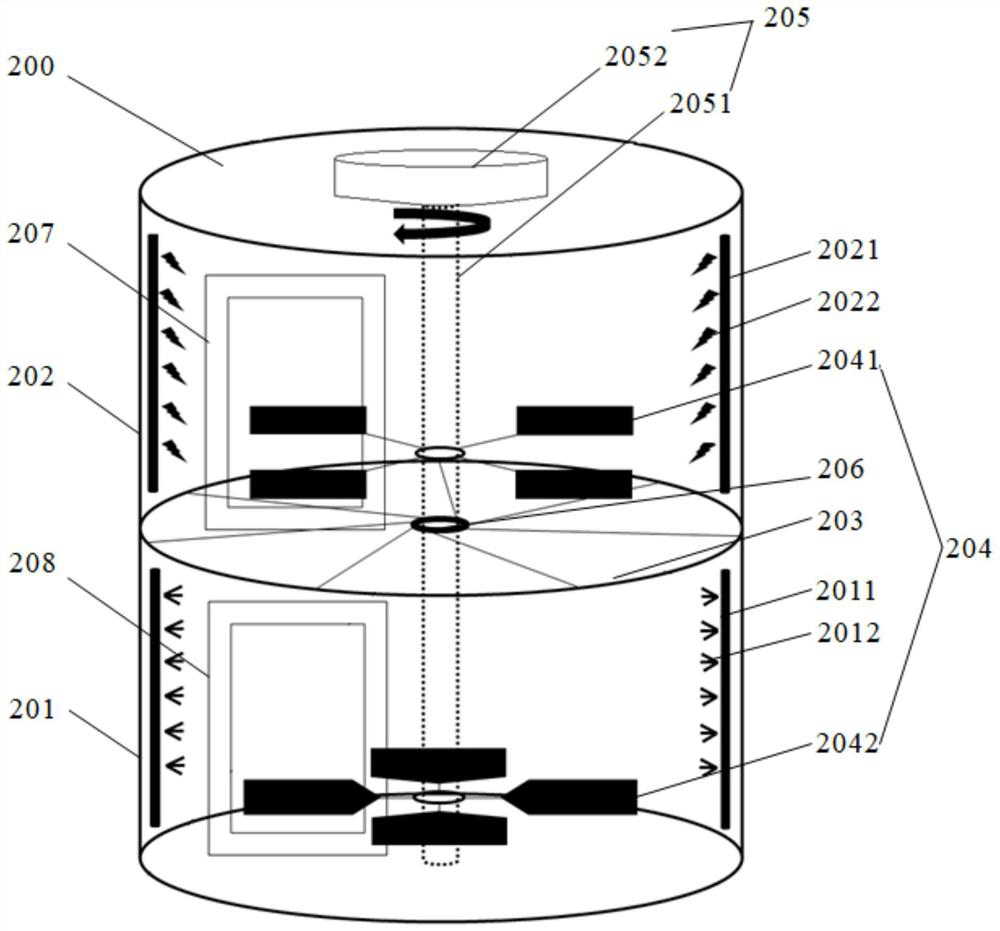

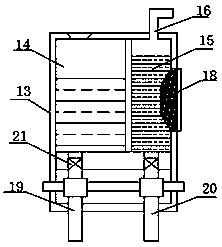

Medical instrument dryer

PendingCN114034165AImprove performanceReduce the difficulty of dryingDrying solid materialsDrying machines with local agitationBiomedical engineeringApparatus instruments

The invention belongs to the technical field of medical instrument drying, and particularly relates to a medical instrument dryer which comprises a dryer body, a storage groove is formed in the middle of the top end of the dryer body, and insulating supporting rollers are equidistantly installed in the middles of the two sides of the inner wall of the storage groove. A first insulating plate is mounted in the middle, close to the insulating supporting roller, of one side of the inner wall of the storage groove, and a first electrode plate is mounted in the middle of one side of the first insulating plate. According to the medical instrument dryer, through use of a telescopic air cylinder, a second insulating plate and a second electrode plate, the position of medical equipment can be adjusted, the use performance of the dryer can be improved, the dryer can conveniently dry the medical equipment of different sizes, through use of an exhaust groove, exhaust holes and an exhaust fan, water vapor in the dryer can be exhausted. Through cooperative use of a first electrode plate, the second electrode plate, a controller and a transformer, medical instruments can be dried, the drying difficulty of the medical instruments can be reduced, and meanwhile the drying rate of the medical instruments can be increased.

