A high-strength porcelain formula for making suspension porcelain insulators

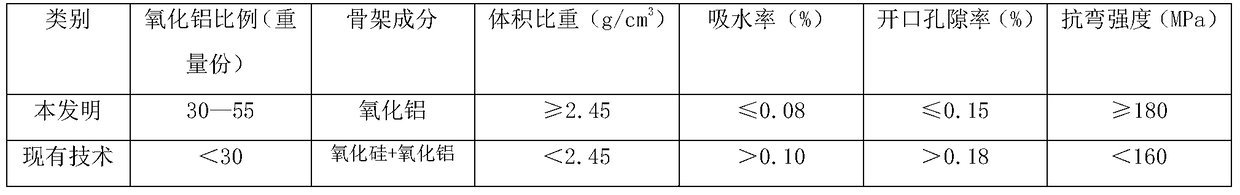

A porcelain insulator, high-strength technology, applied in the field of electric porcelain, can solve the problems of large dispersion of porcelain insulators, threatening the safe operation of the power grid, and low porcelain strength, and achieves improving the flexural strength of porcelain, reducing electromechanical damage. Load dispersion, The effect of improving the properties of porcelain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The high-strength porcelain formulation used to manufacture suspension porcelain insulators consists of the following components by weight:

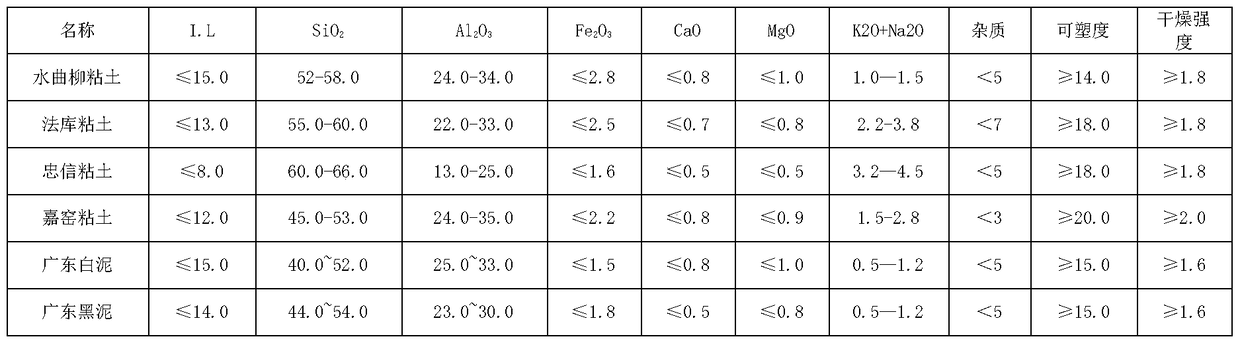

[0023] Clay 49, Bauxite 33, Potassium feldspar 18; The clay is composed of the following components by weight: Fraxinus ash clay 11 produced in Shulan County, Jilin City, Faku Clay 10 produced in Faku County, Shenyang City, Chengde City Zhongxin clay 5 produced in Kuancheng County, Jiayao clay 11 produced in Xinhui District, Jiangmen City, Guangdong white clay produced in Qingyuan City 6, and Guangdong black clay produced in Huizhou City 6; 0.2% of the total mass of the formula added lignin additives plasticizer.

Embodiment 2

[0025] The high-strength porcelain formulation used to manufacture suspension porcelain insulators consists of the following components by weight:

[0026] Clay 51, bauxite 32, potassium feldspar 17; the clay is composed of the following components by weight: Fraxinus ash clay 11 produced in Shulan County, Jilin City, Faku clay produced in Faku County, Shenyang City 4, Chengde City Kuancheng County produces Zhongxin Clay 6, Jiangmen City Xinhui District produces Jiayao Clay 15, Qingyuan City produces Guangdong White Clay 8, and Huizhou City produces Guangdong Black Clay 7; add 0.2% of the total weight of the formula to add lignin plasticizer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com