Forage grass grading and conveying device

A conveying device and forage technology, applied in the field of animal husbandry, can solve problems such as uneven drying, inability to feed young animals and adult livestock separately, and indigestion of young animals, so as to avoid the risk of mildew and reduce the difficulty of drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

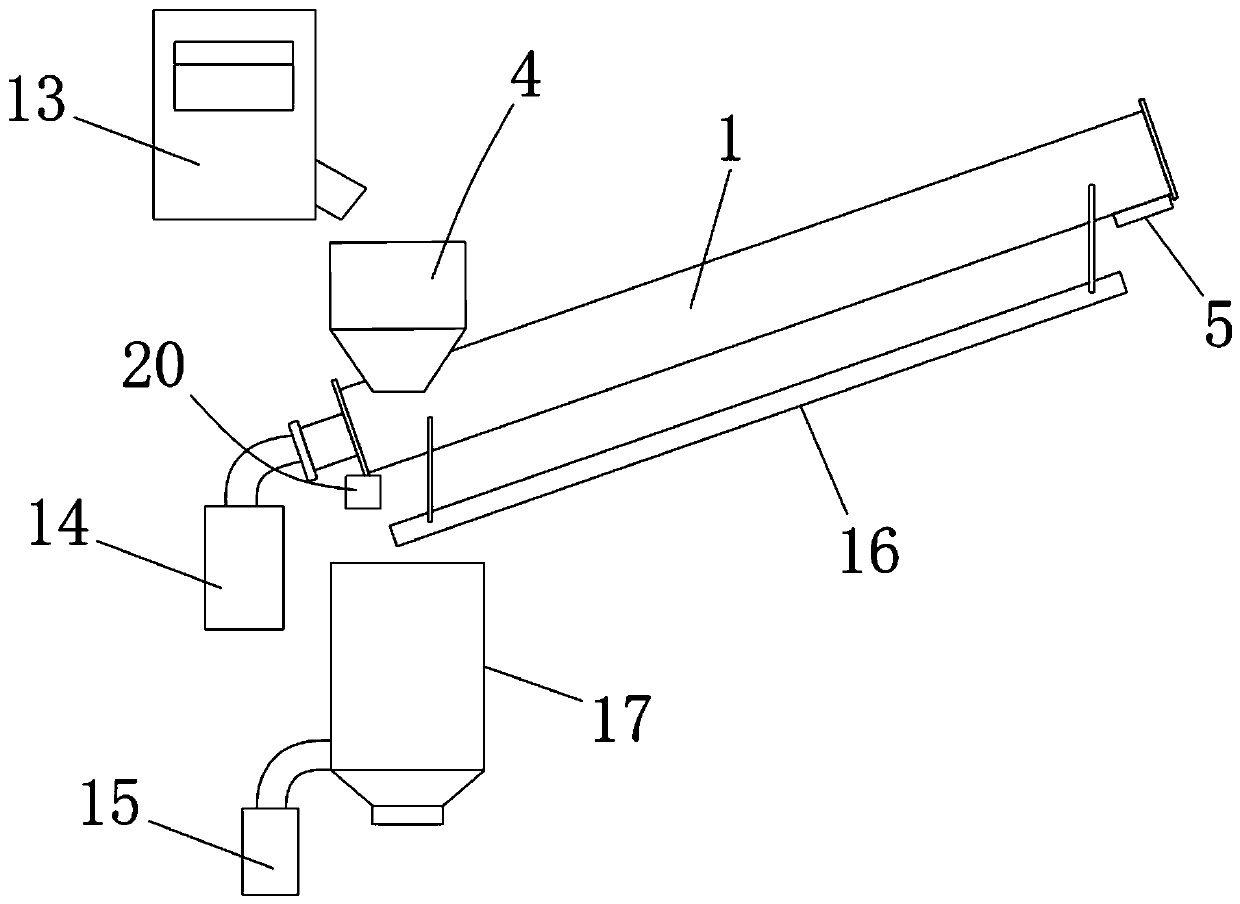

[0060] Example 1, such as Figure 1-6 Shown:

