Pearlite drying and filling system

A pearlescent sand and shell technology, which is used in drying, drying machine, drying solid materials and other directions, can solve the problems of difficult thermal insulation performance of vacuum powder insulation layer, failure to meet equipment use requirements, and reduction of equipment service life, etc. The effect of reducing drying difficulty, reducing drying cost and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

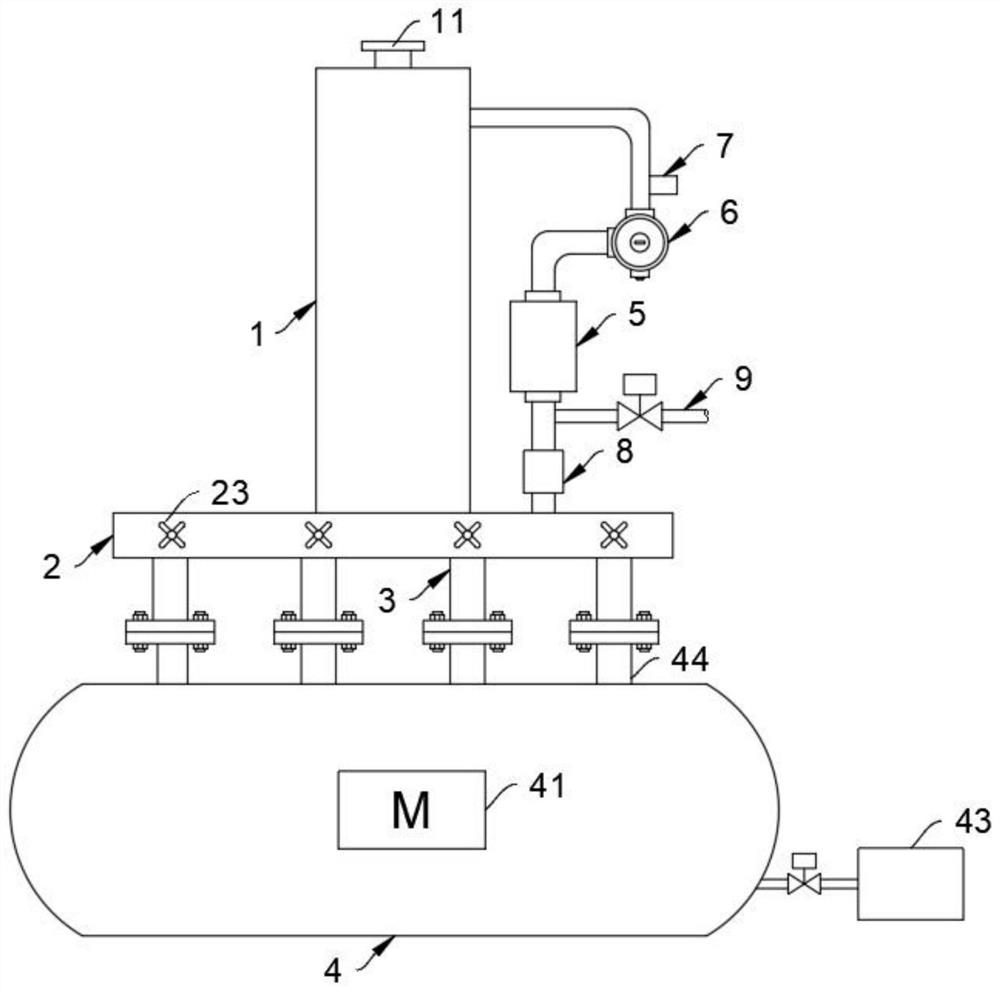

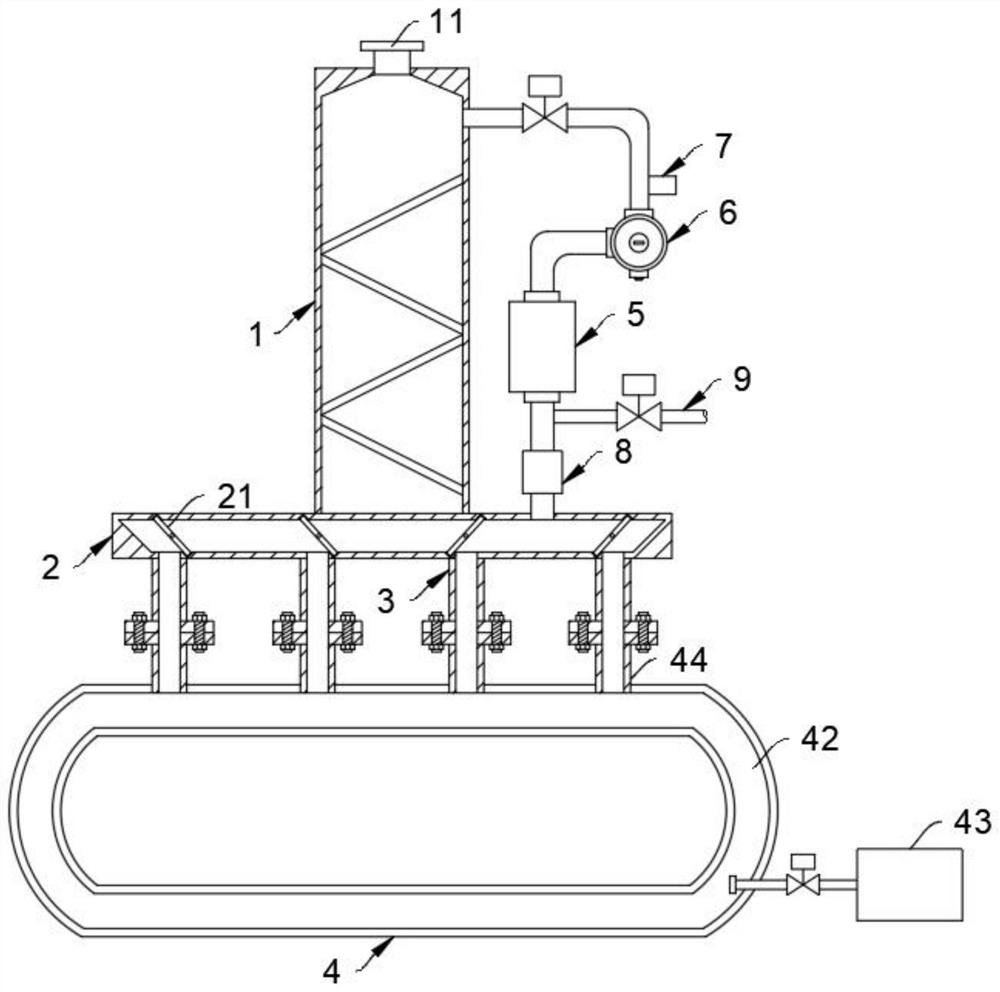

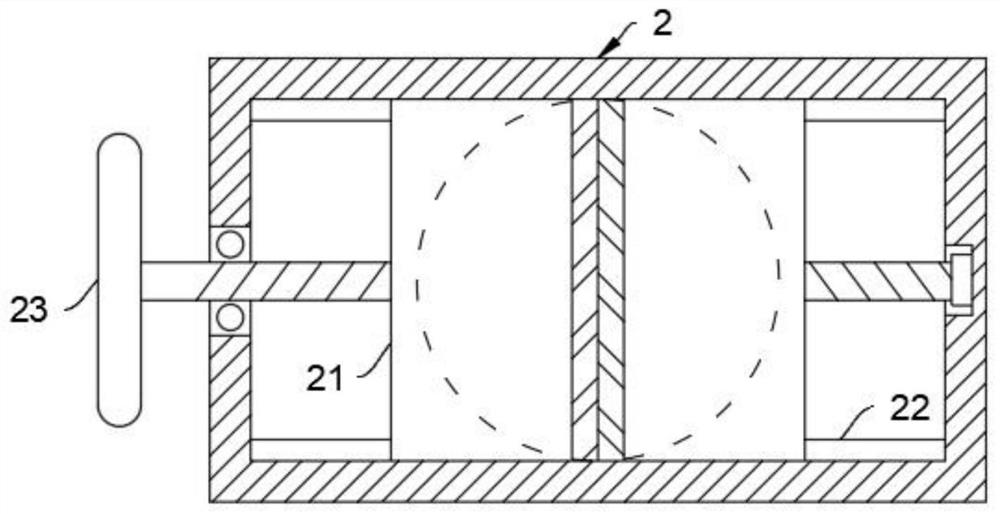

[0028] like Figure 1-6 As shown, a pearlite sand drying and filling system includes a pearlite sand filling tank 1. The pearlite sand filling tank 1 is provided with a base 2, and the base 2 is connected to a low-temperature storage tank 4 through a shunt pipe 3. It should be noted that the pearlite sand The filling tank 1 is used for storing the pearlite to be evacuated, and the cryogenic storage tank 4 is arranged at the bottom of the pearlite filling tank 1 to facilitate the vacuuming of the device.

[0029] The low-temperature storage tank 4 is fixedly connected with a vibration motor 41, and the low-temperature storage tank 4 is provided with a vacuum interlayer 42, and the vacuum interlayer 42 is connected with a vacuum pump 43. The vibration improves the compaction effect of the pearlite, and the vacuum pump 43 is used for vacuuming the cryogeni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com