Method for preparing taltirelin tetrahydrate alpha crystal form crystal by using beater

A technology of tatirelin and tetrahydrate, which is applied in a new field of preparation, can solve the problems of troublesome storage, difficult process drying, low yield, etc., and achieves the advantages of reduced control difficulty, good process stability and strong operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

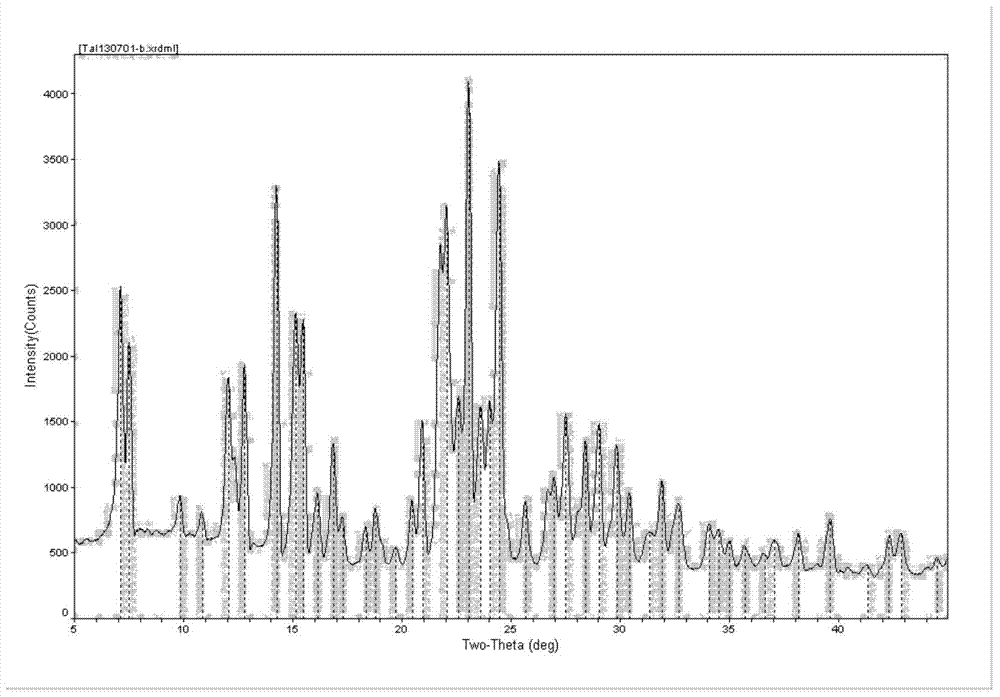

[0050] Add 5.0 g of tatirelin amorphous powder and 25.0 ml of tetrahydrofuran into the reaction flask, control the temperature at 25±2°C, and stir and beat for 6 hours at a speed of 320 / min with a beater. Then cool down to 3±2°C and keep stirring at 3±2°C for 9h. Filter and dry under reduced pressure at 30°C. 4.4 g of white solid was obtained, the yield was 88.0%, the melting point was 67-69°C, and the moisture content was 15.2%. Through X-ray powder diffraction detection, it is obvious that the generated crystals are in α crystal form. See attached figure 1 .