Owner:周圣宜

A kind of countercurrent extraction method of stevia leaf

ActiveCN106146575BReduce consumptionSubsequent production process is stableSugar derivativesSugar derivatives preparationPre treatmentSolvent

The invention discloses a counter-current extraction method for stevia rebaudian, which comprises the following steps: (1) using a cyclone separator for separating and removing light impurities from stevia rebaudian, using a wind power stone remover for removing heavy impurities, crushing stems and then performing multi-level counter-current extraction; (2) in a multi-level counter-current extraction process, extracting the materials at each level and then squeezing water; performing next level of extracting and squeezing on the squeezed material, returning the water squeezed at each level and extracting at the level; (3) in the multi-level counter-current extraction process, using new solvents as all the extraction agents for the latest level extraction; taking extract liquor generated from each level of extraction as the extract liquor for the superior extraction; obtaining the extraction liquor generated from level-1 extraction as final extraction liquor of stevia rebaudian. According to the invention, the pretreatment operation is performed for ensuring the basic constant characters of the materials for extraction and ensuring the stability of the subsequent production. Meanwhile, a multi-level squeezing system is added in the multi-level counter-current extraction system, so that the water consumption is reduced, energy consumption is reduced and the yield of the products is increased.

Owner:CHENGUANG BIOTECH GRP CO LTD

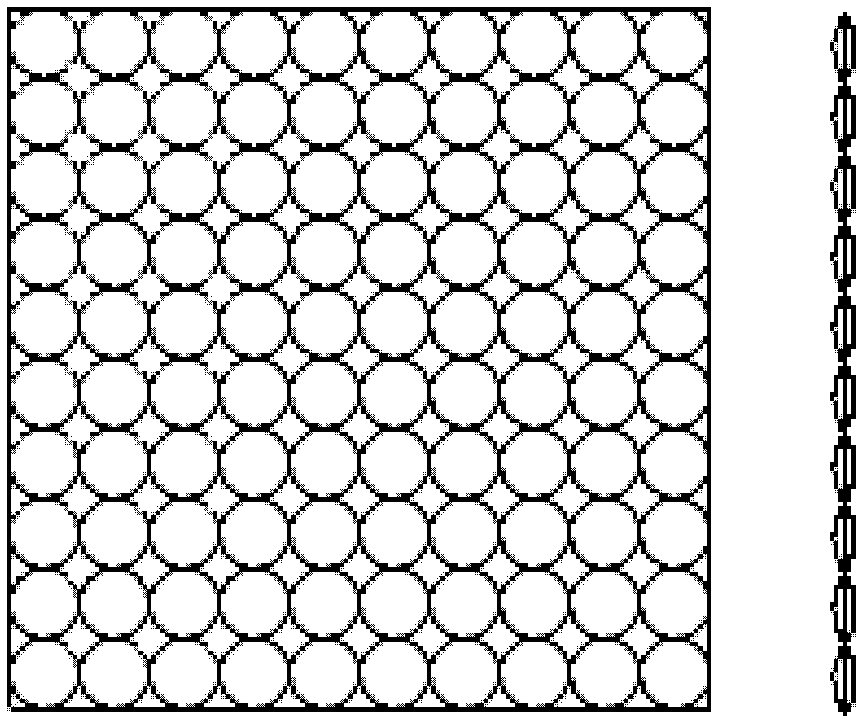

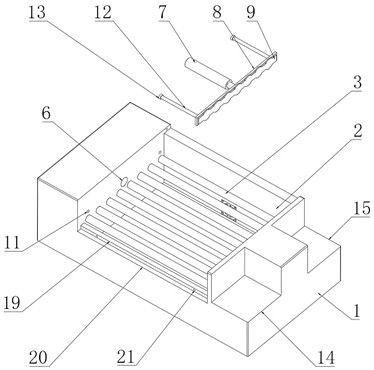

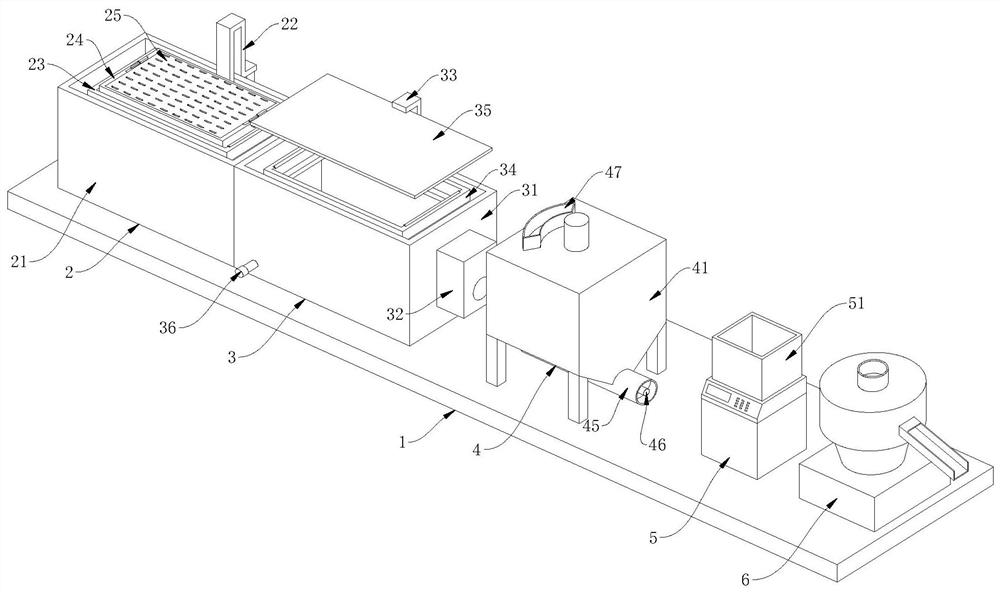

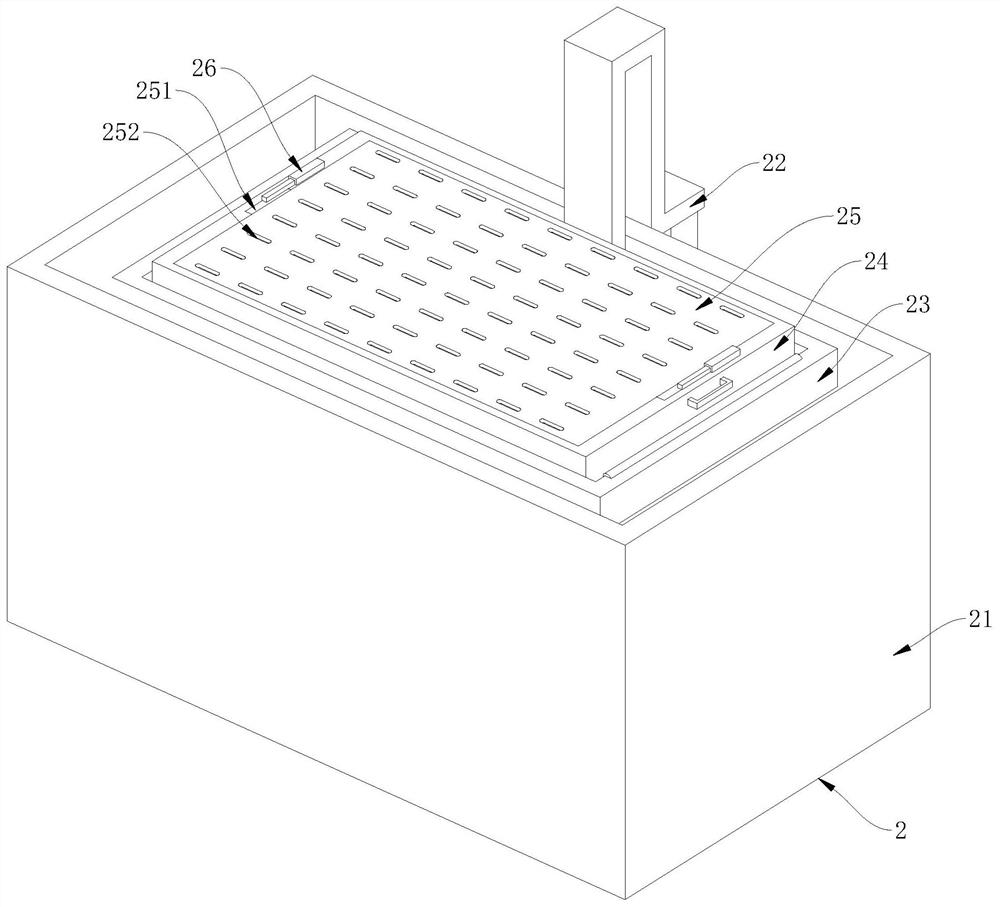

Production device and production process applied to straw combustion particles

InactiveCN112725051AGuaranteed soil removal efficiencyPromote aggregationBiofuelsSolid fuelsElectric machineryWater flow

