Drying process of gelcasting large-sized and complex-shaped silicon carbide ceramic biscuit

A technology of gel injection molding and shape silicon carbide, which is applied in the field of ceramic drying, can solve the problems of easy cracking and deformation of the green body, and achieve the effect of reducing the difficulty of drying, and being easy to transport and store.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] SiC micropowder was provided by Shandong Weifang Huamei Fine Technology Co., Ltd., with a purity of 99.7%. The various chemical reagents used to prepare SiC wet body and configure dry liquid by gel injection molding process were provided by Beijing Chemical Reagent Co., Ltd. The actual purity was Analytical pure.

[0041] Mix absolute ethanol and deionized water, the concentration (volume ratio) is 10%, 20%, 30%, 40%, 60%, 80% and 100%, respectively, the formula is shown in Table 2, and then add the volume ratio 4% glycerol (glycerin) as a plasticizer to obtain dry solutions with different concentrations;

[0042] Table 2

[0043]

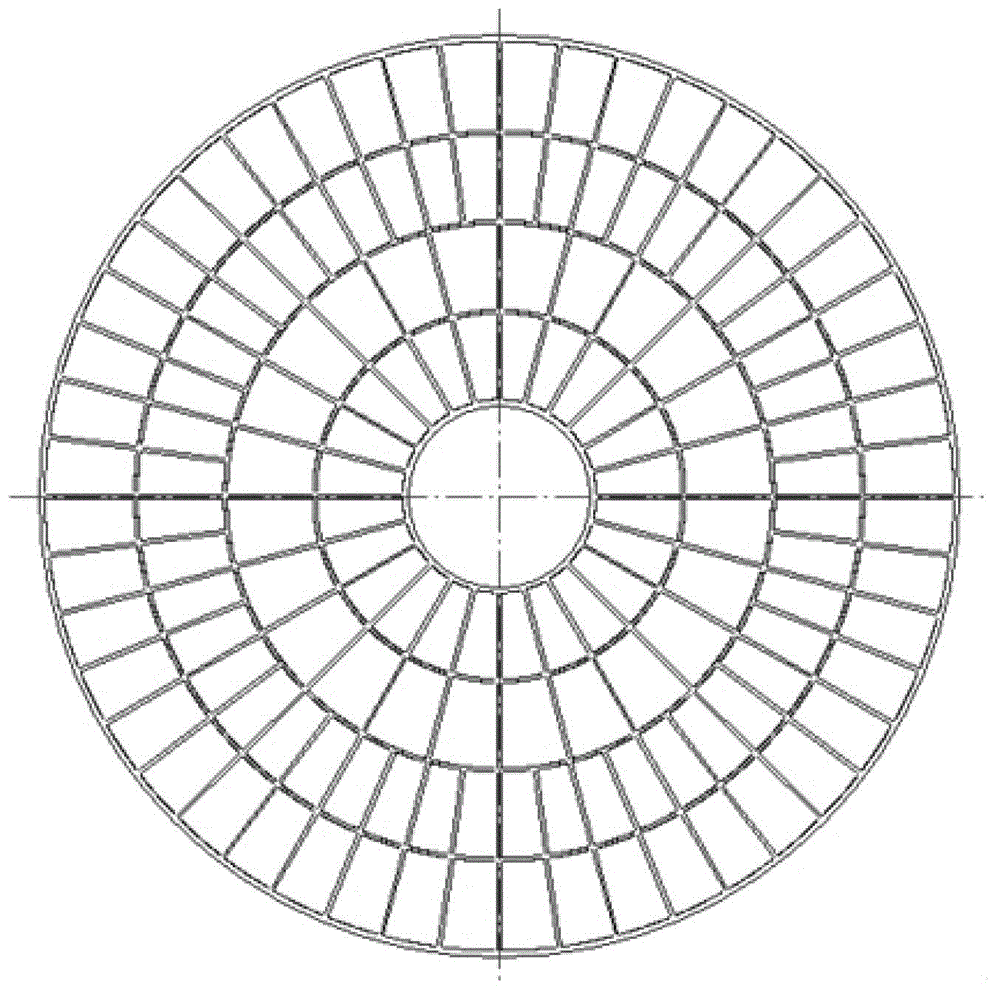

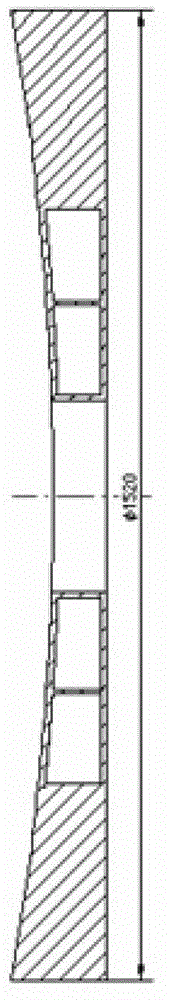

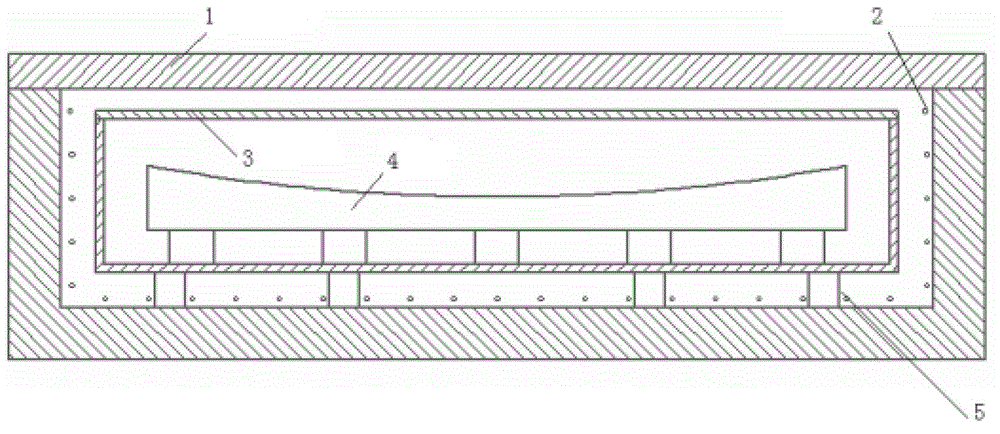

[0044] The Φ1.52m lightweight SiC wet billet was prepared by gel injection molding process, such as figure 1 and figure 2 As shown, put the wet billet into the drying tank, the bottom surface is supported by a porous aluminum plate, and the aluminum plate and the billet are separated by a long-pile carpet. It can greatly reduce the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com