High-content high-universality talcum powder master filler and production equipment and method thereof

A technology of filling masterbatch and talc powder, applied in coating and other directions, can solve the problems of unsightly appearance of the whole particle, difficult recovery of diluent, secondary dust pollution, etc., to solve the problem of high temperature operating environment, small investment site, and energy saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

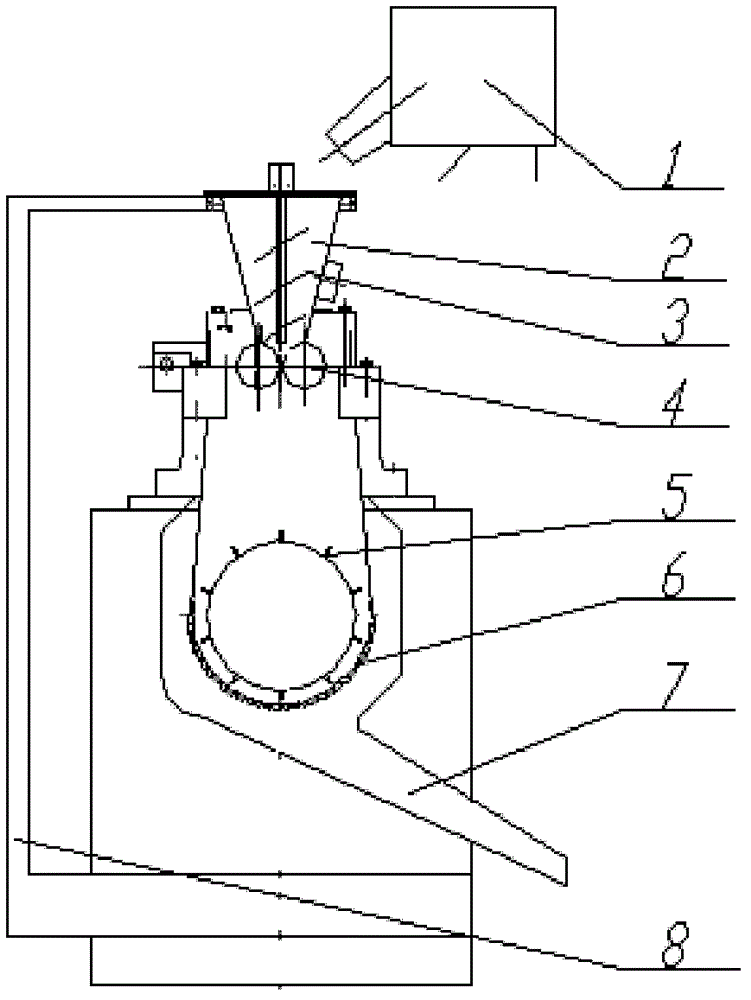

[0038]An equipment for producing talcum powder-filled master batches with high content and wide versatility, including a forced feeder, a pair of extrusion rollers 4, a granulation roller 5, a curved screen 6, a finished product outlet 7, and a powder recovery device 8.

[0039] The forced feeding machine includes a forced feeding bin 2 and a forced feeding screw 3. The forced feeding bin 2 is conical in shape with a wide top and a narrow bottom. The forced feeding screw 3 is located at the central axis in the forced feeding bin 2.

