Grinding equipment for leftover materials of carton production

A pulverizing device and scrap technology, applied in metal processing, grain processing, etc., can solve the problems of low pulverizing quality, low work efficiency, high pulverizing quality and difficulty in pulverizing, so as to reduce the difficulty of pulverization, improve the pulverization efficiency, and improve the pulverization quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

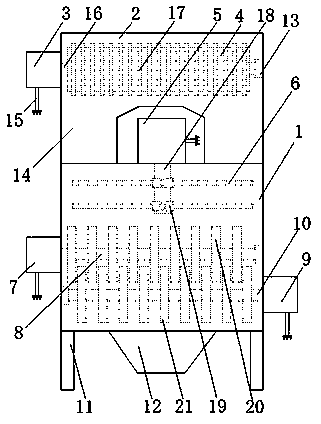

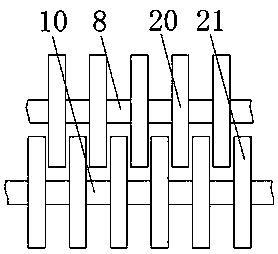

[0018] as attached Figure 1-3 As shown, a scrap grinding device for carton production, including a crushing chamber 1, a feeding bin 2, a motor 3, a rotating roller 4, a motor 2 5, a crushing rod 6, a motor 3 7, a rotating shaft 8, and a motor 4 9 and rotating shaft 2 10, characterized in that: the crushing chamber 1 is set on the support 11, a discharge bin 12 is arranged at the bottom of the crushing chamber 1, and a bearing 13 is arranged on the inner wall of the crushing chamber 1, and the inlet The feed bin 2 is set on the top of the crushing chamber 1, and the bottom of the feed bin 2 is provided with a drop pipe 14 on both sides, and a bearing 13 is arranged on the inner wall of the feed bin 2. The cutting wheel 17 can cut the carton leftovers into strips, cut The strips of carton scraps enter the crushing chamber 1 through the feed pipe 14 for crushing, which reduces the difficulty of crushing the carton scraps and improves the crushing efficiency of the carton scraps...

Embodiment 2

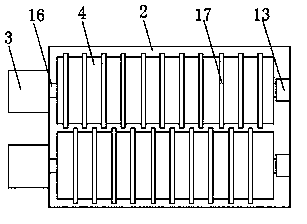

[0023] as attached Figure 4-5As shown, a scrap grinding device for carton production, including a crushing chamber 1, a feeding bin 2, a motor 3, a rotating roller 4, a motor 2 5, a crushing rod 6, a motor 3 7, a rotating shaft 8, and a motor 4 9 and rotating shaft 2 10, characterized in that: the crushing chamber 1 is set on the support 11, a discharge bin 12 is arranged at the bottom of the crushing chamber 1, and a bearing 13 is arranged on the inner wall of the crushing chamber 1, and the inlet The feed bin 2 is set on the top of the crushing chamber 1, and the bottom of the feed bin 2 is provided with a drop pipe 14 on both sides, and a bearing 13 is arranged on the inner wall of the feed bin 2. The cutting wheel 17 can cut the carton leftovers into strips, cut The strips of carton scraps enter the crushing chamber 1 through the feed pipe 14 for crushing, which reduces the difficulty of crushing the carton scraps and improves the crushing efficiency of the carton scraps....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com