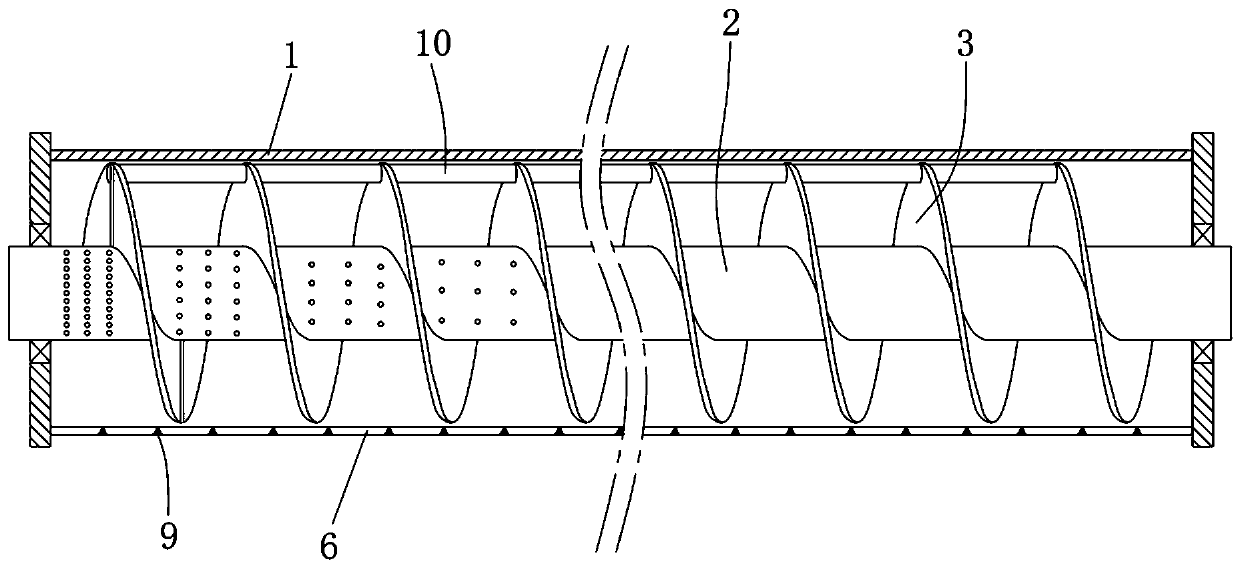

[0061] A pasture grading and conveying device includes an auger, and the auger includes a cylinder body 1, a rotating shaft 2 arranged in the cylinder body 1 and a helical blade 3 arranged on the rotating shaft 2, in the cylinder body 1 Both ends are also provided with a sealing plate, the sealing plate is provided with a bearing for supporting the rotating shaft 2, a feed hopper 4 is provided on the side wall of one end of the cylinder 1, and a hopper is provided under the side wall of the other end. A discharge port 5 is provided on the side, and a strip-shaped notch 6 along the direction of the generatrix of the cylinder 1 is provided on the lower side of the cylinder body 1. The width of the strip-shaped notch 6 is 1 / 2 of the diameter of the grass stalk to be transported. 1 / 4~3 / 4. In this application, the diameter of the forage stalk is the diameter of the middle part of the forage stalk at the mature stage. In the solution...

Embodiment 2

[0076] Example 2, as Figure 1-6 shown:

