Microwave-assisted preparation process of tuna bone meal

A microwave-assisted, preparation technology, applied in food science, animal feed, additional food elements, etc., can solve the problems of reduced utilization rate and use effect, low utilization rate of tuna bone meal, poor solubility and dispersibility, etc., to improve Utilization rate and use effect, improvement of absorption efficiency and use effect, effect of increasing relative content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

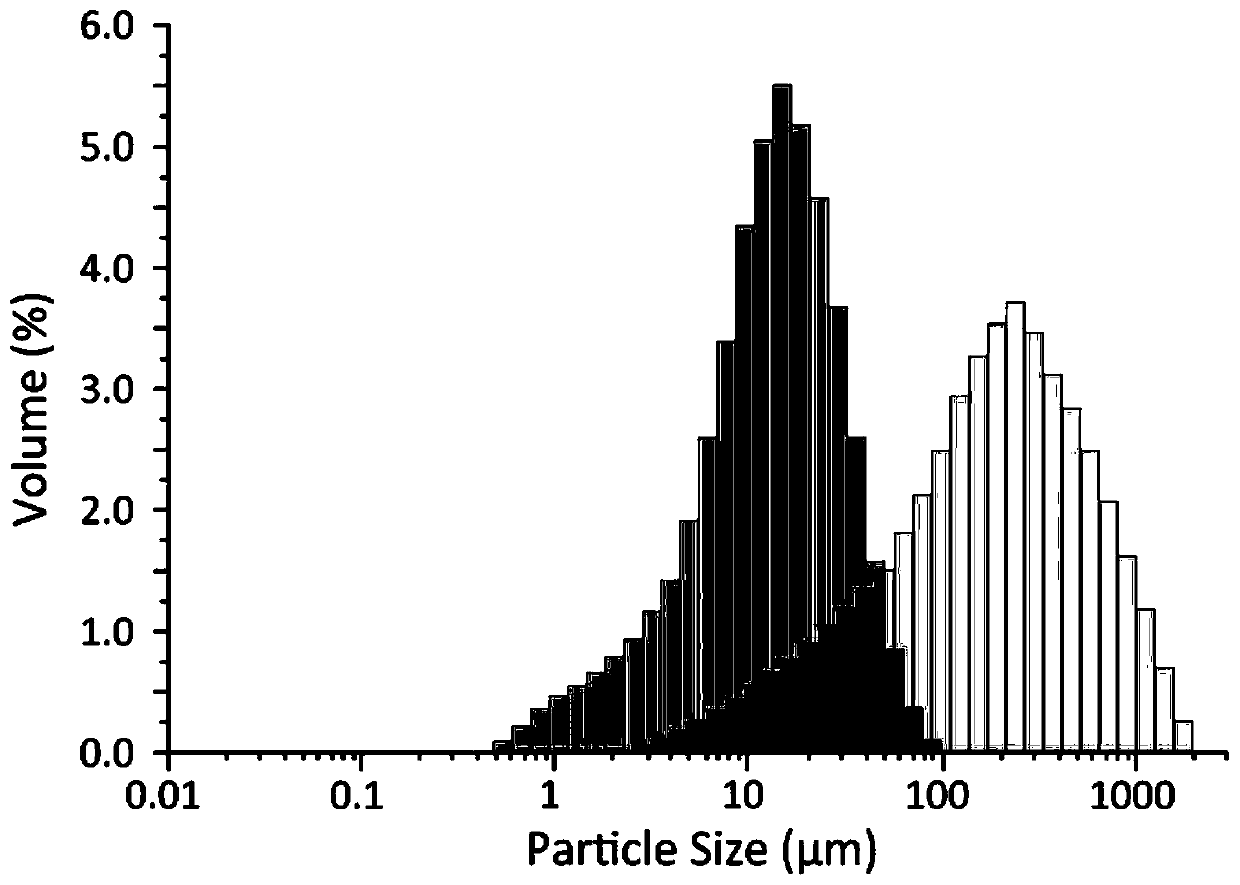

[0032] Experimental Example 1: Using the single-factor rotation method, with product quality (A), microwave power (B) and microwave time (C) as the investigation factors, tuna bones with masses of 60g, 80g, 100g, 120g and 140g were selected as samples in turn , and set the microwave power to 400W, 600W, 800W, 1000W and 1200W respectively, and the microwave heating time to be 30 minutes, 60 minutes, 90 minutes, 120 minutes and 150 minutes, a total of 17 groups of tuna bone experimental groups; then according to the present invention The 17 groups of tuna bone experimental groups were pulverized by the pulverizing method; the particle size of the tuna bone meal obtained after pulverization was measured by a laser particle size distribution analyzer, and the measurement results were shown in Table 1, and the response value was the particle size of the fish bone meal:

[0033] Table 1 Measurement results of particle size of tuna bone meal

[0034]

[0035] It can be seen from t...

experiment example 2

[0036] Experimental example 2: two experimental examples of common fishbone meal group and microwave fishbone meal group are respectively set, wherein common fishbone meal group is pulverized according to the preparation method of the present invention, and the microwave method in step 4. is changed to direct drying treatment, The ordinary fishbone meal sample was obtained; while the microwave fishbone meal group was pulverized according to the preparation method of the present invention, and the microwave parameters were microwave power 800W and microwave time 90 minutes to obtain the microwave fishbone meal sample. Then, the particle sizes of the two groups of fish bone meal samples were observed by scanning electron microscope.

