Intelligent panel type custom furniture conveying production line

A smart board and production line technology, applied to conveyors, manufacturing tools, mechanical conveyors, etc., can solve the problems of high workload and inconsistent production, improve production efficiency, reduce manual handling costs, and work easily and comfortably environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

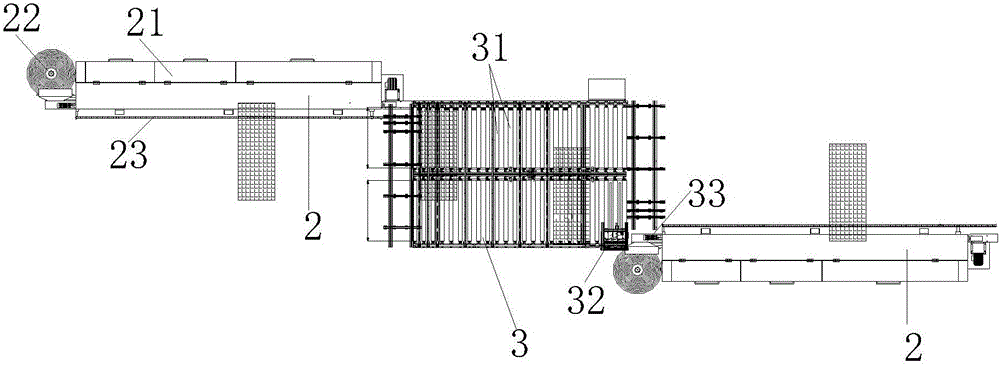

[0019] In order to make the purpose of the present invention, technical solutions and advantages clearer, it is further described in detail, as figure 1 as shown in the figure.

[0020] Intelligent panel-type customized furniture conveying production line, including automatic material preparation conveying system, edge banding system 2 and double-row power translation system 3, the automatic material preparation conveying system is connected with double-row power translation system 3; edge banding system 2 is set in double-row power translation system 3 on both sides, the edge banding system 2 can move along the sides of the double-row power translation system 3;

[0021] The automatic material preparation and conveying system includes a vertical roller support, a small roller, a worm gear reducer, a chain and a heavy roller; the vertical roller support is set on the side, the worm gear reducer is used as power, and the chain connects the small roller and the heavy roller;

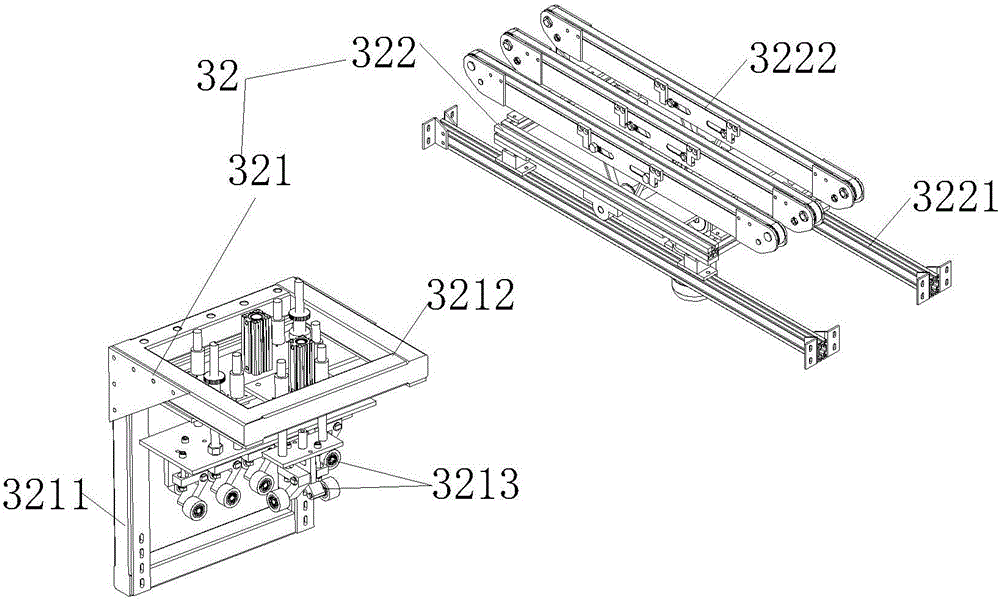

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com