A film box cleaning device and method

A technology for cleaning devices and cassettes, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problems of low economic benefits and large floor space, and achieve high economic benefits, space saving, and drying the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the objects, technical solutions, and advantages of the present invention more clear, the technical solutions of the embodiments of the present invention will be described in contemplation in conjunction with the drawings of the embodiments of the present invention. Obviously, the described embodiments are embodiments of the invention, not all of the embodiments. Based on the embodiments of the invention, all other embodiments obtained by those of ordinary skill in the art are all in the scope of the present invention.

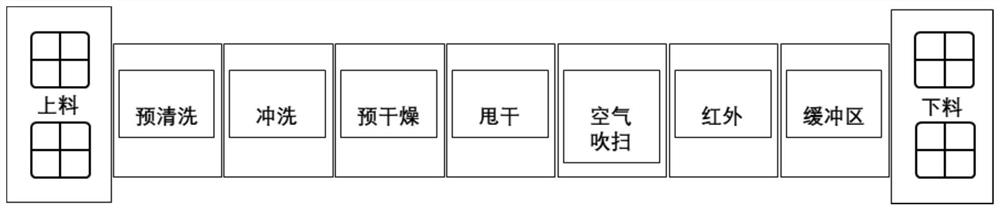

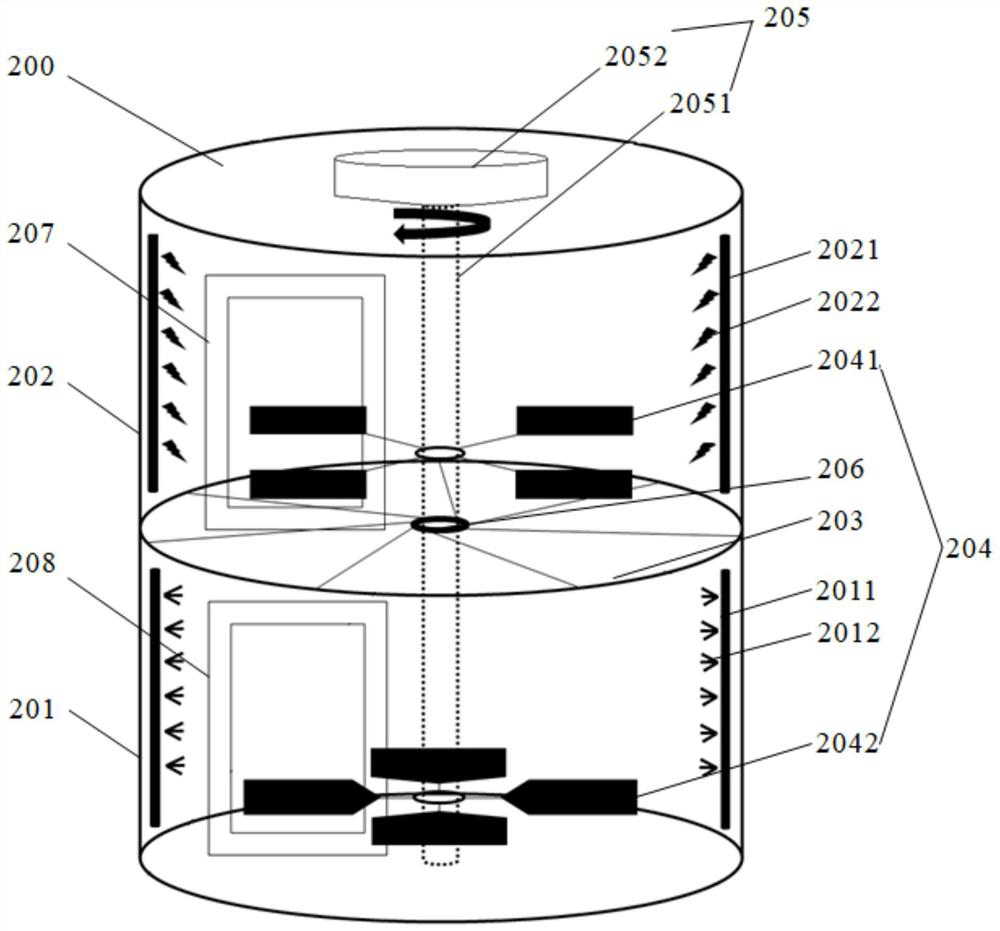

[0039] Cleaning of wafer boxes is an important part of the semiconductor process. At present, commonly used cartridge cleaning machines are mainly orbit cleaning machines and box cleaning machines, please refer to figure 1 , figure 1 For the structural diagram of the cleaning machine in the prior art, the track-type cleaning machine is large, the structure is complex, the cost and post-maintenance costs are high. In addition, due to the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com