Wear-resistant and high-toughness material for 3D printing ceramic

A 3D printing and ceramic technology, applied in the field of ceramic materials, can solve problems such as poor wear resistance and toughness, and achieve the effects of reducing porosity, improving interaction, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

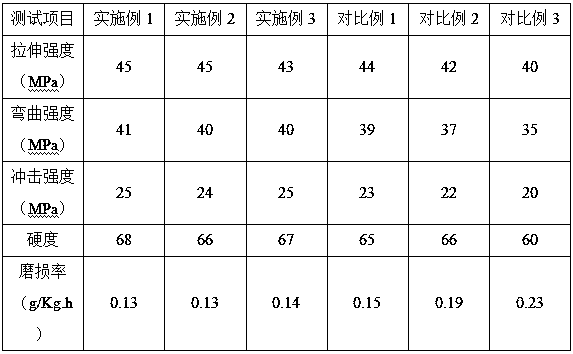

Examples

preparation example Construction

[0032] A preparation method for a composite ceramic base material, comprising the steps of:

[0033](1) According to parts by weight, take 15~30 parts of steel slag, 15~30 parts of palygorskite, 25~40 parts of fly ash, and 3~7 parts of ball milling medium in the ball milling tank and mix them according to the mass ratio of ball to material 20 Add zirconia ball milling beads at ~30:1, mill at 350~550r / min for 2~4h to obtain ball abrasive, take the ball abrasive in an ultra-high temperature heating furnace and roast at 1800~2000°C for 1~3h, and cool to room temperature with the furnace to obtain Roasted product, take the roasted product and crush it through a 200-mesh sieve in a pulverizer, collect the sieved particles according to the mass ratio of 6~10:1, add additives and grind them in the mortar for 1~3 hours to obtain the abrasive, take the abrasive according to the mass ratio of 2: 3~5 Add N-methylpyrrolidone and mix, stir at 350~550r / min for 30~55min to obtain a mixture, ...

Embodiment 1

[0041] Coupling agent: silane coupling agent KH-560.

[0042] Dispersant: Mix dodecyl dimethyl betaine, polyethylene wax and lauryl alcohol at a mass ratio of 4:1:3 to obtain a dispersant.

[0043] Stabilizer: Mix dioctyltin and magnesium stearate at a mass ratio of 2:1 to obtain a stabilizer.

[0044] Ball milling medium: Mix kerosene and absolute ethanol at a mass ratio of 5:1 to obtain a ball milling medium.

[0045] Auxiliary: Mix boron mud, polyphenylene ether sulfone, and microcrystalline paraffin wax at a mass ratio of 3:1:1 to obtain the auxiliary.

[0046] Reagent A: Mix the mass fraction of 12% sulfuric acid solution and sodium sulfate at a mass ratio of 6:1 to obtain reagent A.

[0047] Reagent B: Mix sodium metaaluminate, urea, and water in a mass ratio of 3:1:25 to obtain reagent B.

[0048] A preparation method for a composite ceramic base material, comprising the steps of:

[0049] (1) According to parts by weight, take 15 parts of steel slag, 15 parts of pa...

Embodiment 2

[0057] Coupling agent: silane coupling agent A-174.

[0058] Dispersant: Mix dodecyl dimethyl betaine, polyethylene wax and lauryl alcohol at a mass ratio of 6:1:3 to obtain a dispersant.

[0059] Stabilizer: Mix dioctyltin and magnesium stearate at a mass ratio of 3:1 to obtain a stabilizer.

[0060] Ball milling medium: Mix kerosene and absolute ethanol at a mass ratio of 6:1 to obtain a ball milling medium.

[0061] Auxiliary: Mix boron mud, polyphenylene ether sulfone, and microcrystalline paraffin wax at a mass ratio of 5:1:1 to obtain the auxiliary.

[0062] Reagent A: Mix the mass fraction of 12% sulfuric acid solution and sodium sulfate at a mass ratio of 8:1 to obtain reagent A.

[0063] Reagent B: Mix sodium metaaluminate, urea, and water in a mass ratio of 5:1:25 to obtain reagent B.

[0064] A preparation method for a composite ceramic base material, comprising the steps of:

[0065] (1) According to parts by weight, take 22 parts of steel slag, 22 parts of pal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com