The invention discloses a production device and a production process applied to straw combustion particles, belonging to the technical field of processing of biomass fuel. The production device comprises a mounting base plate, a soil removing mechanism, a drying mechanism, a crushing mechanism, a weighing platform and a granulator, wherein the soil removing mechanism used for cleaning and removing soil from straw, the drying mechanism used for drying the straw, the smashing mechanism used for smashing the straw, the weighing platform used for weighing and proportioning the straw and the granulator used for granulating the straw are sequentially arranged at the top of the mounting base plate from left to right; the soil removing mechanism comprises a cleaning box fixedly arranged at the top of the mounting base plate; and a spoiler rod is movably arranged in the cleaning box. By arranging the soil removing mechanism, the straw to be cleaned is added into a storage box, the straw is immersed into water for cleaning through an electric push rod, a driving motor is started to drive the spoiler rod to stir water flow, and the electric push rod is started to drive a first support to move up and down to assist in cleaning, so soil removing efficiency is guaranteed.

Owner:湖北烽华新能源科技有限公司

Dyeing fabric leaching type water circulation device

InactiveCN111020923AWash thoroughlyWon't fadeWater contaminantsTreatment involving filtrationElectric machineProcess engineering

The invention discloses a dyeing fabric leaching type water circulation device. The dyeing fabric leaching type water circulation device comprises a device main body and a base, wherein the base is riveted at the lower end of the device main body; a sliding door is movably arranged on the outer side surface of the device main body; a rotating motor is erected at the bottom of the device main body;the upper end of the rotating motor is rotationally connected with a rotating rod through a coupler; the rotating rod extends into a conical turntable to be fixed; a plurality of groups of cloth arestacked at the upper end of the conical turntable; and the adjacent cloth are fixed by a magnet. According to the dyeing fabric leaching type water circulation device provided by the invention, uniform leaching of a leaching disc is matched with the principle of centrifugal movement, water drops, dye particles and cloth threads can be effectively thrown to the side wall; on one hand, the purpose of thoroughly cleaning is achieved, and fading is avoided, and on the other hand, it is ensured that the taken-out cloth is dried, a large amount of water is avoided, the subsequent drying difficulty is reduced, the device is suitable for different working conditions, and a better application prospect is brought.

Owner:安徽京威纺织服饰有限公司

Grass grading conveying device

ActiveCN111011011BProportionally largeConvenient drying workGrass dryingDrying gas arrangementsAnimal scienceHelical blade

The present invention relates to the technical field of animal husbandry, in particular to a pasture grading conveying device, which includes an auger, and the auger includes a cylinder body, a rotating shaft arranged in the cylinder body, and a helical blade arranged on the rotating shaft. Both ends of the cylinder are also provided with sealing plates, and the sealing plates are provided with bearings for supporting the rotating shaft. A feed hopper is provided on the upper side of the side wall at one end of the cylinder, and the lower side wall of the other end is A discharge port is provided on the side, and a strip-shaped notch along the direction of the generatrix of the cylinder is provided on the lower side of the cylinder. The width of the strip-shaped notch is 1 / 4 to 3 / 4. In this application, the diameter of the forage stalk is the diameter of the middle part of the forage stalk at the mature stage. The grading conveying device of the present application realizes the separation of the stem segment and the leaf, and when the stem segment passes through the gap, the stem breaks, so it also greatly facilitates the subsequent work of drying the stem segment.