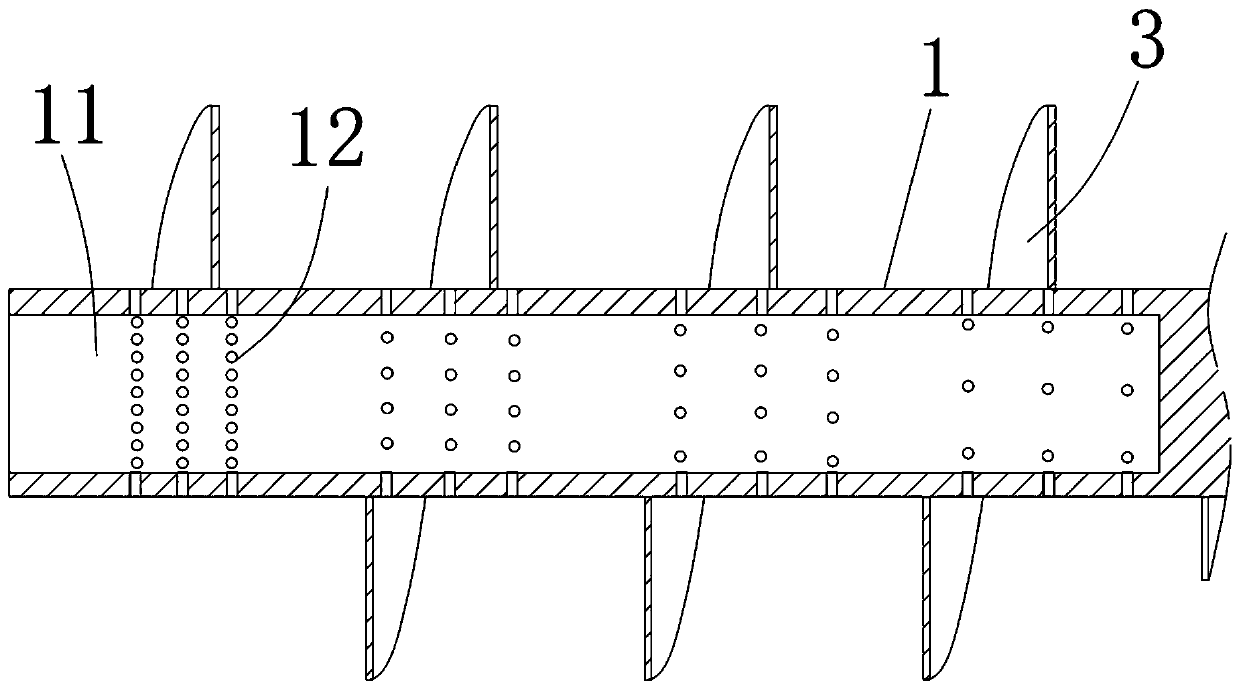

[0077] A grading conveying device for grass conveying, on the basis of the above embodiment, further, the lower end of the rotating shaft 2 passes through the sealing plate, and the end is provided with a blowing hole 11, so the The blowing hole 11 extends along the central axis of the rotating shaft 2 , and the length of the blowing hole 11 is 1 / 4 to 3 / 4 of the length of the rotating shaft 2 . The rotating shaft 2 is located in the cylinder 1 . There are also a number of exhaust holes 12 on the part of the exhaust hole 12, the exhaust holes 12 are arranged along the radial direction of the rotating shaft 2, one end of the exhaust hole 12 is communicated with the blowing hole 11, and the other end is connected with the cylinder The internal space of the body 1 is communicated, and the diameter of the exhaust hole 12 is 2-5mm. In the solution of the present application, hot air is blown into the blast hole 11 through the hot air devic...

Embodiment 3

[0080] Example 3, as Figure 1-7 shown,

[0081] A grass grading and drying system, comprising the grading conveying device described in Embodiment 2, further comprising a grass cutting device 13 and a first hot air device 14, the discharge opening of the grass cutting device 13 is located in the feeding hopper 4 Above, the first hot air device 14 is used for blowing hot air toward the blast hole 11 on the rotating shaft 2 , and a length of the cylindrical notch 6 is also provided below the elongated notch 6 . 6. The matching feeding chute 16, the feeding chute 16 is arranged obliquely, and a drying device is also provided under the lower end of the feeding chute 16, and the drying device is used for drying the feeding chute. 16 Discharged material. In the forage classification and drying system of the present embodiment, the forage cutting device 13 is a conventional device at present, which will not be repeated here. Since the classification and conveying device of the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com