[0037] Observations such as figure 1 As shown (the left curve in the figure is the particle size distribution diagram of microwave fishbone meal, and the right curve is the particle size distribution diagram of ordinary fishbone meal), the average ...

experiment example 3

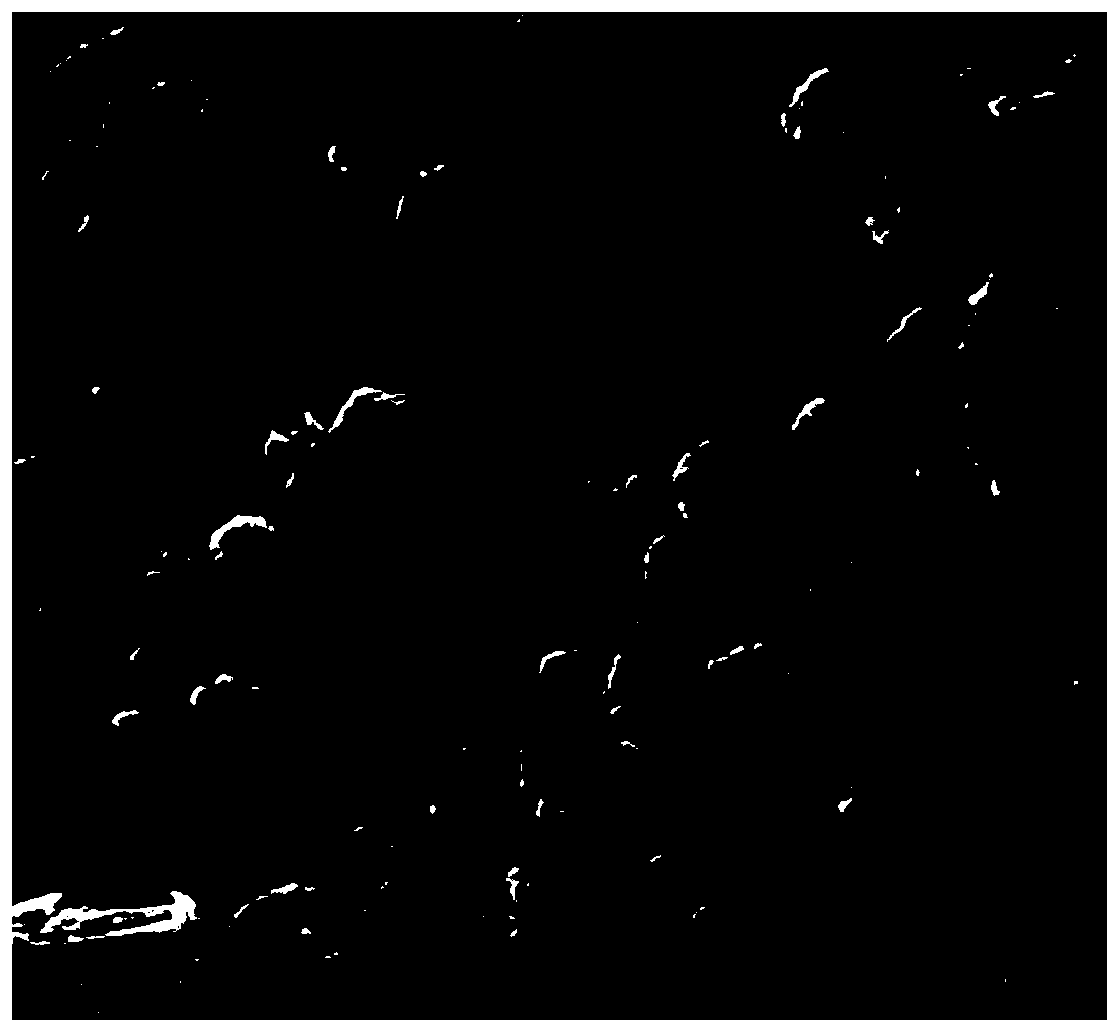

[0038]Experimental Example 3: The two fish bone meal samples prepared in Experimental Example 2 were evenly spread on the insulating glue fixed on the aluminum sample table, and gold was sprayed with an ion sputtering instrument in a vacuum state to make the surface charged. Scanning electron microscope (SEM) was used to observe the surface morphology of fish bone powder under the condition of accelerating voltage of 10kV.

[0039] Observation results such as figure 2 and image 3 as shown ( figure 2 is the surface structure diagram of common tuna bone meal, image 3 is the surface structure diagram of microwave tuna bone meal), the surface and overall shape of ordinary tuna bone meal are relatively complete, only part of the surface is cracked, the overall shape of microwave tuna bone meal no longer maintains integrity, and micropores appear on the surface of fish bone meal. Therefore, the microwave-assisted crushing process used in the present invention can effectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com