Production of nickel-powder by electromechanical modification self-formative process

A forming process and electrochemical technology, applied in electroforming, electrolysis process and other directions, can solve the problems of high production cost, backward process method, complicated process, etc., and achieve the effect of reducing production cost, shortening process flow, and being beneficial to environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

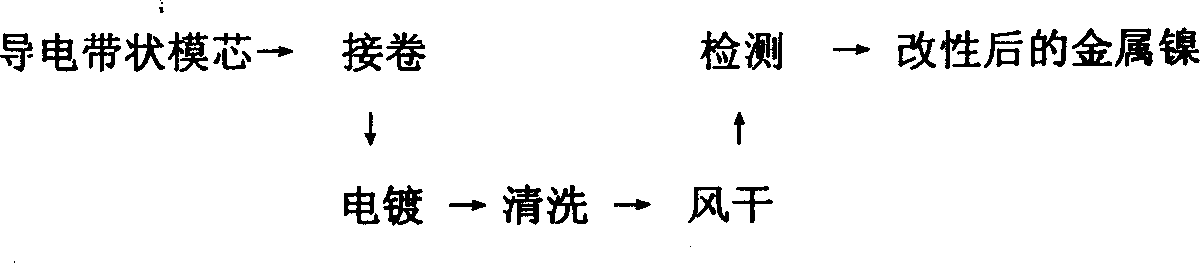

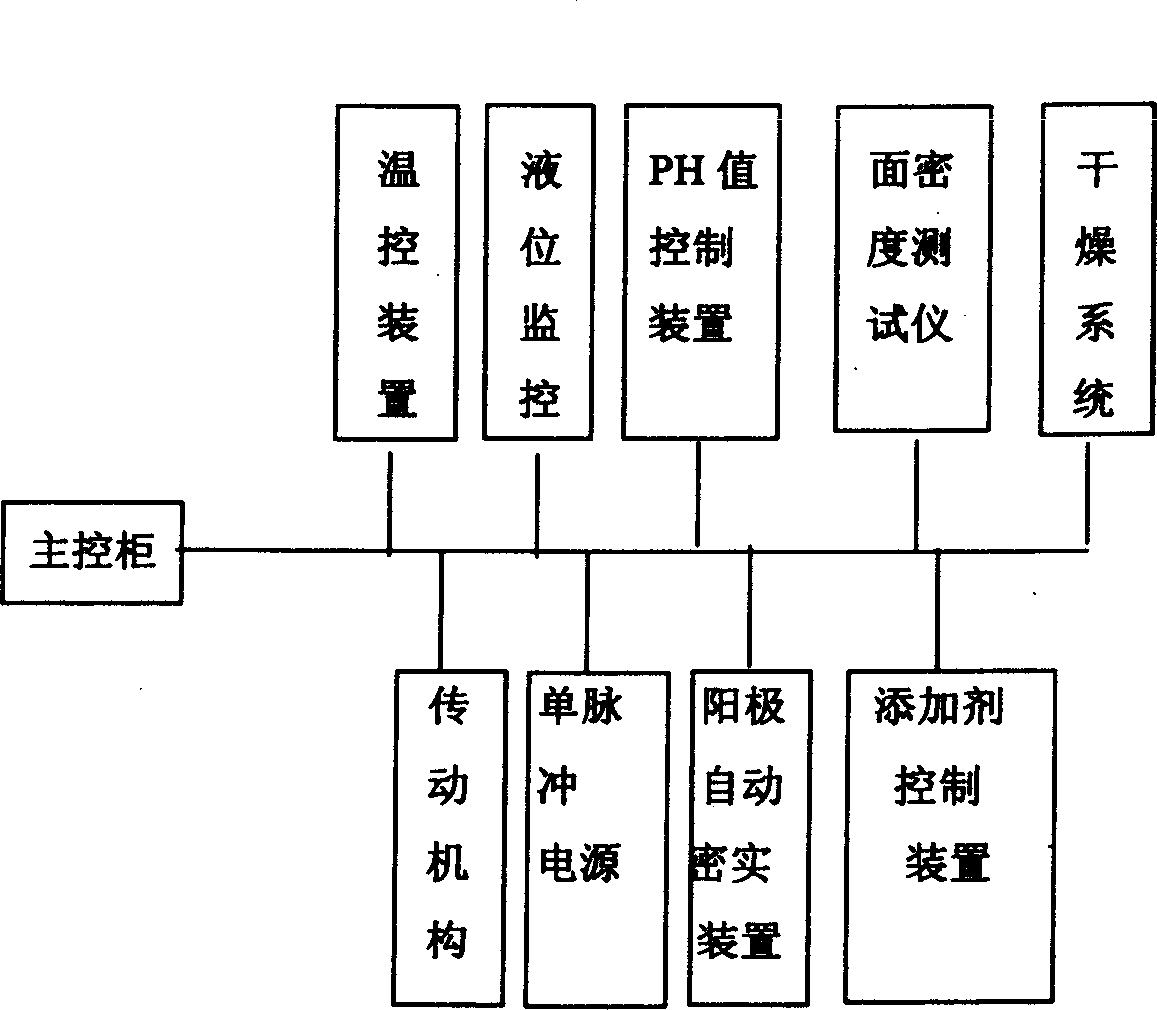

[0017] This embodiment comprises the steps:

[0018] 1) Conductivity of the mold core

[0019] The mold core can be polyurethane, polyester or polyether, and the material is polyester polyol or polyether polyol with two or more hydroxyl groups at the end and diisocyanate, water, surfactant, catalyst and other additives for polymerization The polymer compound formed later contains many repeated -NH-C-O-groups on the main chain, commonly known as polyurethane sponge; the mold core can also be a mesh material of chemical fibers such as nylon and polypropylene or cotton fiber textiles.

[0020] The conductive treatment process of the mold core is as follows:

[0021] The belt-shaped mold core is nickel-plated by magnetron vacuum sputtering on the mold core to form a conductive mold core. Coating power = 80-100 kilowatts, voltage = 400-600 volts, line speed = 0.5-10m / min, thickness of the object to be plated = 0.05-10mm.

[0022] 2) Electrochemical modification of nickel

[002...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com