Preparation method of butyrate-essential oil compound feed additive

A compound feed, butyrate technology, applied in the direction of animal feed, animal feed, application, etc., can solve the problems of discharge, easy volatilization, destruction, etc., and achieve the effect of improving production efficiency, improving effect, and reducing volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

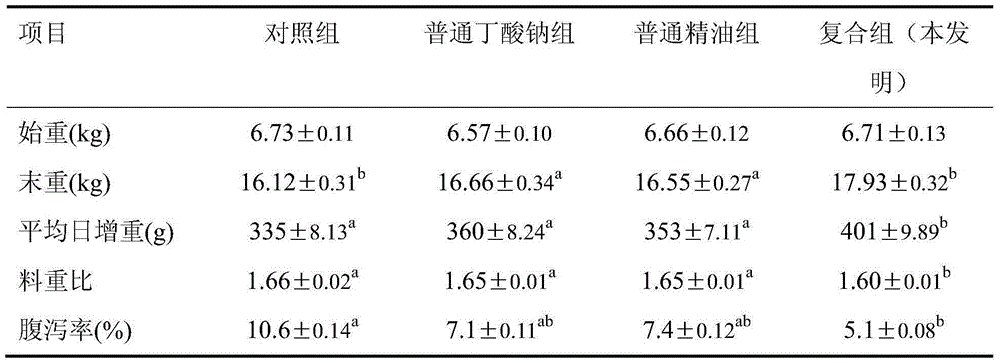

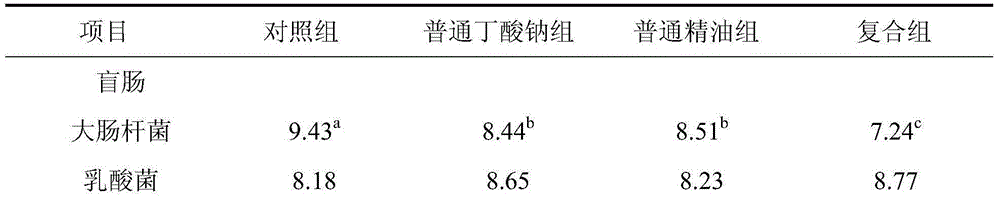

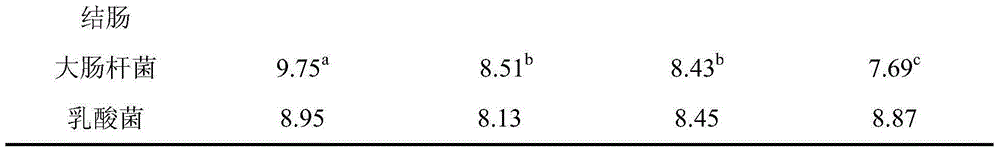

Examples

Embodiment 1

[0032] Embodiment 1, a kind of preparation method of butyrate essential oil compound feed additive is characterized in that carrying out following steps successively:

[0033] 1) Preparation of raw materials:

[0034] Described raw material is made up of the composition of following weight content:

[0035] Butyrate 75%,

[0036] essential oils 10%,

[0037] Coating (fat) 15% for coating;

[0038] The butyrate is: sodium butyrate;

[0039] The essential oil is: cinnamaldehyde and eugenol are mixed in a weight ratio of 5:1;

[0040] The coating material that plays a coating role is: palmitic acid and stearic acid are mixed in a weight ratio of 1:3.

[0041] 2) Put 750 kg of sodium butyrate into the batching bin, and then convey it through a heating screw conveyor. The screw conveyor is equipped with a heating sleeve, and the heating temperature is 250°C-280°C, so that the screw conveyor The sodium butyrate on the machine is melted; the liquid sodium butyrate is transporte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com