Method for preparing porous-structure tire rubber powder by wet crushing

A wet crushing and multi-porous technology, which is applied in the field of tire rubber powder preparation, can solve the problems of affecting the service life of the hammer of the crusher, low production of fine rubber powder, and waste products, so as to reduce the difficulty of crushing and production costs , Shorten the swelling time and increase the production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

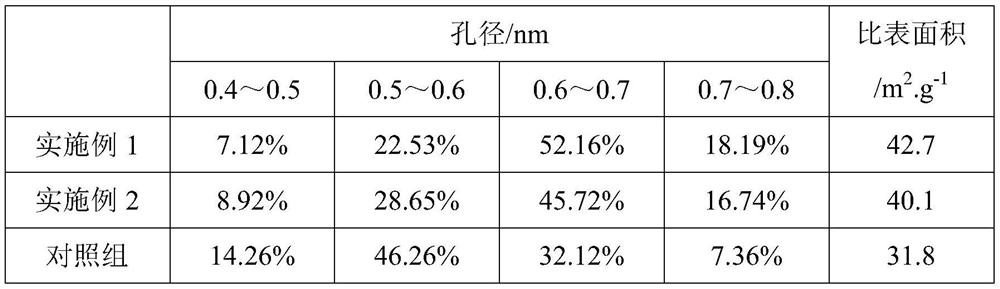

Embodiment 1

[0028] A method for preparing porous structure tire rubber powder by wet pulverization, specifically comprising the following steps:

[0029] (1) After cleaning and drying the waste tires, it is initially pulverized into particles of 30-50 mesh size, and then the waste tire blocks are placed in an organic solvent and swelled under normal temperature and pressure conditions for 12 hours;

[0030] Among them, the organic solvent is toluene, and its usage amount is 1.2 times the mass of waste tire blocks;

[0031] (2) Ultrasonic activation was carried out at 40-60°C for 8 hours, and after the ultrasonic treatment was stopped, the swelling was continued for 24 hours;

[0032] Among them, after the waste tire block undergoes swelling-activation-swelling treatment, the swollen tire block expands to 4-8 times;

[0033] (3) Using the liquid nitrogen cooling method, the swollen waste tire blocks are rapidly cooled in a short time, and the swollen tire blocks are frozen in a liquid nit...

Embodiment 2

[0038] A method for preparing porous structure tire rubber powder by wet pulverization, specifically comprising the following steps:

[0039] (1) After cleaning and drying the waste tires, initially pulverize them into particles of 30-50 mesh size, then place the waste tire blocks in toluene, and the usage amount is 1.2 times the mass of the waste tire blocks. Under normal temperature and pressure conditions swelling for 12h;

[0040] (2) Ultrasonic activation was carried out at 40-60°C for 4 hours, and after the ultrasonic treatment was stopped, the swelling was continued for 24 hours;

[0041] (3) freezing the swollen tire block in a liquid nitrogen environment for 3-10s to obtain a pre-cooled tire block;

[0042] (4) Place the cold and brittle tire particles in the pulverizing equipment, and perform low-temperature fine pulverization treatment. While pulverizing, input compressed cold air into the pulverizing equipment to keep the internal temperature of the pulverizing eq...

Embodiment 3

[0046] The waste tires are directly subjected to mechanical pulverization, and sieved to obtain tire rubber powder of 150-200 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com