Owner:黑龙江省农业科学院畜牧兽医分院

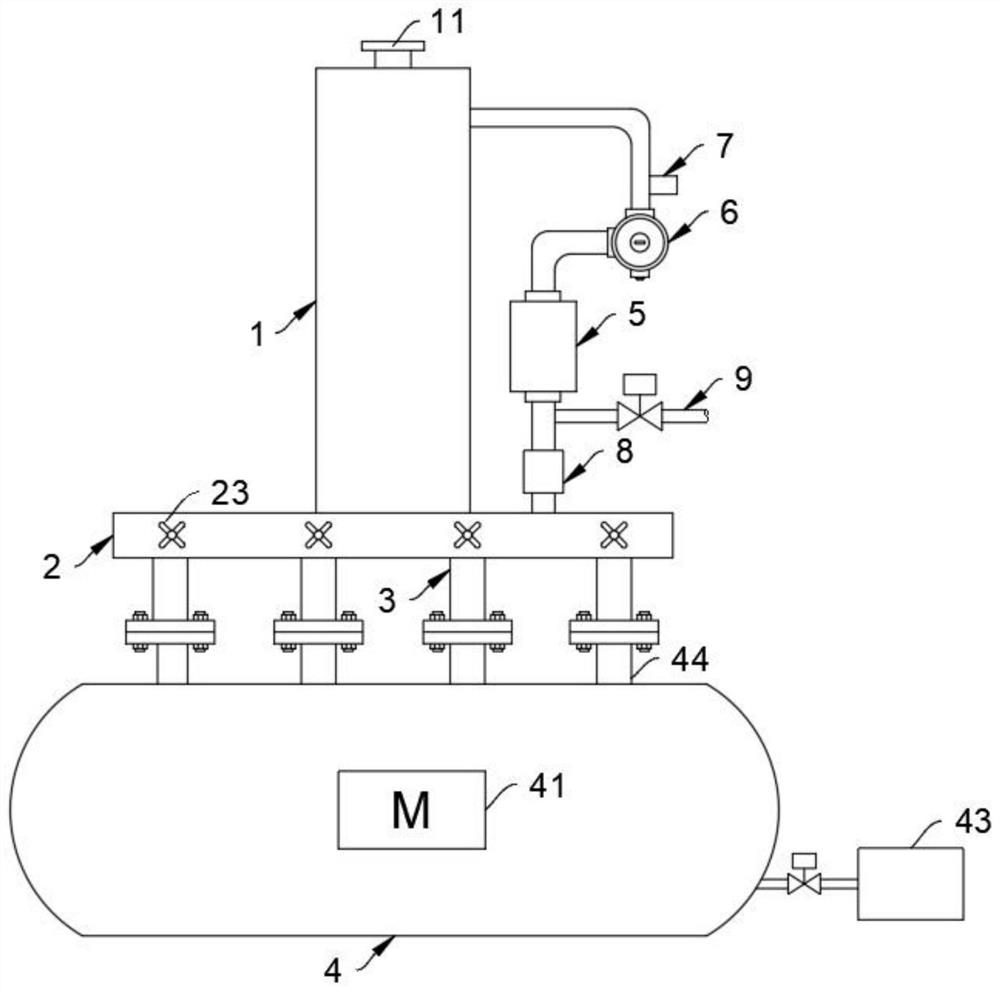

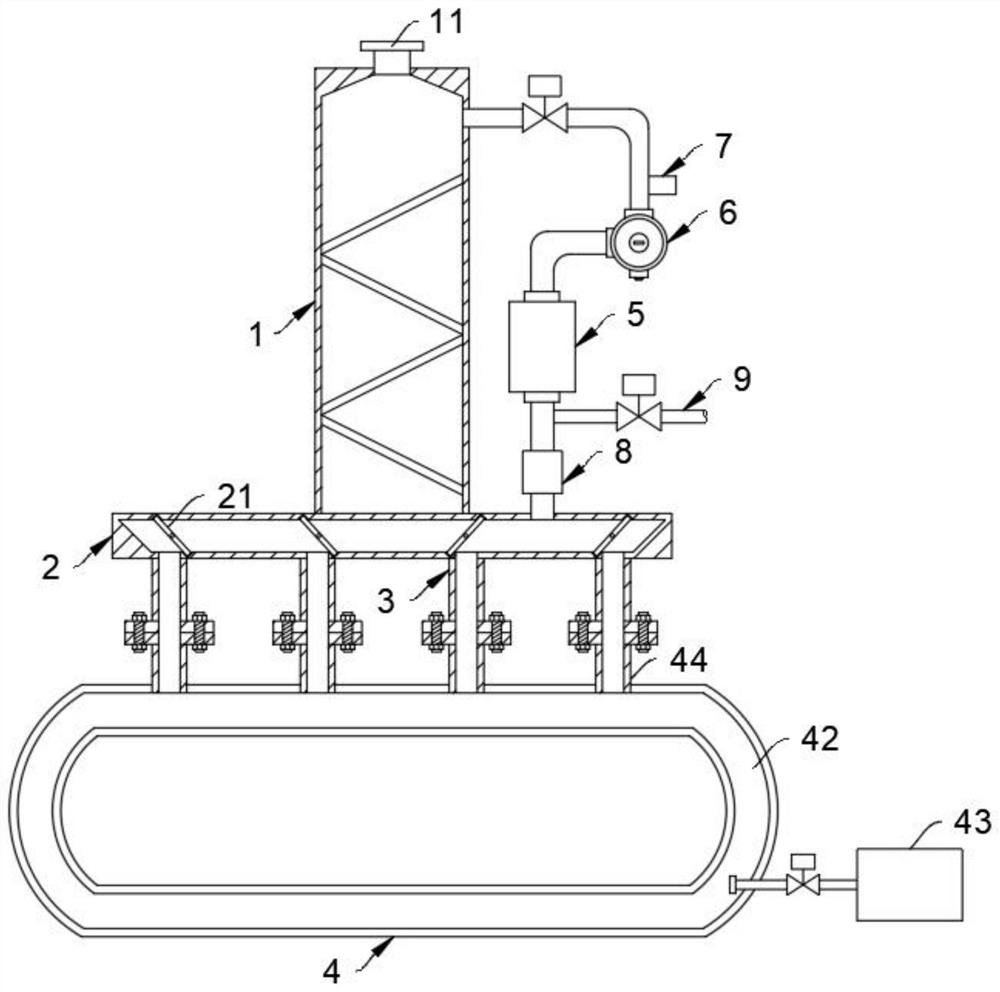

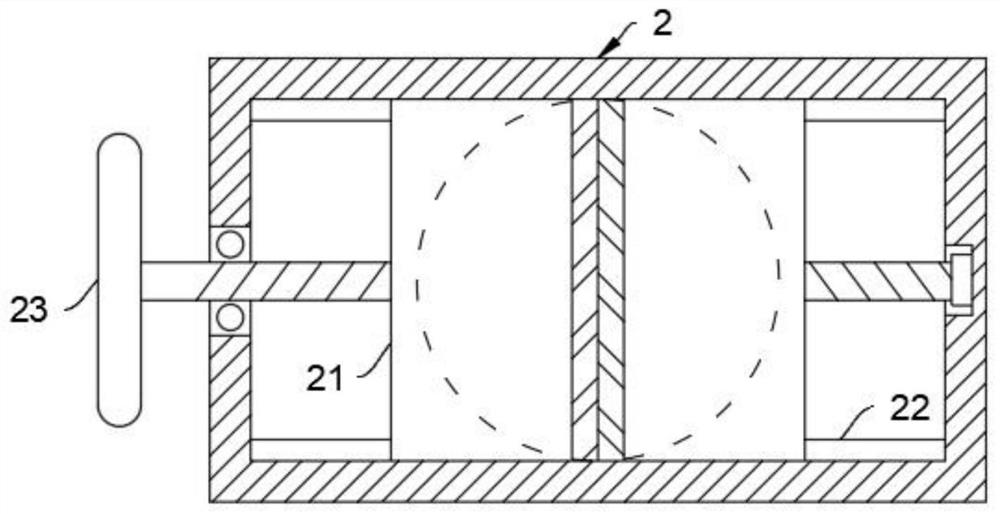

Pearlite drying and filling system

InactiveCN111947445AReduce moisture contentGuaranteed drynessDrying gas arrangementsDrying solid materialsNitrogen gasMechanical engineering

The invention belongs to the field of pearlite filling, and particularly relates to a pearlite drying and filling system. The pearlite drying and filling system comprises a pearlite filling tank, thepearlite filling tank is provided with a base, the base is provided with a low-temperature storage tank in a communicating manner through flow dividing pipes, and the base is fixedly connected with adraught fan. One end of the draught fan communicates with the top of the pearlite filling tank through a filtering mechanism, a dehydrator is arranged between the filtering mechanism and the pearlitefilling tank, the other end of the draught fan communicates with the base through a heating pipe, and a nitrogen input pipe is arranged between the draught fan and the heating pipe in a communicatingmanner. By arranging the filling system for cyclic drying, cyclic drying work is conducted on the low-temperature storage tank and the pearlite filling tank before the vacuumizing procedure of the device is conducted, the drying effect of a vacuum interlayer of the pearlite low-temperature storage tank is guaranteed, meanwhile, the water content of pearlite is effectively reduced, the vacuumizingefficiency of the device is improved, and the service life of the device is prolonged.

Owner:重庆恒中能源装备股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com