Embodiment 2

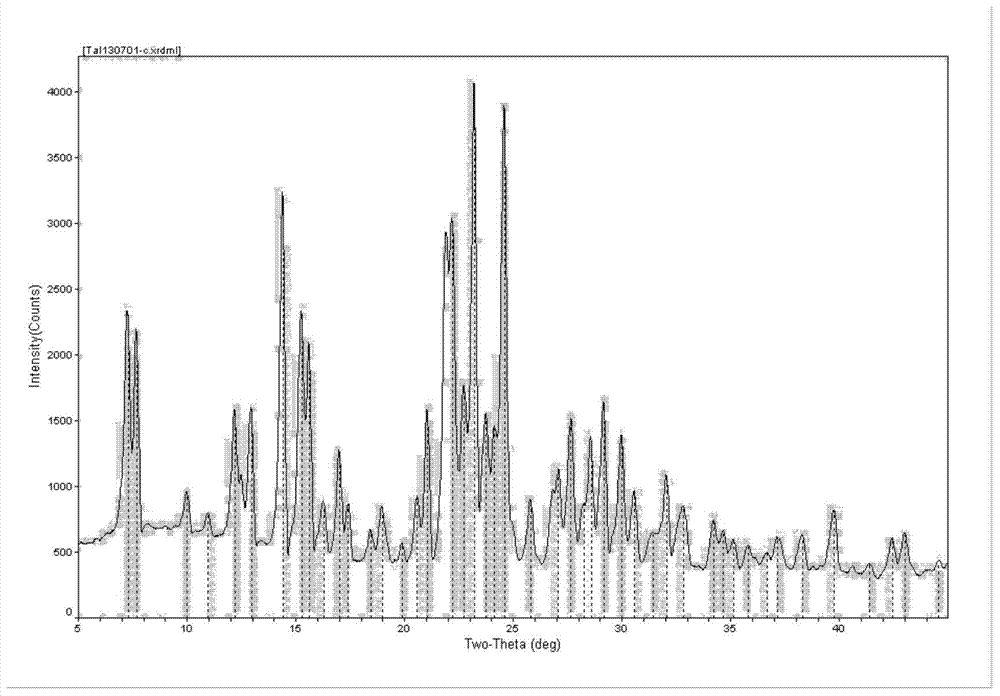

[0052] Add 4.0 g of tatirelin amorphous powder and 28.0 ml of ethyl acetate into the reaction flask, control the temperature at 40±2°C, and stir and beat for 10 hours at a speed of 400 / min with a beater. Then cool down to 5±2°C and keep stirring at 5±2°C for 8h. Filter and dry under reduced pressure at 35°C. 3.7 g of white solid was obtained, the yield was 92.5%, the melting point was 68-70°C, and the moisture content was 14.8%. Through X-ray powder diffraction, differential scanning calorimetry and thermogravimetric analysis, it is obvious that the generated crystals are in the α crystal form, see attached figure 2 And attached image 3 .

Embodiment 3

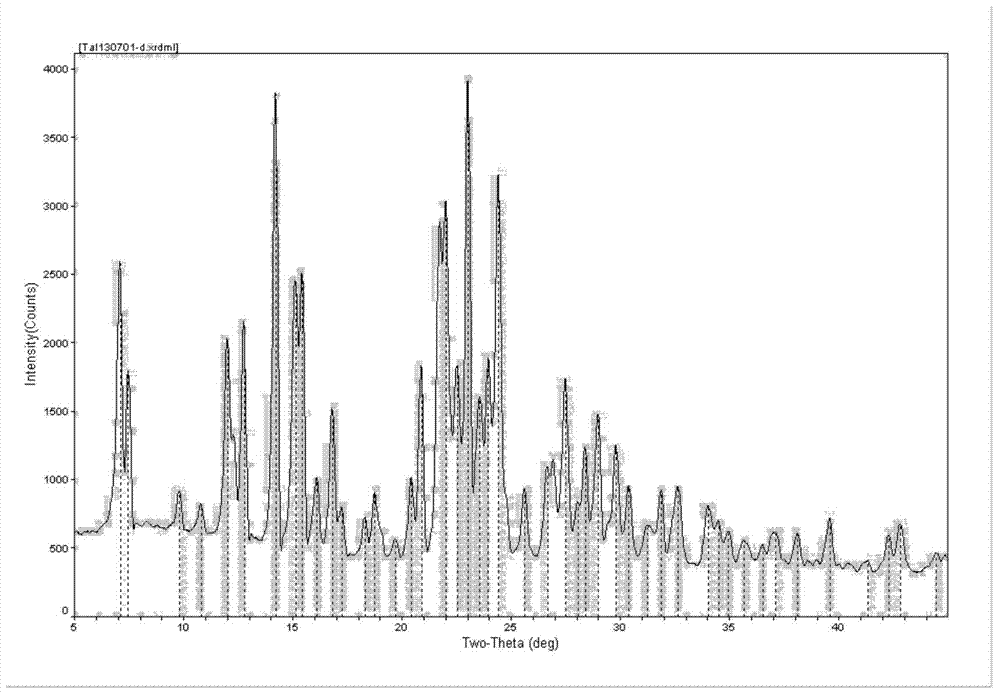

[0054] Add 4.0 g of tatirelin amorphous powder and 44.0 ml of ethyl acetate into the reaction flask, control the temperature at 40±2°C, and stir and beat for 10 hours at a speed of 480 / min with a beater. Then lower the temperature to 5±2°C, keep the temperature at 5±2°C and stir for 8h. Filter and dry under reduced pressure at 35°C. 3.6 g of white solid was obtained, the yield was 90.0%, the melting point was 69-70°C, and the moisture content was 14.6%. Through X-ray powder diffraction detection, it is obvious that the generated crystals are in α crystal form. See attached Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com