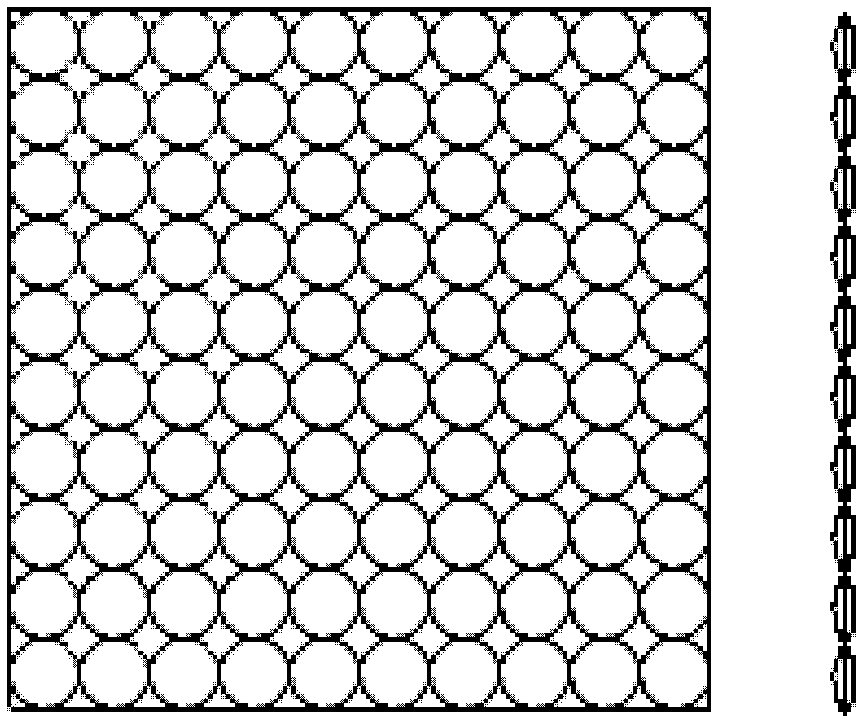

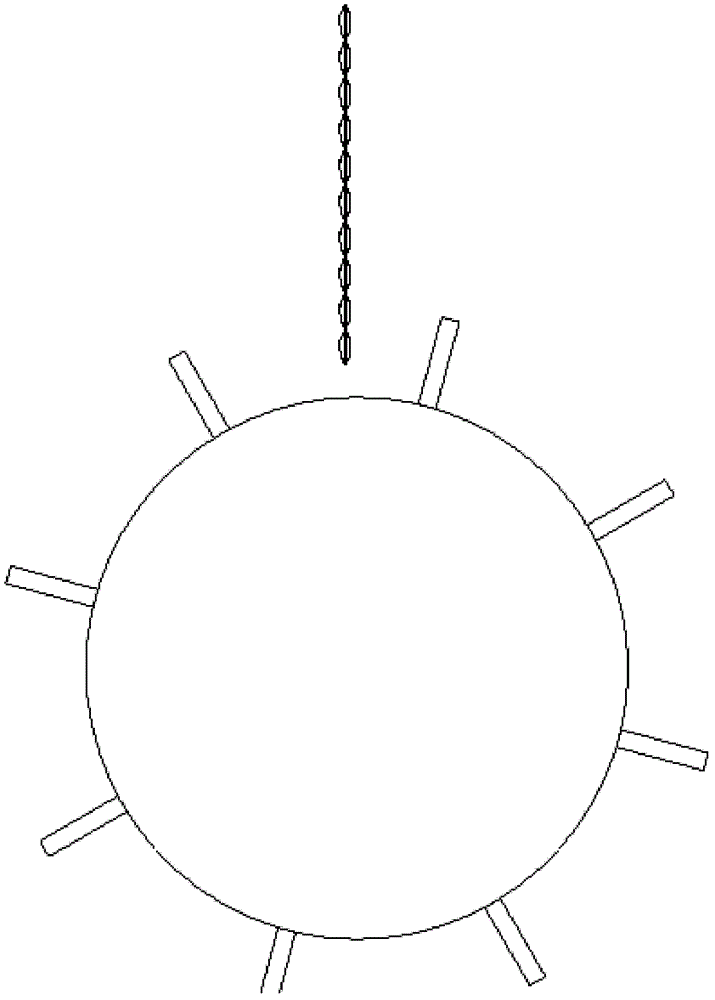

[0040] The upper opening of the forced feeding bin 2 is facing the discharge port of the mixer 1, and the materials coming out of the mixer 1 are sent to the forced feeding machine. The lower opening of the forced feeding bin 2 is facing against the pair of extrusion rollers 4. The extruding pair of rollers 4 is cylindrical, the gap can be adjusted, and its outer diameter is 100-500mm; the surface of the extruding pair of rollers 4 is evenly distr...

Embodiment 2

[0045] A kind of method based on the production high content of embodiment 1 equipment, the talcum powder filling masterbatch of wide versatility, comprises the following steps:

[0046] (1) Dissolve 3 parts of sodium silicate in 5 parts of pure water preheated to 60°C to form a sodium silicate solution; mix 90 parts of talcum powder, 1 part of zinc stearate, 1 part of calcium stearate, and sodium silicate The solution is put into the mixer successively, mixed at a low speed (100rpm) for 1min, and then mixed at a high speed (1000rpm) for 8min; the parts mentioned are parts by weight;

[0047] (2) Put the mixed material into the forced feeder, the material goes to the granulation roller for granulation after passing through the extrusion rollers, and the obtained particles flow to the finished product outlet after being sieved by the curved sieve; sieved by the curved sieve The powder is extruded and granulated again and again through the powder recovery device; then the high-c...

Embodiment 3

[0050] A kind of method based on the production high content of embodiment 1 equipment, the talcum powder filling masterbatch of wide versatility, comprises the following steps:

[0051] (1) Dissolve 1 part of sodium silicate in 3 parts of pure water preheated to 50°C to form a sodium silicate solution; put 95 parts of talc powder, 1 part of zinc stearate, and sodium silicate solution into the mixer in sequence, First mix at low speed (200rpm) for 0.5min, then mix at high speed (1200rpm) for 5min; the parts mentioned are parts by weight;

[0052] (2) Put the mixed material into the forced feeder, the material goes to the granulation roller for granulation after passing through the extrusion rollers, and the obtained particles flow to the finished product outlet after being sieved by the curved sieve; sieved by the curved sieve The powder is extruded and granulated again and again through the powder recovery device; then the high-content and versatile talc powder is collected a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com