Fluidization roasting technology for processing iron ores

A technology of fluidized roasting and iron ore, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve problems such as uneven quality of reduced products, poor discharge, and back-mixing of materials in the reduction reactor , to achieve the effect of improving roasting indicators, preventing harm to people, and preventing air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

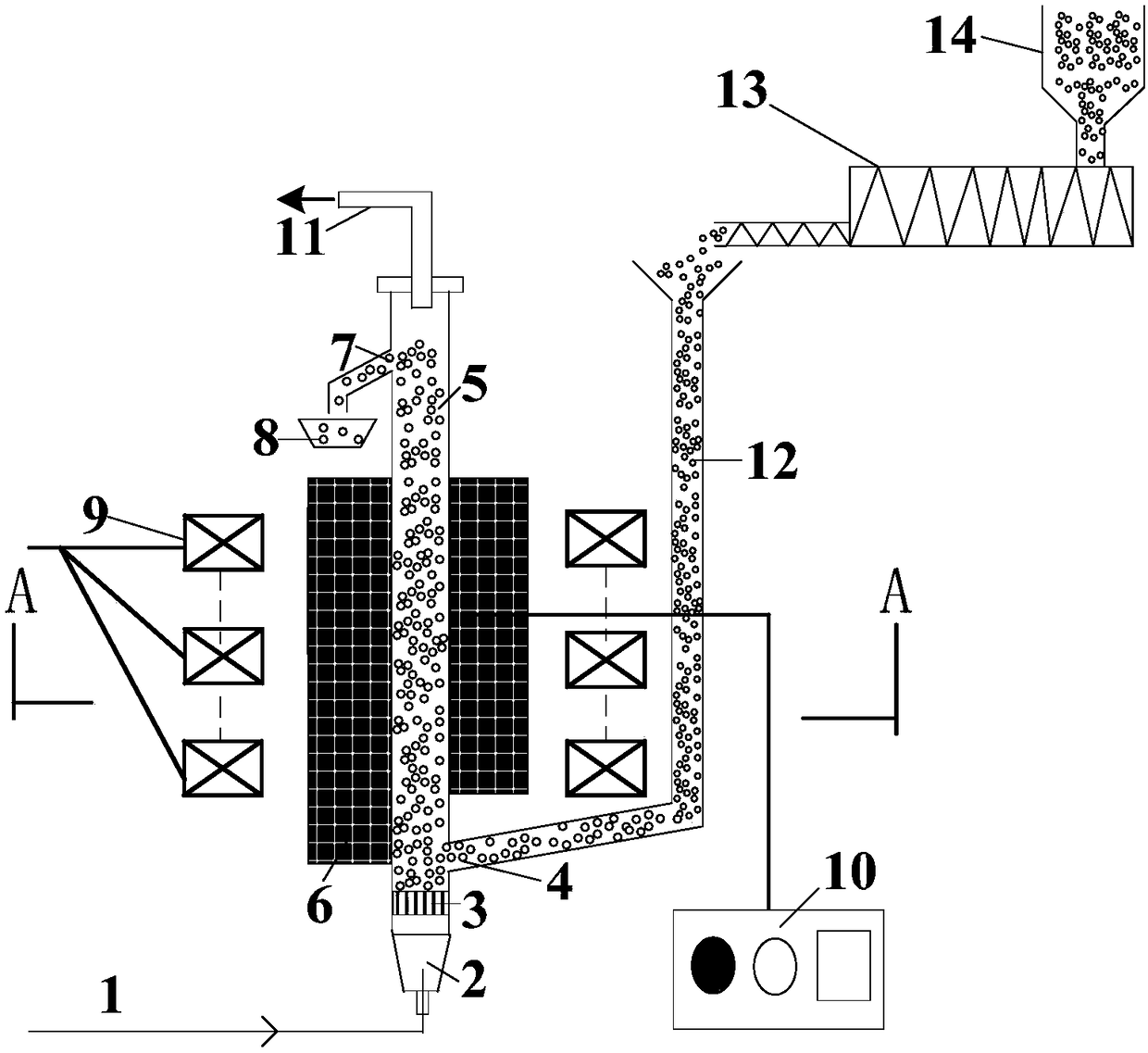

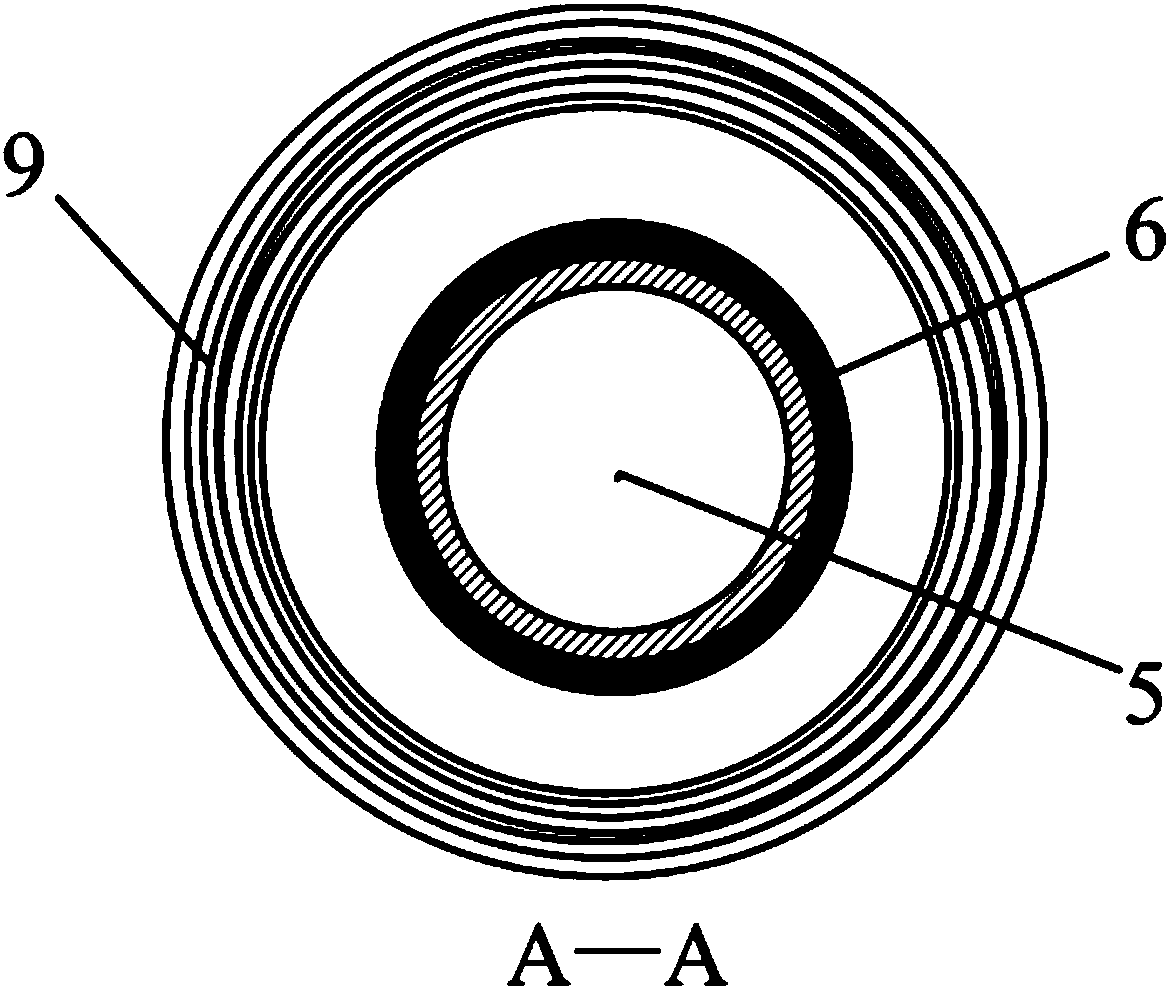

Method used

Image

Examples

Embodiment 1

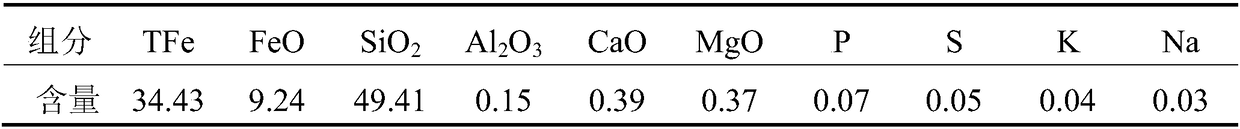

[0045] The iron ore used is the ore of a concentrator in Anshan area, which belongs to hematite-siderite mixed ore. The results of chemical composition analysis of the ore are shown in Table 1, and the results of iron phase analysis are shown in Table 2. It can be seen from Table 1 that the grade of TFe in the ore is 34.43%, the content of FeO is 9.24%, and the content of SiO 2 The content is 49.41%, and the content of harmful elements phosphorus and sulfur is relatively low, being 0.07% and 0.05% respectively. It shows that the main valuable element of the medium ore is iron, and the main impurity component is silicon. As can be seen from Table 2, the iron in brown (brown) iron ore is 26.01%, and the iron occupancy rate is 75.85%; the iron in iron carbonate is 4.98%, and the iron occupancy rate is 14.52%. : Hematite and Siderite.

[0046] Table 1 Analysis of ore chemical composition / %

[0047]

[0048] Table 2 Iron chemical phase analysis results / %

[0049]

[00...

Embodiment 2

[0055] The ore sample used is ore from a concentrator in Yunnan, which belongs to hematite-limonite complex refractory iron ore. The results of chemical composition analysis of the ore are shown in Table 4, and the results of iron phase analysis are shown in Table 5. It can be seen from Table 4 that the grade of TFe in the ore is 35.25%, the content of FeO is 9.24%, and the content of SiO 2 The content is 49.41%, and the harmful element phosphorus content is low, which is 0.88%. It shows that the main valuable element of the medium ore is iron, and the main impurity component is silicon. It can be seen from Table 5 that the iron in hematite (limonite) is 34.74%, and the iron occupancy rate is 98.85%. Therefore, the main recovery objects of this middle ore are: hematite and limonite.

[0056] Table 4 Analysis of ore chemical composition / %

[0057]

[0058] Table 5 Iron chemical phase analysis results / %

[0059]

[0060] The iron ore is finely ground to -0.074mm, acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com