Processing method for high-strength environment-friendly concrete

An environmentally friendly concrete and processing method technology, applied in chemical instruments and methods, manufacturing tools, clay preparation equipment, etc., can solve the problems of increasing the difficulty of grinding waste PPR powder, inconvenient grinding of waste PPR powder, and surface fracture of polymer concrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

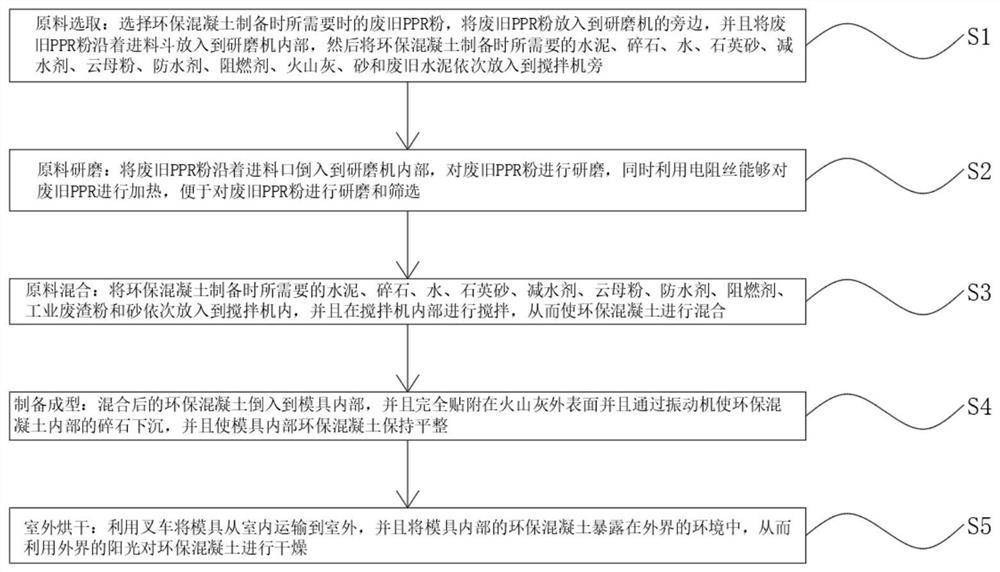

[0041] Such as figure 1 Shown, a kind of processing method of high-strength environmental protection concrete, processing comprises the following steps:

[0042] S1. Raw material selection: select the waste PPR powder required for the preparation of environmentally friendly concrete, put the waste PPR powder next to the grinder, and put the waste PPR powder into the grinder along the feeding hopper, and then put the waste PPR powder into the grinder, and then put the waste PPR powder into the grinder. Cement, gravel, water, quartz sand, water reducing agent, mica powder, waterproofing agent, flame retardant, volcanic ash, sand and waste cement required for concrete preparation are placed next to the mixer in sequence;

[0043] S2. Raw material grinding: pour the waste PPR powder into the grinder along the feed port, and grind the waste PPR powder. At the same time, use the resistance wire to heat the waste PPR, which is convenient for grinding and screening the waste PPR powde...

Embodiment 2

[0051] Such as figure 1 Shown, a kind of processing method of high-strength environmental protection concrete, processing comprises the following steps:

[0052] S1. Raw material selection: select the waste PPR powder required for the preparation of environmentally friendly concrete, put the waste PPR powder next to the grinder, and put the waste PPR powder into the grinder along the feeding hopper, and then put the waste PPR powder into the grinder, and then put the waste PPR powder into the grinder. Cement, gravel, water, quartz sand, water reducing agent, mica powder, waterproofing agent, flame retardant, volcanic ash, sand and waste cement required for concrete preparation are placed next to the mixer in sequence;

[0053] S2. Raw material grinding: pour the waste PPR powder into the grinder along the feed port, and grind the waste PPR powder. At the same time, use the resistance wire to heat the waste PPR, which is convenient for grinding and screening the waste PPR powde...

Embodiment 3

[0061] Such as figure 1 Shown, a kind of processing method of high-strength environmental protection concrete, processing comprises the following steps:

[0062] S1. Raw material selection: select the waste PPR powder required for the preparation of environmentally friendly concrete, put the waste PPR powder next to the grinder, and put the waste PPR powder into the grinder along the feeding hopper, and then put the waste PPR powder into the grinder, and then put the waste PPR powder into the grinder. Cement, gravel, water, quartz sand, water reducing agent, mica powder, waterproofing agent, flame retardant, volcanic ash, sand and waste cement required for concrete preparation are placed next to the mixer in sequence;

[0063] S2. Raw material grinding: pour the waste PPR powder into the grinder along the feed port, and grind the waste PPR powder. At the same time, use the resistance wire to heat the waste PPR, which is convenient for grinding and screening the waste PPR powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com