Smashing device for leftover material of automotive spoiler and operation method thereof

A crushing device and spoiler technology, applied in the field of crushing devices, can solve the problems of low crushing efficiency, poor crushing effect, waste of materials, etc., and achieve the effects of improving quality and utilization efficiency, reducing waste, improving crushing efficiency and crushing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

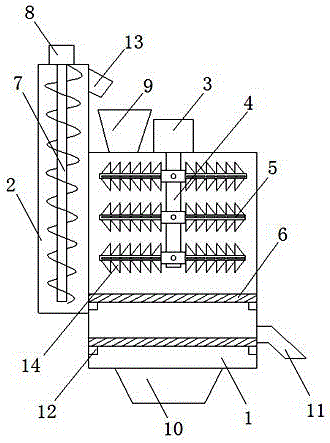

[0019] as attached figure 1 Shown: a crushing device for automobile spoiler leftovers, including a crushing box 1, a lifting cylinder 2, a motor 3, a rotating shaft 4, a stirring rod 5, a vibrating screen 6 and an auger 7, characterized in that, The crushing box 1 is provided with a feed inlet 9, a discharge port 10, and a discharge port 11, and a vibrating motor 12 is arranged on the inner wall of the crushing box 1, and one end of the lifting cylinder 2 is arranged on the crushing On the outer wall of the box 1, and at the other end of the lifting cylinder 2, a motor two 8 and a return pipe 13 are arranged, the motor one 3 is arranged on the crushing box 1, and the rotating shaft 4 is arranged in the crushing box 1 , and one end thereof is connected with a motor one 3, the stirring rod 4 is arranged on the rotating shaft 4, and a cutting knife 14 is arranged on the stirring rod 5, and the cutting knife 14 is arranged as a triangular structure, the described The vibrating sc...

Embodiment 2

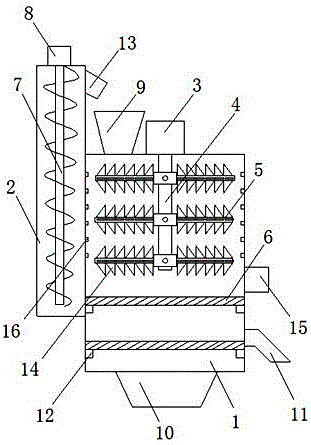

[0026] as attached figure 2 Shown: a crushing device for leftover scraps of automobile spoilers, including a crushing box 1, a lifting cylinder 2, a motor 3, a rotating shaft 4, a stirring rod 5, a vibrating screen 6, an auger 7, and a blower 15. It is characterized in that the crushing box 1 is provided with a feed inlet 9, a discharge port 10, and a discharge port 2 11, and a vibrating motor 12 and a blade 16 are arranged on the inner wall of the crushing box 1, and the blade 16 Set as a spiral structure, the crushing efficiency of the leftover scrap of the automobile spoiler can be improved by the blade 16, and the crushing quality of the scrap of the automobile spoiler can also be enhanced. One end of the lifting cylinder 2 is arranged on the outer wall of the crushing box 1, and The other end of the feeding cylinder 2 is provided with a motor two 8 and a return pipe 13. The motor one 3 is arranged on the crushing box 1, and the rotating shaft 4 is arranged in the crushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com